oSIST prEN IEC 62745:2026

(Main)Safety of machinery - Requirements for cableless control systems of machinery

Safety of machinery - Requirements for cableless control systems of machinery

Sicherheit von Maschinen - Anforderungen für kabellose Steuerungen an Maschinen

Sécurité des machines - Exigences pour les systèmes de commande sans fil des machines

Varnost strojev - Zahteve za brezžično povezavo upravljalnikov nadzornih sistemov strojev

General Information

- Status

- Not Published

- Public Enquiry End Date

- 15-Feb-2026

- Technical Committee

- MOV - Measuring equipment for electromagnetic quantities

- Current Stage

- 4020 - Public enquire (PE) (Adopted Project)

- Start Date

- 02-Dec-2025

- Due Date

- 21-Apr-2026

Relations

- Effective Date

- 03-May-2022

- Effective Date

- 03-May-2022

Overview

The oSIST prEN IEC 62745:2026 standard, titled Safety of Machinery - Requirements for Cableless Control Systems of Machinery, is developed by the Committee for Electrotechnical Standardization (CLC). This international standard addresses the growing use of wireless or cableless control systems (CCS) as operator interfaces for machinery. These systems replace traditional wired controls to offer enhanced flexibility, safety, and operational convenience.

This standard outlines essential safety and performance requirements for the design, function, verification, and use of cableless control systems in industrial machinery environments. It aims to ensure that such systems operate reliably and safely, minimizing risks related to unintended commands, unauthorized operation, or electromagnetic interference.

Key Topics

- Functional Safety Requirements: Includes prevention of inadvertent actuation, unintended commands, and unauthorized operation to reduce operational risks.

- Communication and Transmission: Emphasizes safe serial data transfer, establishment and indication of reliable transmission, as well as handling cessation of transmission functions.

- Safety-Related Stop Functions: Defines critical stop functions classifications ensuring emergency and safety stops are promptly and reliably executed.

- Multiple Configurations: Addresses diverse configurations including single/multiple base and remote stations to support complex machine control systems.

- Cybersecurity Measures: Specifies protections against cyber-attacks, jamming, replay attacks, and measures to secure the communication integrity of cableless controls.

- Verification & Testing: Requirements for labeling, functional verification, environmental testing, and acceptance criteria to validate system safety and performance.

- Environmental Conditions: Defines operating temperature ranges, humidity, and degree of protection to ensure reliable system operation in industrial environments.

- User Information and Documentation: Mandates clear documentation and information provision for proper use, system integration, and maintenance.

- Electrical Safety: Guidelines on protection against electric shock, power supply terminals, and fault protection to guarantee operator safety.

Applications

Cableless control systems compliant with oSIST prEN IEC 62745:2026 are critical in various industrial scenarios such as:

- Manufacturing Automation: Wireless controls provide operators with enhanced mobility and flexibility in automated production lines.

- Robotics: Safe remote operation and emergency stops prevent accidents in robotic workcells and collaborative robots.

- Heavy Machinery Operation: Control systems for cranes, construction equipment, and material handling machines benefit from secure cableless interfaces.

- Machine Tool Operation: Enables safe override, emergency shutdown, and configuration from remote stations without tangled or restrictive cabling.

- Process Control Systems: Industrial processes requiring modular, reconfigurable control interfaces leverage wireless control for ease of use and maintenance.

This standard ensures that cableless control systems meet stringent safety and reliability demands in these high-risk, complex industrial environments.

Related Standards

oSIST prEN IEC 62745:2026 complements and interfaces with several other international standards, including:

- IEC 61508 – Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems, establishing overall safety lifecycle requirements.

- ISO 13849 – Safety of Machinery – Safety-related parts of control systems, supporting risk reduction frameworks.

- IEC 61511 – Functional safety for process industry instrumentation, relevant for process control cableless systems.

- IEC 62209 – Electromagnetic compatibility standards addressing interference issues in industrial environments.

- ISO/IEC 27000 series – Cybersecurity standards relevant to wireless data communication protection.

- EN ISO 12100 – General Principles for Risk Assessment in Machinery Safety, foundational for all safety-related machinery standards.

By adhering to oSIST prEN IEC 62745:2026, manufacturers and system integrators ensure cableless control systems achieve regulatory compliance, operational safety, and robust performance in diverse industrial applications. This promotes safer workplaces, reduces machine downtime, and supports innovation in wireless machinery control technology.

Frequently Asked Questions

oSIST prEN IEC 62745:2026 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Safety of machinery - Requirements for cableless control systems of machinery". This standard covers: Safety of machinery - Requirements for cableless control systems of machinery

Safety of machinery - Requirements for cableless control systems of machinery

oSIST prEN IEC 62745:2026 is classified under the following ICS (International Classification for Standards) categories: 13.110 - Safety of machinery; 29.020 - Electrical engineering in general; 35.100.01 - Open systems interconnection in general. The ICS classification helps identify the subject area and facilitates finding related standards.

oSIST prEN IEC 62745:2026 has the following relationships with other standards: It is inter standard links to SIST EN 62745:2017/A11:2020, SIST EN 62745:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

oSIST prEN IEC 62745:2026 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 2014/35/EU, 2023/1230; Standardization Mandates: M/396, M/511, M/605. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

oSIST prEN IEC 62745:2026 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2026

Varnost strojev - Zahteve za brezžično povezavo upravljalnikov nadzornih

sistemov strojev

Safety of machinery - Requirements for cableless control systems of machinery

Sicherheit von Maschinen - Anforderungen für kabellose Steuerungen an Maschinen

Sécurité des machines - Exigences pour les systèmes de commande sans fil des

machines

Ta slovenski standard je istoveten z: prEN IEC 62745:2025

ICS:

13.110 Varnost strojev Safety of machinery

35.100.01 Medsebojno povezovanje Open systems

odprtih sistemov na splošno interconnection in general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

44/1071/CDV

COMMITTEE DRAFT FOR VOTE (CDV)

PROJECT NUMBER:

IEC 62745 ED2

DATE OF CIRCULATION: CLOSING DATE FOR VOTING:

2025-11-28 2026-02-20

SUPERSEDES DOCUMENTS:

44/1054/CD, 44/1059A/CC

IEC TC 44 : SAFETY OF MACHINERY - ELECTROTECHNICAL ASPECTS

SECRETARIAT: SECRETARY:

United Kingdom Mrs Nyomee Hla-Shwe Tun

OF INTEREST TO THE FOLLOWING COMMITTEES: HORIZONTAL FUNCTION(S):

TC 65

ASPECTS CONCERNED:

Electromagnetic Compatibility,Safety

SUBMITTED FOR CENELEC PARALLEL VOTING NOT SUBMITTED FOR CENELEC PARALLEL VOTING

Attention IEC-CENELEC parallel voting

The attention of IEC National Committees, members of

CENELEC, is drawn to the fact that this Committee Draft for

Vote (CDV) is submitted for parallel voting.

The CENELEC members are invited to vote through the

CENELEC online voting system.

This document is still under study and subject to change. It should not be used for reference purposes.

Recipients of this document are invited to submit, with their comments, notification of any relevant patent rights of which

they are aware and to provide supporting documentation.

Recipients of this document are invited to submit, with their comments, notification of any relevant “In Some Countries”

clauses to be included should this proposal proceed. Recipients are reminded that the CDV stage is the final stage for

submitting ISC clauses. (SEE AC/22/2007 OR NEW GUIDANCE DOC).

TITLE:

Safety of machinery - Requirements for cableless control systems of machinery

PROPOSED STABILITY DATE: 2027

NOTE FROM TC/SC OFFICERS:

electronic file, to make a copy and to print out the content for the sole purpose of preparing National Committee positions.

You may not copy or "mirror" the file or printed version of the document, or any part of it, for any other purpose without

permission in writing from IEC.

IEC CDV 62745 © IEC 2025

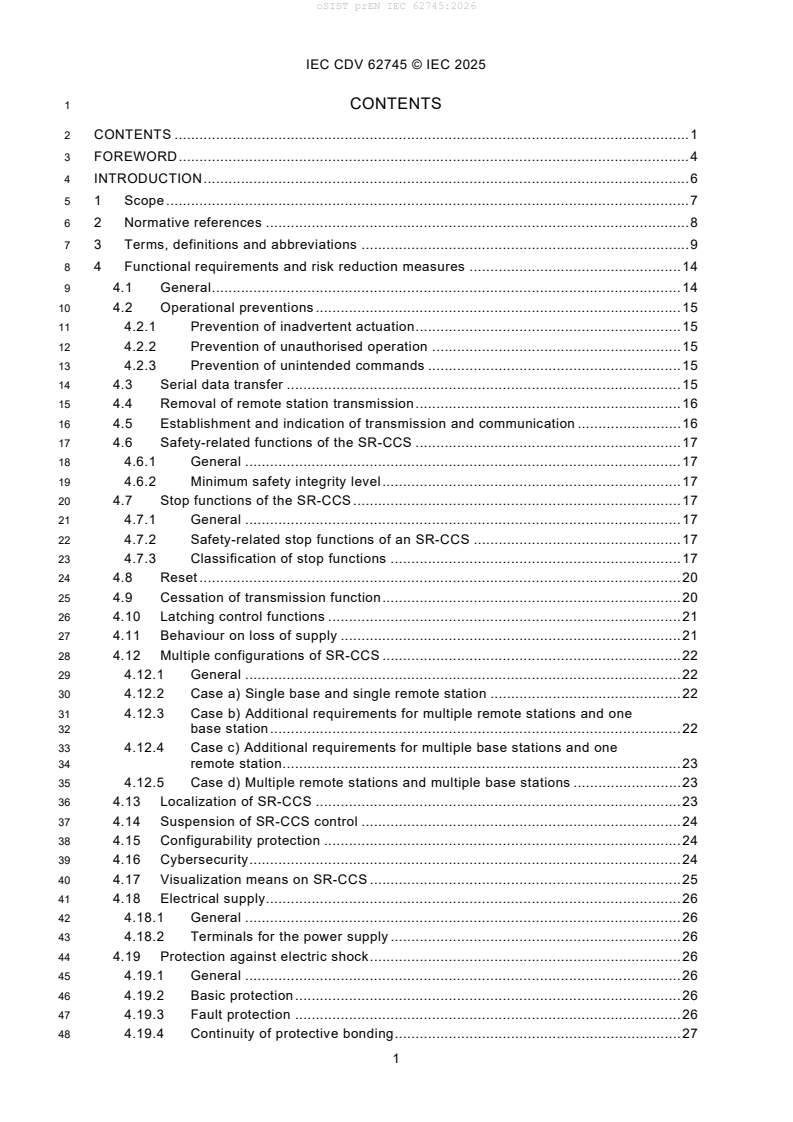

1 CONTENTS

2 CONTENTS . 1

3 FOREWORD . 4

4 INTRODUCTION . 6

5 1 Scope . 7

6 2 Normative references . 8

7 3 Terms, definitions and abbreviations . 9

8 4 Functional requirements and risk reduction measures . 14

9 4.1 General . 14

10 4.2 Operational preventions . 15

11 4.2.1 Prevention of inadvertent actuation . 15

12 4.2.2 Prevention of unauthorised operation . 15

13 4.2.3 Prevention of unintended commands . 15

14 4.3 Serial data transfer . 15

15 4.4 Removal of remote station transmission . 16

16 4.5 Establishment and indication of transmission and communication . 16

17 4.6 Safety-related functions of the SR-CCS . 17

18 4.6.1 General . 17

19 4.6.2 Minimum safety integrity level . 17

20 4.7 Stop functions of the SR-CCS . 17

21 4.7.1 General . 17

22 4.7.2 Safety-related stop functions of an SR-CCS . 17

23 4.7.3 Classification of stop functions . 17

24 4.8 Reset . 20

25 4.9 Cessation of transmission function . 20

26 4.10 Latching control functions . 21

27 4.11 Behaviour on loss of supply . 21

28 4.12 Multiple configurations of SR-CCS . 22

29 4.12.1 General . 22

30 4.12.2 Case a) Single base and single remote station . 22

31 4.12.3 Case b) Additional requirements for multiple remote stations and one

32 base station . 22

33 4.12.4 Case c) Additional requirements for multiple base stations and one

34 remote station. 23

35 4.12.5 Case d) Multiple remote stations and multiple base stations . 23

36 4.13 Localization of SR-CCS . 23

37 4.14 Suspension of SR-CCS control . 24

38 4.15 Configurability protection . 24

39 4.16 Cybersecurity . 24

40 4.17 Visualization means on SR-CCS . 25

41 4.18 Electrical supply . 26

42 4.18.1 General . 26

43 4.18.2 Terminals for the power supply . 26

44 4.19 Protection against electric shock . 26

45 4.19.1 General . 26

46 4.19.2 Basic protection . 26

47 4.19.3 Fault protection . 26

48 4.19.4 Continuity of protective bonding . 27

IEC CDV 62745 © IEC 2025

49 4.20 Colour of actuators . 27

50 4.21 Indicator lights and displays . 27

51 4.22 Protection against abnormal temperatures . 27

52 4.23 Degree of protection . 27

53 4.24 Environmental operating conditions . 27

54 5 Verification . 28

55 5.1 General . 28

56 5.2 Labelling and markings . 28

57 5.3 Documentation . 28

58 5.4 Acceptance criteria . 28

59 5.5 Operating parameters for tests . 28

60 5.6 Selection of test samples . 28

61 5.7 Functional verifications . 29

62 5.8 Environmental testing . 34

63 6 Information for use . 35

64 6.1 General . 35

65 6.2 Information to be provided . 35

66 6.3 List of verifications on a CCS to be required to the system integrator . 37

67 7 Labelling and markings . 39

68 Annex A (informative) Logic of stop functions . 40

69 Annex B (informative) Relationship between requirements of GSS and EMS . 42

70 C.1 Levels of SR-CCS cybersecurity behaviour . 44

71 C.2 Difficulty level in CCS signal identification and tracking. 44

72 C.3 Level of protection against attack vectors . 44

73 D.1 Environmental operating conditions . 46

74 E.1 Circular economy . 48

75 Bibliography . 49

77 Figure A.1 – Logic for stop functions . 43

79 For the purposes of this document, the following terms, definitions and abbreviations

80 apply. 13

81 ISO and IEC maintain terminology databases for use in standardization at the following

82 addresses: . 13

83 • ISO Online browsing platform: available at https://www.iso.org/obp . 13

84 Table 1 – Alphabetical list of definitions . 13

85 Table 2 – Abbreviations . 14

86 Table 3 – Overview of stop functions of the SR-CCS . 22

87 Table 4 – Possible configurations of SR-CCS . 26

88 Table 5 – Possible situation with multiple base station . 27

89 Table 6 – SR-CCS related particular attack vectors . 28

90 Table 7 – Environmental conditions for tests . 32

91 Table 8 – Verification of functional requirements . 34

92 Table 9 – Reference for environmental testing . 39

93 Table 10 – List of required verifications to the system integrator . 42

94 Table B.1 – Relationship between requirements of GSS and EMS . 46

IEC CDV 62745 © IEC 2025

95 Table 11 – Cableless signal identification and tracking level . 48

96 Table 12 – Level of protection against jamming (JA) . 49

97 Table 13 – Level of protection against Record and Replay (RR) . 49

IEC CDV 62745 © IEC 2025

100 INTERNATIONAL ELECTROTECHNICAL COMMISSION

101 ____________

103 SAFETY OF MACHINERY –

104 CABLELESS CONTROL SYSTEMS OF MACHINERY: GENERAL

105 REQUIREMENTS

107 FOREWORD

108 1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

109 all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

110 co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

111 in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

112 Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

113 preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

114 may participate in this preparatory work. International, governmental and non-governmental organizations liaising

115 with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

116 Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

117 2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

118 consensus of opinion on the relevant subjects since each technical committee has representation from all

119 interested IEC National Committees.

120 3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

121 Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

122 Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

123 misinterpretation by any end user.

124 4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

125 transparently to the maximum extent possible in their national and regional publications. Any divergence between

126 any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

127 5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

128 assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

129 services carried out by independent certification bodies.

130 6) All users should ensure that they have the latest edition of this publication.

131 7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

132 members of its technical committees and IEC National Committees for any personal injury, property damage or

133 other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

134 expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

135 Publications.

136 8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

137 indispensable for the correct application of this publication.

138 9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

139 rights. IEC shall not be held responsible for identifying any or all such patent rights.

140 International Standard IEC 62745 has been prepared by IEC technical committee 44: Safety of

141 machinery – Electrotechnical aspects.

142 This bilingual version (2018-01) corresponds to the monolingual English version, published in

143 2017-03.

144 The text of this standard is based on the following documents:

FDIS Report on voting

44/783/FDIS 44/785/RVD

146 Full information on the voting for the approval of this International Standard can be found in the

147 report on voting indicated in the above table.

148 The French version of this standard has not been voted upon.

149 This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

IEC CDV 62745 © IEC 2025

150 The committee has decided that the contents of this document will remain unchanged until the

151 stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

152 the specific document. At this date, the document will be:

153 • reconfirmed,

154 • withdrawn,

155 • replaced by a revised edition, or

156 • amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

IEC CDV 62745 © IEC 2025

160 INTRODUCTION

161 Cableless control systems (CCS) are increasingly being used to provide an operator interface

162 on a wide range of machinery. The functions of a CCS and the way in which they interface with

163 the overall machine control system can therefore affect the safety of the machinery. The risk

164 assessment can require the CCS to incorporate safety-related functions; in this case the CCS

165 becomes a safety-related cableless control system (SR-CCS).

166 IEC 62745 specifies requirements for the functions of a CCS incorporating safety-related

167 functions that is interfaced with or is part of a machine control system for use as an operator

168 control station on a machine. Additional requirements can be necessary for particular

169 applications.

170 The extent to which the safety-related functions of a CCS are relied upon to reduce risk on a

171 machine is a key selection criterion. It is therefore important to select a CCS that provides

172 suitable control functions with an appropriate safety integrity in accordance with the risk

173 assessment at the machine.

IEC CDV 62745 © IEC 2025

180 SAFETY OF MACHINERY –

181 CABLELESS CONTROL SYSTEMS OF MACHINERY: GENERAL

182 REQUIREMENTS

185 1 Scope

186 This standard specifies requirements for the functionality and interfacing of cableless control

187 systems, including safety-related functions, that provide cableless communication (for example

188 radio, infra-red) between operator control station(s) and the control system of a machine.

189 Specific requirements are included for operator control stations that are movable or portable by

190 the operator.This document does not deal with cableless communication between parts of a

191 machine(s) that are not operator control stations.

192 This document is not intended to specify all the necessary requirements for the design and

193 construction of a cableless control system. For example, it does not specify communication

194 protocols, frequency or bandwidth aspects, nor the full range of constructional requirements

195 such as electromagnetic compatibility, etc.

196 The provisions of this document are intended to be applied in addition to the requirements for

197 electrical equipment in relevant parts of IEC 60204 series.

198 This document is a type-B2 standard as stated in ISO 12100.

IEC CDV 62745 © IEC 2025

201 2 Normative references

202 The following documents are referred to in the text in such a way that some or all of their content

203 constitutes requirements of this document. For dated references, only the edition cited applies.

204 For undated references, the latest edition of the referenced document (including any

205 amendments) applies.

206 IEC 60068-2-27:2008, Environmental testing – Part 2-27: Tests - Test Ea and guidance: Shock

207 IEC 60068-2-31:2008, Environmental testing – Part 2-31: Tests – Test Ec – Rough handling

208 shocks, primarily for equipment-type specimens

209 IEC 60204-1:2016+AMD1:2021, Safety of machinery – Electrical equipment of machines – Part

210 1: General requirements

211 IEC 60364-4-41:2005+AMD1:2017 Low voltage electrical installations - Part 4-41: Protection

212 for safety - Protection against electric shock

213 IEC 60529:1989+AMD1:1999+AMD2:2013 Degrees of protection provided by enclosures (IP

214 Code)

215 IEC 60664-1:2020+AMD1:2025 Insulation coordination for equipment within low-voltage supply

216 systems - Part 1: Principles, requirements and tests

217 IEC 60947-5-1:2024, Low-voltage switchgear and controlgear – Part 5-1: Control circuit devices

218 and switching elements – Electromechanical control circuit devices

219 IEC 60947-5-5:1997+AMD1:2005+AMD2:2016, Low-voltage switchgear and controlgear – Part

220 5-5: Control circuit devices and switching elements – Electrical emergency stop device with

221 mechanical latching function

222 IEC 61140:2016, Protection against electric shock - Common aspects for installation and

223 equipment

224 IEC 61508 (all parts), Functional safety of electrical/electronic/programmable electronic safety-

225 related systems

226 IEC 62061:2021+AMD1:2024, Safety of machinery – Functional safety of safety-related

227 electrical, electronic and programmable electronic control systems

228 ISO 13849-1:2023, Safety of machinery – Safety-related parts of control systems – Part 1:

229 General principles for design

230 ISO 13849-2:2012, Safety of machinery – Safety-related parts of control systems – Part 2:

231 Validation

232 ISO 13850:2015, Safety of machinery – Emergency stop function– Principles for design

233 ISO 20607:2019, Safety of machinery — Instruction handbook — General drafting principles

IEC CDV 62745 © IEC 2025

236 3 Terms, definitions and abbreviations

237 For the purposes of this document, the following terms, definitions and abbreviations apply.

238 ISO and IEC maintain terminology databases for use in standardization at the following

239 addresses:

240 • ISO Online browsing platform: available at https://www.iso.org/obp

241 IEC Electropedia: available at https://www.electropedia.org

242 Table 1 – Alphabetical list of definitions

Term Definition number

active stop 3.18

address code 3.8

automatic stop 3.20

base station 3.14

cableless control 3.1

cableless control system 3.2

safety-related cableless control system 3.3

error detection code 3.10

frame 3.7

Hamming distance 3.12

manual stop 3.21

neutral frame 3.11

OFF-state 3.16

operating command signal 3.9

operator control station 3.6

passive stop 3.19

receiver 3.4

remote station 3.13

safety-related stop function 3.17

stop output 3.15

transmitter 3.5

valid signal 3.22

cybersecurity 3.23

IEC CDV 62745 © IEC 2025

244 Table 2 – Abbreviations

Term Abbreviation

automatic stop (4.7.3.5) ATS

cableless control system (3.2) CCS

safety-related cableless control system (3.3) SR-CCS

emergency stop (4.7.3.4) EMS

general safe stop (4.7.3.3) GSS

remote station (3.13) RST

base station (3.14) BST

246 3.1

247 cableless control

248 transmission of the machine operator's commands without a wired connection

249 3.2 cableless control system

250 CCS

251 system that consisting of at least one remote station and one base station, which uses cableless

252 control to transmit commands, controls signals and data between them

253 3.3

254 safety-related cableless control system

255 SR-CCS

256 cableless control system that includes safety-related functions

257 Note 1 to entry: In the Ed. 1 of this document safety-related cableless control system was

258 named only CCS.

259 3.4

260 receiver

261 part of a cableless control system which receives frames from a transmitter

262 3.5

263 transmitter

264 part of a cableless control system which sends frames to a receiver

265 3.6

266 operator control station

267 assembly of one or more control actuators (part of a device to which an external manual action

268 is to be applied by an operator) fixed on the same panel or located in the same enclosure

269 Note 1 to entry: An operator control station can also contain related equipment, for example, potentiometers, signal

270 lamps, instruments, display devices, etc.

271 3.7

272 frame

273 "packet" of information exchanged between a remote station and a base station

274 Note 1 to entry: Frame can consist of, for example address code, operating command signals, error detection code,

275 signals or information.

276 Note 2 to entry: Sometimes “frame” is also called “telegram” or “message”.

277 3.8

278 address code

279 part of a frame that identifies the intended receiver of the frame

IEC CDV 62745 © IEC 2025

280 Note 1 to entry: The base station or remote station respond to commands that have the relevant address code.

281 3.9

282 operating command signal

283 control signal that is intended to initiate, set or maintain a machine operation

284 3.10

285 error detection code

286 information included in each frame to enable the detection of transmission errors

287 3.11

288 neutral frame

289 frame in which all operating command signals are in a state such that when it is received at the

290 base station it does not activate any outputs intended for control of hazardous operations of the

291 machine

292 Note 1 to entry: Neutral frames can be used to maintain communication (i.e. a valid signal) between a transmitter

293 and receiver, for example to preclude automatic initiation of the stop function at a machine.

294 Note 2 to entry: Neutral frame transmission is intended to prevent unexpected or unintended behaviour of the SR-

295 CCS resulting from establishment or re-establishment of communication.

296 Note 3 to entry: Neutral frames can contain data, for example parameterisation data, and commands that are not

297 intended to cause hazardous operations of the machine.

298 3.12

299 Hamming distance

300 number of bit positions in which any two frames of the same length differ from each other

301 3.13

302 remote station

303 part of a safety-related cableless control system which is not physically connected to the

304 machine control system intended to control the operations of the machine

305 Note 1 to entry: The remote station of a cableless control system is sometimes referred to as a “transmitter”, but a

306 remote station that is part of a bi-directional cableless control system will incorporate both a transmitter and a

307 receiver.

308 Note 2 to entry: The remote station forms the operator control station of a cableless control system.

309 Note 3 to entry: The remote station can be portable or non-portable

310 3.14

311 base station

312 part of the safety-related cableless control system physically connected to the machine control

313 system

314 Note 1 to entry: The base station of a cableless control system is sometimes referred to as a “receiver”, but a base

315 station that is part of a bi-directional cableless control system will incorporate both a receiver and a transmitter.

316 Note 2 to entry: The base station can be installed on stationary or mobile machines.

317 Note 3 to entry: The base station is not necessarily a discrete physical entity, but it includes all of the components

318 that fulfill the requirements specified in this standard for the base station.

319 3.15

320 stop output

321 output circuit of the base station that interfaces with the control system of the machine to initiate

322 a stop function

323 Note 1 to entry: Stop outputs can be safety-related or non-safety-related. See also Table 3.

324 Note 2 to entry: Interfaces to field bus part of an SR-CCS base station can also be considered as a stop output

325 circuit.

IEC CDV 62745 © IEC 2025

326 3.16

327 OFF-state

328 state of safety-related stop output(s) of the base station used to initiate one or more stop

329 functions of a machine

330 3.17

331 safety-related stop function

332 stop function provided by the SR-CCS that results in an OFF-state and whose failure can result

333 in an immediate increase of the risk(s)

334 3.18

335 active stop

336 stop resulting from transmission of a stop signal from the remote station to the base station

337 3.19

338 passive stop

339 safety-related stop resulting from absence of a valid signal at the base station

340 Note 1 to entry: A passive stop can be initiated by, for example, an out of range condition, battery failure,

341 electromagnetic interference.

342 3.20

343 automatic stop

344 safety-related stop initiated without manual actuation of a device by an operator

345 3.21

346 manual stop

347 stop initiated by actuation of a device by an operator

348 3.22

349 valid signal

350 any received frame, including a neutral frame, that is accepted by the error checking routines

351 of the receiver and contains the relevant address code for the receiver

352 3.23

353 cybersecurity

354 set of activities necessary to protect SR-CCS and information systems of the SR-CCS, the users

355 of such systems, and other persons from cyber threats, typically regarding the aspects of

356 confidentiality, integrity and availability

357 [SOURCE: IEC TS 63074:2023, 3.1.6, modified removing and

358 “network” and “machine control system”.]

360 3.24

361 portable remote station

362 remote station intended to be carried by a person during its operation

363 Note 1 to entry: Portable remote station is sometimes referred to as hand-held remote station.

364 Note 2 to entry: Non-portable remote station can be fixed installed (e.g. installed on or near to the machine) or

365 movable.

366 [SOURCE: IEV 426-01-11, modified changing with ]

368 3.25

369 movable remote station

370 remote station intended to be installed on mobile means (e.g. vehicle-mounted or installed on

371 a trolley)

IEC CDV 62745 © IEC 2025

372 3.26

373 safe state

374 condition which continues to preserve safety

375 [SOURCE: IEV 821-12-49]

377 3.27

378 system integrator

379 person(s) or entity responsible for integration of components, devices, equipment and

380 subsystems into a whole over system (or machine), ensuring that such parts are assembled,

381 interconnected, interfaced and work together as intended.

382 Note 1 to entry: This stakeholder is typically present on projects that deal with multiple providers.

383 Note 2 to entry: The integrator can be a manufacturer, an engineering company or the user of the product.

IEC CDV 62745 © IEC 2025

386 4 Functional requirements and risk reduction measures

387 4.1 General

388 A safety-related cableless control system shall comply with all applicable requirements of this

389 document and have at least, one safety-related function.

390 NOTE A CCS presenting one or more safety-related functions that does not comply with the following requirements

391 can not be considered as SR-CCS.

392 Figure 1 illustrates an example of the main elements of an SR-CCS and its interaction with the

393 machine control system.

396 Figure 1 – Block diagram example of an SR-CCS

397 and its interaction as part of the machine control system

399 NOTE The references to IEC 60204-1:2016 in this standard can have corresponding

400 requirements in other relevant parts of IEC 60204 series (e.g. IEC 60204-32).

IEC CDV 62745 © IEC 2025

401 4.2 Operational preventions

402 4.2.1 Prevention of inadvertent actuation

403 The remote station and its control actuators shall be designed and arranged so as to minimise

404 the possibility of inadvertent actuation (for example, caused by dropping to the floor or striking

405 an obstruction) generating an unintended hazardous command.

406 Measure to reduce inadvertent actuation include, for example: collars, enabling devices, hold-

407 to-run control (e.g., dead-man switches).

409 Depending on the specific application or design, where collars are used to protect operating

410 devices, they shall surround totally or partially such devices (e.g. push-button); surrounding

411 protective collars shall not be lower than the protected devices. For EMS see 4.7.3.4.

413 Note: sometimes collars can be higher than the profile (height of the device).

415 4.2.2 Prevention of unauthorised operation

416 Means to prevent unauthorised use (for example, key-operated switch, access code) shall be

417 provided.

418 4.2.3 Prevention of unintended commands

419 Measures shall be taken to ensure that operating command signals:

420 • affect only the intended base station or remote station (for example, using unique address

421 code);

422 • initiate only the intended functions in that base station or remote station.

423 Upon detection of malfunction or faults in these measures, an automatic stop function ATS shall

424 initiate. Where hardware switches (for example, DIP) are used for device addressing, additional

425 measures (for example, parity checking) shall be required to fulfil the requirements.

426 NOTE Typical methods include factory-set coding, which are more robust than user-configurable methods because

427 they cannot be defeated (either intentionally or inadvertently) by the user.

428 4.3 Serial data transfer

429 The serial data transfer shall satisfy one of the following requirements:

430 • means shall be provided that ensure the probability of an erroneous frame being received

-8 -3

431 undetected, R(P ), is less than 1 × 10 , given an input bit error probability of P = 10 , if

e e

432 no better input bit error probability can be proven, or

433 • the minimum Hamming distance shall be either 4 or the total number of bits in a frame

434 divided by 20, whichever is greater.

-3

435 NOTE 1 An input bit error probability of P = 10 can be assumed as typical estimate for a wireless channel

e

436 disturbed by Additive White Gaussian Noise (AWGN) and electromagnetic interference (EMI).

437 NOTE 2 IEC 60870-5-1:1990 defines a set of possible transmission frame formats.

438 NOTE 3 Increasing the reliability of serial data transmission only reduces the possibility of errors that can be

439 occurring in the transmission media.

440 In addition, for safety-related functions of an SR-CCS the residual error probability Λ of

441 undetected error per hour shall be less than 1 % of the specified PFH value for the respective

442 function of the SR-CCS. Residual probability of undetected error per hour Λ shall be calculated

443 by:

444 Λ(P ) = R(P ) × ν × b [1/h]

e e

IEC CDV 62745 © IEC 2025

445 where:

446 Λ(P ): residual probability of undetected error per hour in relation to the input bit error

e

447 probability

448 R(P ): residual probability of undetected error per frame in relation to the input bit error

e

449 probability

-

450 P : input error probability: if no better input bit error probability can be proven, P = 1 × 10

e e

451 applies

452 ν: maximum number of safety-related messages per hour

453 b: maximum number of listening base stations

454 NOTE 4 For a definition of PFH (average frequency of a dangerous failure per hour) see IEC 62061:2021 or

455 ISO 13849-1:2023.

456 NOTE 5 Λ(P ) calculation is based on IEC 61784-3:2021+AMD1:2024; this approach is valid for cyclic transmission

e

457 of safety-related messages.

458 NOTE 6 Equation (B.3) or (B.4) from IEC 61784-3:2021+AMD1:2024can be applied in order to determine R(P )

e

-3

459 with an input bit error probability of P = 1 × 10 , when using CRC as hash-function: for more details see IEC 61784-

e

460 3:2021+AMD1:2024.

461 NOTE 7: The SR-CCS can be equipped with indicator of transmission reliability. See 6.2.

462 NOTE 8 It is not necessary to provide a separate warning indicator for each condition that can affect transmission

463 reliability.

464 Use of industrial wireless fieldbus technologies in accordance with the IEC 61784 series can

465 satisfy the requirements of this clause.

466 4.4 Removal of remote station transmission

467 Means shall be provided to readily cease transmission from the remote station. This shall be

468 achieved by one or more of the following:

469 a) a device that interrupts the power supply of transmission for the remote station, where such

470 a device shall have direct opening action in accordance with IEC 60947-5-1:2024, Annex K,

471 or

472 b) removal of the battery without the use of a tool, or

473 c) a dedicated transmission removal function in accordance with with 4.6.2.

474 A passive stop shall result from the ceasing of transmission.

475 4.5 Establishment and indication of transmission and communication

476 Power up of the remote station or re-establishment of communication (for example, after power

477 supply interruption, remote station battery replacement, lost signal condition) shall not activate

478 any output that is intended for control of hazardous operations of the machine. Initiation or re-

479 initiation of such operations shall require a deliberate action (for example, releasing a control

480 actuator from its energised position and then pressing it again).

481 The base station shall not respond to operating command signals that can activate outputs

482 intended for control of hazardous operations of the machine until a neutral frame has been

483 received (i.e. following re-establishment of communication).

484 When transmission from a remote station is taking place, this shall be indicated on the remote

485 station (for example, by an indicating light, a visual display indication, etc.); the indication shall

486 remain until the transmission ends.

487 NOTE It can also be useful to provide a means of indicating when a base station is receiving transmissions from an

488 associated remote station. For example, an output(s) on the base station can be designated for this purpose, and/or

IEC CDV 62745 © IEC 2025

489 a confirmation signal can be transmitted to the remote station if bi-directional communication is available. Where the

490 base station does not provide a designated means of indication, see 6.2.

491 4.6 Safety-related functions of the SR-CCS

492 4.6.1 General

493 Functions of the SR-CCS that are intended for safety-related applications, other than those

494 specified in 4.7.2, shall have an appropriate safety integrity. The requirements of

495 IEC 62061:2021, IEC 61508 series or ISO 13849-1:2023, ISO 13849-2:2012 shall apply.

496 Upon detection of faults, all safety-related stop outputs shall result in OFF-state. The detection

497 of a fault in the remote station that can lead to the loss of a safety-related function, shall cease

498 the transmission in accordance with 4.4.

499 NOTE Further information on the design of safety-related aspects of control functions is given in ISO 12100:2010

500 and IEC 61508 series.

501 4.6.2 Minimum safety integrity level

502 According to IEC 62061:2021, IEC 61508 series or ISO 13849-1:2023 each safety-related

503 function of an SR-CCS shall have a safety integrity of:

504 • SIL1, HFT = 1 or

505 • PL c Category 3.

506 4.7 Stop functions of the SR-CCS

507 4.7.1 General

508 The SR-CCS shall provide an automatic stop function (ATS).

509 At least one safety-related stop function shall be provided that is initiated by a deliberate human

510 action on a control device provided specifically for that purpose; portable and movable remote

511 station shall be provided with GSS or EMS, according to 4.7.3. Information about logic of all

512 stop functions is given in Annex A.

513 NOTE 1 In most applications this manually-initiated stop function is either a GSS or EMS (see 4.7.3).

514 NOTE 2 In most SR-CCS ATS and the additional safety-related manually-initiated stop function is combined in the

515 same stop output circuit.

516 NOTE 3 Emergency stop devices on SR-CCS is not be the sole means of initiating the emergency stop function of a

517 machine according to IEC 60204-1:2016.

518 4.7.2 Safety-related stop functions of an SR-CCS

519 Each safety-related stop function of an SR-CCS shall initiate an OFF-state of the stop output(s)

520 at the base station.

521 The safety-related stop function of an SR-CCS shall have at least a safety integrity according

522 to 4.6.2.

523 4.7.3 Classification of stop functions

524 4.7.3.1 General

525 Stop functions of an SR-CCS are classified as:

526 • control stop;

IEC CDV 62745 © IEC 2025

527 • general safe stop (GSS);

528 • emergency stop (EMS);

529 • automatic stop (ATS).

530 Table 3 describes the characteristics of the different stop functions.

531 Table 3 – Overview of stop functions of the SR-CCS

Type of stop Control actuator

Safety- Availability

Effect on

Function Clause related &

(see Fig.

SR-CCS

Type Colour

function operability

A1)

Defined state

of (a) stop

output(s), or

of another

output

Active

associated

No

with release

Operational See

Black

of a hold-to-

when the IEC 60204-1:2

run

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...