SIST EN 12952-5:2022

(Main)Water-tube boilers and auxiliary installations - Part 5: Workmanship and construction of pressure parts of the boiler

Water-tube boilers and auxiliary installations - Part 5: Workmanship and construction of pressure parts of the boiler

This European Standard specifies requirements for the workmanship and construction of water-tube boilers as defined in EN 12952-1.

Wasserrohrkessel und Anlagenkomponenten - Teil 5: Verarbeitung und Bauausführung für drucktragende Kesselteile

Chaudières à tubes d'eau et installations auxiliaires - Partie 5: Fabrication et construction des parties sous pression des chaudières

Vodocevni kotli in pomožne napeljave - 5. del: Izdelava in izvedba tlačno obremenjenih delov kotla

Ta evropski standard določa zahteve za izdelavo in izvedbo vodocevnih kotlov iz standarda EN 12952-1.

General Information

- Status

- Published

- Public Enquiry End Date

- 02-Apr-2020

- Publication Date

- 18-Jan-2022

- Technical Committee

- TLP - Pressure vessels

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 17-Jan-2022

- Due Date

- 24-Mar-2022

- Completion Date

- 19-Jan-2022

Relations

- Effective Date

- 01-Feb-2022

Overview

SIST EN 12952-5:2022 - Water‑tube boilers and auxiliary installations - Part 5: Workmanship and construction of pressure parts of the boiler - specifies workmanship, fabrication and construction requirements for the pressure parts of water‑tube boilers as defined in EN 12952-1. Issued as a CEN (European) standard, it addresses manufacturing practices, material identification, marking, forming, welding, testing and mechanical connections to ensure safe, reliable boiler pressure parts.

Keywords: SIST EN 12952-5:2022, water‑tube boilers, pressure parts, workmanship, boiler construction, welding requirements

Key topics and technical requirements

The standard organizes practical requirements across manufacturing stages. Major topics include:

- Scope and definitions - applicability to drums, headers, tubes and similar pressure components in water‑tube boilers.

- Material identification and marking - responsibilities, temporary and permanent marking procedures for traceability of pressure and non‑pressure parts.

- Cutting, forming and fabrication tolerances - permitted cutting methods, post‑cutting treatment, forming of drums/headers/ends and dimensional tolerances for assemblies.

- Tube bends and reducers - manufacturing controls for tube bending, dimensional testing, limits and assessment of thinning/thickening on intrados/extrados for various nominal outside diameters, post‑bend heat treatment and surface quality (ripples, circularity).

- Welding - design considerations for welded joints, material selection, pre‑requisites, welding consumables, procedure qualification (including application of EN ISO 15614‑1:2017 Level 2), welder/operator qualification, pre‑/post‑weld heat treatment, repairs and traceability of welders.

- Non‑destructive examination and testing - requirements for production test plates, NDE of repairs and recording of weld repairs.

- Mechanical connections and access openings - design and size considerations for manholes, doors, flanges, studs and attachments.

Practical applications and who uses it

SIST EN 12952-5:2022 is a practical, prescriptive document used by organizations and professionals involved in boiler pressure‑part manufacture and inspection:

- Boiler manufacturers and fabricators (drums, headers, tube panels)

- Welding and quality control engineers responsible for PQR/WPS and welder qualification

- NDE and testing specialists performing dimensional checks, heat treatments and inspections

- Purchasing and material control teams ensuring marking and traceability

- OEMs, engineering contractors and regulatory bodies enforcing conformity with the EN 12952 series

Using this standard helps ensure consistent workmanship, safe pressure‑part construction, regulatory compliance and clear manufacturer traceability.

Related standards

- EN 12952‑1 (definition and general requirements for water‑tube boilers)

- EN ISO 15614‑1:2017 (welding procedure qualification referenced in the standard)

SIST EN 12952-5:2022 is essential for anyone specifying or producing pressure parts for water‑tube boilers to meet recognized European workmanship and construction best practices.

Frequently Asked Questions

SIST EN 12952-5:2022 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Water-tube boilers and auxiliary installations - Part 5: Workmanship and construction of pressure parts of the boiler". This standard covers: This European Standard specifies requirements for the workmanship and construction of water-tube boilers as defined in EN 12952-1.

This European Standard specifies requirements for the workmanship and construction of water-tube boilers as defined in EN 12952-1.

SIST EN 12952-5:2022 is classified under the following ICS (International Classification for Standards) categories: 27.060.30 - Boilers and heat exchangers. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 12952-5:2022 has the following relationships with other standards: It is inter standard links to SIST EN 12952-5:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 12952-5:2022 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 12952-5:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2022

Nadomešča:

SIST EN 12952-5:2012

Vodocevni kotli in pomožne napeljave - 5. del: Izdelava in izvedba tlačno

obremenjenih delov kotla

Water-tube boilers and auxiliary installations - Part 5: Workmanship and construction of

pressure parts of the boiler

Wasserrohrkessel und Anlagenkomponenten - Teil 5: Verarbeitung und Bauausführung

für drucktragende Kesselteile

Chaudières à tubes d'eau et installations auxiliaires - Partie 5: Fabrication et construction

des parties sous pression des chaudières

Ta slovenski standard je istoveten z: EN 12952-5:2021

ICS:

27.060.30 Grelniki vode in prenosniki Boilers and heat exchangers

toplote

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12952-5

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2021

EUROPÄISCHE NORM

ICS 27.040 Supersedes EN 12952-5:2011

English Version

Water-tube boilers and auxiliary installations - Part 5:

Workmanship and construction of pressure parts of the

boiler

Chaudières à tubes d'eau et installations auxiliaires - Wasserrohrkessel und Anlagenkomponenten - Teil 5:

Partie 5: Fabrication et construction des parties sous Verarbeitung und Bauausführung für drucktragende

pression des chaudières Kesselteile

This European Standard was approved by CEN on 1 November 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12952-5:2021 E

worldwide for CEN national Members.

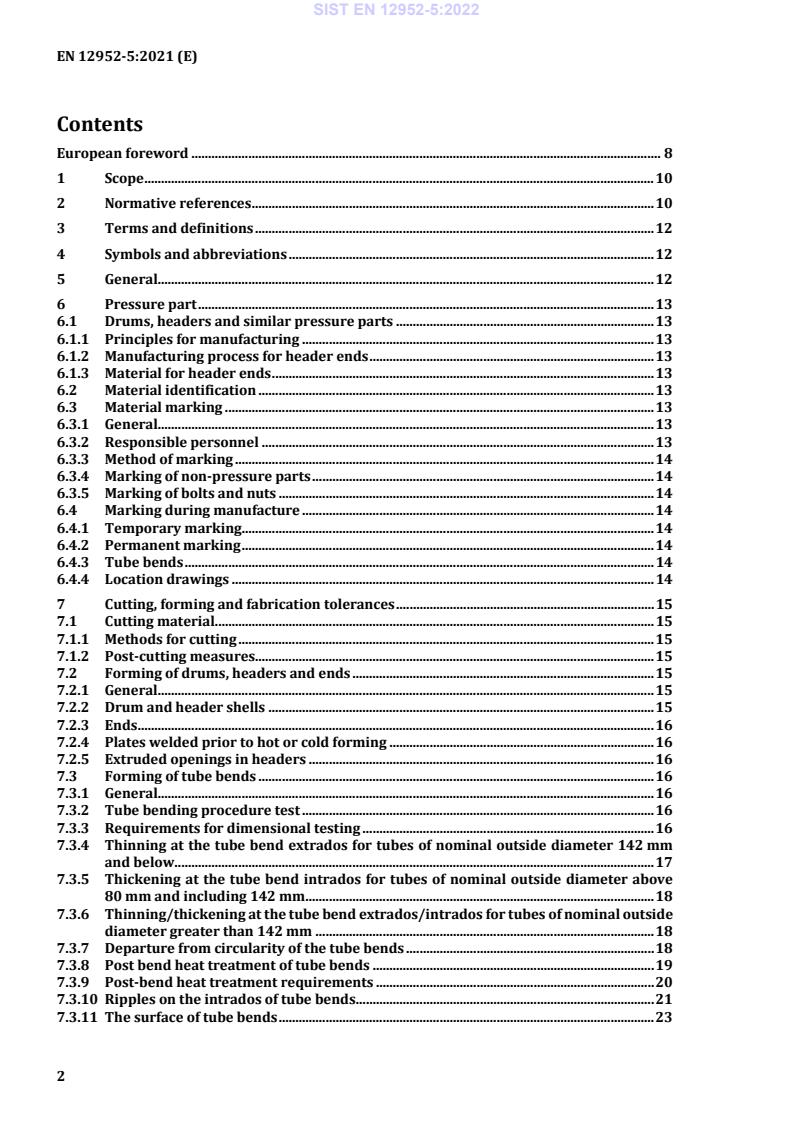

Contents

European foreword . 8

1 Scope . 10

2 Normative references . 10

3 Terms and definitions . 12

4 Symbols and abbreviations . 12

5 General. 12

6 Pressure part . 13

6.1 Drums, headers and similar pressure parts . 13

6.1.1 Principles for manufacturing . 13

6.1.2 Manufacturing process for header ends . 13

6.1.3 Material for header ends . 13

6.2 Material identification . 13

6.3 Material marking . 13

6.3.1 General. 13

6.3.2 Responsible personnel . 13

6.3.3 Method of marking . 14

6.3.4 Marking of non-pressure parts . 14

6.3.5 Marking of bolts and nuts . 14

6.4 Marking during manufacture . 14

6.4.1 Temporary marking. 14

6.4.2 Permanent marking . 14

6.4.3 Tube bends . 14

6.4.4 Location drawings . 14

7 Cutting, forming and fabrication tolerances . 15

7.1 Cutting material . 15

7.1.1 Methods for cutting . 15

7.1.2 Post-cutting measures. 15

7.2 Forming of drums, headers and ends . 15

7.2.1 General. 15

7.2.2 Drum and header shells . 15

7.2.3 Ends . 16

7.2.4 Plates welded prior to hot or cold forming . 16

7.2.5 Extruded openings in headers . 16

7.3 Forming of tube bends . 16

7.3.1 General. 16

7.3.2 Tube bending procedure test . 16

7.3.3 Requirements for dimensional testing . 16

7.3.4 Thinning at the tube bend extrados for tubes of nominal outside diameter 142 mm

and below . 17

7.3.5 Thickening at the tube bend intrados for tubes of nominal outside diameter above

80 mm and including 142 mm . 18

7.3.6 Thinning/thickening at the tube bend extrados/intrados for tubes of nominal outside

diameter greater than 142 mm . 18

7.3.7 Departure from circularity of the tube bends . 18

7.3.8 Post bend heat treatment of tube bends . 19

7.3.9 Post-bend heat treatment requirements . 20

7.3.10 Ripples on the intrados of tube bends . 21

7.3.11 The surface of tube bends . 23

7.3.12 Gang bending of tube panels. 23

7.3.13 Bending of composite materials tubing . 23

7.3.14 Manufacturing of tube reducers . 23

7.4 Drum and header fabrication tolerances . 24

7.4.1 Assembly tolerances for shells and fabricated from plate and end to shells. 24

7.4.2 Finished tolerances for shells . 25

7.4.3 Finished tolerances for ends . 26

8 Welding . 26

8.1 Design and other requirements specific to welding . 26

8.1.1 General . 26

8.1.2 Material selection with regard to welding . 27

8.1.3 Indication of the welded seams in the drawings . 27

8.1.4 Pre-requisites for welding . 27

8.1.5 Oxy-acetylene welding . 27

8.1.6 Butt welds in tube bends . 27

8.1.7 Minimum distances between adjacent seams . 27

8.1.8 Longitudinal butt welds in drum strakes. 28

8.1.9 Offset of longitudinal butt welds in the case of several strakes . 28

8.1.10 Joints of dissimilar materials . 28

8.1.11 Protection from the weather . 28

8.1.12 Availability of the welding procedure specification . 28

8.2 Welding consumables . 29

8.3 Welding procedure qualification . 29

8.3.1 General . 29

8.3.2 Application of EN ISO 15614-1:2017, Level 2 . 29

8.4 Qualification of welders and welding operators . 31

8.5 General production requirements for welding . 32

8.5.1 Surface condition before welding . 32

8.5.2 Assembly of components for welding . 32

8.5.3 Temporary attachments . 32

8.5.4 Stray arcing . 32

8.5.5 Traceability of welders . 32

8.6 Repairs to welds . 33

8.6.1 General . 33

8.6.2 Repair of longitudinal and circumferential butt welds of drums and headers requiring

test plates . 33

8.6.3 Non-destructive examination. 33

8.6.4 Records of weld repairs. 33

8.7 Pre-heating . 33

8.8 Post-weld heat treatment . 33

8.9 Welding subsequent to final post-weld heat treatment . 34

8.10 Welded joints, connections and production test plates. 35

8.10.1 Longitudinal and circumferential butt welds and test plates in drums and headers 35

8.10.2 Welded header end closures . 37

8.10.3 Welded branches, nozzles, stubs and other attachments on drums and headers . 37

8.10.4 Pads, reinforcing plates and manhole frames . 38

8.11 Attachment of non-pressure parts to drums and headers by welding. 38

8.12 Welding of tubes . 39

8.12.1 General . 39

8.12.2 Continuity of welding . 39

8.12.3 Completion of welding . 39

8.12.4 Proximity of butt welds in straight tubes . 39

8.12.5 Alignment of tube bores . 39

8.12.6 Angular alignment of butt welded tubes . 40

8.12.7 Fabricated bends . 40

8.12.8 Backing rings . 40

8.12.9 Purging of welds . 40

8.12.10 Welding of branches, nozzles and stubs to tubes . 40

8.12.11 Attachment by welding of non-pressure parts to tubes . 41

8.13 Flash butt welding of tubes . 41

8.14 Welded tube water walls . 41

8.15 Arc stud welding . 41

9 Mechanical connections . 41

9.1 General. 41

9.2 Access openings . 41

9.2.1 Types . 41

9.2.2 Size . 42

9.2.3 Internal doors . 42

9.2.4 External doors . 42

9.3 Branches and nozzles mechanically connected to the main pressure parts . 43

9.3.1 Scope and restrictions . 43

9.3.2 Screwed connections . 43

9.3.3 Studded connections. 43

9.4 Tube connections . 43

9.4.1 Expanded connections . 43

9.4.2 Tube to tube mechanical connections . 46

9.4.3 Connection of non-pressure parts to pressure parts . 46

10 Thermal treatment . 46

10.1 General. 46

10.2 Heating cycles and heat treatment(s) associated with plate forming operations . 46

10.2.1 Heating cycles associated with hot forming . 46

10.2.2 Heat treatment associated with forming. 47

10.2.3 Shells and strakes . 47

10.2.4 Ends . 47

10.2.5 Production test requirements for formed components . 48

10.3 Pre-heating for welding and thermal cutting . 48

10.3.1 General. 48

10.3.2 Pre-heating for welding . 48

10.3.3 Pre-heating for thermal cutting . 49

10.3.4 Measurement of pre-heat . 49

10.4 Post weld heat treatment . 50

10.4.1 General. 50

10.4.2 Methods of post weld heat treatment . 55

10.4.3 Post-weld heat treatment procedures . 58

10.5 Heat treatment of production test plates . 59

Annex A (normative) Tube bending procedure tests . 60

A.1 General. 60

A.2 Hot or cold formed bends in tubes with outside diameter ≤ 142 mm . 60

A.2.1 Types of bending processes . 60

A.2.2 Post bending heat treatment (PBHT) . 61

A.2.3 Validity range of tests . 61

A.2.4 Qualification test requirements . 62

A.2.4.1 General . 62

A.2.4.2 Ripples on intrados of the bend . 62

A.2.4.3 Surface defects . 62

A.2.4.4 Bend geometry. 63

A.2.4.5 Hardness test . 63

A.2.4.6 Mechanical tests . 63

A.2.4.7 Gang bending of tube panels. 63

A.3 Cold formed bends in tubes with outside diameter > 142 mm . 63

A.3.1 Types of bending processes . 63

A.3.2 Post bending heat treatment . 63

A.3.3 The validity range of the test . 64

A.3.4 Qualification test requirements . 64

A.3.4.1 General . 64

A.3.4.2 Ripples on intrados of the bend . 64

A.3.4.3 Surface imperfections . 64

A.3.4.4 Bend geometry. 64

A.3.4.5 Hardness test . 64

A.3.4.6 Mechanical testing . 65

A.4 Hot formed bends in tubes with outside diameter > 142 mm . 65

A.4.1 Types of bending processes . 65

A.4.2 Post bending heat treatment . 65

A.4.3 The validity range of the test . 65

A.4.4 Qualification test requirements . 65

A.4.4.1 General . 65

A.4.4.2 Ripples on intrados of the bend . 66

A.4.4.3 Surface imperfections . 66

A.4.4.4 Bend geometry. 66

A.4.4.5 Mechanical testing . 66

A.4.4.5.1 General . 66

A.4.4.5.2 Metallographic examination . 66

A.4.4.5.3 Definitive and comparative tests . 66

A.4.4.5.4 Tensile test in accordance with EN ISO 6892-1:2019 . 67

Annex B (informative) Welded pressure connections and non-pressure containing

attachments . 69

Annex C (normative) Manufacture of welded tubewalls . 70

C.1 General . 70

C.2 Methods of manufacture . 70

C.2.1 General. 70

C.2.2 Tubes finned by welding . 70

C.2.3 Integrally finned tubes . 70

C.2.4 Other methods . 70

C.3 Allowable materials . 70

C.3.1 Tubes . 70

C.3.2 Fins . 70

C.3.3 Filler materials . 71

C.4 Manufacturing processes and controls . 71

C.4.1 Welding process . 71

C.4.2 Specific requirements for manufacturers . 71

C.4.2.1 Surface cleanliness . 71

C.4.2.2 Fin to tube attachment welds . 71

C.4.2.3 Welding imperfections in fin to tube welds . 72

C.4.2.4 Site welding . 72

C.4.3 Heat treatment . 72

C.4.3.1 Pre-heating . 72

C.4.3.2 Post-weld heat treatment . 72

C.5 Welding procedure approvals . 72

C.6 Production tests . 72

C.7 Non-destructive examination (NDE) . 73

Annex D (normative) Coiled boilers and coiled superheaters . 77

D.1 General. 77

D.2 Special requirements . 77

Annex E (normative) Special requirements for chemical recovery boilers . 78

E.1 General. 78

E.2 Special requirements for forming of composite tube bends . 78

E.2.1 General. 78

E.2.2 Application of forming rules to composite tubing . 78

E.2.2.1 Range of tube bending procedure test approval . 78

E.2.2.2 Additional tests required for composite tubes . 78

E.2.2.2.1 Ultrasonic testing of a composite tube bend concerning the metallurgical bonding

E.2.2.2.2 Hardness test . 78

E.3 Special requirements for manufacture of welded tubewalls from composite tubes . 78

E.3.1 General. 78

E.3.2 Fins . 79

E.3.3 Fin-to-tube attachment welds on composite tubes . 79

E.4 Material marking . 79

E.5 Flash butt welding . 79

E.6 Special requirements of qualification of welding procedures for fusion welding . 79

E.6.1 General . 79

E.6.2 Application of EN ISO 15614-1:2017, Level 2 to composite tubes . 79

E.6.2.1 Range of qualification . 79

E.6.2.2 Additional tests required . 79

E.6.2.2.1 Depth of penetration of clad weld . 79

E.6.2.2.2 Hardness test . 80

E.6.2.2.3 Bend test . 80

E.6.2.2.4 Transverse tensile test . 80

E.6.2.2.5 Microscopic examination . 80

E.7 Special requirements for welder’s qualification for fusion welding of composite tubes

................................................................................................................................................................... 80

E.7.1 General . 80

E.7.2 Application of EN ISO 9606-1:2017 to composite tubes . 80

E.7.2.1 Range of qualification . 80

E.7.2.2 Additional tests required - Macroscopic examination . 81

Annex F (informative) Guidelines for the determination of the competency of boiler

manufacturers . 82

F.1 General . 82

F.2 Responsibility of the purchaser . 82

F.3 Responsibility of the manufacturer . 82

F.4 Requirements concerning the manufacturer’s competency . 82

F.5 Manufacturer’s competency declaration . 83

Annex G (informative) Significant technical changes between this document and the

previous edition . 94

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive 2014/68/EU aimed to be covered . 95

Bibliography . 96

European foreword

This document (EN 12952-5:2021) has been prepared by Technical Committee CEN/TC 269 “Shell and

water-tube boilers”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2022, and conflicting national standards shall be

withdrawn at the latest by June 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 12952-5:2011.

Annex G provides details of significant technical changes between this document and the previous

edition.

EN 12952 series concerning water-tube boilers and auxiliary installations consists of the following parts:

• Part 1: General;

• Part 2: Materials for pressure parts of boilers and accessories;

• Part 3: Design and calculation for pressure parts;

• Part 4: In-service boiler life expectancy calculations;

• Part 5: Workmanship and construction of pressure parts of the boiler;

• Part 6: Inspection during construction, documentation and marking of pressure parts of the boiler;

• Part 7: Requirements for equipment for the boiler;

• Part 8: Requirements for firing systems for liquid and gaseous fuels for the boiler;

• Part 9: Requirements for firing systems for pulverized solid fuels for the boiler;

• Part 10: Requirements for safeguards against excessive pressure;

• Part 11: Requirements for limiting devices of the boiler and accessories;

• Part 12: Requirements for boiler feedwater and boiler water quality;

• Part 13: Requirements for flue gas cleaning systems;

• Part 14: Requirements for flue gas DENOX systems using liquefied pressurized ammonia and ammonia

water solution;

• Part 15: Acceptance tests;

• Part 16: Requirements for grate and fluidized-bed firing systems for solid fuels for the boiler;

• CR 12952 Part 17: Guideline for the involvement of an inspection body independent of the

manufacturer.

• Part 18: Operating instructions

Although these parts can be obtained separately, it should be recognized that the parts are inter-

dependent. As such, the design and manufacture of water-tube boilers requires the application of more

than one part in order for the requirements of the document to be satisfactorily fulfilled.

NOTE A “Boiler Helpdesk” has been established in CEN/TC 269 which canbe contacted for any questions

regarding the application of EN 12952 series and EN 12953 series, see the following website: http://www.boiler-

helpdesk.din.de

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of EU

Directive(s) / Regulation(s).

For relationship with EU Directive(s) / Regulation(s), see informative Annex ZA, which is an integral part

of this document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

1 Scope

This document specifies requirements for the workmanship and construction of water-tube boilers as

defined in EN 12952-1:2015.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1092-1:2018, Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PN

designated - Part 1: Steel flanges

EN 1759-1:2004, Flanges and their joint - Circular flanges for pipes, valves, fittings and accessories, Class

designated - Part 1: Steel flanges, NPS 1/2 to 24

EN 10025-2:2019, Hot rolled products of structural steels - Part 2: Technical delivery conditions for non-

alloy structural steels

EN 10028-2:2017, Flat products made of steels for pressure purposes - Part 2: Non-alloy and alloy steels

with specified elevated temperature properties

EN 10204:2004, Met

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...