SIST EN 13114:2003+A1:2010

(Main)Tannery machines - Rotating process vessels - Safety requirements

Tannery machines - Rotating process vessels - Safety requirements

1.1 This European Standard specifies safety requirements for design, construction, operation, adjustment, setting, cleaning and maintenance of a machine.

1.2 This standard covers the following machines (see annex C and Figures 1 and 2 for typical configurations):

a) horizontal rotating vessels;

b) inclined rotating vessels.

1.3 This standard does not apply to machines using substances containing solvent, that would generate fume and/or vapour detrimental to health, or that may lead to fire or explosive atmosphere.

1.4 This standard takes account of intended use, foreseeable misuse, component and systems failure.

The machines are for fixed installation.

1.5 This document is not applicable to the rotating vessels which are manufactured before the date of its publication as EN.

1.6 This standard does not establish any requirements for electromagnetic disturbances.

NOTE Directive 94/9/EC concerning equipment and protective systems intended for use in potentially explosive atmospheres can be applicable to the type of machine or equipment covered by this European Standard. The present standard does not necessarily comply with Directive 94/9/EC. Additional safety requirements in a future revision of this standard can be necessary to satisfy Directive 94/9/EC.

Gerberei-Maschinen - Rotierende Bearbeitungsgefäße - Sicherheitsanforderungen

1.1 Diese Europäische Norm spezifiziert Sicherheitsanforderungen bezüglich Konstruktion, Bau, Betrieb, Regelung, Einrichten, Reinigung und Wartung von Maschinen.

1.2 Diese Norm umfasst die folgenden Maschinen (typische Ausführungen siehe Anhang C und Bilder 1 und 2):

a) Horizontal rotierende Gefäße;

b) Schräg gelagerte rotierende Gefäße.

1.3 Die Norm gilt nicht für Maschinen, bei denen lösemittelhaltige Substanzen eingesetzt werden, die gesundheitsschädliche Rauchgase bzw. Dampf erzeugen oder zu einer feuergefährlichen oder explosions-fähigen Atmosphäre führen können.

1.4 Diese Norm befasst sich mit der bestimmungsgemäßen Verwendung, vorhersehbarem Missbrauch und möglichem Versagen der Bauteile und des Systems.

Diese Maschinen sind Festinstallationen.

1.5 !Dieses Dokument gilt nicht für rotierende Gefäße, die vor dem Datum seiner Veröffentlichung als Europäische Norm gebaut werden."

1.6 Diese Norm legt keine Anforderungen für elektromagnetische Verträglichkeit fest.

ANMERKUNG Die Richtlinie 94/9/EG zu Ausstattung und Sicherheitssystemen in potentiell explosionsfähiger Atmosphäre kann für die in dieser Europäischen Norm behandelten Arten von Maschinen oder Ausrüstung Anwendung finden. Die derzeitige Norm entspricht jedoch nicht in allem der Richtlinie 94/9/EG. In eine zukünftige Überarbeitung müssen zur Erfüllung der Richtlinie 94/9/EG möglicherweise zusätzliche Sicherheitsanforderungen aufgenommen werden.

Machines de tannerie - Tonneaux tournants - Prescriptions de sécurité

Strojarski stroji - Vrteče se procesne posode - Varnostne zahteve

Ta evropski standard opredeljuje varnostne zahteve za načrtovanje, gradnjo, obratovanje, prilagoditev, nastavitev, čiščenje in vzdrževanje stroja. Ta standard vključuje naslednje stroje (glej Prilogo C in Sliki 1 in 2 za značilne konfiguracije): a) horizontalne vrteče se posode; b) vrteče se posode z naklonom. Ta standard ne velja za stroje, ki uporabljajo snovi z vsebovanim topilom, katero bi povzročalo nastanek zdravju škodljivih plinov in/ali hlapov, ali ki bi lahko vodilo k nastanku požara ali eksplozivne atmosfere. Ta standard obravnava predvideno uporabo, predvidljivo napačno uporabo ter okvaro komponent in sistemov. Stroji so namenjeni fiksni namestitvi. Ta dokument se ne nanaša na vrteče se posode, ki so proizvedene pred datumom, ko je dokument objavljen kot EN. Ta standard ne vzpostavlja nikakršnih zahtev za elektromagnetne motnje.

General Information

- Status

- Published

- Publication Date

- 16-Dec-2009

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 23-Nov-2009

- Due Date

- 28-Jan-2010

- Completion Date

- 17-Dec-2009

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 01-Jan-2010

- Consolidates

SIST EN 13114:2003/kFprA1:2009 - Tannery machines - Rotating process vessels - Safety requirements - Effective Date

- 01-Jan-2010

Overview

EN 13114:2002+A1:2009 - published by CEN - is the European safety standard for tannery machines in which materials are processed in rotating process vessels. It defines safety requirements for the design, construction, operation, adjustment, cleaning and maintenance of fixed-installation rotating vessels used in leather processing. The scope covers horizontal and inclined rotating vessels and takes into account intended use, foreseeable misuse and component failures. Key exclusions include machines manufactured before the EN publication date and machines using solvents that produce harmful fumes, vapours, fire or explosive atmospheres. The standard does not set requirements for electromagnetic disturbances.

Key topics and technical requirements

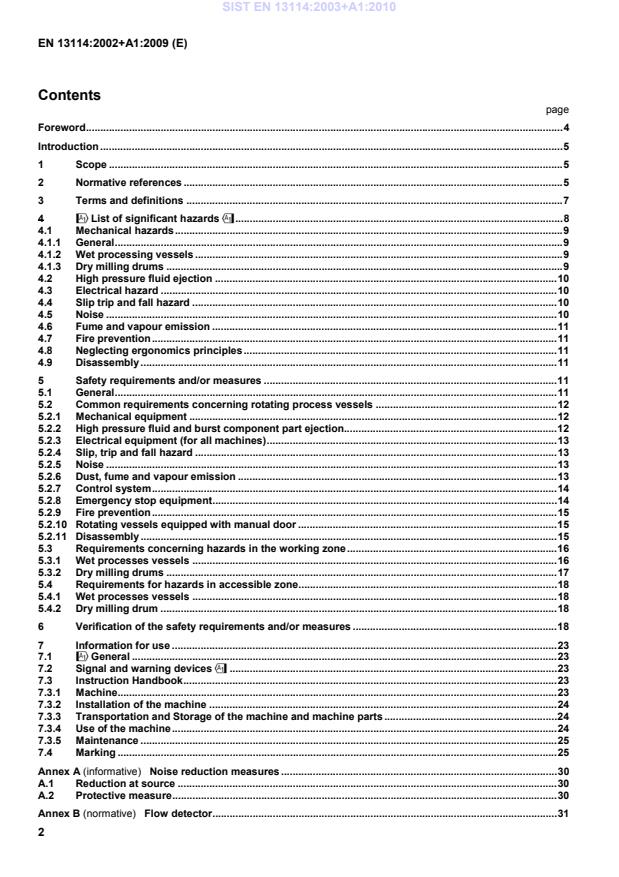

EN 13114 addresses the principal hazards and the measures required to reduce risk in rotating tannery equipment. Main topics include:

- Mechanical hazards (guards, rotating parts, prevention of unexpected start-up)

- High-pressure fluid and burst component ejection protection

- Electrical safety for all machines and associated control systems

- Slip, trip and fall prevention and ergonomic design considerations

- Noise - identification of noise sources and noise reduction measures (Annex A)

- Dust, fume and vapour emission control (with solvent-related exclusions)

- Fire prevention and emergency stop equipment

- Requirements for manual doors, disassembly and maintenance access

- Verification, testing and information for use - marking, instruction handbook, installation, transport, storage and maintenance information

- Normative annexes include a flow detector, machinery descriptions and informative annexes linking the standard to EU Machinery Directives (Annex ZA/ZB).

Applications and practical value

EN 13114 is intended to:

- Guide machine manufacturers in designing safe rotating process vessels for tanneries

- Provide safety criteria for machine builders, design engineers and OEMs to meet EU machinery essential requirements

- Inform safety managers, maintenance teams and installers about required guarding, controls and safe procedures

- Support procurement and conformity assessment when specifying tannery equipment

Practical benefits include reduced operator injury risk, clearer maintenance and guarding requirements, improved noise and fume management, and consistent documentation for compliance.

Who should use this standard

- Tannery machine manufacturers and designers

- Safety engineers and CE conformity assessors

- Plant managers, maintenance supervisors and health & safety officers in leather-processing plants

- Procurement teams specifying rotating vessels

Related standards

EN 13114 references several machinery safety standards (examples):

- EN ISO 12100 (machinery safety - basic concepts)

- EN 294, EN 953 (guards and safety distances)

- EN 982 / EN 983 (fluid power safety)

- Relevant acoustics standards for noise measurement and reduction

Keywords: EN 13114, tannery machines, rotating process vessels, safety requirements, leather processing, machinery safety, CEN.

Frequently Asked Questions

SIST EN 13114:2003+A1:2010 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Tannery machines - Rotating process vessels - Safety requirements". This standard covers: 1.1 This European Standard specifies safety requirements for design, construction, operation, adjustment, setting, cleaning and maintenance of a machine. 1.2 This standard covers the following machines (see annex C and Figures 1 and 2 for typical configurations): a) horizontal rotating vessels; b) inclined rotating vessels. 1.3 This standard does not apply to machines using substances containing solvent, that would generate fume and/or vapour detrimental to health, or that may lead to fire or explosive atmosphere. 1.4 This standard takes account of intended use, foreseeable misuse, component and systems failure. The machines are for fixed installation. 1.5 This document is not applicable to the rotating vessels which are manufactured before the date of its publication as EN. 1.6 This standard does not establish any requirements for electromagnetic disturbances. NOTE Directive 94/9/EC concerning equipment and protective systems intended for use in potentially explosive atmospheres can be applicable to the type of machine or equipment covered by this European Standard. The present standard does not necessarily comply with Directive 94/9/EC. Additional safety requirements in a future revision of this standard can be necessary to satisfy Directive 94/9/EC.

1.1 This European Standard specifies safety requirements for design, construction, operation, adjustment, setting, cleaning and maintenance of a machine. 1.2 This standard covers the following machines (see annex C and Figures 1 and 2 for typical configurations): a) horizontal rotating vessels; b) inclined rotating vessels. 1.3 This standard does not apply to machines using substances containing solvent, that would generate fume and/or vapour detrimental to health, or that may lead to fire or explosive atmosphere. 1.4 This standard takes account of intended use, foreseeable misuse, component and systems failure. The machines are for fixed installation. 1.5 This document is not applicable to the rotating vessels which are manufactured before the date of its publication as EN. 1.6 This standard does not establish any requirements for electromagnetic disturbances. NOTE Directive 94/9/EC concerning equipment and protective systems intended for use in potentially explosive atmospheres can be applicable to the type of machine or equipment covered by this European Standard. The present standard does not necessarily comply with Directive 94/9/EC. Additional safety requirements in a future revision of this standard can be necessary to satisfy Directive 94/9/EC.

SIST EN 13114:2003+A1:2010 is classified under the following ICS (International Classification for Standards) categories: 59.140.40 - Machines and equipment for leather and fur production. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13114:2003+A1:2010 has the following relationships with other standards: It is inter standard links to SIST EN 13114:2003, SIST EN 13114:2003/kFprA1:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13114:2003+A1:2010 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13114:2003+A1:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Gerberei-Maschinen - Rotierende Bearbeitungsgefäße - SicherheitsanforderungenMachines de tannerie - Tonneaux tournants - Prescriptions de sécuritéTannery machines - Rotating process vessels - Safety requirements59.140.40Stroji in oprema za proizvodnjo usnja in krznaMachines and equipment for leather and fur productionICS:Ta slovenski standard je istoveten z:EN 13114:2002+A1:2009SIST EN 13114:2003+A1:2010en,fr01-januar-2010SIST EN 13114:2003+A1:2010SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13114:2002+A1

November 2009 ICS 59.140.40 Supersedes EN 13114:2002English Version

Tannery machines - Rotating process vessels - Safety requirements

Machines de tannerie - Tonneaux tournants - Prescriptions de sécurité

Gerberei-Maschinen - Rotierende Bearbeitungsgefäße - Sicherheitsanforderungen This European Standard was approved by CEN on 27 December 2001 and includes Amendment 1 approved by CEN on 10 October 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13114:2002+A1:2009: ESIST EN 13114:2003+A1:2010

Noise reduction measures . 30A.1 Reduction at source . 30A.2 Protective measure . 30Annex B (normative)

Flow detector . 31SIST EN 13114:2003+A1:2010

Machinery description . 32Annex ZA (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC" . 33Annex ZB (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC" . 34Bibliography . 35SIST EN 13114:2003+A1:2010

Directive 94/9/EC concerning equipment and protective systems intended for use in potentially explosive atmospheres can be applicable to the type of machine or equipment covered by this European Standard. The present standard does not necessarily comply with Directive 94/9/EC. Additional safety requirements in a future revision of this standard can be necessary to satisfy Directive 94/9/EC. 2 Normative references !The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies." !deleted text" EN 294:1992, Safety of machinery — Safety distances to prevent danger zones being reached by the upper limbs !deleted text" EN 626-1:1994, Safety of machinery — Reduction of risk to health from hazardous substances emitted by machinery — Part 1: Principles and specifications for machinery manufacturers SIST EN 13114:2003+A1:2010

(ISO 11203:1995) !EN ISO 11204:1995", Acoustics — Noise emitted by machinery and equipment — Measurement of emission sound pressure levels at a work station and at other specified positions — Method requiring environmental corrections (ISO 11204:1995) !EN ISO 11688-1:1998", Acoustics — Recommended practice for the design of low noise machinery and equipment — Part 1: Planning (ISO/TR 11688-1:1995) !EN ISO 11688-2:2000", Acoustics — Recommended practice for the design of low-noise machinery and equipment — Part 2: Introduction to the physics of low-noise design (ISO/TR 11688-2:1998) !EN ISO 12100-1:2003, Safety of machinery — Basic concepts, general principles for design — Part 1: Basic terminology, methodology (ISO 12100-1:2003)" !EN ISO 12100-2:2003, Safety of machinery — Basic concepts, general principles for design — Part 2: Technical principles (ISO 12100-2:2003)" !EN ISO 13849-1:2008, Safety of machinery — Safety-related parts of control systems — Part 1: General principles for design (ISO 13849-1:2006)" !EN ISO 13850:2008, Safety of machinery — Emergency stop — Principles for design (ISO 13850:2006)" !EN ISO 14121-1:2007, Safety of machinery — Risk assessment — Part 1: Principles (ISO 14121-1:2007)" !EN 60204-1:2006, Safety of machinery — Electrical equipment of machines — Part 1: General requirements (IEC 60204-1:2005, modified)" EN 60529:1991, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989) !EN 61496-1:2004, Safety of machinery — Electro-sensitive protective equipment — Part 1: General requirements and tests (IEC 61496-1:2004, modified)" !CLC/TS 61496-2:2006, Safety of machinery — Electro-sensitive protective equipment — Particular requirements for equipment using active optoelectronic protective devices (AOPDs) (IEC 61496-2:2006)" 3 Terms and definitions !For the purposes of this document, the terms and definitions given in EN ISO 12100-1:2003 and the following apply." 3.1 rotating process vessels machines used for the processing of animal hides and skins (as described in annex C). They are vessel type processing machines which are equipped with: a) upward and downward rotation of external bodies; b) opening and closing movement of the door. 3.2 accessible zone any danger zone except the working zone 3.3 automatic door drum door in which both operations, release and sliding, are made by a remote control SIST EN 13114:2003+A1:2010

Figure Safety requirements 4.1 Mechanical hazards 4.1.1 General 4.1.1.1 Manual door with horizontal and vertical sliding - door opening and closing movements

Crushing

Shearing

H,G

1a, 1b

5.2.10.2 5.2.10.3 4.1.1.2 Moving transmission part

Crushing

Shearing Entanglement Trapping

B

5.2.1.1 4.1.2 Wet processing vessels 4.1.2.1 Rotating body access from the front

- moving

- stopped Crushing Entanglement Trapping Impact Impact A

A 2

2 5.3.1.1

5.3.1.3 4.1.2.2 Rotating body access

- loading area

Crushing Entanglement Trapping Impact

D

5.3.1.2 5.3.1.3 4.1.2.3 Powered door

- closing and opening movements Crushing Shearing Trapping

H,G

1a, 1b

5.3.1.4

4.1.2.4 Rotating body access from the sides

Crushing Entanglement Trapping Impact

C,E,F

5.4.1 4.1.3 Dry milling drums 4.1.3.1

Rotating body access from the front

- moving

- stopped Crushing Entanglement Trapping Impact

Impact A

A 3

3 5.3.2.1

5.3.2.2 SIST EN 13114:2003+A1:2010

Danger Zone and source of hazard Hazard Zone

Figure Safety requirements4.1.3.2

Rotating body access from the rear

Crushing Entanglement Trapping Impact D 3 5.3.2.3 4.1.3.3 Powered door

- closing and opening movements Crushing Shearing Trapping

H,G

1a, 1b

5.3.2.4

4.1.3.4 Rotating body access from the sides

Crushing Entanglement Trapping Impact

C

5.4.2 4.2 High pressure fluid ejection High pressure fluid and burst component part ejection Burn and injury from hot oil or tubing under pressure

5.2.2 4.3 Electrical hazard Electrical contact, direct or indirect caused by:- component failure - insulation failure incorrect design, installation or component specification of the electrical equipment

Electric shock, burns

5.2.3 4.4 Slip trip and fall hazard Discharge of water, grease and chemical product from rotating vessel upon the floor Slip and fall

5.2.4 4.5 Noise Noise generated by: - mechanical action of hides and skins during rotation - hydraulic unit - transmission and working parts Hearing loss

Interference with communication and acoustic signals

5.2.5 SIST EN 13114:2003+A1:2010

Danger Zone and Source of hazard Hazard Zone

Figure Safety requirements4.6 Fume and vapour emission Fume and vapour emission - door opening

Dust emission - door opening Noxious and/or toxic vapour emission

Risk of occupational disease

5.2.6.1

5.2.6.2 4.7 Fire prevention The contact between dust and hot surfaces Fire

5.2.9 4.8 Neglecting ergonomics principles Manual door opening and closing movement

- Vertical, horizontal and removable

Risk of occupational disease

Fatigue

G,H

1a, 1b

5.2.10.1 5.2.10.2 5.2.10.3 4.9 Disassembly Instability from disassembly for maintenance -

-

-

5.2.11

5 Safety requirements and/or measures !deleted text" 5.1 General !Machinery shall comply with the safety requirements and/or protective measures of this clause. In addition, the machine shall be designed according to the principles of EN ISO 12100-2 for relevant but not significant hazards which are not dealt with by this document. For hazards which are to be reduced by the application of a type B-standard such as EN 294, EN 953,

EN ISO 13850, EN 60204-1 etc., the manufacturer shall carry out a risk assessment to establish the requirements of the B-standards which are to be applied." SIST EN 13114:2003+A1:2010

EN ISO 12100-2)" with a position “night” shall be provided. In the case of electrical blackout, this shall enable automatic machine restart with a delay of at least 30 seconds after reconnection of the power supply. During this period warning devices (e.g. horn and lamp) shall indicate machine restart. If a safety device or an interlocking guard has been actuated during electrical blackout the rotating vessel movement shall be prevented. 5.2.7.4 Unless otherwise permitted by 5.2.7.5 or 5.3, safety related parts of the machine control system shall have at least the same level as the safeguarding used or, where not otherwise specified, !shall as a minimum comply with performance level “d” as defined in EN ISO 13849-1." 5.2.7.5 The use of programmable electronic systems (PES) shall not reduce any level of safety laid down in this standard. When a machine is fitted with programmable electronic systems, safety related function shall not rely solely on it. This requirement is met, if using additional hardwired control system, or duplicated solid state channel. 5.2.8 Emergency stop equipment 5.2.8.1 The emergency stop equipment function shall be independent from the normal control systems of the machines and shall comply with !EN ISO 13850", Category 0 requirements. For specific requirements for electrical equipment see !EN 60204-1". SIST EN 13114:2003+A1:2010

EN ISO 13849-1" placed on the door danger zones when the movable interlocking guard with guard locking is opened or the electrosensitive protective device is actuated. 5.3.1.4.3 A mechanical block shall be activated in order to prevent the door from gravity fall. This requirement is met for example by an irreversible gear box or a self-brake system. 5.3.2 Dry milling drums 5.3.2.1 Crushing, trapping, entanglement and impact hazards (see zone A in Figures 3) shall be safeguarded by one of the safety requirements contained in 5.3.1.1 of this standard. 5.3.2.2 Crushing, trapping, entanglement and impact hazards (see zone A in Figures 3) during the loading operations, shall be safeguarded by one of the following safety requirements: Locking system The locking system shall be activated when interlocking guards are opened. The locking system shall also prevent the rotation of the rotating body: in case of energy supply interruption; in case of breakdown of the control circuit; when safety systems are activated. The braking couple (M) shall be equal or greater than Q × R/2 where Q is the maximum loading capacity, expressed in kilogrammes, of the machine and R its outside radius, measured in metres. 5.3.2.3 Crushing, entanglement, trapping and impact hazards (see zone D in Figure 3), during work process, shall be protected by: fixed distance guards which comply with EN 953, !EN ISO 12100-2" and the distances given in appropriate Table (1, 3 or 4) of EN 294:1992. 5.3.2.4 Crushing, shearing and trapping hazards (see zones G and H in Figures 1 and 2), during door movement, shall be safeguarded by the safety measures in 5.3.2.4.1 or 5.3.2.4.2. In addition, for vertical sliding opening doors, by 5.3.2.4.3. 5.3.2.4.1 The movable interlocking guard with guard locking (see 5.3.1.1.1 of this standard) is closed or the electrosensitive protective device (see 5.3.1.1.2 of this standard) is not actuated. 5.3.2.4.2 A pressure sensitive protective device of type 3.1 or 3.2 according to !EN 1760-2 and with the related parts of the control system as a minimum complying with performance level “d” as defined in

EN ISO 13849-1" placed on the door danger zones when the movable interlocking guard with guard locking is opened or the electrosensitive protective device is actuated. SIST EN 13114:2003+A1:2010

fixed distance guards which comply with EN 953 and !5.3.3.1 of EN ISO 12100-2:2003" and the distances given in appropriate Tables (1, 3 or 4) of EN 294:1992. 6 Verification of the safety requirements and/or measures Verification of the requirements defined in clauses 5 and 7 s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...