SIST EN 13445-4:2021+A1:2023

(Main + Amendment)Unfired pressure vessels - Part 4: Fabrication

Unfired pressure vessels - Part 4: Fabrication

This document specifies requirements for the manufacture of unfired pressure vessels and their parts, made of steels, including their connections to non-pressure parts. It specifies requirements for material traceability, manufacturing tolerances, welding requirements, requirements for permanent joints other than welding, production tests, forming requirements, heat treatment, repairs and finishing operations.

Unbefeuerte Druckbehälter - Teil 4: Herstellung

Dieses Dokument enthält Anforderungen an die Herstellung von unbefeuerten Druckbehältern und Druckbehälterteilen aus Stählen, einschließlich deren Verbindungen zu nicht drucktragenden Teilen. Es enthält Anforderungen an die Rückverfolgbarkeit von Werkstoffen, Fertigungstoleranzen, Schweißanforderungen, Anforderungen an nicht geschweißte dauerhafte Verbindungen, Arbeitsproben, Umformanforderungen, Wärmebehandlung, Reparaturen und Fertigbearbeitung.

Récipients sous pression non soumis à la flamme - Partie 4 : Fabrication

Le présent document spécifie les exigences relatives à la fabrication des récipients sous pression non soumis à la flamme et de leurs parties sous pression, réalisés en acier, y compris leur raccordement avec des parties non soumises à la pression. Il spécifie des exigences concernant la traçabilité des matériaux, les tolérances de fabrication, les exigences de soudage, les exigences concernant les assemblages permanents autres que le soudage, les coupons-témoins, les exigences de formage, les traitements thermiques, les réparations, et la finition.

Nekurjene tlačne posode - 4. del: Proizvodnja (vključuje dopolnilo A1)

Ta dokument določa zahteve za proizvodnjo nekurjenih tlačnih posod in njihovih delov, izdelanih iz jekel, vključno z njihovimi priključki na netlačne dele. Določa zahteve za sledljivost materiala, proizvodna odstopanja, zahteve za varjenje, zahteve za trajne spoje, ki niso varjeni, proizvodne preskuse, zahteve za oblikovanje, toplotno obdelavo, popravila in zaključne operacije.

General Information

- Status

- Published

- Publication Date

- 17-Oct-2023

- Technical Committee

- TLP - Pressure vessels

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 25-Aug-2023

- Due Date

- 30-Oct-2023

- Completion Date

- 18-Oct-2023

Relations

- Effective Date

- 01-Nov-2023

- Effective Date

- 01-Nov-2023

Overview

EN 13445-4:2021+A1:2023 is the CEN European standard that specifies fabrication requirements for unfired pressure vessels and their parts made of steels, including connections to non‑pressure parts. Adopted as a European standard (with Amendment A1 in 2023), this document defines manufacturing controls such as material traceability, welding and permanent joint requirements, manufacturing tolerances, production testing, forming, heat treatment (including PWHT), repairs and finishing operations.

Key Topics and Requirements

The standard addresses practical, production‑level requirements for safe and compliant fabrication:

- Material traceability and identification - systems, visibility, transfer of markings and review of material certificates.

- Manufacturing tolerances - surface geometry, alignment, out‑of‑roundness, deviation from axis, local thinning and dished end tolerances.

- Welding requirements - welding procedure specification (WPS), welding procedure qualification (WPQR), welder/operator qualification and filler materials.

- Production testing of welds - tensile, impact, bend, macro/micro examination, hardness tests, retests and test reporting.

- Permanent joints other than welding - mechanical roller expansion, brazing and other acceptable joining methods.

- Forming and cold/hot forming procedures - ratios of deformation, forming of dished ends, cylinders, cones and tube bends, with sampling and testing of formed coupons.

- Heat treatment and PWHT - conditions, methods, procedures and post‑treatment mechanical property requirements.

- Repairs and finishing operations - acceptable repair methods for parent metal and weld defects plus final finishing and documentation.

- Quality and subcontracting controls - requirements for manufacturing responsibility and subcontracted work.

Practical Applications

This standard is used to ensure safe, repeatable fabrication processes and to demonstrate compliance for:

- Manufacturing of pressure vessels for chemical, petrochemical, power generation and industrial process plants

- Fabrication shops producing shells, heads, nozzles, flanges and assemblies of steel unfired vessels

- Inspection and QA/QC programs verifying welding, forming and heat treatment operations

- Procurement specifications and acceptance criteria for suppliers and subcontractors

Who Should Use This Standard

- Pressure vessel fabricators and welding shops

- Quality managers, welding coordinators and inspectors (NDT/inspection)

- Design engineers and project managers specifying manufacturing requirements

- Regulators and certification bodies assessing compliance with European fabrication practices

Related Standards

EN 13445‑4:2021+A1:2023 is Part 4 of the EN 13445 series (unfired pressure vessels) and is intended to be used alongside other parts of the EN 13445 suite and applicable national regulations when specifying design, materials and testing requirements.

Keywords: EN 13445-4:2021+A1:2023, unfired pressure vessels, fabrication standard, welding requirements, material traceability, PWHT, manufacturing tolerances, production tests, CEN.

Frequently Asked Questions

SIST EN 13445-4:2021+A1:2023 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Unfired pressure vessels - Part 4: Fabrication". This standard covers: This document specifies requirements for the manufacture of unfired pressure vessels and their parts, made of steels, including their connections to non-pressure parts. It specifies requirements for material traceability, manufacturing tolerances, welding requirements, requirements for permanent joints other than welding, production tests, forming requirements, heat treatment, repairs and finishing operations.

This document specifies requirements for the manufacture of unfired pressure vessels and their parts, made of steels, including their connections to non-pressure parts. It specifies requirements for material traceability, manufacturing tolerances, welding requirements, requirements for permanent joints other than welding, production tests, forming requirements, heat treatment, repairs and finishing operations.

SIST EN 13445-4:2021+A1:2023 is classified under the following ICS (International Classification for Standards) categories: 23.020.30 - Pressure vessels, gas cylinders; 23.020.32 - Pressure vessels. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13445-4:2021+A1:2023 has the following relationships with other standards: It is inter standard links to SIST EN 13445-4:2021, SIST EN 13445-4:2021/A1:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13445-4:2021+A1:2023 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU, EUR-PUB; Standardization Mandates: M/071, M/601. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13445-4:2021+A1:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2023

Nadomešča:

SIST EN 13445-4:2021

SIST EN 13445-4:2021/A1:2023

Nekurjene tlačne posode - 4. del: Proizvodnja (vključuje dopolnilo A1)

Unfired pressure vessels - Part 4: Fabrication

Unbefeuerte Druckbehälter - Teil 4: Herstellung

Récipients sous pression non soumis à la flamme - Partie 4 : Fabrication

Ta slovenski standard je istoveten z: EN 13445-4:2021+A1:2023

ICS:

23.020.32 Tlačne posode Pressure vessels

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13445-4:2021+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

August 2023

EUROPÄISCHE NORM

ICS 23.020.30

English Version

Unfired pressure vessels - Part 4: Fabrication

Récipients sous pression non soumis à la flamme - Unbefeuerte Druckbehälter - Teil 4: Herstellung

Partie 4 : Fabrication

This European Standard was approved by CEN on 24 February 2021 and includes Amendment 1 approved by CEN on 3 March

2023 and Amendment 1 approved by CEN on 13 June 2023.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13445-4:2021+A1:2023 E

worldwide for CEN national Members.

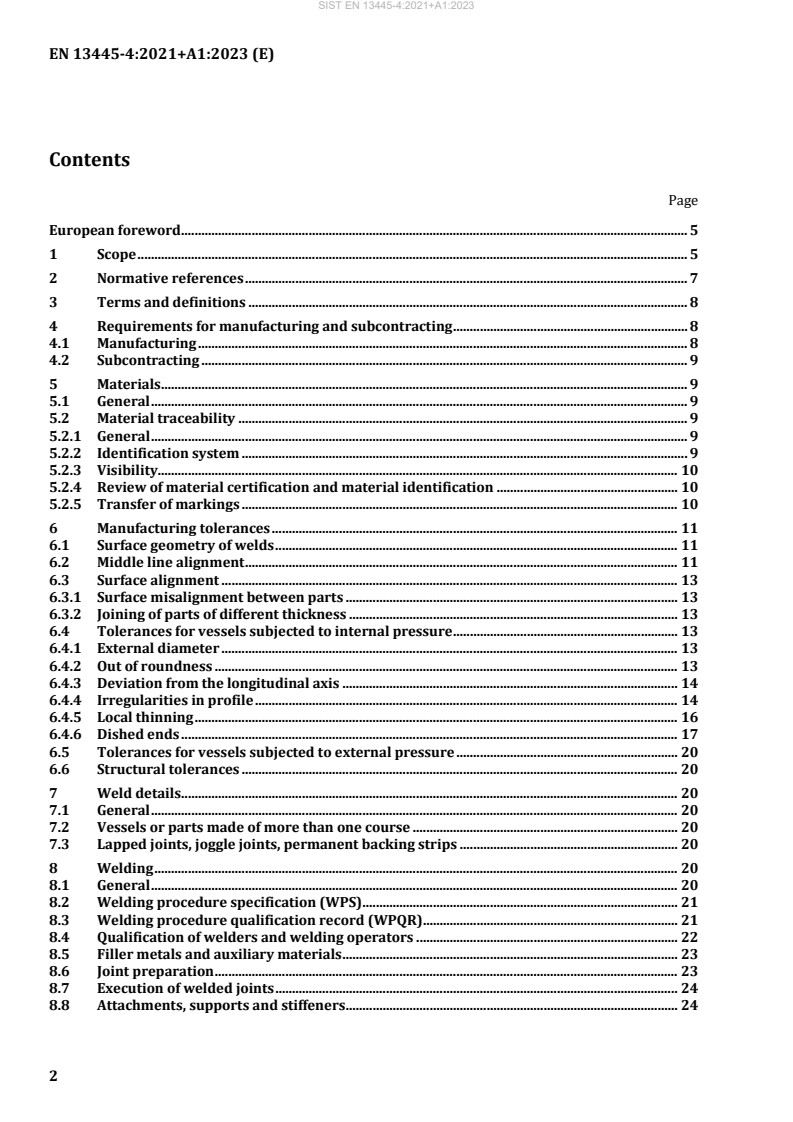

Contents

Page

European foreword . 5

1 Scope . 5

2 Normative references . 7

3 Terms and definitions . 8

4 Requirements for manufacturing and subcontracting . 8

4.1 Manufacturing . 8

4.2 Subcontracting . 9

5 Materials . 9

5.1 General . 9

5.2 Material traceability . 9

5.2.1 General . 9

5.2.2 Identification system . 9

5.2.3 Visibility. 10

5.2.4 Review of material certification and material identification . 10

5.2.5 Transfer of markings . 10

6 Manufacturing tolerances . 11

6.1 Surface geometry of welds . 11

6.2 Middle line alignment . 11

6.3 Surface alignment . 13

6.3.1 Surface misalignment between parts . 13

6.3.2 Joining of parts of different thickness . 13

6.4 Tolerances for vessels subjected to internal pressure . 13

6.4.1 External diameter . 13

6.4.2 Out of roundness . 13

6.4.3 Deviation from the longitudinal axis . 14

6.4.4 Irregularities in profile . 14

6.4.5 Local thinning . 16

6.4.6 Dished ends . 17

6.5 Tolerances for vessels subjected to external pressure . 20

6.6 Structural tolerances . 20

7 Weld details . 20

7.1 General . 20

7.2 Vessels or parts made of more than one course . 20

7.3 Lapped joints, joggle joints, permanent backing strips . 20

8 Welding . 20

8.1 General . 20

8.2 Welding procedure specification (WPS) . 21

8.3 Welding procedure qualification record (WPQR) . 21

8.4 Qualification of welders and welding operators . 22

8.5 Filler metals and auxiliary materials . 23

8.6 Joint preparation . 23

8.7 Execution of welded joints . 24

8.8 Attachments, supports and stiffeners . 24

8.9 Preheat . 24

8.10 Permanent joints other than welding . 24

8.10.1 General . 24

8.10.2 Mechanical roller expansion . 25

8.10.3 Brazing . 25

9 Manufacture and testing of welds — Production test . 25

9.1 General . 25

9.2 Reference criteria . 26

9.3 Extent of testing . 30

9.4 Performance of tests and acceptance criteria . 32

9.4.1 General . 32

9.4.2 Transverse tensile test . 32

9.4.3 Longitudinal weld tensile test . 32

9.4.4 Impact test . 32

9.4.5 Bend test . 32

9.4.6 Macro examination . 33

9.4.7 Micro examination . 33

9.4.8 Hardness test . 33

9.4.9 Retests . 33

9.4.10 Test report . 34

10 Forming of pressure parts . 34

10.1 General . 34

10.2 Ratio of deformation . 34

10.2.1 Dished circular products . 34

10.2.2 Cylinders and cones made by rolling . 35

10.2.3 Other product types . 36

10.2.4 Tube bends . 37

10.2.5 Forming of Segments . 37

10.3 Forming procedures . 38

10.3.1 Cold forming . 38

10.3.2 Hot forming . 39

10.4 Heat treatment after forming . 41

10.4.1 General . 41

10.4.2 Heat treatment of flat products after cold forming . 41

10.4.3 Heat treatment of tubular products after cold forming. 42

10.4.4 Heat treatment of clad steels after cold forming . 43

10.4.5 Heat treatment after hot forming . 43

10.4.6 Heat treatment of clad steels after hot forming . 44

10.5 Sampling of formed test coupons . 44

10.5.1 Cold formed products without heat treatment . 44

10.5.2 Hot formed or cold formed products with heat treatment . 44

10.6 Tests . 45

10.6.1 Base material . 45

10.6.2 Butt welds . 45

10.6.3 Acceptance criteria for formed test coupons . 46

10.6.4 Retests of formed coupons . 46

10.7 Visual inspection and control of dimension . 47

10.8 Marking . 47

10.9 Documentation . 47

11 Post weld heat treatment (PWHT) . 47

11.1 General . 47

11.2 Heat treatment conditions . 48

11.3 Method of PWHT . 51

11.4 PWHT procedure . 52

11.5 Mechanical properties after heat treatment . 53

11.6 Dissimilar ferritic joints . 55

11.7 Special materials . 56

11.8 Heat Treatment for reasons other than welding . 56

12 Repairs . 56

12.1 Repairs of surface defects in the parent metal . 56

12.2 Repair of weld defects . 57

13 Finishing operations . 57

Annex A (informative) Structural tolerances . 59

Annex B (informative) Example of a sub-contractors form . 63

Annex C (normative) Specification and approval of expansion procedures and operators . 64

C.1 General . 64

C.1.1 Introduction . 64

C.1.2 Responsibility . 64

C.1.3 Specification of expansion procedures . 64

C.1.4 Technical content of expansion procedure specification (EPS) . 65

C.1.5 Expansion procedure qualification test (EPQT) . 66

C.2 Examination and testing . 66

C.2.1 General . 66

C.2.2 Visual examination . 66

C.2.3 Dimensional verification . 66

C.2.4 Testing . 67

C.3 Range of approval . 67

C.3.1 General . 67

C.3.2 Manufacturer . 67

C.3.3 Material . 67

C.3.4 Tube dimensions . 68

C.3.5 Expansion factor . 68

C.3.6 Joint design . 68

C.3.7 Tool. 68

C.3.8 PWHT . 68

C.4 Expansion Procedure Approval Record (EPAR) . 69

C.5 Expansion operator approval . 69

C.5.1 General . 69

C.5.2 Validity range of expansion operator qualification. 69

C.5.3 Qualification tests . 69

C.5.4 Examination and testing . 70

C.5.5 Period of validity . 70

C.5.6 Certification . 70

Annex Y (informative) History of EN 13445-4 . 71

Y.1 Differences between EN 13445-4:2014 and EN 13445-4:2021 . 71

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2014/68/EU aimed to be covered . 72

Bibliography . 73

European foreword

This document (EN 13445-4:2021+A1:2023) has been prepared by Technical Committee CEN/TC 54

“Unfired pressure vessels”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by February 2024, and conflicting national standards shall

be withdrawn at the latest by February 2024.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes !EN 13445-4:2021".

This document includes Amendment 1 approved by CEN on 3 March 2023.

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

This document has been prepared under a standardisation request addressed to [the relevant ESO] by

the European Commission. The Standing Committee of the EFTA States subsequently approves these

requests for its Member States.

For the relationship with EU Legislation, see informative Annex ZA, which is an integral part of this

document.

The list of all parts in the EN 13445 series can be found on the CEN website.

Although these Parts may be obtained separately, it should be recognised that the Parts are inter-

dependant. As such the manufacture of unfired pressure vessels requires the application of all the

relevant Parts in order for the requirements of the Standard to be satisfactorily fulfilled.

Corrections to the standard interpretations where several options seem possible are conducted through

the Migration Help Desk (MHD). Information related to the Help Desk can be found at http://www.unm.fr

(en13445@unm.fr). A form for submitting questions can be downloaded from the link to the MHD

website. After subject experts have agreed an answer, the answer will be communicated to the

questioner. Corrected pages will be given specific issue number and issued by CEN according to CEN

Rules. Interpretation sheets will be posted on the website of the MHD.

This document supersedes EN 13445-4:2014. This new edition incorporates the Amendments which

have been approved previously by CEN members, and the corrected pages up to Issue 5 without any

further technical change. Annex Y provides details of significant technical changes between this European

Standard and the previous edition.

Amendments to this new edition may be issued from time to time and then used immediately as

alternatives to rules contained herein. It is intended to deliver a new Issue of EN 13445:2021 each year,

starting with the precedent as Issue 1, consolidating these Amendments and including other identified

corrections.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

1 Scope

This document specifies requirements for the manufacture of unfired pressure vessels and their parts,

made of steels, including their connections to non-pressure parts. It specifies requirements for material

traceability, manufacturing tolerances, welding requirements, requirements for permanent joints other

than welding, production tests, forming requirements, heat treatment, repairs and finishing operations.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

!deleted references"

EN 13134:2000, Brazing — Procedure approval

EN 13445-1:2021, Unfired pressure vessels — Part 1: General

EN 13445-2:2021, Unfired pressure vessels — Part 2: Materials

EN 13445-3:2021, Unfired pressure vessels — Part 3: Design

EN 13445-5:2021, Unfired pressure vessels — Part 5: Inspection and testing

!EN 14276-1:2020", Pressure equipment for refrigerating systems and heat pumps — Part 1: Vessels

— General requirements

!EN ISO 3834-2:2021, Quality requirements for fusion welding of metallic materials — Part 2:

Comprehensive quality requirements (ISO 3834-2:2021)"

!EN ISO 3834-3:2021, Quality requirements for fusion welding of metallic materials — Part 3: Standard

quality requirements (ISO 3834-3:2021)"

EN ISO 4136:2012, Destructive tests on welds in metallic materials — Transverse tensile test

(ISO 4136:2012)

EN ISO 5173:2010, Destructive tests on welds in metallic materials — Bend tests (ISO 5173:2009)

!EN ISO 5178:2019, Destructive tests on welds in metallic materials — Longitudinal tensile test on weld

metal in fusion welded joints (ISO 5178:2019)"

EN ISO 9015-1:2011, Destructive tests on welds in metallic materials — Hardness testing — Part 1:

Hardness test on arc welded joints (ISO 9015-1:2001)

!EN ISO 9016:2022, Destructive tests on welds in metallic materials — Impact tests — Test specimen

location, notch orientation and examination (ISO 9016:2022)"

EN ISO 9606-1:2017, Qualification testing of welders — Fusion welding — Part 1: Steels (ISO 9606‐

1:2012 including Cor 1:2012 and Cor 2:2013)

EN ISO 13585:2012, Brazing — Qualification test of brazers and brazing operators (ISO 13585:2012)

EN ISO 14732:2013, Welding personnel — Qualification testing of welding operators and weld setters for

mechanized and automatic welding of metallic materials (ISO 14732:2013)

!EN ISO 15609-1:2019, Specification and qualification of welding procedures for metallic materials —

Welding procedure specification — Part 1: Arc welding (ISO 15609-1:2019)"

EN ISO 15611:2003, Specification and qualification of welding procedures for metallic materials —

Qualification based on previous welding experience (ISO 15611:2003)

EN ISO 15612:2018, Specification and qualification of welding procedures for metallic materials —

Qualification by adoption of a standard welding procedure (ISO 15612:2018)

EN ISO 15613:2004, Specification and qualification of welding procedures for metallic materials —

Qualification based on pre-production welding test (ISO 15613:2004)

!EN ISO 15614-1:2017, Specification and qualification of welding procedures for metallic materials —

Welding procedure test — Part 1: Arc and gas welding of steels and arc welding of nickel and nickel alloys

(ISO 15614-1:2017, Corrected version 2017-10-01)"

!EN ISO 17639:2022, Destructive tests on welds in metallic materials — Macroscopic and microscopic

examination of welds (ISO 17639:2022)"

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

4 Requirements for manufacturing and subcontracting

4.1 Manufacturing

The general responsibilities of the pressure vessel manufacturer are stated in EN 13445-1:2021.

Additionally to those requirements, the manufacturer shall ensure that:

a) the organisation for the control of manufacturing operations which includes special processes such

as welding, forming and heat treatment shall be clearly defined by the manufacturer;

b) the manufacturing procedures such as welding, forming and heat treatment are adequate for the

purpose and the pressure vessel meets the requirements of this standard. Where specific

requirements are associated with materials these shall be taken into account, e.g. EAMs;

c) the manufacturing equipment is adequate for fabrication;

d) the staff is adequate for the assigned tasks;

NOTE As far as welding co-ordination is concerned, the qualifications, tasks and responsibilities can be defined

by the manufacturer in accordance with !EN ISO 14731:2019" [1] in the job assignment.

e) the quality requirements for welding defined in !EN ISO 3834-3:2021" are met as a minimum.

4.2 Subcontracting

The manufacturer may subcontract work, but shall ensure that the subcontractor carries out the work in

accordance with the requirements of this document. The manufacturer is responsible for the adequate

definition of the subcontracted task and the need for any associated records.

On all occasions that the subcontractor work includes

a) welding;

b) forming including associated heat treatment;

c) post weld heat treatment;

d) non-destructive testing of welds (see EN 13445-5:2021),

e) the manufacturer shall obtain a subcontractor form (see Annex B).

Where welding operations are subcontracted, the manufacturer shall also either obtain copies of the

welding procedure and welding operator qualification records or take other action to ensure that they

comply with this standard.

In discharging his responsibility to ensure that the subcontractor carries out the work in accordance with

this standard the manufacturer shall ensure that surveillance of the subcontracted work is performed.

Where a manufacturer is producing equipment that requires the intervention of a responsible authority,

the manufacturer should inform the responsible authority of his intention to subcontract so that the

responsible authority has the opportunity to take part in the subcontractor surveillance.

NOTE 1 See also EN 764-3:2002, 2.11 [2] and CR 13445-7.

NOTE 2 When the manufacturer is producing equipment based on quality assurance, the controls a manufacturer

applies over subcontractors should be described in his approved quality system.

5 Materials

5.1 General

Materials for pressure vessels and the grouping of materials for pressure vessels shall be in accordance

with EN 13445-2:2021.

The grouping applies regardless of product form, i.e. plate, forging, piping.

5.2 Material traceability

5.2.1 General

The vessel manufacturer shall have and maintain an identification system for materials used in

fabrication, so that all material subject to stress due to pressure and those welded thereto in the

completed work can be traced to its origin. This includes the use of welding consumables.

5.2.2 Identification system

5.2.2.1 The vessel manufacturer's identification system shall assure that all materials to be used in the

vessel have been subjected to and satisfactorily passed the following:

a) examination of material before fabrication for the purpose of detecting, as far as possible,

imperfections which would affect the safety of the work;

b) check of material to determine that it has the required thickness;

c) check of the material to assure that the materials are permitted by this document, fully traceable to

the correct material certification and as specified in the design documentation;

d) check of the welding consumables to assure the correct markings and that correct conditions are

maintained to prevent deterioration.

5.2.2.2 Material traceability to the original identification markings shall be by one or more of the

following methods:

a) accurate transfer of the original identification markings to a location where the markings will be

visible on the completed vessel;

b) identification by a coded marking traceable to the original required marking;

c) recording the identification markings using material lists or as built sketches which assure

identification of each piece of material during fabrication and subsequent identification in the

completed vessel;

d) !the EN- or EN-ISO-designation or brand name of the welding consumables shall be recorded."

5.2.3 Visibility

Materials which cannot be stamped or which will not be visible after the vessel is completed or for small

multiple parts or non pressure parts the manufacturer may operate a documented system which ensures

material traceability for all materials in the completed vessel.

5.2.4 Review of material certification and material identification

All material certification shall be reviewed upon receipt. The review shall cover the completeness and

adequacy of the reports against the following:

a) mechanical and chemical properties required to be reported by the material specification;

b) assuring that the reported results meet the requirements of the specification;

c) all markings required by the material specification are satisfied and that there is traceability between

the actual markings and those recorded on the material certification.

All materials certification shall be made readily available throughout manufacture.

5.2.5 Transfer of markings

In case the original identification markings are unavoidably cut out or the material is divided into two or

more pieces the markings shall be accurately transferred by the manufacturer's nominated personnel

prior to cutting.

The actual material marking shall be by methods which are not harmful to the material in subsequent

use/operation.

The transfer of markings shall take place before partitioning of the product and after verification of the

marks present with the corresponding certification.

6 Manufacturing tolerances

6.1 Surface geometry of welds

The surface geometry of welded butt and fillet joints shall meet the requirements of EN 13445-5:2021,

5.3 and 6.6, unless the drawing specifies more stringent requirements.

6.2 Middle line alignment

The misalignment tolerances of middle lines shall be as specified in Tables 6.2-1, 6.2-2, 6.2-3 and

Figure 6.2-1.

a) Middle line alignment d at equal thickness e = b) Middle line alignment d at different thickness e

1 1 1 1

e ≤ e

2 2

Figure 6.2-1 — Middle line alignment d

For longitudinal welds in cylinders, cones and rectangular/prismatic structures the middle lines of

adjacent components (whether of equal or different thickness) shall be aligned within the tolerances

specified in Table 6.2-1.

Table 6.2-1 — Offset of middle lines for longitudinal welds in cylinders, cones

and rectangular/prismatic structures

Dimensions in millimetres

Thinner part thickness e Maximum misalignment d

1 1

e ≤ 2 0,5

2 < e ≤ 4 e1/4

4 < e1 ≤ 10

e1/10

10 < e1 ≤ 30

30 < e ≤ 60 e1/30 + 2

60 < e1 4

For longitudinal welds in dished ends and welds in spherical components the middle lines of adjacent

parts (whether of equal or different thickness) shall be aligned within the tolerances specified in

Table 6.2-2.

Table 6.2-2 — Offset of middle lines for longitudinal welds in dished

ends and in spherical components of adjacent parts

Dimensions in millimetres

Thinner part thickness e1 Maximum misalignment d1

e ≤ 2 0,5

2 < e ≤ 4 e1/4

4 < e1 ≤ 10

e /10

10 < e1 ≤ 30 1

30 < e ≤ 120 e1/30 + 2

120 < e1 6

For circumferential welds the middle lines of adjacent parts (whether of equal or different thickness)

shall be aligned within the tolerances specified in Table 6.2-3.

Table 6.2-3 — Offset of middle lines of circumferential

welds of adjacent parts

Dimensions in millimetres

Thinner part thickness e1 Maximum misalignment d1

e1/10 + 1

e1 ≤ 30

30 < e ≤ 150 e1/30 + 3

150 < e1 8

6.3 Surface alignment

6.3.1 Surface misalignment between parts

Where there is misalignment at the surface between parts of the same nominal thickness the transition

across the weld shall be smooth and gradual with a slope of 1 in 4 over the width of the weld. If this taper

cannot be accommodated within the weld width it is permissible to either:

a) grind the higher plate surface, where this will not reduce the joint thickness at any point below the

nominal specified plate thickness minus the plate thickness tolerance;

b) build up the lower plate surface with added weld metal

6.3.2 Joining of parts of different thickness

Where different thickness are being joined a taper shall be produced in accordance with EN 13445-

3:2021 by either:

a) taper the thicker plate in accordance with the design drawing and then applying the requirements

above for the same nominal thickness parts; or

b) obtain the required slope across the width of the welds, or by a combination of weld build up on the

lower surface with added weld metal and thereafter obtain the required slope across the weld width.

6.4 Tolerances for vessels subjected to internal pressure

6.4.1 External diameter

For cylindrical and spherical pressure vessels the mean external diameter derived from the

circumference shall not deviate by more than 1,5 % from the specified external diameter.

For rectangular vessels and/or prismatic structures each external dimension shall not deviate by more

than 1,5 % from the specified external dimension.

6.4.2 Out of roundness

Out of roundness (O) shall be calculated in accordance with the following Formula (6.4-1):

2 ⋅ (D − D )

max min

O [%] = ⋅100

(6.4-1)

D + D

max min

It shall not exceed the following values:

a) 1,5 % for the ratio of e/D < 0,01;

b) 1,0 % for the ratio of e/D ≥ 0,01.

NOTE The determination of the out of roundness need not consider the elastic deformation due to the

deadweight of the pressure vessel.

Irregularities in vessel profile (e.g. dents, buckling, flats on nozzle positions) shall be also within the

tolerances in a) and b). A greater out of roundness may be acceptable provided they have been proven

admissible by calculation or strain gauge measurements.

6.4.3 Deviation from the longitudinal axis

The deviation from the longitudinal axis over the length of the cylindrical portion of the pressure vessel

shall not exceed 0,5 % of the length of the shell.

6.4.4 Irregularities in profile

a) Local irregularities in vessel profile

Irregularities in profile (e.g. dents, buckling, flats on nozzle positions) shall be smooth and the depth shall

be checked by a 20° gauge and shall not exceed the following values:

1) 2 % of the gauge length; or

2) 2,5 % of the gauge length provided that the length of the irregularities does not exceed one

quarter of the length (with a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...