SIST EN 1559-2:2014

(Main)Founding - Technical conditions of delivery - Part 2: Additional requirements for steel castings

Founding - Technical conditions of delivery - Part 2: Additional requirements for steel castings

This part of EN 1559 specifies the additional technical delivery conditions for steel castings unless other conditions have been agreed at the time of enquiry and order.

This European Standard is also applicable to nickel and cobalt alloy castings.

Gießereiwesen - Technische Lieferbedingungen - Teil 2: Zusätzliche Anforderungen an Stahlgussstücke

Dieser Teil von EN 1559 legt die zusätzlichen technischen Lieferbedingungen für Stahlgussstücke fest, soweit nicht zum Zeitpunkt der Anfrage und Bestellung andere Bedingungen vereinbart wurden.

Dieser Teil von EN 1559 gilt auch für Gussstücke aus Nickel- und Kobaltlegierungen.

Fonderie - Condition techniques de fourniture - Partie 2: Spécifications complémentaires pour les pièces moulées en acier

La présente partie de l'EN 1559 spécifie les conditions techniques complémentaires de fourniture pour les pièces moulées en acier, à moins que d'autres conditions aient été convenues au moment de l'appel d'offres et de la commande.

La présente norme peut aussi être utilisée pour les pièces moulées en alliages de nickel et de cobalt.

Livarstvo - Tehnični dobavni pogoji - 2. del: Dodatne zahteve pri jeklenih ulitkih

Ta del standarda EN 1559 določa dodatne tehnične dobavne pogoje za jeklene ulitke, razen če je bil v času povpraševanja in naročila sklenjen dogovor o drugih pogojih.

Ta del standarda EN 1559 se uporablja tudi za ulitke iz nikljeve in kobaltove zlitine.

General Information

- Status

- Published

- Public Enquiry End Date

- 24-Oct-2012

- Publication Date

- 21-Oct-2014

- Technical Committee

- IFEK - Ferrous metals

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 13-Oct-2014

- Due Date

- 18-Dec-2014

- Completion Date

- 22-Oct-2014

Relations

- Effective Date

- 01-Dec-2014

Overview

EN 1559-2:2014 - Founding: Technical conditions of delivery - Part 2: Additional requirements for steel castings specifies the additional contractual and technical delivery conditions for steel castings (and explicitly extends to nickel and cobalt alloy castings) unless alternative arrangements are agreed at enquiry and order. It is intended to be used together with EN 1559-1 (General) and forms part of the EN 1559 series covering delivery conditions for castings.

Key Topics

- Scope and applicability

- Additional delivery conditions for steel, nickel and cobalt alloy castings; complements EN 1559-1.

- Information to be supplied by the purchaser

- Mandatory and optional data (e.g., relevant wall thickness, special product requirements).

- Designations

- Steel designations per EN 10027-1/2.

- Manufacture and processing

- Melting requirements (electric melting or secondary refining), optional heat treatment, welding operations and reporting, responsibility for purchaser post-delivery processing.

- Material requirements

- Chemical composition control and permissible deviations for product analyses (table of allowable deviations is included).

- Casting requirements

- Casting-specific technical conditions (surface, defects, welding excavations - criteria may be agreed).

- Inspection and testing

- Detailed provisions on inspection types, test units, sample castings and test pieces.

- References to non-destructive testing methods and standards: ultrasonic, radiographic, magnetic particle, liquid penetrant, computed radiography and visual testing.

- Provisions for validation of test results, retests, reporting and reprocessing.

- Marking, packaging and complaints

- Delivery marking, packaging/specimen protection and handling of nonconformities.

Applications / Who uses it

- Foundries and steel casting manufacturers - to define production and delivery requirements, inspection and reporting obligations.

- Purchasers, specifiers and procurement teams - to prepare clear enquiry/order documentation and contractual specifications.

- Quality managers and inspectors - for acceptance criteria, sampling, testing and NDT requirements.

- Design and engineering teams - to ensure material designation, heat treatment and weldability requirements are met.

- Third-party inspectors and certification bodies - to verify compliance with delivery conditions.

Practical uses include preparing contracts for supply of cast components, defining NDT regimes for cast parts, setting chemical analysis tolerances, and coordinating responsibilities for welding and heat treatment.

Related Standards (if applicable)

- EN 1559-1:2011 (General delivery conditions)

- EN 1559-3/4/5/6 (iron, aluminium, magnesium, zinc castings)

- Normative NDT and test references cited (examples): EN 12680 (ultrasonic), EN 12681 (radiographic), EN ISO 148-1 (Charpy), EN ISO 6892 (tensile), EN 1370/1371 (surface/penetrant testing)

Keywords: EN 1559-2:2014, steel castings standard, technical delivery conditions, foundry standard, NDT for castings, chemical composition tolerances, nickel cobalt alloy castings.

Frequently Asked Questions

SIST EN 1559-2:2014 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Founding - Technical conditions of delivery - Part 2: Additional requirements for steel castings". This standard covers: This part of EN 1559 specifies the additional technical delivery conditions for steel castings unless other conditions have been agreed at the time of enquiry and order. This European Standard is also applicable to nickel and cobalt alloy castings.

This part of EN 1559 specifies the additional technical delivery conditions for steel castings unless other conditions have been agreed at the time of enquiry and order. This European Standard is also applicable to nickel and cobalt alloy castings.

SIST EN 1559-2:2014 is classified under the following ICS (International Classification for Standards) categories: 77.140.80 - Iron and steel castings. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1559-2:2014 has the following relationships with other standards: It is inter standard links to SIST EN 1559-2:2000. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1559-2:2014 is associated with the following European legislation: EU Directives/Regulations: 97/23/EC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1559-2:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Gießereiwesen - Technische Lieferbedingungen - Teil 2: Zusätzliche Anforderungen an StahlgussstückeFonderie - Condition techniques de fourniture - Partie 2: Spécifications complémentaires pour les pièces moulées en acierFounding - Technical conditions of delivery - Part 2: Additional requirements for steel castings77.140.80Železni in jekleni ulitkiIron and steel castingsICS:Ta slovenski standard je istoveten z:EN 1559-2:2014SIST EN 1559-2:2014en,fr,de01-december-2014SIST EN 1559-2:2014SLOVENSKI

STANDARDSIST EN 1559-2:20001DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1559-2

October 2014 ICS 77.140.80 Supersedes EN 1559-2:2000English Version

Founding - Technical conditions of delivery - Part 2: Additional requirements for steel castings

Fonderie - Conditions techniques de fourniture - Partie 2: Spécifications complémentaires pour les pièces moulées en acier

Gießereiwesen - Technische Lieferbedingungen - Teil 2: Zusätzliche Anforderungen an Stahlgussstücke This European Standard was approved by CEN on 18 July 2014.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2014 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1559-2:2014 ESIST EN 1559-2:2014

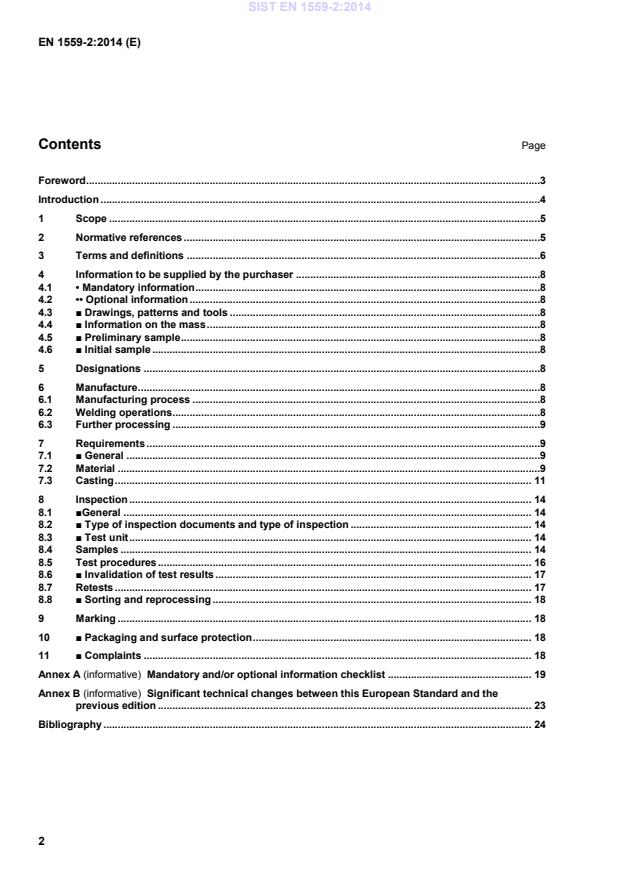

jandatory and/or optional information checklist . 19 Annex B (informative)

Significant technical changes between this European Standard and the previous edition . 23 Bibliography . 24

purchaser v

3.2 manufacturer v

3.3 casting v

3.4 as-cast casting v

3.5 as-delivered casting v

3.6 initial sample v

3.7 preliminary sample v

3.8 relevant wall thickness v

3.10 continuous inspection v

3.11 inspection representative v

3.12 test unit v

3.13 sample casting v

3.14 sample v

Note 1 to entry: In steel foundry industry the term used for sample is “test block”. 3.15 test piece v

3.16 sequential testing v

3.17 acceptance criteria v

3.18 drawing v

3.19 finishing welding v

3.20 joint welding v

3.21 excavation cavity produced by the removal of cast material prior to subsequent welding Note 1 to entry: It can be of minor or major nature according to its depth (over 40 % of the section thickness the excavations are major). SIST EN 1559-2:2014

> 0,030 ≤ 0,080 ±0,01

> 2,00 ≤ 5,00 ±0,20

> 0,080 ≤ 0,30 ±0,02 Nitrogen ≤ 0,30 ±0,02

> 0,30 ≤ 0,60 ±0,03 Niobium ≤ 1,00 ±0,05

> 0,60 ≤ 1,20 ±0,05

> 1,00 ±0,10

> 1,20 ≤ 2,00 ±0,06 Molybdenum ≤ 1,00 ±0,07

> 2,00 ±0,08

> 1,00 ≤ 2,00 ±0,10 Silicon ≤ 2,00 ±0,10

> 2,00 ≤ 5,00 ±0,15

> 2,00 ±0,20

> 5,00 ≤ 10,00 ±0,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...