SIST EN 16602-70-03:2015

(Main)Space product assurance - Black-anodizing of metals with inorganic dyes

Space product assurance - Black-anodizing of metals with inorganic dyes

This Standard defines requirements for measurements and verifications to guarantee that an anodized coating is adequate for the intended application. The requirements set by this Standard ensure high reliability of surface treatments intended to withstand normal terrestrial conditions and environment loads imposed on spacecraft and associated equipment where surfaces require high solar absorptance, high emittance, high optical blackness, or a combination of these properties. This standard may be tailored for the specific characteristics and constraints of a space project, in conformance with ECSS-S-ST-00.

Raumfahrtproduktsicherung - Schwarzes anodisieren von Metallen mit anorganischen Farben

Assurance produit des projets spatiaux - Anodisation noire des métaux avec colorants non organiques

Zagotavljanje varnih proizvodov v vesoljski tehniki - Črno eloksiranje kovin z anorganskimi barvili

Ta standard določa zahteve za meritve in preverjanja, da se zagotovi, da je eloksiran premaz ustrezen za načrtovano uporabo. Zahteve iz tega standarda zagotavljajo visoko zanesljivost površinskih prevlek, ki naj bi prenesle običajne zemeljske pogoje in okoljske obremenitve, ki jih prenašajo vesoljska plovila ter povezana oprema, kadar so za površine potrebne visoka sončna absorptanca, visoka emisivnost, visoka optična črnina ali kombinacija teh lastnosti. Ta standard se lahko prilagodi posameznim lastnostim in omejitvam vesoljskega projekta v skladu s standardom ECSS-S-ST-00.

General Information

- Status

- Published

- Publication Date

- 01-Dec-2014

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 06-Nov-2014

- Due Date

- 11-Jan-2015

- Completion Date

- 02-Dec-2014

Overview

EN 16602-70-03:2014 - Space product assurance: Black-anodizing of metals with inorganic dyes - is a CEN European Standard that defines requirements for verifying and measuring anodized coatings used on spacecraft hardware. The standard ensures that black-anodized surfaces meet the thermo‑optical needs of space and terrestrial handling: high solar absorbance, high emittance, and optical blackness. It is intended to be tailored per project in conformance with ECSS-S-ST-00 and originates from ECSS-Q-ST-70-03C.

Key topics and technical requirements

- Scope & intent: Requirements to guarantee coating adequacy and high reliability under spacecraft environmental loads and normal terrestrial conditions.

- Materials & suitability: Focus on metals commonly treated (aluminium, titanium and alloys). Notes that certain aluminium alloys with high Cu (

5%), Zn (6%) or Si (~5%) content respond poorly to some treatments. - Work-piece selection & preparation:

- Parts should be from the same alloy and batch; avoid mixed metals, fasteners, or retained chemicals.

- Surface cleaning, masking, and appropriate handling (lint-free gloves) are specified.

- Design considerations to allow thorough rinsing (e.g., drain holes) and control of dimensional impact.

- Facilities & safety: Clean work area, filtered ventilation, and compliance with national health and safety regulations.

- Process control:

- Electrical contact for each part and monitoring of key parameters: voltage/current/current density, electrolyte composition and pH, electrode placement, bath temperature, agitation, electrolyte volume and process time.

- Process data recording and traceability are mandatory.

- Colouring methods: Both two-step (anodize then dye/seal) and integral colouring approaches are covered; Annex A provides dyeing recipes (e.g., cobalt sulphide, nickel sulphide) and safety/hazard notes.

- Acceptance & verification:

- Visual inspection and verification testing, including thermo‑optical measurements.

- Thermo-optical metrics: solar absorbance (αs) and emittance (ε) - methods include spectroscopic measurement (0.25–2.5 µm) and portable xenon-flash relative measurements.

- Peel/pull-off strength and process verification per ECSS-Q-ST-70 methods.

Applications and users

Who benefits:

- Spacecraft thermal-control engineers and materials specialists

- Prime contractors and parts suppliers performing black-anodizing

- Quality assurance, process engineers and test labs validating coatings Why use it:

- To specify and verify coatings that control surface equilibrium temperature

- To ensure repeatable, radiation‑resistant optical properties using inorganic dyes suitable for space environments

- To document process controls, acceptance criteria and traceability for flight hardware

Related standards

- ECSS-Q-ST-70 series (space product assurance - materials, processes)

- EN 16602-70-09 / ECSS-Q-ST-70-09 (measurement of thermo‑optical properties)

- ECSS-S-ST-00-01 (ECSS system glossary and tailoring guidance)

Keywords: EN 16602-70-03, black-anodizing, space product assurance, inorganic dyes, anodized coating, solar absorbance, emittance, spacecraft surface treatments, ECSS.

Frequently Asked Questions

SIST EN 16602-70-03:2015 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Space product assurance - Black-anodizing of metals with inorganic dyes". This standard covers: This Standard defines requirements for measurements and verifications to guarantee that an anodized coating is adequate for the intended application. The requirements set by this Standard ensure high reliability of surface treatments intended to withstand normal terrestrial conditions and environment loads imposed on spacecraft and associated equipment where surfaces require high solar absorptance, high emittance, high optical blackness, or a combination of these properties. This standard may be tailored for the specific characteristics and constraints of a space project, in conformance with ECSS-S-ST-00.

This Standard defines requirements for measurements and verifications to guarantee that an anodized coating is adequate for the intended application. The requirements set by this Standard ensure high reliability of surface treatments intended to withstand normal terrestrial conditions and environment loads imposed on spacecraft and associated equipment where surfaces require high solar absorptance, high emittance, high optical blackness, or a combination of these properties. This standard may be tailored for the specific characteristics and constraints of a space project, in conformance with ECSS-S-ST-00.

SIST EN 16602-70-03:2015 is classified under the following ICS (International Classification for Standards) categories: 49.140 - Space systems and operations; 87.040 - Paints and varnishes. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 16602-70-03:2015 is associated with the following European legislation: Standardization Mandates: M/496. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 16602-70-03:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Raumfahrtproduktsicherung - Schwarzes anodisieren von Metallen mit anorganischen FarbenAssurance produit des projets spatiaux - Anodisation noire des métaux

avec colorants non organiquesSpace product assurance - Black-anodizing of metals with inorganic dyes87.040Barve in lakiPaints and varnishes49.140Vesoljski sistemi in operacijeSpace systems and operationsICS:Ta slovenski standard je istoveten z:EN 16602-70-03:2014SIST EN 16602-70-03:2015en,fr,de01-januar-2015SIST EN 16602-70-03:2015SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16602-70-03

October 2014 ICS 49.140

English version

Space product assurance - Black-anodizing of metals with inorganic dyes

Assurance produit des projets spatiaux - Anodisation noire des métaux

avec colorants non organiques

Raumfahrtproduktsicherung - Schwarzes anodisieren von Metallen mit anorganischen Farben This European Standard was approved by CEN on 20 March 2014.

CEN and CENELEC members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN and CENELEC member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN and CENELEC member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN and CENELEC members are the national standards bodies and national electrotechnical committees of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels © 2014 CEN/CENELEC All rights of exploitation in any form and by any means reserved worldwide for CEN national Members and for CENELEC Members. Ref. No. EN 16602-70-03:2014 E SIST EN 16602-70-03:2015

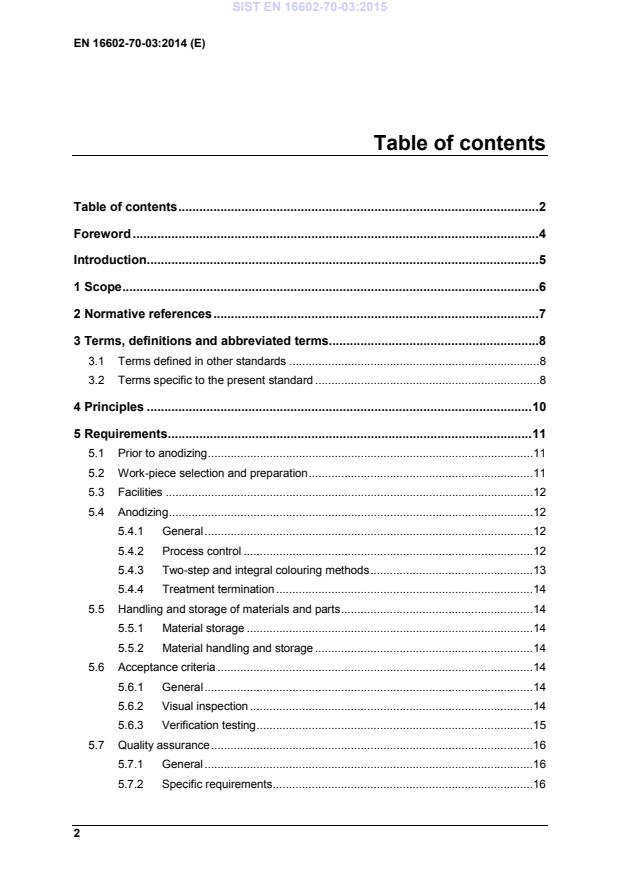

Tables Table A-1 : Chemical species and associated hazard . 19 Table A-2 : Anodizing electrolyte composition limits. . 21 Table A-3 : Summary of pre-treatment (see A.4) . 23 Table A-4 : Summary of anodizing (see A.5) . 23 Table A-5 : Dyeing with cobalt sulphide (see A.6.2) . 24 Table A-6 : Dyeing with nickel sulphide (see A.6.3) . 24

For dated references, subsequent amendments to, or revision of any of these publications do not apply, However, parties to agreements based on this ECSS Standard are encouraged to investigate the possibility of applying the more recent editions of the normative documents indicated below. For undated references, the latest edition of the publication referred to applies.

EN reference Reference in text Title EN 16601-00-01 ECSS-S-ST-00-01 ECSS system – Glossary of terms EN 16602-20 ECSS-Q-ST-20

Space product assurance – Quality assurance EN 16602-70 ECSS-Q-ST-70 Space product assurance – Materials, mechanical parts and processes EN 16602-70-04 ECSS-Q-ST-70-04 Space product assurance – Thermal testing for the evaluation of space materials, processes, mechanical parts and assemblies EN 16602-70-09 ECSS-Q-ST-70-09 Space product assurance – Measurement of thermo-optical properties of thermal control materials EN 16602-70-13 ECSS-Q-ST-70-13 Space product assurance – Measurements of the peel and pull-off strength of coatings and finishes using pressure-sensitive tapes SIST EN 16602-70-03:2015

Differentiation is made between: • Hemispherical emittance (εh) - conditions for incidence or viewing of flux over a hemispherical region. • Normal emittance (εn) - conditions for incidence or viewing through a solid angle normal to the specimen. Ratio refers to the emissivity normal to the surface of the emitting body. 3.2.4 solar absorbance (αs) ratio of the solar radiant flux absorbed by a material (or body) to that incident upon it NOTE

Measurement methods are: • Spectroscopic method using a photo-spectrometer covering the range from 0,25 µm SIST EN 16602-70-03:2015

NOTE

A test piece can be destructively tested. 3.2.6 workpiece

piece that is intended to be used as space-hardware and for which the adequacy of the treatment is assessed by tests performed on work pieces treated in as similar as possible conditions than the workpiece SIST EN 16602-70-03:2015

Wrought alloys are generally easier to treat than cast alloys. The manufacturing process of the part to be coated can have an impact on its response to the black- anodizing process. Also the geometry of the hardware can limit the possibility to coat the part. The surface quality of the parts to be coated has an influence of the coating results, since the anodization layer mimics the surface characteristics of the underlying substrate. Several requirements are therefore identified in order to select and prepare suitable work-pieces. Annex A describes for information a coating process for aluminium alloy. SIST EN 16602-70-03:2015

a. The supplier shall ensure that no damages or degradations occurred during handling and transportation of the parts to be black anodized. NOTE

The coating mimics all imperfections of the surface. b. In case of scratching, shock or any other event disturbing the surface aspect, the customer shall be informed and a nonconformance report issued.

c. The growth mechanisms of the layer and its impact on final hardware dimensions, including the potential grinding off of a porous part, shall be communicated to the customer. NOTE

The layer formed during anodizing consumes the bulk metal to grow both within and outside the initial dimensions of the bulk. d. The customer shall provide a written agreement on geometry impact prior to starting the black-anodizing process. 5.2 Work-piece selection and preparation a. The parts to be treated shall be made of the same alloy and shall be from the same batch. b. The parts shall only be made of the metal to be black-anodized, and any insertion of another metal shall be avoided. c. The parts shall be designed in such a way that the chemical products used in the process can be thoroughly rinsed.

NOTE

The presence of drain holes is a possible means to avoid the retention of chemical within the hardware. d. The parts shall contain no screws, no rivets nor other fastener elements. e. If a part contains welded elements, a verification programme shall be set up to qualify the black anodizing on the specific weld which includes a verification of the cleaning method used to rinse off the chemicals used for anodizing. SIST EN 16602-70-03:2015

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...