SIST EN 50693:2020

(Main)Product category rules for life cycle assessments of electronic and electrical products and systems

Product category rules for life cycle assessments of electronic and electrical products and systems

This document defines product category rules (PCR) for electronic and electrical products and systems (EEPS).

It specifies the process and requirements on how to conduct life cycle assessment in the context of

environmental declarations.

PCR is complemented by additional product-specific rules (PSR), which further define e.g. functional units and

default scenarios in the product-specific context. Therefore, it also provides guidance on how to develop PSR

in corresponding technical committees.

This document provides common rules for:

a) life cycle assessment (LCA), including the requirements for developing default scenarios;

b) the LCA report;

c) the development of product specific rules.

This document provides further guidelines for environmental declarations.

The basic LCA principles and framework are based on the EN ISO 14040 series of standards (i.e EN ISO 14040

and ISO 14044), and therefore out of scope of the standard.

Verfahren zur quantitativen, umweltgerechten Produktgestaltung durch Ökobilanzen und Umweltdeklarationen mittels Produktkategorieregeln für elektronische und elektrotechnische Geräte

Méthode d'écoconception quantitative par l'évaluation du cycle de vie et les déclarations environnementales par l'intermédiaire de règles relatives aux catégories de produits pour les EEE

Pravila za kategorije proizvodov za ocenjevanje življenjskega cikla elektronskih in električnih proizvodov in sistemov

General Information

- Status

- Published

- Publication Date

- 15-Jun-2020

- Technical Committee

- ITIV - Electronics assembly technology and Environmental standardization

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 29-May-2020

- Due Date

- 03-Aug-2020

- Completion Date

- 16-Jun-2020

Relations

- Effective Date

- 01-Oct-2025

Overview

EN 50693:2019 (adopted nationally as SIST EN 50693:2020) defines product category rules (PCR) for conducting life cycle assessments (LCA) and producing environmental declarations for electronic and electrical products and systems (EEPS). Published by CENELEC/CLC, the standard establishes core rules to ensure consistent, transparent and comparable LCA results and Environmental Product Declarations (EPDs) across the electrotechnical sector.

Key topics and technical requirements

- Scope and purpose: Core PCR for EEPS LCA, LCA reporting and guidance for developing product-specific rules (PSR).

- LCA framework alignment: Built on ISO/EN LCA principles (EN ISO 14040, EN ISO 14044) and EN ISO 14025 for Type III declarations.

- Functional unit & reference flow: Requirements to define a clear functional unit or declared unit for comparability.

- System boundaries: Rules for which life cycle stages to include (manufacture, transport, use, end-of-life) and how to document boundaries.

- Life cycle inventory (LCI): Data collection and reporting expectations for materials, energy, and flows.

- Allocation and cut-off rules: Instructions for handling co-products, recycling and allocation of environmental burdens and benefits.

- Data quality and units: Minimum data quality requirements and consistent unit usage for LCA inputs/outputs.

- Scenario development: Default and product-specific scenarios for transportation, use phase, and end-of-life treatment.

- Life cycle impact assessment (LCIA): Guidance on choosing impact categories and methods; Annex B lists recommended impact categories.

- LCA report & environmental declaration: Required content and transparency for LCA reports and EPD-like documents; Annex E–F provide content templates and examples.

- Annexes of note: Correlation with the EU Product Environmental Footprint (PEF) initiative (Annex C), correlation with EN 15804 (Annex D), and rules for recovery and circularity (Annex G).

Practical applications

- Preparing Environmental Product Declarations (EPDs) and public environmental information for electronic and electrical products.

- Supporting eco-design and product development by quantifying life cycle hotspots (materials, energy use, end-of-life).

- Enabling comparative assessments and benchmarking between product families when PSRs are defined.

- Aggregating product LCAs to system-level assessments (e.g., building electrical systems, control cabinets).

- Informing procurement, regulatory compliance, and sustainability reporting with standardized LCA outputs.

Who should use this standard

- Product manufacturers and designers of EEPS preparing LCA-based environmental information.

- LCA practitioners and consultants performing LCAs for electronic and electrical products.

- Program operators and certification bodies developing PSRs or EPD programs for electrotechnical products.

- Technical committees preparing product-specific standards that require consistent LCA rules.

- Regulators and procurement teams seeking standardized environmental data for EEPS.

Related standards

- EN ISO 14040 / EN ISO 14044 (LCA principles and requirements)

- EN ISO 14025 (Type III environmental declarations)

- EN 15804 (construction product LCAs) - correlation guidance included in EN 50693

Keywords: EN 50693:2019, product category rules, PCR, life cycle assessment, LCA, electronic and electrical products, EEPS, environmental declaration, EPD, CENELEC, PSR, LCI, LCIA.

Frequently Asked Questions

SIST EN 50693:2020 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Product category rules for life cycle assessments of electronic and electrical products and systems". This standard covers: This document defines product category rules (PCR) for electronic and electrical products and systems (EEPS). It specifies the process and requirements on how to conduct life cycle assessment in the context of environmental declarations. PCR is complemented by additional product-specific rules (PSR), which further define e.g. functional units and default scenarios in the product-specific context. Therefore, it also provides guidance on how to develop PSR in corresponding technical committees. This document provides common rules for: a) life cycle assessment (LCA), including the requirements for developing default scenarios; b) the LCA report; c) the development of product specific rules. This document provides further guidelines for environmental declarations. The basic LCA principles and framework are based on the EN ISO 14040 series of standards (i.e EN ISO 14040 and ISO 14044), and therefore out of scope of the standard.

This document defines product category rules (PCR) for electronic and electrical products and systems (EEPS). It specifies the process and requirements on how to conduct life cycle assessment in the context of environmental declarations. PCR is complemented by additional product-specific rules (PSR), which further define e.g. functional units and default scenarios in the product-specific context. Therefore, it also provides guidance on how to develop PSR in corresponding technical committees. This document provides common rules for: a) life cycle assessment (LCA), including the requirements for developing default scenarios; b) the LCA report; c) the development of product specific rules. This document provides further guidelines for environmental declarations. The basic LCA principles and framework are based on the EN ISO 14040 series of standards (i.e EN ISO 14040 and ISO 14044), and therefore out of scope of the standard.

SIST EN 50693:2020 is classified under the following ICS (International Classification for Standards) categories: 13.020.60 - Product life-cycles; 29.020 - Electrical engineering in general; 31.020 - Electronic components in general. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 50693:2020 has the following relationships with other standards: It is inter standard links to SIST EN IEC 63366:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 50693:2020 is associated with the following European legislation: EU Directives/Regulations: 2009/125/EC; Standardization Mandates: M/495. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 50693:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2020

Pravila za kategorije proizvodov za ocenjevanje življenjskega cikla elektronskih in

električnih proizvodov in sistemov

Product category rules for life cycle assessments of electronic and electrical products

and systems

Méthode d'écoconception quantitative par l'évaluation du cycle de vie et les déclarations

environnementales par l'intermédiaire de règles relatives aux catégories de produits pour

les EEE

Ta slovenski standard je istoveten z: EN 50693:2019

ICS:

13.020.60 Življenjski ciklusi izdelkov Product life-cycles

29.020 Elektrotehnika na splošno Electrical engineering in

general

31.020 Elektronske komponente na Electronic components in

splošno general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD EN 50693

NORME EUROPÉENNE

EUROPÄISCHE NORM

August 2019

ICS 13.020.20; 29.020

English Version

Product category rules for life cycle assessments of electronic

and electrical products and systems

Règles de définition des catégories de produits pour Verfahren zur quantitativen, umweltgerechten

l'analyse du cycle de vie des produits et systèmes Produktgestaltung durch Ökobilanzen und

électriques et électroniques Umweltdeklarationen mittels Produktkategorieregeln für

elektronische und elektrotechnische Geräte

This European Standard was approved by CENELEC on 2019-08-12. CENELEC members are bound to comply with the CEN/CENELEC

Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC

Management Centre or to any CENELEC member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CENELEC member into its own language and notified to the CEN-CENELEC Management Centre has the

same status as the official versions.

CENELEC members are the national electrotechnical committees of Austria, Belgium, Bulgaria, Croatia, Cyprus, the Czech Republic,

Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, the

Netherlands, Norway, Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

European Committee for Electrotechnical Standardization

Comité Européen de Normalisation Electrotechnique

Europäisches Komitee für Elektrotechnische Normung

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CENELEC All rights of exploitation in any form and by any means reserved worldwide for CENELEC Members.

Ref. No. EN 50693:2019 E

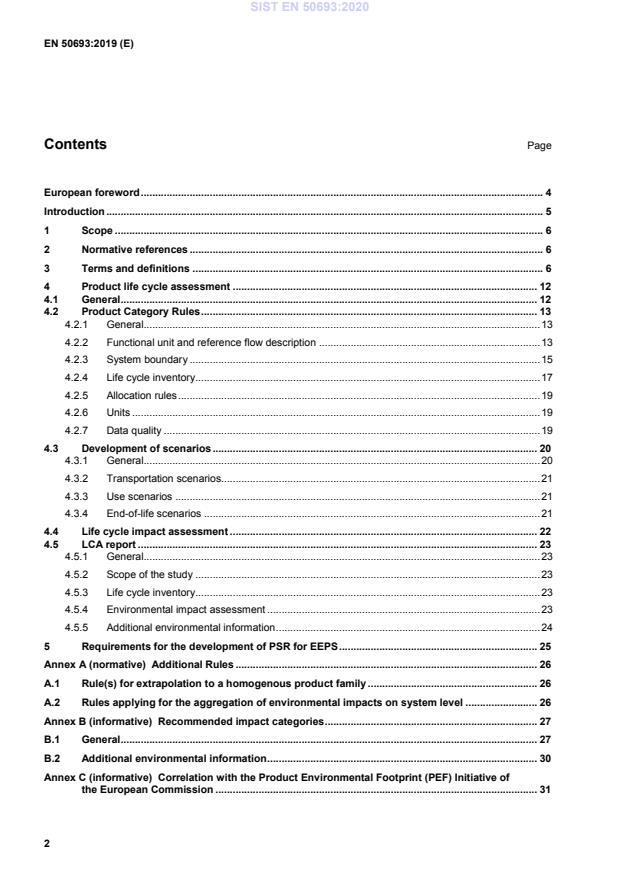

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Product life cycle assessment . 12

4.1 General . 12

4.2 Product Category Rules . 13

4.2.1 General. 13

4.2.2 Functional unit and reference flow description . 13

4.2.3 System boundary . 15

4.2.4 Life cycle inventory . 17

4.2.5 Allocation rules . 19

4.2.6 Units . 19

4.2.7 Data quality . 19

4.3 Development of scenarios . 20

4.3.1 General. 20

4.3.2 Transportation scenarios. 21

4.3.3 Use scenarios . 21

4.3.4 End-of-life scenarios . 21

4.4 Life cycle impact assessment . 22

4.5 LCA report . 23

4.5.1 General. 23

4.5.2 Scope of the study . 23

4.5.3 Life cycle inventory . 23

4.5.4 Environmental impact assessment . 23

4.5.5 Additional environmental information . 24

5 Requirements for the development of PSR for EEPS . 25

Annex A (normative) Additional Rules . 26

A.1 Rule(s) for extrapolation to a homogenous product family . 26

A.2 Rules applying for the aggregation of environmental impacts on system level . 26

Annex B (informative) Recommended impact categories . 27

B.1 General . 27

B.2 Additional environmental information . 30

Annex C (informative) Correlation with the Product Environmental Footprint (PEF) Initiative of

the European Commission . 31

Annex D (informative) Correlation with EN 15804 standard . 36

Annex E (informative) General content of a product’s environmental declaration . 38

E.1 General . 38

E.2 List of information in environmental declarations . 38

E.2.1 Information about the manufacturer . 38

E.2.2 Description of the product family, the reference product and its packaging . 38

E.2.3 Constitutive materials and substances . 38

E.2.4 Information on life cycle stages and potential impacts . 39

Annex F (informative) Example of a product’s environmental declaration . 40

F.1 General . 40

F.2 Basic example . 40

Annex G (informative) Recovery activities: Allocation, calculation and default values . 44

G.1 Circular formula . 44

G.2 Formula without benefits . 44

G.3 Formula with benefits . 45

G.4 Formula with net benefits . 46

G.5 Default values for R , R and R . 47

1 2 3

Bibliography . 49

European foreword

This document (EN 50693:2019) has been prepared by CLC/TC 111X “Environment”.

The following dates are fixed:

• latest date by which this document has (dop) 2020-08-12

to be implemented at national level by

publication of an identical national

standard or by endorsement

• latest date by which the national (dow) 2022-08-12

standards conflicting with this document

have to be withdrawn

The TC 111X Working Group 8 has been assigned to deal with the NWIP to define product category core rules

for life cycle assessment as basis for environmental declarations. This document has been elaborated to ensure

a harmonized and compatible approach through harmonized methods of assessing the environmental

performance and providing environmental declarations for electrical and electronic products and systems

(EEPS).

Key points:

a) requirements how to conduct life cycle assessments for environmental declarations;

b) requirements how to compile an associated life cycle assessment report;

c) requirements how to develop product specific rules in vertical, product specific technical committees.

It is the intention of the working group that this document, once finalized as European standard, will be further

processed to an international consensus in IEC according to the UAP procedure agreement between CENELEC

and IEC.

Future standards defining product specific rules have to be consistent with this standard during their preparation.

Any product specific standard already including these topics, e.g. EN 50598-3, should adapt their content to this

standard within their usual maintenance circles.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. CENELEC shall not be held responsible for identifying any or all such patent rights.

Introduction

In the recent years, environmental aspects of electrical and electronic products and systems gained in

importance for interested parties, such as customers and regulators.

In addition to qualitative approaches already widely applied in the context of environmental conscious design

process, quantitative information on the potential environmental impacts of the full life cycle of products gained

further interest. This generates the need to provide harmonized rules for the underlying life cycle assessment

(LCA) in order to provide robust and consistent quantitative environmental data on electrical and electronic

products and systems (EEPS), as well as to enable data aggregation at system level, like e.g. buildings, power

drive systems and control cabinets.

The definition of product category rules (PCR), derived from EN ISO 14025, is an established method for a

consistent approach by setting minimum quality standards for life cycle assessment in context to environmental

product declarations (EPD) and hence are now defined as core rules in this standard for the variety of electrical

and electronic products and systems.

On the base of the overarching PCR set out as core rules for EEPS, product specific rules (PSR) should be

elaborated to further detail the requirements for the LCA in the specific context of the products or systems in

scope. This can be done e.g. by product specific standardization committees or environmental declaration

programs.

1 Scope

This document defines product category rules (PCR) for electronic and electrical products and systems (EEPS).

It specifies the process and requirements on how to conduct life cycle assessment in the context of

environmental declarations.

PCR is complemented by additional product-specific rules (PSR), which further define e.g. functional units and

default scenarios in the product-specific context. Therefore, it also provides guidance on how to develop PSR

in corresponding technical committees.

This document provides common rules for:

a) life cycle assessment (LCA), including the requirements for developing default scenarios;

b) the LCA report;

c) the development of product specific rules.

This document provides further guidelines for environmental declarations.

The basic LCA principles and framework are based on the EN ISO 14040 series of standards (i.e EN ISO 14040

and ISO 14044), and therefore out of scope of the standard.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references, the

latest edition of the referenced document (including any amendments) applies.

EN ISO 14040, Environmental management - Life cycle assessment - Principles and framework (ISO 14040)

EN ISO 14044:2006, Environmental management - Life cycle assessment - Requirements and guidelines (ISO

14044:2006)

EN ISO 14020, Environmental labels and declarations - General principles (ISO 14020)

EN ISO 14021:2016, Environmental labels and declarations - Self-declared environmental claims (Type II

environmental labelling) (ISO 14021:2016)

EN ISO 14025, Environmental labels and declarations - Type III environmental declarations - Principles and

procedures (ISO 14025)

CEN ISO/TS 14027, Environmental labels and declarations – Development of product category rules

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

collection

means the gathering of waste, including the preliminary sorting and preliminary storage of waste for the purposes

of transport to a waste treatment facility

[SOURCE: Directive 2008/98/EC]

3.2

co-product

two or more products coming from the same unit process or product system

Note 1 to entry: Co-product, by-product and product have the same status and are used for identification of several

distinguished flows of products from the same unit process. From co-product, by-product and product, waste is the only

output to be distinguished as a non-product.

[SOURCE: EN ISO 14040:2006, 3.10]

3.3

cut-off criteria

specification of the amount of material or energy flow or the level of environmental significance associated with

unit processes or product system to be excluded from a study

[SOURCE: EN ISO 14040:2006, 3.18]

3.4

declared unit

quantity of the product used as a reference unit for the environmental declaration when a functional unit cannot

be directly used

Note 1 to entry: The declared unit might differ from the functional unit in terms of the declaration.

[SOURCE: EN 15804:2012+A1:2013, 3.8, modified]

3.5

disposal

operation which is not recovery even where the operation has as a secondary consequence the reclamation of

substances or energy

Note 1 to entry: Annex I of Directive 2008/98/EC sets 231 out a non-exhaustive list of disposal operations.

[SOURCE: EN 50625-1:2014, 3.12]

3.6

energy recovery

production of useful energy through direct and controlled combustion or other processing of waste

Note 1 to entry: Energy recovery is a recovery operation where the material is used principally as a fuel or other means to

generate energy, see R1 of Annex II of Directive 2008/98/EC

[SOURCE: EN 50625-1:2014, 3.14]

3.7

environment

surroundings in which an organization operates, including air, water, land, natural resources, flora, fauna,

humans and their interrelationships

Note 1 to entry: Surroundings can extend from within an organization to the local, regional and global system.

Note 2 to entry: Surroundings can be described in terms of biodiversity, ecosystems, climate or other characteristics.

[SOURCE: EN ISO 14001:2015, 3.2.1]

3.8

environmental aspect

element of an organization's activities or products or services that interacts or can interact with the environment

Note 1 to entry: An environmental aspect can cause (an) environmental impact(s) (3.2.4). A significant environmental aspect

is one that has or can have one or more significant environmental impact(s).

Note 2 to entry: Significant environmental aspects are determined by the organization applying one or more criteria.

[SOURCE: EN ISO 14001:2015, 3.2.2]

3.9

environmental claim

statement, symbol or graphic that indicates an environmental aspect of a product, a component or packaging

Note 1 to entry: An environmental claim may be made on product or packaging labels, through product literature, technical

bulletins, advertising, publicity, telemarketing, as well as through digital or electronic media such as the internet.

[SOURCE: EN ISO 14021:2016, 3.1.4]

3.10

environmental impact

change to the environment, whether adverse or beneficial, wholly or partially resulting from an organization's

environmental aspects

[SOURCE: EN ISO 14001:2015, 3.2.4]

3.11

environmental declaration

claim which indicates the environmental aspects of a product or service

Note 1 to entry: An environmental label or declaration may take the form of a statement, symbol or graphic on a product or

package label, in product literature, in technical bulletins, in advertising or in publicity, amongst other things.

[SOURCE: EN ISO 14020:2001, 2.1]

3.12

environmental management system

part of the management system used to manage environmental aspects, fulfil compliance obligations, and

address risks and opportunities

[SOURCE: EN ISO 14001:2015, 3.1.2]

3.13

functional unit

FU

quantified performance of a product system for use as a reference unit

[SOURCE: EN ISO 14040:2006, 3.20]

3.14

hazardous substances and preparations

substance or preparation that can adversely impact the human health and/or the environment with immediate

or retarded effect

[SOURCE: IEC Guide 109:2012, modified]

3.15

homogenous product family

subgroup of a product family based on the underlying technology or build where the environmental impacts can

reasonably be expected to be similar and therefore scalable over the group through a function of certain physical

characteristics, e.g. power or weight

3.16

interested party

person or organization that can affect, be affected by, or perceive itself to be affected by a decision or activity

EXAMPLE Customers, communities, suppliers, regulators, non-governmental organizations, investors and employees

Note 1 to entry: To “perceive itself to be affected” means the perception has been made known to the organization

[SOURCE: EN ISO 14001:2015, 3.1.6]

3.17

landfill

waste disposal site for the deposit of the waste onto or into land (i.e. underground), including: Internal waste

disposal sites (i.e. landfill where a producer of waste is carrying out its own waste disposal at the place of

production) and a permanent site (i.e. more than one year) which is used for temporary storage of waste

Note 1 to entry: Excluded are facilities where waste is unloaded in order to permit its preparation for further transport for

recovery, treatment or disposal elsewhere, and storage of waste prior to recovery or treatment for a period less than three

years as a general rule, or storage of waste prior to disposal for a period less than one year.

[SOURCE: Directive 1999/31/EC]

3.18

LCA report

accompanying document to the life cycle assessment. Used as a complement to the environmental declaration

giving further detailed information about the inputs, outputs, used LCI-data and assumptions in regard to this

standard

Note 1 to entry: This LCA report is not meant for external communication. but has to be kept for justification purposes in

terms of environmental declaration verification or market surveillance.

3.19

life cycle

consecutive and interlinked stages of a product system, from raw material acquisition or generation from natural

resources to final disposal

Note 1 to entry: The phrase ’life cycle phase’ is sometimes used interchangeably with ‘life cycle stage’

[SOURCE: EN ISO 14040:2006, 3.1]

3.20

life cycle assessment

LCA

compilation and evaluation of the inputs, outputs and the potential environmental impacts of a product system

throughout its life cycle

[SOURCE: EN ISO 14040:2006, 3.2]

3.21

life cycle inventory analysis

LCI

phase of life cycle assessment involving the compilation and quantification of inputs and outputs for a product

throughout its life cycle

[SOURCE: EN ISO 14040:2006, 3.3]

3.22

material recovery

any recovery operation, excluding energy recovery and the reprocessing into materials which are to be used as

fuel

[SOURCE: EN 50625-1:2014, 3.23; Decision 2011/753/EU]

3.23

organization

person or group of people that has its own functions with responsibilities, authorities and relationships to achieve

its objectives

[SOURCE: EN ISO 14001:2015, 3.1.4 - modified]

3.24

packaging

material that is used to protect or contain a product during transportation, storage, marketing or use

Note 1 to entry: For the purposes of this standard, the term “packaging” also includes any item that is physically attached to,

or included with, a product or its container for the purpose of marketing the product or communicating information about the

product.

[SOURCE: EN ISO 14021:2016, 3.1.13]

3.25

product system

collection of unit processes with elementary and product flows, performing one or more defined functions, and

which models the life cycle of a product

[SOURCE: EN ISO 14040:2006, 3.28]

3.26

process

set of interrelated or interacting activities which transforms inputs into outputs

Note 1 to entry: A process can be documented or not.

[SOURCE: EN ISO 14001:2015, 3.3.5]

3.27

product

output of an organization that can be produced without any transaction taking place between the organization

and the customer

Note 1 to entry: Production of a product is achieved without any transaction necessarily taking place between provider and

customer, but can often involve this service element upon its delivery to the customer.

Note 2 to entry: The dominant element of a product is that it is generally tangible.

Note 3 to entry: Hardware is tangible and its amount is a countable characteristic (e.g. tyres). Processed materials are

tangible and their amount is a continuous characteristic (e.g. fuel and soft drinks). Hardware and processed materials are

often referred to as goods. Software consists of information regardless of delivery medium (e.g. computer programme, mobile

phone app, instruction manual, dictionary content, musical composition copyright, driver's license).

[SOURCE: ISO 9000:2015, 3.7.6 ]

3.28

product category

group of products that can fulfil equivalent functions

[SOURCE: EN ISO 14025:2010, 3.12]

3.29

product category rules

PCR

set of specific rules, requirements and guidelines for conducting life cycle assessment to develop environmental

declarations for one or more product categories

[SOURCE: EN ISO 14025:2010, 3.5 - modified]

3.30

product family

subgroup of a product category – technologically or functionally similar products

3.31

product specific rules

PSR

set of specific rules, requirements and guidelines, based upon and complementing the PCR, for a specific

product family

3.32

raw material

primary or secondary material that is used to produce a product

Note 1 to entry: Secondary material includes recycled material.

[SOURCE: EN ISO 14040:2006, 3.15]

3.33

reference flow

measure of the outputs from processes in a given product system required to fulfil the function expressed by the

functional unit

Note 1 to entry: The reference flows translate the abstract functional unit into specific product systems needed to fulfil the

required function with a required level of performance

[SOURCE: EN ISO 14040:2006, 3.29 - modified]

3.34

reference product

product or product system, supplied by the manufacturer, modelled in the LCA and taken as reference to

extrapolate the environmental impact of other products or product systems matching the same functional unit

(i.e homogeneous product family) and covered by the environmental declaration

[SOURCE: PEP Ecopassport PCR ed.3 - modified]

3.35

reference service life

RSL

service life that may be expected for a product and/or product system according to a particular set, i.e., a

reference set, of ambient and operating conditions during use stage and that may be used to estimate the service

life under other conditions during the use stage

Note 1 to entry: The reference service life is a theoretical period used for calculation purposes. It can never be compared to

the minimum, average or actual service life of the product

[SOURCE: EN 15804:2012+A1:2013, modified]

3.36

substance

chemical elements and their compounds in the natural state or obtained by any production process, including

any additive necessary to preserve the stability of the product and any impurities deriving from the process used,

but excluding any solvent which may be separated without affecting the stability of the substance or changing

its composition

[SOURCE: Globally Harmonized System of Classification and Labelling (GHS):2017, Chapter 1.2, Definitions

and Abbreviations]

3.37

waste

any substance or object which the holder discards or intends or is required to discard

[SOURCE: EN 50625-1:2014, 3.39]

3.38

waste electrical and electronic equipment

WEEE

electrical or electronic equipment which is waste within the meaning of Article 3(1) of Directive 2008/98/EC,

including all components, sub-assemblies and consumables which are part of the product at the time of

discarding

Note 1 to entry: This standard covers whole equipment discarded as WEEE and fractions thereof.

[SOURCE: EN 50625-1:2014, 3.40 – modified]

4 Product life cycle assessment

4.1 General

To quantify the potential environmental impacts caused by EEPS, LCA compliant with EN ISO 14040 and

EN ISO 14044 shall be performed. And results can then be used to identify improvement potentials in terms of

e.g. environmental conscious product design. In addition, the requirements of this PCR and applicable PSR

shall be applied in case the LCA results are further intended to be used in external communication. This is valid

when the form of an environmental product declaration (EPD), as laid out in the EN ISO 14021/14025 standards,

is used.

4.2 Product Category Rules

4.2.1 General

The product category rules (PCR) provide a uniform approach to perform the LCA, serving three purposes:

— to ensure a consistent quality of the LCA results,

— to enable data aggregation in larger systems, e.g. buildings or industrial production machinery,

— to serve as basis for environmental declarations using quantitative environmental impacts.

The PCR should be complemented with corresponding, product specific rules (PSR) to further specify

assumptions and methodology to be used for specific product families.

Product PSR shall be developed in the respective product technical committees according to the requirements

set out in this standard. If there are no PSR available yet but there’s the need for quantitative environmental

information based on LCA for a certain product group, the LCA practitioner shall complete the missing

specifications according to the requirements of EN ISO 14044 and shall disclose his specifications along with

the evaluated data.

NOTE For the completion of the missing information various sources might be available, like for instance environmental

declaration programs or PSR in standards by other product groups.

4.2.2 Functional unit and reference flow description

A product or system may have several functions and the main function(s) delivered to the user shall be selected

for the LCA study.

The functional unit (FU) is the product or system main function(s)’ quantified, to which the inputs and outputs

are related to.

The functional unit shall be defined by:

a) The main function(s) delivered to the user;

b) The magnitude and level of performance to be achieved for the main function(s). This level shall be

quantified and determined according to the market habits, regulatory requirements, standards and/or the

technical state of the art;

c) the reference service life (RSL) for the reference product, corresponding to the stipulations set out in ii).

The FU is used as a reference unit to allow comparison between different alternatives (e.g. products, systems

or technical solutions) intended to provide the main functions with the required level of performance.

NOTE 1 Some products or systems may have complex FU descriptions, for example multifunctional products such as

smartphones.

In PSR development it shall be taken into account that the definition of the RSL could lead to distortions for

product groups with a considerable range of product life span, where for some products the environmental

impacts would be underestimated, while for others it would be overestimated. Hence this should be reflected in

the FU and RSL, as well as the EPD, e.g. by providing annualised data.

Examples of functional units:

1) Motor: To provide (50 kW) of (mechanical power), over (20) years RSL with (260) days of operation per

year and (16) operating hours per day.

2) Cables (Energy distribution networks in the area of infrastructures): To transmit energy expressed for 1A

over a distance of 1 km for 40 years and a 100 % use rate in accordance with relevant standards (mention

the relevant standards or refer the product technical data sheet).

NOTE 2 Examples taken from CENELEC TC2 Working Group and PEP Ecopassport declaration program. (PCR ed3 -

PSR-0001-ed3-EN-2015 10 16)

Each functional unit shall be further specified in product specific rules (PSR) for each product or system family

to allow fair assessment and comparison. If no PSR is available, the FU shall be defined and documented

according to the requirements mentioned above and ISO standards EN ISO 14040 / EN ISO 14044.

The reference flow describes all the needed flows to fulfil the functional unit. A specific reference flow matches

each specific technical solution fulfilling the functional unit.

The reference flow shall include:

a) The quantitative amount of product(s), e.g. specified through their mass in kg, used to fulfil the functional

unit: they will be named “reference product”;

b) In addition, intermediate flows, for instance auxiliary materials and packaging, including waste and

discarded materials generated at each life cycle stage.

This relationship between functional unit, technical solution and reference flow is further illustrated in Figure 1

through an example.

Figure 1 — Graphical visualization of functional unit, technical solution and reference flow relationship

Since this reference flow is very product-system specific it shall be described in detail in product specific rules

(PSR).

A product may have several possible functions. Based on the goal and scope of the conducted LCA, the LCA

may relate to a specific function and scenario using a functional unit or it may cover a range of functionalities

and scenarios using a declared unit (DU). The declared unit shall be used as an alternative to the functional unit

if no functional unit can be defined. This is the case when the product can be used in many different ways in the

context of its application, or when the precise function of the product or scenarios of the system in which it is

integrated is not stated or is unknown.

The declared unit shall clearly mention:

a) The quantity of product;

2 3

b) The unit used (item, mass (kg), length (m), area (m ), volume (m ));

c) The mathematical relation between functional unit and declared unit, if applicable.

If a DU is used, it shall be documented accordingly in the LCA report.

If relevant, the DU shall be specified further in the corresponding PSR.

4.2.3 System boundary

4.2.3.1 General

LCA is conducted by defining product systems as models that describe the key elements of the physical systems.

The system boundary then defines the unit processes that shall be included in the product system.

In this context it should be noted, that the product system used as a term in LCA may be different from the

understanding of a product system as for instance used in engineering.

The life cycle of the EEPS under study shall at least cover the following main life cycle stages:

a) Manufacturing stage, including the relevant upstream process (e.g. acquisition of raw material, preparation

of semi-finished goods etc.) and the main manufacturing and processing steps;

b) Distribution stage

c) Use stage, including the required maintenance steps within the RSL associated to the reference product;

d) End-of-life stage, including the necessary steps until and for the final disposal or recovery of the product

system.

Additionally, the following life cycle stages can be relevant and should then be considered in the LCA

accordingly:

e) Installation stage, including the relevant steps for the preparation of the product for use;

f) De-installation, including the relevant steps for the preparation of the product for end-of-life;

The LCA shall include all relevant flows to the system, as energy and material resources and from the system,

as emissions to air, soil, water and waste, allocated to the respective life cycle stage.

Figure 2 — Scheme of the analysed product system’s boundaries, including the life cycle stages and

unit processes, which separate it from the ecosphere (natural environment)

Each life cycle stage includes all the aspects related to its inputs and outputs. For example, regarding waste

management, each stage includes the production, transportation, treatment and disposal of the waste generated

at the considered stage (discarded products, materials, etc.).

Further specifications concerning the system boundary shall be defined in the PSR.

4.2.3.2 Exclusions from System Boundary

The capital goods, such as buildings, machinery, tools and infrastructure, the packaging for internal transport

(i.e. boxes use to transport parts, components to the assembly point) and administrative overhead activities (e.g.

Business travel, marketing and advertisement…,), which cannot be allocated directly to the production of the

reference product, may be excluded from the system boundary.

4.2.3.3 Cut-off criteria

Criteria for the exclusion of inputs and outputs (cut-off criteria) in the LCA are intended to support an efficient

calculation procedure. They shall not be applied to hide data.

Based on established LCA practice, the cut-off criteria are set to a maximum of 5 % of the overall environmental

impact of the analysed product system given by its life cycle impact assessment (LCIA) results. Details

concerning cut-off criteria may be developed, defined and justified in PSR based on e.g. conducted LCA case

studies or compiled from literature and research papers. These PSR may address cut-off by defining criteria for

mass and energy cut-off, and / or main (and auxiliary) products parts, which are mandatory for the life cycle

assessment. Therefore, PSR can be stricter and more specific in that context. Any exclusion of inputs and

outputs shall be documented and justified.

4.2.4 Life cycle inventory

4.2.4.1 General

This section defines the inputs and outputs corresponding to the aspects of each of the life cycle stages that

shall be considered in the LCA. Further details concerning the modelling of the life cycle stages are laid out in

4.3 of this standard concerning the development of scenarios. The relevance of the life cycle stages and their

underlying processes itself shall be defined further in corresponding PSR.

4.2.4.2 Manufacturing

The inputs and outputs related to the following aspects shall be included in the manufacturing stage:

a) Production of the materials and components making up the reference product, including the final packaging

and technical documentation it is supplied with:

— Production (extraction, treatment, transformation, etc.) of raw materials necessary to manufacture the

components, including the flows associated with waste and discarded materials generated by the

manufacturing processes up to their end-of-waste status or disposal of final residues;

— Industrial transforming and manufacturing processes of the various parts, components, and products;

— Transportation of materials, components and subassemblies from the supplier’s production site to the

assembly site(s) and/or packaging site(s).

b) If applicable and relevant, production (extraction, treatment, transformation, transportation, etc.) of ancillary

materials used in manufacturing but not supplied with the final product.

c) Industrial processes used to assemble the reference product and packaging components;

d) Transportation of the packaged product from the packaging site to the manufacturer's last logistics platform.

4.2.4.3 Distribution

The inputs and outputs associated with the following aspects shall be included in the distribution stage:

a) Transportation of the product in its packaging from the manufacturer's last logistics platform to the distributor

and from the distributor to the place of installation and/or operation.

b) Processes, including the required materials and components, e.g. additional packing materials, needed for

the distribution and transportation of the product

c) In case of repacking, end-of-life management of generated waste (e.g. material recovery, energy recovery,

disposal).

4.2.4.4 Installation

This stage shall be considered separately only when a specific installation process is defined for the respective

product or corresponding regulatory requirements exist. This shall be defined in the PSR. If no PSR clearly

indicates how installation should be handled, but installation processes are relevant, the LCA practitioner shall

consider these and document it in the LCA report.

The inputs and outputs associated with the following aspects shall be included in the installation stage:

a) Processes, including the required materials and components, needed for installation, e.g. as specified by

the manufacturer and/or applicable regulations and standards

b) Management of the waste generated at the installation place (collection and treatment up to its final

treatment (e.g. material recovery, energy recovery, disposal):

— Packaging;

— Discarded installation materials;

— Waste associated with the installation processes.

If applicable, the processes, components and energy included in the installation stage shall be described and

justified in the LCA report.

4.2.4.5 Use

The inputs and outputs associated with the following aspects shall be included in the use stage:

a) Energy consumption and other flows (emissions, water, etc.) of the product during its use over the RSL;

b) Production, distribution, installation and end-of-life of elements required to operate, service and maintain

the reference product over the RSL.

Processes aiming at extending product lifetime such as repair, reuse, remanufacture shall be taken into account

in the use stage.

4.2.4.6 De-installation

This stage shall be considered separately only when a specific process is defined for the respective product or

corresponding regulatory requirements exist. This shall be defined in the PSR. If no PSR clearly indicates how

de-installation should be handled, but associated processes are relevant, the LCA practitioner may consider

these as part of the end-of-life stage. These assumptions shall be documented in the LCA report.

The inputs and outputs associated with the following aspects shall be included in the de-installation stage:

a) Processes needed for de-installation, e.g. as specified by the manufacturer and/or applicable regulations

and standards

b) Management of the waste generated at the de-installation place (collection and treatment up to its final

treatment (e.g. material recovery, energy recovery, disposal…):

— Discarded de-installation materials;

— Waste associated with the de-installation processes.

If applicable, the processes, components and energy included in the de-installation stage shall be described

and justified in the LCA report.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...