SIST EN 16602-70-31:2015

(Main)Space product assurance - Application of paints and coatings on space hardware

Space product assurance - Application of paints and coatings on space hardware

This Standard defines the approach for producing a defined surface finish to spacecraft or associated equipment, by means of the

controlled application of a paint. This also includes measurements and verifications to be performed.

This standard may be tailored for the specific characteristic and constrains of a space project in conformance with ECSS-S-ST-00.

Raumfahrtproduktsicherung - Anwendung von Farben und Beschichtungen auf Raumflug-Hardware

Assurance produit des projets spatiaux - Application des peintures et revêtements des matériels d'un projet spatial

La présente norme définit l'approche relative à la production d'une finition de surface définie, destinée à un engin spatial ou à des équipements associés, au moyen de l'application contrôlée d'une peinture. Elle comprend également les mesures et vérifications à effectuer.

La présente norme peut être adaptée aux caractéristiques et contraintes spécifiques d'un projet spatial, conformément à la norme ECSS-S-ST-00.

Zagotavljanje varnih proizvodov v vesoljski tehniki - Uporaba barv in premazov na vesoljski strojni opremi

Ta standard določa pristop za izdelavo določene površinske obdelave za vesoljska plovila in povezano opremo, in sicer z nadzorovano uporabo barve. To zajema tudi meritve in preverjanja, ki jih je treba izvesti. Ta standard se lahko prilagodi posameznim lastnostim in omejitvam vesoljskega projekta v skladu s standardom ECSS-S-ST-00.

General Information

- Status

- Published

- Public Enquiry End Date

- 27-Feb-2014

- Publication Date

- 01-Dec-2014

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 06-Nov-2014

- Due Date

- 11-Jan-2015

- Completion Date

- 02-Dec-2014

Overview

EN 16602-70-31:2014 - "Space product assurance - Application of paints and coatings on space hardware" (CEN) defines a structured approach for producing controlled surface finishes on spacecraft and related equipment by the controlled application of paints and coatings. The standard covers process definition, preparatory conditions, measurement and verification, quality assurance and acceptance criteria, and may be tailored for specific projects in conformance with ECSS‑S‑ST‑00.

Key topics and technical requirements

- Verification programme: Adequacy of a paint process must be demonstrated via a verification programme; project-specific acceptance criteria may be applied.

- Materials compliance: Only materials registered under REACH and documented via Material Safety Data Sheets (MSDS) are permitted.

- Substrate and qualification: Paint–substrate combinations must be qualified on representative test pieces that mirror composition, surface state and geometry.

- Preparatory and environmental controls:

- Clean work area, filtered ventilation and clean handling (powder‑free, lint‑free gloves).

- Recommended ambient conditions: 22 ± 3 °C and 55 ± 10 % RH (unless otherwise qualified). Workpiece temperature must remain above dew point; suspend operations if condensation appears.

- Facilities and equipment: Typical utilities include a spray booth with controlled exhaust, oven for controlled curing, ultrasonic bath and fume cupboard. Spray guns and brushes are specified per application.

- Sampling and tests:

- Adhesion and pull‑off tests (e.g., ECSS‑Q‑ST‑70‑13, ISO 2409).

- Thermo‑optical property measurements (ECSS‑Q‑ST‑70‑09).

- Dry‑film thickness and non‑destructive thickness measurement (ASTM D1005/D1400, ISO 2360).

- Acceptance criteria: Include aspect, thickness, adhesion, thermo‑optical and electrical properties; supplier quality assurance, traceability, calibration and nonconformance control are required.

- Handling, storage and labelling: Limited‑life materials must be labelled with shelf life and dates; packaged parts must be protected against contamination and mechanical damage.

Applications and users

EN 16602-70-31 is intended for organizations involved in spacecraft surface finishing and space product assurance:

- Spacecraft manufacturers and systems integrators

- Surface treatment shops and qualified paint applicators

- Procurement and quality assurance teams in space projects

- Suppliers of primers, paints and coatings for space hardware

Typical applications include thermal control coatings, conductive/insulating finishes, optical surface treatments and protective coatings on structures, harnesses and instrument housings.

Related standards (selection)

- ECSS‑S‑ST‑00 - system tailoring and glossary

- ECSS‑Q‑ST‑70 (materials, processes)

- ECSS‑Q‑ST‑70‑09 - thermo‑optical measurements

- ECSS‑Q‑ST‑70‑13 - adhesion testing

- ISO 2409, ISO 2360; ASTM D1005, ASTM D1400

- REACH (EC 1907/2006) compliance

EN 16602-70-31 provides practical guidance to ensure paint and coating processes on space hardware meet traceability, safety and performance requirements critical for mission success.

Frequently Asked Questions

SIST EN 16602-70-31:2015 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Space product assurance - Application of paints and coatings on space hardware". This standard covers: This Standard defines the approach for producing a defined surface finish to spacecraft or associated equipment, by means of the controlled application of a paint. This also includes measurements and verifications to be performed. This standard may be tailored for the specific characteristic and constrains of a space project in conformance with ECSS-S-ST-00.

This Standard defines the approach for producing a defined surface finish to spacecraft or associated equipment, by means of the controlled application of a paint. This also includes measurements and verifications to be performed. This standard may be tailored for the specific characteristic and constrains of a space project in conformance with ECSS-S-ST-00.

SIST EN 16602-70-31:2015 is classified under the following ICS (International Classification for Standards) categories: 49.140 - Space systems and operations; 87.040 - Paints and varnishes. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 16602-70-31:2015 is associated with the following European legislation: Standardization Mandates: M/496. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 16602-70-31:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Zagotavljanje varnih proizvodov v vesoljski tehniki - Uporaba barv in premazov na vesoljski strojni opremiRaumfahrtproduktsicherung - Anwendung von Farben und Beschichtungen auf Raumflug-HardwareAssurance produit des projets spatiaux - Application des peintures et revêtements des matériels d'un projet spatialSpace product assurance - Application of paints and coatings on space hardware87.040Barve in lakiPaints and varnishes49.140Vesoljski sistemi in operacijeSpace systems and operationsICS:Ta slovenski standard je istoveten z:EN 16602-70-31:2014SIST EN 16602-70-31:2015en01-januar-2015SIST EN 16602-70-31:2015SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16602-70-31

October 2014 ICS 49.140

English version

Space product assurance - Application of paints and coatings on space hardware

Assurance produit des projets spatiaux - Application des peintures et revêtements des matériels d'un projet spatial

Raumfahrtproduktsicherung - Anwendung von Farben und Beschichtungen auf Raumflug-Hardware This European Standard was approved by CEN on 11 April 2014.

CEN and CENELEC members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN and CENELEC member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN and CENELEC member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN and CENELEC members are the national standards bodies and national electrotechnical committees of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels © 2014 CEN/CENELEC All rights of exploitation in any form and by any means reserved worldwide for CEN national Members and for CENELEC Members. Ref. No. EN 16602-70-31:2014 E SIST EN 16602-70-31:2015

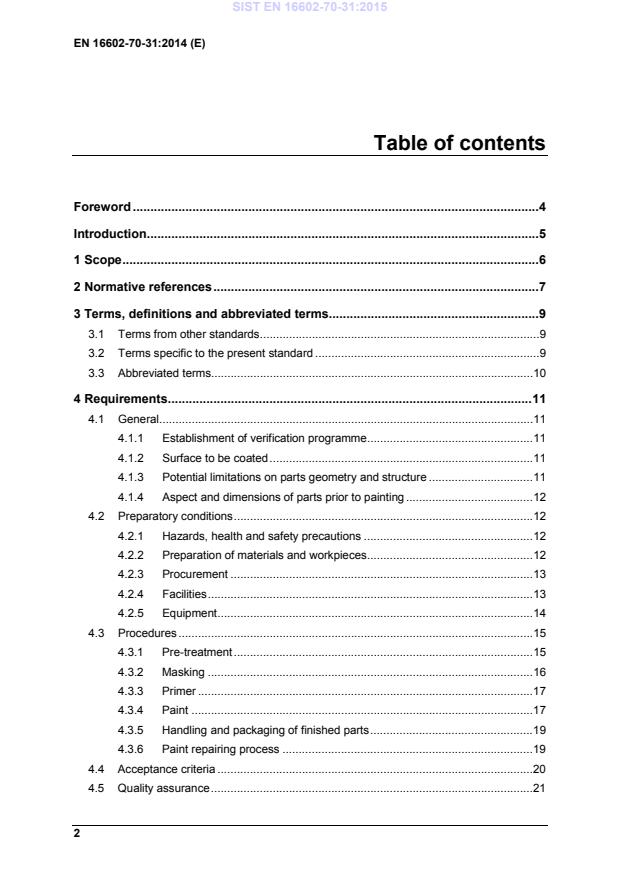

The parameters to be defined are: • For substrate: Cleanliness Roughness or other preparation • For primer: Quality Thickness Adhesion

Time between application of primer and application of paint • For paint:

Aspect Thickness Adhesion Thermo-optical properties Electrical properties NOTE

This list is not exhaustive. SIST EN 16602-70-31:2015

EN reference Reference in text Title EN 16601-00-01 ECSS-S-ST-00-01 ECSS system — Glossary of terms EN 16602-10-09 ECSS-Q-ST-10-09 Space product assurance - Nonconformance control system EN 16602-20 ECSS-Q-ST-20 Space product assurance - Quality assurance EN 16602-70 ECSS-Q-ST-70 Space product assurance - Materials, mechanical parts and processes EN 16602-70-02 ECSS-Q-ST-70-02 Space product assurance - Thermal vacuum outgassing test for the screening of space materials

EN 16602-70-09 ECSS-Q-ST-70-09 Space product assurance - Measurement of thermo-optical properties of thermal control materials

EN 16602-70-13 ECSS-Q-ST-70-13 Space product assurance - Measurement of the peel and pull-off strength of coatings and finishes using pressure-sensitive tapes EN 16602-70-22 ECSS-Q-ST-70-22 Space product assurance - Control of limited shelf-life materials

ASTM D1005-95 Standard Test Method for Measurement of Dry-Film Thickness of Organic Coatings Using Micrometers

ASTM D1400-94 Standard Test Method for Non-destructive Measurement of Dry Film Thickness of Nonconductive Coatings Applied to a Nonferrous Metal Base

ISO 2409:2007 Paints and Varnishes – Cross-cut test

ISO 2360:2003 Non-conductive coatings on non-magnetic electrically conductive basis materials – Measurement of coating thickness – Amplitude-sensitive eddy current method SIST EN 16602-70-31:2015

EC 1907/2006

European regulation for the registration, evaluation, authorisation and restriction of chemicals SIST EN 16602-70-31:2015

Examples are: • Hemispherical emittance (εh) -- conditions for incident or viewing of flux over a hemispherical region. • Normal emittance (εn) -- conditions for incidence or viewing through a solid angle normal to the specimen. 3.2.2 solar absorptance (αs) ratio of the solar radiant flux absorbed by a material (or body) to that incident upon it NOTE

Differentiation is made between two methods: • Spectroscopic method using a photospectrometer covering the range from 0,25 μm to 2,5 μm for the determination of αs. • Portable equipment using a xenon flash for relative measurements (αp). 3.2.3 toxic substance causing serious, acute or chronic effects, even death, when inhaled, swallowed or absorbed through the skin SIST EN 16602-70-31:2015

Abbreviation Meaning RML recovered mass loss REACH registration, evaluation, authorisation of chemicals

4.1 General 4.1.1 Establishment of verification programme

a. The adequacy of a paint process shall be demonstrated through a verification programme. b. Depending on the specific project requirements, the paint applied shall fulfil part or all the acceptance criteria given in 4.4 of this Standard. c. ECSS-Q-ST-70 shall apply. d. The supplier shall use for paint applications only materials that are registered in the REACH database and follow the REACH instructions. 4.1.2 Surface to be coated a. All couples paint - substrate shall be qualified for the given application, taking into account the use conditions. NOTE 1 Examples of use conditions are temperature, thermal cycling, optical, mechanical and electrical properties. NOTE 2 There exist no universal paint systems that can be applied to all substrates. b. The suitability of the substrate with respect to the paint process shall be demonstrated on representative test pieces having the same specific characteristics as the workpiece. NOTE

Representative sample does not only concern the composition, but also the state of the surface and the geometry of the work piece. 4.1.3 Potential limitations on parts geometry and structure a. The paint application process shall be adapted to the geometry of the surface to be coated. NOTE

The geometry of the surface to be coated has an impact on the characteristics of the paints SIST EN 16602-70-31:2015

While handling the parts to be coated, it is important to note that the paint layer mimics the underlying substrate. 4.2 Preparatory conditions 4.2.1 Hazards, health and safety precautions a. The details of hazards for each material used in the process shall be available to all personnel involved into the application. b. All Material Safety Data Sheets shall be available and known to the operators and supervising staff. c. In addition, hazards to personnel, equipment, environment and materials shall be controlled and reduced to an acceptable risk. NOTE

Hazard can be reduced by using protective clothing. 4.2.2 Preparation of materials and workpieces 4.2.2.1 Handling and storage a. The conditions for handling and storage of materials used in this process shall be clearly indicated to all operators and supervising staff. b. The workpiece or sample shall only be handled with clean, powder-free and lint-free gloves and shall be stored in a clean area. c. Gloves shall be compatible with all compounds used. NOTE

For example: compatibility between paint, solvents, and cleaning agents. d. Coated surfaces shall be shielded from contact by using appropriate bags or sheets. NOTE

The suitable bags are for example plastic bags with desiccators, sheet of tissue-paper, sheet of polyethylene foam. e. Mechanical damage shall be avoided in the standard way by wrapping the packed pieces in clean, dust- and lint-free material. f. Limited-life materials shall be labelled with their relative shelf-lives and dates

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...