SIST EN 13457:2005+A1:2010

(Main)Footwear, leather and imitation leather goods manufacturing machines - Splitting, skiving, cutting, cementing and cement drying machines - Safety requirements

Footwear, leather and imitation leather goods manufacturing machines - Splitting, skiving, cutting, cementing and cement drying machines - Safety requirements

This document applies to splitting, skiving, edge trimming, strip cutting, cementing and cement drying machines used in the manufacture of footwear, leather and imitation leather goods and other related components.

1.2 This document does not apply to:

- trimming machines with rotary milling tool for the purpose of trimming edges of material, see EN 930;

- splitting and band knife machines used in tanneries, see EN 13112;

- portable machines.

1.3 This document specifies safety requirements for construction, transport, installation, adjustment, setting, teaching or process change-over, operation, cleaning, maintenance, decommissioning, dismantling and, as far as safety is concerned, disposal for machines mentioned in 1.1.

It takes account of intended use , foreseeable misuse, component and system failure.

1.4 This document deals with significant hazards relevant to the footwear, leather and imitation leather goods manufacturing industries. (For a list of hazards see Clause 4.)

The document does not deal with precise technical measures for reducing the risks of fumes and dusts detrimental to health.

The use of machines falling within the scope of this document for purposes other than those specified in 1.1, may give rise to hazards not considered during its preparation.

1.5 This document also applies to equipment for material handling and operations which are an integral part of the machine.

1.6 This document assumes the machines

- are operated by adequately trained persons

- are used with adequate workplace lighting conforming the local regulations or to EN 12464-1

1.7 This document is not applicable to splitting, skiving, edge trimming, strip cutting, cementing and cement drying machines which are manufactured before the date of its publication as EN.

Maschinen zur Herstellung von Schuhen, Leder- und Kunstlederewaren - Spalt-, Schärf-, Schneid-, Klebstoffauftrag- und Klebstofftrockenmaschinen - Sicherheitsanforderungen

Diese Norm gilt für Spalt-, Schärf-, Schneid-, Klebstoffauftrag- und Klebstofftrocknungsmaschinen, die

bei der Herstellung von Schuhen, Leder- und Kunstlederwaren und verwandten Teilen verwendet werden.

1.2 Diese Norm gilt nicht für:

Kantenbearbeitungsmaschinen mit rotierendem Werkzeug zum Bearbeiten von Materialkanten, siehe

EN 930;

in Gerbereien verwendete Spalt- und Bandmessermaschinen, siehe EN 13112;

Maschinen nicht ortsfester Bauart.

1.3 Diese Norm spezifiziert die Sicherheitsanforderungen für Bau, Transport, Installation, Einstellen,

Einrichten, Programmierung oder Verfahrensumstellung, Bedienung, Reinigung, Wartung, Beseitigung, Abbau

und, soweit es die Sicherheit betrifft, auch die Entsorgung der in 1.1 genannten Maschinen.

Sie berücksichtigt deren bestimmungsgemäße Verwendung !, vorhersehbaren Missbrauch" sowie den

Ausfall von Komponenten und Systemfehler.

1.4 Diese Norm behandelt alle Gefährdungen, die in der Schuhindustrie und bei der Herstellung von

Leder- und Kunstlederwaren auftreten (Liste der Gefährdungen siehe Abschnitt 4.)

In dieser Norm werden nicht präzise technische Maßnahmen zur Herabsetzung der Gefährdung durch

Dämpfe und Stäube behandelt.

Der Einsatz von Maschinen nach dem Anwendungsbereich dieser Norm in anderen als den in 1.1 genannten

Industriezweigen kann zu Gefährdungen führen, die bei ihrer Ausarbeitung nicht berücksichtigt wurden.

1.5 Diese Norm gilt auch für Materialzufuhr- und Handhabungseinrichtungen, die Teil der jeweiligen

Maschine sind.

1.6 Diese Norm geht davon aus, dass die Maschinen

von speziell ausgebildeten Personen bedient werden;

mit geeigneter Arbeitsstättenbeleuchtung, die örtlichen Reglungen oder EN 12464-1 !gestrichener

Text" genügt, genutzt werden.

1.7 !Dieses Dokument gilt nicht für Spalt-, Schärf-, Schneid-, Klebstoffauftrag- und Klebstofftrocknungsmaschinen,

die vor Veröffentlichung als EN hergestellt wurden."

Machines de fabrication de chaussures et d'articles en cuir et en matériaux similaires - Machines à refendre, à parer, à couper, à encoller et à sécher l'adhésif - Prescriptions de sécurité

1.1 Le présent document s'applique aux machines à refendre, à parer, à rafraîchir les bords, à couper en bandes,

à encoller et à sécher l'adhésif utilisées pour la fabrication de chaussures et d'articles en cuir et en matériaux

similaires et autres composants associés.

1.2 Le présent document ne s'applique pas :

— aux machines à fraiser munies d'une fraise rotative pour fraiser les arêtes des matériaux, voir l'EN 930 ;

— aux machines à refendre et à ruban tranchant utilisées en tannerie, voir l'EN 13112 ;

— aux machines portatives.

1.3 Le présent document spécifie les prescriptions de sécurité concernant la construction, le transport,

l'installation, la mise au point, le réglage, l'apprentissage ou le changement de processus de fabrication,

le fonctionnement, le nettoyage, la maintenance, la mise hors service, le démontage et, pour ce qui concerne

la sécurité, la mise au rebut des machines mentionnées en 1.1.

Elle tient compte de l'utilisation normale, !des situations prévisibles d’utilisation impropre".

1.4 Le présent document traite tous les phénomènes dangereux significatifs liés aux industries de fabrication de

chaussures et d'articles en cuir et en matériaux similaires (pour la liste des phénomènes dangereux, voir l'article 4).

Le document ne traite pas des mesures techniques précises pour la réduction des risques liés aux vapeurs

et poussières nuisibles à la santé.

L'utilisation de machines entrant dans le domaine d'application du présent document pour des secteurs industriels

différents de ceux spécifiés en 1.1 peut entraîner des phénomènes dangereux non envisagés au cours de son

élaboration.

1.5 Le présent document s'applique également aux équipements supplémentaires pour la manutention des

matériaux et le fonctionnement qui font partie intégrante de la machine.

1.6 Le présent document suppose que les machines :

- sont utilisées par des personnes formées de manière adéquate ;

- sont utilisées avec un éclairage approprié (...)

Stroji za izdelavo obutve ter izdelkov iz usnja in njegovih imitacij - Stroji za cepljenje, brušenje, rezanje ter nanos in sušenje lepila - Varnostne zahteve

Ta dokument velja za stroje za cepljenje, brušenje, rezanje robov, rezanje trakov, nanos in sušenje lepila, ki se uporabljajo v proizvodnji obutve, izdelkov iz usnja ali njegovih imitacij in ostalih povezanih sestavnih delov. Ta dokument se ne nanaša na: - stroje za obrezovanje z vrtečimi orodji za mletje za namen obrezovanja robov materiala, glej EN 930; - stroje za cepljenje in stroje s tračnimi noži, ki se uporabljajo v strojarnah, glej EN 13112; - prenosne stroje. Ta dokument določa varnostne zahteve za izgradnjo, transport, postavitev, prilagoditev, nastavitev, poučevanje ali spreminjanje procesov, delovanje, čiščenje, vzdrževanje, izločitvijo iz uporabe, razgradnjo in kar se varnosti tiče, odstranitev omenjenega stroja, omenjeno v točki 1.1. Ta standard obravnava predvideno uporabo, »predvidljivo napačno uporabo« ter okvaro komponent in sistemov. Ta dokument obravnava velike nevarnosti, povezane s proizvodno industrijo obutve, izdelkov iz usnja in njegovih imitacij. (Za seznam nevarnosti glej Klavzulo 4.) Ta dokument ne obravnava natančnih tehničnih meritev za zmanjšanje tveganja škodljivih hlapov in prahu. Ta dokument ne obravnava natančnih tehničnih meritev za zmanjšanje tveganja hlapov in prahu, ki so škodljivi zdravju. Uporaba strojev, ki spadajo na področje uporabe tega dokumenta, za druge namene kot tiste, navedene v točki 1.1, lahko povzroči nevarnosti, ki niso bile upoštevane med njegovo pripravo. Ta dokument prav tako velja za opremo za rokovanje z materialom in delovanja, ki so sestavni del stroja. Ta dokument predvideva, da se stroji – upravljani z ustrezno usposobljenimi osebami – uporabljajo z ustrezno razsvetljavo delovnega prostora v skladu z lokalnimi predpisi ali z EN 12464-1. Ta dokument ne velja za stroje za cepljenje, brušenje, obrezovanje robov, rezanje trakov, nanos in sušenje lepila, ki so bili proizvedeni, preden je bil objavljen kot EN.

General Information

- Status

- Published

- Publication Date

- 01-Jun-2010

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 12-May-2010

- Due Date

- 17-Jul-2010

- Completion Date

- 02-Jun-2010

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 01-Jul-2010

- Effective Date

- 01-Jul-2010

Overview - EN 13457 (SIST EN 13457:2005+A1:2010)

SIST EN 13457:2005+A1:2010 (EN 13457:2004+A1:2010) is the European safety standard for machines used in footwear, leather and imitation leather goods manufacture. It covers splitting, skiving, edge trimming, strip cutting, cementing and cement drying machines, and also applies to material-handling equipment that is an integral part of those machines. The standard sets safety requirements across the machine lifecycle - from design and construction through installation, operation, maintenance and decommissioning - while accounting for intended use, foreseeable misuse and component or system failure.

Key topics and technical requirements

The standard is a Type C machine-specific standard and addresses significant hazards (see Clause 4). Major technical topics include:

- General safety principles for machine construction and layout

- Mechanical, electrical and thermal protection, including fire prevention

- Guards and interlocking devices (Annexes A, B, I) and requirements for protective devices such as trip devices and hold-to-run controls (Annexes C, D)

- Control systems and additional safety devices to prevent unexpected start-up and hazardous operation

- Noise control at the design stage and declared noise emission values (Annex E)

- Ergonomics and operator interface requirements

- Pressurized fluid systems (hydraulics/pneumatics) and their safety (EN 982/983 referenced)

- Fumes and dust: the standard identifies related hazards but does not prescribe precise technical measures for controlling harmful fumes/dusts

- Verification, marking and information for use (instruction manuals, signal devices)

The standard also includes specific additional requirements per machine type (splitting, skiving, cutting, strip cutting, cementing, cement drying) and normative annexes covering testing and special protective devices.

Practical applications - who uses EN 13457

- Machine manufacturers designing and certifying footwear and leather-processing equipment to meet EU safety requirements and support CE marking

- Safety engineers and compliance officers evaluating machine risk and conformity with 2006/42/EC (Machinery Directive)

- Plant managers and maintenance teams establishing safe procedures for installation, operation, cleaning and servicing

- Procurement specialists specifying safety features in tenders for splitting, skiving, cutting and cementing machinery

- Training providers developing operator training based on assumed operator competency and required workplace lighting (EN 12464-1 referenced)

Related standards and references

EN 13457 references multiple normative standards important for compliance and design, including:

- EN 60204-1 (electrical equipment of machines)

- EN 12464-1 (workplace lighting)

- EN 953 / EN 1088 (guards and interlocking)

- EN 982 / EN 983 (fluid power safety)

- EN ISO 12100 (machine safety principles)

- Noise and explosion prevention annexes (EN 12545, EN 1127-1)

For manufacturers and users of footwear manufacturing machines, EN 13457 is the primary safety benchmark to reduce machine-related hazards and to document conformity with European machinery safety requirements.

Frequently Asked Questions

SIST EN 13457:2005+A1:2010 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Footwear, leather and imitation leather goods manufacturing machines - Splitting, skiving, cutting, cementing and cement drying machines - Safety requirements". This standard covers: This document applies to splitting, skiving, edge trimming, strip cutting, cementing and cement drying machines used in the manufacture of footwear, leather and imitation leather goods and other related components. 1.2 This document does not apply to: - trimming machines with rotary milling tool for the purpose of trimming edges of material, see EN 930; - splitting and band knife machines used in tanneries, see EN 13112; - portable machines. 1.3 This document specifies safety requirements for construction, transport, installation, adjustment, setting, teaching or process change-over, operation, cleaning, maintenance, decommissioning, dismantling and, as far as safety is concerned, disposal for machines mentioned in 1.1. It takes account of intended use , foreseeable misuse, component and system failure. 1.4 This document deals with significant hazards relevant to the footwear, leather and imitation leather goods manufacturing industries. (For a list of hazards see Clause 4.) The document does not deal with precise technical measures for reducing the risks of fumes and dusts detrimental to health. The use of machines falling within the scope of this document for purposes other than those specified in 1.1, may give rise to hazards not considered during its preparation. 1.5 This document also applies to equipment for material handling and operations which are an integral part of the machine. 1.6 This document assumes the machines - are operated by adequately trained persons - are used with adequate workplace lighting conforming the local regulations or to EN 12464-1 1.7 This document is not applicable to splitting, skiving, edge trimming, strip cutting, cementing and cement drying machines which are manufactured before the date of its publication as EN.

This document applies to splitting, skiving, edge trimming, strip cutting, cementing and cement drying machines used in the manufacture of footwear, leather and imitation leather goods and other related components. 1.2 This document does not apply to: - trimming machines with rotary milling tool for the purpose of trimming edges of material, see EN 930; - splitting and band knife machines used in tanneries, see EN 13112; - portable machines. 1.3 This document specifies safety requirements for construction, transport, installation, adjustment, setting, teaching or process change-over, operation, cleaning, maintenance, decommissioning, dismantling and, as far as safety is concerned, disposal for machines mentioned in 1.1. It takes account of intended use , foreseeable misuse, component and system failure. 1.4 This document deals with significant hazards relevant to the footwear, leather and imitation leather goods manufacturing industries. (For a list of hazards see Clause 4.) The document does not deal with precise technical measures for reducing the risks of fumes and dusts detrimental to health. The use of machines falling within the scope of this document for purposes other than those specified in 1.1, may give rise to hazards not considered during its preparation. 1.5 This document also applies to equipment for material handling and operations which are an integral part of the machine. 1.6 This document assumes the machines - are operated by adequately trained persons - are used with adequate workplace lighting conforming the local regulations or to EN 12464-1 1.7 This document is not applicable to splitting, skiving, edge trimming, strip cutting, cementing and cement drying machines which are manufactured before the date of its publication as EN.

SIST EN 13457:2005+A1:2010 is classified under the following ICS (International Classification for Standards) categories: 59.140.40 - Machines and equipment for leather and fur production; 61.060 - Footwear. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13457:2005+A1:2010 has the following relationships with other standards: It is inter standard links to SIST EN 13457:2005/kFprA1:2009, SIST EN 13457:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13457:2005+A1:2010 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13457:2005+A1:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stroji za izdelavo obutve ter izdelkov iz usnja in njegovih imitacij - Stroji za cepljenje, brušenje, rezanje ter nanos in sušenje lepila - Varnostne zahteveMaschinen zur Herstellung von Schuhen, Leder- und Kunstlederewaren - Spalt-, Schärf-, Schneid-, Klebstoffauftrag- und Klebstofftrockenmaschinen - SicherheitsanforderungenMachines de fabrication de chaussures et d'articles en cuir et en matériaux similaires - Machines à refendre, à parer, à couper, à encoller et à sécher l'adhésif - Prescriptions de sécuritéFootwear, leather and imitation leather goods manufacturing machines - Splitting, skiving, cutting, cementing and cement drying machines - Safety requirements61.060ObuvalaFootwear59.140.40Stroji in oprema za proizvodnjo usnja in krznaMachines and equipment for leather and fur productionICS:Ta slovenski standard je istoveten z:EN 13457:2004+A1:2010SIST EN 13457:2005+A1:2010en,fr01-julij-2010SIST EN 13457:2005+A1:2010SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13457:2004+A1

April 2010 ICS 59.140.40; 61.060 Supersedes EN 13457:2004English Version

Footwear, leather and imitation leather goods manufacturing machines - Splitting, skiving, cutting, cementing and cement drying machines - Safety requirements

Machines de fabrication de chaussures et d'articles en cuir et en matériaux similaires - Machines à refendre, à parer, à couper, à encoller et à sécher l'adhésif - Prescriptions de sécurité

Maschinen zur Herstellung von Schuhen, Leder- und Kunstlederewaren - Spalt-, Schärf-, Schneid-, Klebstoffauftrag- und Klebstofftrockenmaschinen - Sicherheitsanforderungen This European Standard was approved by CEN on 8 August 2004 and includes Amendment 1 approved by CEN on 18 March 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13457:2004+A1:2010: ESIST EN 13457:2005+A1:2010

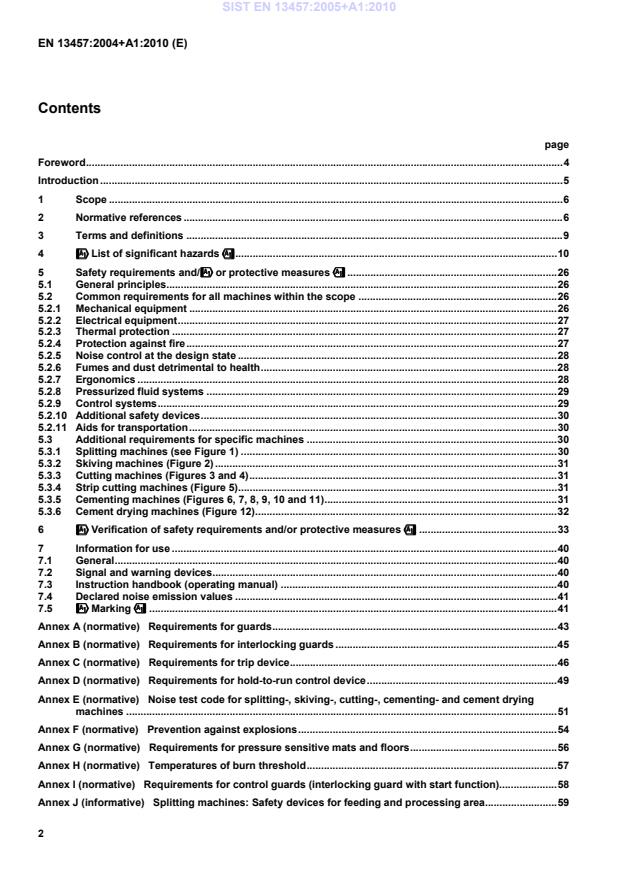

Requirements for guards . 43Annex B (normative)

Requirements for interlocking guards . 45Annex C (normative)

Requirements for trip device . 46Annex D (normative)

Requirements for hold-to-run control device . 49Annex E (normative)

Noise test code for splitting-, skiving-, cutting-, cementing- and cement drying machines . 51Annex F (normative)

Prevention against explosions . 54Annex G (normative)

Requirements for pressure sensitive mats and floors . 56Annex H (normative)

Temperatures of burn threshold . 57Annex I (normative)

Requirements for control guards (interlocking guard with start function). 58Annex J (informative)

Splitting machines: Safety devices for feeding and processing area. 59SIST EN 13457:2005+A1:2010

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC . 60Annex ZB (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC"""" . 61SIST EN 13457:2005+A1:2010

– Lighting of work places – Part 1: Indoor work places SIST EN 13457:2005+A1:2010

tactile signals (IEC 61310-1:2007)" EN 61496-1:2004, Safety of machinery – Electro-sensitive protective equipment – Part 1: General requirements and tests (IEC 61496-1:2004, modified) !CLC/TS 61496-2:2006, Safety of machinery – Electro-sensitive protective equipment – Particular requirements for equipment using active opto-electronic protective devices (AOPDs) (IEC 61496-2:2006)" !deleted text" !EN ISO 11688-1:2009", Acoustics – Recommended practice for the design of low-noise machinery and equipment – Part 1: Planning (ISO/TR 11688-1:1995) EN ISO 11688-2:2000, Acoustics – Recommended practice for the design of low-noise machinery and equipment – Part 2: Introduction to the physics of low-noise design (ISO/TR 11688-2:1998) !EN ISO 11689:1996", Acoustics – Procedure for the comparison of noise-emission data for machinery and equipment (ISO 11689:1996) EN ISO 12100-1:2003, Safety of machinery – Basic concepts, general principles for design – Part 1: Basic terminology, methodology (ISO 12100-1:2003) EN ISO 12100-2:2003, Safety of machinery – Basic concepts, general principles for design – Part 2: Technical principles (ISO 12100-2:2003) !EN ISO 13732-1:2008, Ergonomics of the thermal environment — Methods for the assessment of human responses to contact with surfaces — Part 1: Hot surfaces (ISO 13732-1:2006)" !EN ISO 13849-1:2008, Safety of machinery — Safety-related parts of control systems — Part 1: General principles for design (ISO 13849-1:2006)" !EN ISO 13850:2008, Safety of machinery — Emergency stop — Principles for design (ISO 13850:2006)" !EN ISO 13857:2008, Safety of machinery — Safety distances to prevent hazard zones being reached by upper and lower limbs (ISO 13857:2008)" !EN ISO 14122-1:2001", Safety of machinery – Permanent means of access to machinery – Part 1: Choice of fixed means of access between two levels (ISO 14122-1:2001) EN ISO 14122-2:2001, Safety of machinery – Permanent means of access to machinery – Part 2: Working platforms and walkways (ISO 14122-2:2001) SIST EN 13457:2005+A1:2010

4.3.1 Transmission and drive mechanisms entanglement, drawing-in and trapping, friction, crushing, shearing

4.3.2 Moving machinery parts of

- electrical crushing, shearing, impact, drawing-in

- hydraulic

- pneumatic

- mechanical units and workpieces

4.3.3 Loading and unloading area

- clamping device crushing

- guiding rollers drawing-in, crushing J.1

- handling device crushing, shearing

- conveyor shearing, drawing in 12 4.3.4 Processing area

a) Splitting, skiving, edge trimming, last margin and strip cutting machines

- cutting areas edge of running or stationary cutting, severing

• splitting knife 1

• skiving knife 2

• edge trimming knife cutting, severing 3

• last margin trimming knife 4

• strip cutting knife 5

- rotating grinding wheel abrasion, ejection of parts, injury to eyes

- setting, adjustment of

• skiving, splitting, strip cutting and

cutting, severing

• edge trimming knife

• grinding wheel abrasion, bursting

• sparks from dressing of grinding wheel injuries to skin and eyes, ignition source

• falling down/out of the uptilted skiving machine by gravity crushing, shearing

b) Cementing machines

area between transport roller and application roller crushing, drawing-in, abrasion 6, 7

area between fixed machine parts

e. g. dip tank and moveable suspension device shearing, crushing 8

centrifugal device for counters and heels trapping 8

area between moving sole or last shoe and moving brush crushing 11

c) Cement drying machines

area between fixed machine parts and conveyor trapping, drawing-in, shearing 12 4.3.5 Operator’s standing area

- uneven, sloping, slippery platforms slipping

- steps tripping

- protruding parts falling

4.3.6 Movement of machine due to gravity while being transported crushing, shearing

4.4 Electrical hazards

Electrical contact, directly or indirectly, caused by

- component failure electric shock, burns

- insulation failure

- incorrect design, installation or component specifications of the electrical equipment

4.5 Thermal hazards

Accidental contact with

- roller dressed by hot melt cement risk of burns

- hot melt chamber

- nozzle

- reactivation unit

- during suspension or by squirting

4.6 Fire hazards

splitting, skiving machines

- the ignition of dust created by the action of the tool on the material being worked burns

cementing and cement drying machines

- the ignition of fumes of flammable liquid (solvent, solvent containing glue) burns

Table 1 — !!!!List of significant hazards"""" (concluded) Danger zone or source of hazard Type of hazard 4.7 Explosion hazards

cementing and cement drying machines

- the ignition of explosive atmosphere of inflammable liquid (solvent, solvent containing glue)

4.8 Noise

- hydraulic unit loss of hearing, interference with speech communication and perception of acoustic signals

- pneumatic equipment

- extraction equipment

- machine parts and tools 4.9 Emission of fumes or skin contact risk of occupational disease (breathing system, skin, nervous system)

cementing and cement drying machines using solvent containing glue during

- operation

- setting

- cleaning

- overheating of hot melt

- skin contact with solvents

splitting and skiving machines

- dust generated by cutting (breathing system, skin) 4.10 Neglect of ergonomic principles risk of occupational disease

- inadequate local lighting accidents resulting from poor visibility

- poor operator posture fatigue

- excessive effort during loading and unloading physical and mental stress

- poor control layout and display identification psychological stress

- unsuitable height and size in relation to human body dimensions muscolo-skeletal injury/repetitive strain injury (work related upper limb disorder) 4.11 Functional disorders:

- failure of control system (malfunction safety devices and machine control) all possible hazards generated by unexpected dangerous movements (e. g. unexpected start or closing movement, prevention of stop function)

- fault of energy supply (irregularity failure, unexpected reconnection)

- electromagnetic disturbances 4.12 High pressure fluid ejection or ejection of part of a burst component

by failure of hydraulic or pneumatic unit (broken hoses, fittings and pipework) injury from hot oil or impact from flexible hoses

Key a

Band knife splitting machine b

Processing area c

Splitting machine with fixed knife profiling splitting machine 1

Profile roller 2

Profiling roller 3

Counter roll 4

Drawing in mechanism 5

Feeding table Figure 1 — Splitting machine SIST EN 13457:2005+A1:2010

Key a

Skiving machine (front view) with bell shaped knife b

Computerised skiving machine with bell shaped knife 1

Processing area Figure 2 — Skiving machine

Key 1

Processing area Figure 3 — Edge trimming machine for linings with oscillating knife SIST EN 13457:2005+A1:2010

Key 1

Processing area

Figure 4 — Last margin trimming machine SIST EN 13457:2005+A1:2010

Key a

Strip cutting machine with circular knives b

Continuous cutting machine 1

Knife shaft 2

Limit bar 3

Spreader table 4

Processing area 5

Knife pair 6

Material 7

Belt Figure 5 — Strip cutting machine SIST EN 13457:2005+A1:2010

Key 1

Feed roller 2

Application roller 3

Processing area 4

Drive mechanism Figure 6 — Roller cementing machine designed for solvent based adhesive

Key 1

Feed roller 2

Application roller 3

Processing area 4

Tension roller 5

Spreader table 6

Application roller 7

Stripper 8

Adhesive tank Figure 7 — Roller cementing machine designed for water based adhesive

Key a

Cement-dipping machine for heels b

Cement-dipping machine for counters (centrifugal method) 1

Conveyor 2

Hanging device 3

Feeding 4

Dip tank 5

Centrifugal drive Figure 8 — Cementing machine

Figure 9 — Hot melt fixed applicator for multi use SIST EN 13457:2005+A1:2010

Key 1

Cement container 2

Support Figure 10 — Spraying applicator for water based adhesive SIST EN 13457:2005+A1:2010

Key 1

Processing area 2

Feeding area Figure 11 — Automatic bottom cementing machine with rotary brush SIST EN 13457:2005+A1:2010

Key a

Cement drying machine with conveyor configuration b

Cement drying machine with conveyor with additional ventilation system 1

Loading end 2

Unloading end 3

Reactivation system 4

Conveyor 5

Fan 6

Ventilation system Figure 12 — Cement drying machine SIST EN 13457:2005+A1:2010

5 Safety requirements and/!!!!or protective measures"""" 5.1 General principles Machines conforming to this standard shall satisfy the requirements and all measures set out in this clause. For the reduction of hazards not identified in this document the principles contained in EN ISO 12100 (all parts) !shall" be applied. For hazards which are reduced by application of a B-Level standard such as !EN ISO 13850, EN ISO 13857", EN 60204-1 etc., the manufacturer shall carry out a risk assessment to establish the requirements of the B-standard to be applied. This specific risk assessment shall be part of the general risk assessment of the machine. 5.2 Common requirements for all machines within the scope 5.2.1 Mechanical equipment 5.2.1.1 Transmission and drive mechanisms !All transmission machinery and drive mechanisms shall be safeguarded by fixed enclosing guards which meet the requirements of EN 953 and A.4." 5.2.1.2 Machinery parts, tools and workpieces 5.2.1.2.1 Unless otherwise specified by 5.3 and with consideration of !usability/applicability", hazardous movements of machinery parts, tools and workpieces shall be safeguarded by the means shown in the following listing given in order of preference: !fixed enclosing guards which meet the requirements of A.4 and EN 953; or" !fencing which meets the requirements of A.3 and A.4; or" !fixed covers which meet the requirements of A.1 and A.4; or" interlocking guards which meet the requirements of B.2 of this document. 5.2.1.2.2 Where the protective measures given in 5.2.1.2.1 cannot be provided, devices shall be provided which will effect a shut down of the hazardous motion before the danger point is reached. Devices which will effect this are: trip devices which meet the requirements of Annex C of this document, such as electrosensitive protective devices or mechanical trip devices; pressure sensitive bars which meet the requirements of EN 1760-2; hold to run control devices which meet the requirements of Clause D.1 of this document, unless otherwise specified in 5.3. 5.2.1.2.3 Safety distances and gap limitations for guard shall comply at least with Tables 1, 3, 4 of

!EN ISO 13857:2008", unless otherwise specified in 5.3. 5.2.1.2.4 Safeguards at crushing, shearing, drawing-in, trapping and friction points are not required if the maximum force of moving parts is limited to 150 N and the contact pressure is limited to 50 N/cm². SIST EN 13457:2005+A1:2010

EN ISO 14122-1. 5.2.2 Electrical equipment 5.2.2.1 Electrical systems and equipment shall be in accordance with EN 60204-1. With respect to some clauses of !EN 60204-1:2006", stated hereafter, the following shall apply: 4.3: A.C. supplies: 4.3.2; D.C. supplies: 4.3.3; 6.2: Protection in accordance with 6.2.2 or 6.2.3 and, where applicable 6.2.4; 9.2.5.3/4: stop function and emergency switching off: Category 0; 9.4: the safety related parts of the control system shall meet the requirements of 5.2.9.4 and 5.2.9.5 of this document; !!!!11.3"""": degree of protection: at least IP 54 (in case of fine dust, a higher degree than IP 54 can be necessary). 5.2.2.2 All operating control devices requiring frequent adjustment for altering process settings shall be located outside the electrical control cabinet. NOTE Controls for routine electrical adjustment are, for instance, to vary feed, speed, time, temperature or pressure. 5.2.3 Thermal protection Hot surfaces within reach shall be avoided or safeguards provided against accidental contact such that, the temperatures of burn threshold for the material concerned and a contact time of less than 1 s, given in

!EN ISO 13732-1", are not exceeded. Selected values on the basis of Figures 2, 5 and 6 of

!EN ISO 13732-1:2008" are given in Annex H. 5.2.4 Protection against fire 5.2.4.1 Machines which generate dust shall be designed and constructed such, that dust accumulation which may be ignited by a machine overheating or by sparks is prevented, according to EN 13478. 5.2.4.2 Enclosed zones of a machine where dust accumulation could cause a fire hazard shall be cleanable by the operator without the need for auxiliary means to gain access. These zones shall not contain danger points caused by mechanical hazards. Information on these zones and cleaning methods shall be included in the instructions for use, together with recommendations on disposal of the dust. 5.2.4.3 For collection, transportation and disposal of generated dust the machines shall be equipped with a provision for dust removal (e.g. dust collection bag or bin). Dust collectors shall be made out of non-flammable materials. Dust filters shall be made flame retardant. 5.2.4.4 Internal dust exhaust equipment shall be interlocked with the drive mechanism of the machine. !The parts of the control system related to the interlocking shall present at least a performance level "c" defined in accordance with EN ISO 13849-1." SIST EN 13457:2005+A1:2010

EN ISO 11688-1 and EN ISO 11688-2. Examples of noise control measures are: a) reduction of vibration through static and dynamic balancing of rotation parts; b) reduction of vibration within the machine by reducing both the mass of moving parts and their acceleration; c) reduction of impactive over-clearance of rotational bearings by application of positive preloading; d) proper choice and design of energy transfer-components to eliminate bouncing; e) proper choice and design of transmission components (gears, pulleys, belts, bearings etc.); f) proper design of machine structures taking into account vibration damping and avoidance of structural resonance; g) sound deadening of pneumatic discharges, vibration damping of hydraulic circuits. The above list is not exhaustive. Other noise control measures with the same or better efficacy can be used by a manufacturer. 5.2.6 Fumes and dust detrimental to health Reduction of risk to health from fumes and dusts shall be carried out by observing the state of the art and Clause 6 of EN 626-1:1994. The machine shall either be designed with its own filter system or designed to enable it to be fitted to a suitable capture hood. Because of the range of materials concerned in the process covered by this document, it is not possible to give more precise precautions. In recirculating systems dust filter shall meet dust class L and penetration 1 % of Annex AA of EN 60335-2-69:2003. 5.2.7 Ergonomics Machine design shall incorporate the ergonomic principles described in 4.8 of EN ISO 12100-2:2003 and EN 614-1. In particular, the design shall consider: the working height; operator posture and movement; operator physical strength especially during setting, in accordance with EN 1005-2 and

EN 1005-3; ease of access and compatibility of control actuators in accordance with EN 894-3; operator access to the working area in accordance with EN 547-1 and EN 547-2; if necessary, a suitable platform in accordance with EN ISO 14122-2 shall be provided; the platform shall be non-sloping; design of displays in accordance with EN 894-2; additional local lighting on the machine in accordance with EN 12464-1 !deleted text". SIST EN 13457:2005+A1:2010

!EN ISO 13849-1". Safety related parts are for example emergency stopping systems, safety interlocking systems for guards, safety devices, the monitoring, emergency system for the ventilation in case of explosion risk. 5.2.9.3 In general the following principles apply: !safety related parts of pneumatic and hydraulic control systems shall present at least a performance level "c" defined in accordance with EN ISO 13849-1;" !safety related parts of electrical / electronic control systems shall normally present at least a performance level "d" defined in accordance with EN ISO 13849-1. Depending on the risk assessment the parts of the control system related to the emergency stop system shall present a performance level of at least "c" defined in accordance with EN ISO 13849-1." !NOTE This requirement includes that safety related functions shall not solely rely on normal traditional programmable electronic systems (PES): the required performance level should be realised by the use of, for example, an additional hardwired circuit, a redundant solid state channel, or other provisions for redundancy. when using a performance level "d" (based on the risk assessment) with a category 2 the test interval shall be as short as required and not more than 4 h. the parts of the control system processing the signal of a safety device shall comply at least with the performance level of that device." 5.2.9.4 Interlocking devices for safeguards and devices for muting of safeguards shall only be operated by position sensors (pressure, time or programme controlled commands of interlocks alone are not permitted). Electrical position sensors shall comply with EN 60947-5-1 and be appropriate for functioning in the positive mode according to EN 1088. According to 5.1 of EN 1088:1995, non-positive mode actuation is only allowed in conjunction with a detector with positive mode actuation, notably to avoid common cause failures. 5.2.9.5 Appropriate provisions shall be provided, taking into account the requirements of EN 1037,

EN 982, EN 983, EN 60204-1, against all hazards related to failure of the power supply, including irregularities, unexpected reconnection after interruption of the power supply, or when the control circuit has been switched off. 5.2.9.6 Foot-actuated controls which actuate hazardous motion and which are not fixed to the machine, and foot-actuated controls at standing working positions, shall be provided with a cover around the foot-actuated control to prevent accidental operation.

5.2.9.7 The machine shall have sufficient immunity in relation with electromagnetic disturbances to enable them to operate safety as intended and not fail to danger when exposed to the levels and types of disturbances intended by the manufacturer. SIST EN 13457:2005+A1:2010

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...