SIST EN 15714-6:2022

(Main)Industrial valves - Actuators - Part 6: Hydraulic linear actuators for industrial valves - Basic requirements

Industrial valves - Actuators - Part 6: Hydraulic linear actuators for industrial valves - Basic requirements

This document specifies basic requirements for piston type hydraulic linear actuators for industrial valve, both double acting and single acting, used for on-off and modulating control duties. It includes criteria, method and guidelines for design, qualification, corrosion protection, control and testing.

It does not apply to hydraulic actuators which are integral parts of control valves. Other requirements, or conditions of use, different from those indicated in this document, are expected to be subject to negotiations, between the purchaser and the manufacturer/supplier, prior to order.

Industriearmaturen - Stellantriebe - Teil 6: Hydraulische Linearantriebe - Grundlegende Anforderungen

Dieses Dokument legt Grundanforderungen an hydraulische, von Kolben angetriebene Linearantriebe für Industriearmaturen, die sowohl einfach als auch in beide Richtungen wirken und für Auf-Zu-Einschaltdauer und modulierende Steuerungsfunktionen verwendet werden, fest. Es enthält Kriterien, Verfahren und Leitlinien für Konstruktion, Qualifizierung, Korrosionsschutz, Kontrolle und Prüfung.

Es gilt nicht für hydraulische Stellantriebe, die feste Bestandteile von Regelventilen sind. Andere Anforderungen oder Anwendungsbedingungen als die, die in diesem Dokument angegeben sind, werden erwartungsgemäß vor Auftragserteilung zwischen dem Käufer und dem Hersteller/Lieferanten verhandelt.

Robinetterie industrielle - Actionneurs - Partie 6 : Actionneurs linéaires hydrauliques - Prescriptions de base

Le présent document spécifie les prescriptions de base pour les actionneurs linéaires hydrauliques à piston d’appareils de robinetterie, à double et à simple effet, utilisés pour des fonctions tout ou rien et des fonctions de régulation. Il comprend des critères, une méthode et des lignes directrices pour la conception, la qualification, la protection contre la corrosion, le contrôle et les essais.

Il ne s’applique pas aux actionneurs hydrauliques qui font partie intégrante des robinets de régulation. Des prescriptions ou conditions relatives à l’utilisation, autres que celles mentionnées dans le présent document, sont prévues pour être négociées entre l’acheteur et le fabricant/fournisseur, avant la commande.

Industrijski ventili - Pogoni - 6. del: Hidravlični linearni pogoni za industrijske ventile - Osnovne zahteve

General Information

- Status

- Published

- Public Enquiry End Date

- 30-Nov-2021

- Publication Date

- 14-Nov-2022

- Technical Committee

- TLP - Pressure vessels

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 26-Oct-2022

- Due Date

- 31-Dec-2022

- Completion Date

- 15-Nov-2022

Overview

EN 15714-6:2022 - Industrial valves - Actuators - Part 6 specifies the basic requirements for piston-type hydraulic linear actuators used with industrial valves. The standard covers both double acting (DA) and single acting (SA) actuators for on‑off and modulating control duties. It sets out criteria, methods and guidelines for design, qualification, corrosion protection, control and testing. Note: it excludes hydraulic actuators that are integral parts of control valves; any deviations from this standard are to be agreed between purchaser and manufacturer.

Key topics and technical requirements

This standard addresses key technical areas relevant to hydraulic linear actuators:

- Classification / designation - duty classification (on‑off, modulating) and action type (double acting, single acting).

- Motive energy - requirements for operating medium, quality and pressure definitions (MAP, design, working, structural test, minimum moving pressure).

- Basic performances - displacement volume, operating time, thrust definitions and guaranteed output thrust characteristics.

- Design requirements - safety, actuator attachment interfaces, nominal stroke, size of attachments, leakage limits, endurance and structural safety factors.

- Environmental & corrosion protection - ambient temperature ranges, enclosure protection (IP), and corrosion protection guidelines.

- Pressure connections & pilot valves - rules for remote and direct-mounted pilot valve arrangements.

- Optional equipment - position indicators, manual operation devices, anti-rotation devices, mechanical end stops, brackets and ancillaries.

- Conformity assessment & testing - type tests, control of production process, endurance test procedure (Annex A normative), and acceptance criteria.

- Marking & documentation - mandatory and optional marking information and documentation requirements.

- Selection guidance - informative annexes with actuator selection parameters and performance criteria for SA versions.

Practical applications and users

EN 15714-6:2022 is intended for professionals involved in the specification, design, selection, manufacture, testing and procurement of hydraulic actuators for industrial valves:

- Valve and actuator manufacturers - to ensure products meet harmonized basic requirements.

- Plant engineers and integrators - for selecting actuators for on‑off and modulating valves in oil & gas, water, power and process industries.

- Procurement and QA teams - to define technical orders and acceptance criteria.

- Test laboratories and certification bodies - for type testing and conformity assessment.

- Maintenance and reliability engineers - to understand endurance, leakage and corrosion protection expectations.

Related standards

Relevant referenced documents include:

- EN 15714-1 (Terminology & definitions)

- EN ISO 5210:2017 (Actuator attachments)

- EN 12570 (Sizing the operating element)

- EN 60529 (IP Code)

- ISO 4401 (Hydraulic mountings)

- ISO 286‑1 (Tolerances)

Keywords: EN 15714-6:2022, hydraulic linear actuators, industrial valves, piston type actuators, double acting, single acting, on‑off, modulating control, actuator selection, endurance test, corrosion protection.

Frequently Asked Questions

SIST EN 15714-6:2022 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Industrial valves - Actuators - Part 6: Hydraulic linear actuators for industrial valves - Basic requirements". This standard covers: This document specifies basic requirements for piston type hydraulic linear actuators for industrial valve, both double acting and single acting, used for on-off and modulating control duties. It includes criteria, method and guidelines for design, qualification, corrosion protection, control and testing. It does not apply to hydraulic actuators which are integral parts of control valves. Other requirements, or conditions of use, different from those indicated in this document, are expected to be subject to negotiations, between the purchaser and the manufacturer/supplier, prior to order.

This document specifies basic requirements for piston type hydraulic linear actuators for industrial valve, both double acting and single acting, used for on-off and modulating control duties. It includes criteria, method and guidelines for design, qualification, corrosion protection, control and testing. It does not apply to hydraulic actuators which are integral parts of control valves. Other requirements, or conditions of use, different from those indicated in this document, are expected to be subject to negotiations, between the purchaser and the manufacturer/supplier, prior to order.

SIST EN 15714-6:2022 is classified under the following ICS (International Classification for Standards) categories: 23.060.20 - Ball and plug valves. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 15714-6:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2022

Industrijski ventili - Pogoni - 6. del: Hidravlični linearni pogoni za industrijske

ventile - Osnovne zahteve

Industrial valves - Actuators - Part 6: Hydraulic linear actuators for industrial valves -

Basic requirements

Industriearmaturen - Stellantriebe - Teil 6: Hydraulische Linearantriebe - Grundlegende

Anforderungen

Robinetterie industrielle - Actionneurs - Partie 6 : Actionneurs linéaires hydrauliques -

Prescriptions de base

Ta slovenski standard je istoveten z: EN 15714-6:2022

ICS:

23.060.20 Zapirni ventili (kroglasti in Ball and plug valves

pipe)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 15714-6

EUROPEAN STANDARD

NORME EUROPÉENNE

October 2022

EUROPÄISCHE NORM

ICS 23.060.20

English Version

Industrial valves - Actuators - Part 6: Hydraulic linear

actuators for industrial valves - Basic requirements

Robinetterie industrielle - Actionneurs - Partie 6 : Industriearmaturen - Stellantriebe - Teil 6:

Actionneurs linéaires hydrauliques - Prescriptions de Hydraulische Linearantriebe - Grundlegende

base Anforderungen

This European Standard was approved by CEN on 19 September 2022.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 15714-6:2022 E

worldwide for CEN national Members.

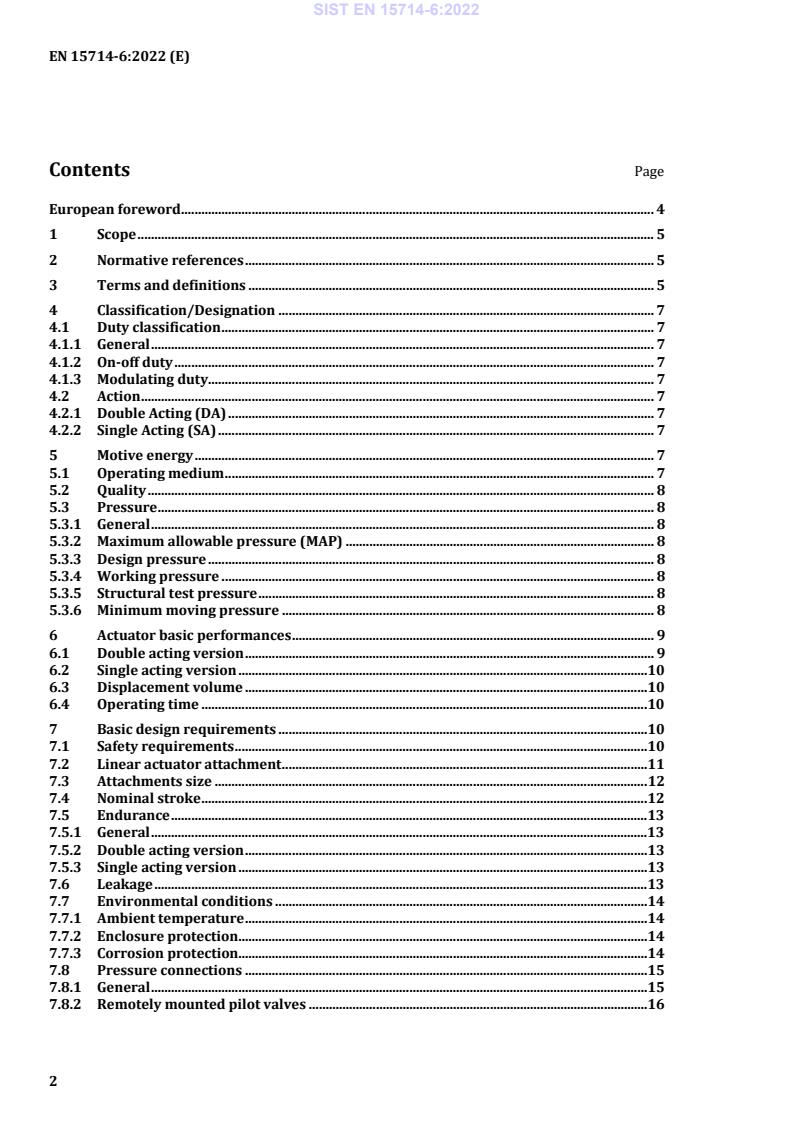

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Classification/Designation . 7

4.1 Duty classification . 7

4.1.1 General . 7

4.1.2 On-off duty . 7

4.1.3 Modulating duty . 7

4.2 Action . 7

4.2.1 Double Acting (DA) . 7

4.2.2 Single Acting (SA) . 7

5 Motive energy . 7

5.1 Operating medium . 7

5.2 Quality . 8

5.3 Pressure . 8

5.3.1 General . 8

5.3.2 Maximum allowable pressure (MAP) . 8

5.3.3 Design pressure . 8

5.3.4 Working pressure . 8

5.3.5 Structural test pressure . 8

5.3.6 Minimum moving pressure . 8

6 Actuator basic performances . 9

6.1 Double acting version . 9

6.2 Single acting version .10

6.3 Displacement volume .10

6.4 Operating time .10

7 Basic design requirements .10

7.1 Safety requirements .10

7.2 Linear actuator attachment .11

7.3 Attachments size .12

7.4 Nominal stroke .12

7.5 Endurance .13

7.5.1 General .13

7.5.2 Double acting version .13

7.5.3 Single acting version .13

7.6 Leakage .13

7.7 Environmental conditions .14

7.7.1 Ambient temperature .14

7.7.2 Enclosure protection.14

7.7.3 Corrosion protection.14

7.8 Pressure connections .15

7.8.1 General .15

7.8.2 Remotely mounted pilot valves .16

7.8.3 Direct mounted pilot valves . 17

7.9 Structural safety factors . 18

8 Optional equipment . 18

8.1 General . 18

8.2 Ancillaries . 18

8.3 Manual operation device . 19

8.4 Mechanical end stop . 19

8.5 Position indicator . 19

8.6 Bracket . 19

8.7 Anti-rotation device . 19

9 Conformity assessment . 19

9.1 General . 19

9.2 Type tests . 19

9.3 Control of production process . 20

10 Marking . 22

10.1 Mandatory requirements . 22

10.2 Optional requirements . 22

11 Documentation . 23

12 Linear actuator selection guidelines . 23

Annex A (normative) Endurance test procedure . 24

A.1 General . 24

A.2 Test equipment. 24

A.3 Test conditions . 24

A.4 Test procedure . 24

A.5 Acceptance criteria . 25

Annex B (informative) Actuator selection guidelines . 26

B.1 General . 26

B.2 Selection parameters . 26

B.2.1 General . 26

B.2.2 Valve questions . 26

B.2.3 Actuator questions . 27

B.2.4 Ancillary questions . 27

B.2.5 Environmental conditions . 27

B.3 Actuator selection . 27

Annex C (informative) Guideline to establish the basic performances for single acting

version . 28

C.1 General . 28

C.2 Specific thrusts definitions relevant to the single acting version . 28

C.3 Criteria for performances selection . 28

Bibliography . 30

European foreword

This document (EN 15714-6:2022) has been prepared by Technical Committee CEN/TC 69 “Industrial

valves”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by April 2023, and conflicting national standards shall be

withdrawn at the latest by April 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

1 Scope

This document specifies basic requirements for piston type hydraulic linear actuators for industrial valve,

both double acting and single acting, used for on-off and modulating control duties. It includes criteria,

method and guidelines for design, qualification, corrosion protection, control and testing.

It does not apply to hydraulic actuators which are integral parts of control valves. Other requirements, or

conditions of use, different from those indicated in this document, are expected to be subject to

negotiations, between the purchaser and the manufacturer/supplier, prior to order.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN ISO 5210:2017, Industrial valves - Multi-turn valve actuator attachments (ISO 5210:2017)

EN 12570, Industrial valves - Method for sizing the operating element

EN 15714-1, Industrial valves - Actuators - Part 1: Terminology and definitions

EN 60529, Degrees of protection provided by enclosures (IP Code)

ISO 286-1, Geometrical product specifications (GPS) — ISO code system for tolerances on linear sizes — Part

1: Basis of tolerances, deviations and fits

ISO 4401, Hydraulic fluid power — Four-port directional control valves — Mounting surfaces

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 15714-1 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

stroke

single and complete movement from one end of travel to the other

3.2

end stop

mechanical part designed to stop the actuator drive train at an end position

Note 1 to entry: End stop can be fixed or adjustable.

3.3

thrust

3.3.1

output thrust

minimum guaranteed output thrust capability of the actuator, in both directions, at specified supply

pressures conditions as provided by the manufacturer/supplier

Note 1 to entry: Where the output thrust varies with the stroke, in a linear or nonlinear relationship with pressure,

tabulated data and/or thrust versus stroke diagram shall be provided at significant pressure values for each

direction of movement.

3.3.2

nominal thrust

3.3.2.1

double acting version

minimum guaranteed output thrust of the actuator, at any point of the stroke, with nominal supply

pressure

Note 1 to entry: See 4.2.1.

3.3.2.2

single acting version

guaranteed output thrust of the actuator with hydraulic nominal supply at the beginning of the stroke in

the direction to compress the spring

Note 1 to entry: See 4.2.2.

3.3.3

start thrust

actuator output thrust at the beginning of the stroke in the direction of movement

3.4

single acting version

3.4.1

Fluid Starting Thrust

OST

output thrust, at specified pressure value, at the beginning of the stroke in opposition to the spring

3.4.2

Fluid Ending Thrust

OET

output thrust, at specified pressure value, at the end of the stroke when spring is at its maximum

compression

3.4.3

Spring Ending Thrust

SET

output thrust generated by the spring at the end of its stroke with no fluid in the cylinder

3.4.4

Spring Starting Thrust

SST

output thrust generated by the spring at its maximum compression with no fluid in the cylinder

3.4.5

Spring Running Thrust

SRT

any output thrust value between SST and SET

4 Classification/Designation

4.1 Duty classification

4.1.1 General

According to their intended function, two versions of linear valve actuators are specified by this

document: on-off duty and modulating duty.

4.1.2 On-off duty

The actuator is required to drive the valve through its entire travel from the fully open position to the

fully closed position or vice-versa.

4.1.3 Modulating duty

The actuator is required to continuously drive the valve to any position between fully open and fully

closed or vice-versa.

4.2 Action

4.2.1 Double Acting (DA)

Double acting defines the type of actuator which requires the supply of motive energy to operate in both

travel directions.

4.2.2 Single Acting (SA)

Single acting defines the type of actuator which requires external power to operate the valve in one

direction only, the return stroke being powered by an alternative form of stored energy (Fail-Safe

actuators).

For the purpose of this document, the stored energy shall be supplied by a mechanical spring.

5 Motive energy

5.1 Operating medium

The operating medium shall be hydraulic fluid.

The fluid used, on agreement between the manufacturer/supplier and purchaser, shall be selected for

pressure, compatible with internal actuator parts and shall have lubricant properties.

The flashpoint shall be of not less than 93 °C for pressures below 10 bar and 157 °C for pressures above

10 bar. The chemical and physical properties of the hydraulic fluid shall be suitable for use with the

materials used in the design of the actuator and its accessories. The hydraulic fluid shall be suitable for

operation of the hydraulic system through the entire temperature range to which it may be subjected in

service.

5.2 Quality

The operating medium shall have a contamination level specified to ISO 4406 class 18/16/13 as a

maximum.

When necessary the actuator shall be properly flushed to guarantee an internal cleanliness consistent

with the above specified contamination level.

5.3 Pressure

5.3.1 General

As a general information the manufacturer/supplier shall indicate, for each actuator model, the pressure

limits including at least the maximum allowable pressure and working pressure range for a specific

application. Other pressure values shall be available on demand.

5.3.2 Maximum allowable pressure (MAP)

The pressure not to be exceeded for the supply to the hydraulic actuator. Recommended values for

maximum allowable pressure are in Table 1.

Table 1 — Pressure level

MPa bar psi

PN 50 5,5 55 800

PN 100 10,3 103 1 500

PN 200 20,7 207 3 000

PN 350 34,5 345 5 000

5.3.3 Design pressure

The design pressure shall be at least 1,1 times the maximum allowable pressure.

5.3.4 Working pressure

The pressure applied to the actuator to guarantee the performances on a specific application.

5.3.5 Structural test pressure

For structural test under pressure, consider a minimum value 1,5 times the design pressure for a

minimum holding period 5 min after pressure stabilization.

Structural test under pressure is carried out to validate the capability of the pressure retaining parts of

the actuator to withstand the pressure without permanent deformations.

5.3.6 Minimum moving pressure

The minimum moving pressure required, at ambient temperature, to complete the specified stroke

without external load, starting from not pressurized conditions shall be made available by the

manufacturer/supplier upon request.

6 Actuator basic performances

6.1 Double acting version

Table 2 — Double acting selection chart

a

Actuator Inner cylinder

Maximum thrust

b

diameter

designation

kN

mm

for specified maximum allowable pressure

bar

55 103 207 345

L25D 25 2,6 4,9 9,8 16,3

L30D 30 3,7 7,0 14,0 23,4

L40D 40 6,6 12,4 25,0 41,6

L50D 50 10,4 19,4 39,0 65,0

L60D 60 14,9 28,0 56,2 93,6

L70D 70 20,3 38,1 76,5 127,5

L80D 80 26,5 49,7 99,9 166,5

L90D 90 33,6 62,9 126,4 210,7

L100D 100 41,5 77,7 156,1 260,1

L125D 125 64,8 121,3 243,9 406,4

L150D 150 106,2 174,7 351,2 585,3

L200D 200 165,9 310,6 624,3 —

L250D 250 259,2 485,4 — —

L300D 300 373,2 698,9 — —

L350D 350 508,0 — — —

L400D 400 663,5 — — —

a

Maximum thrust is referred to the net piston size without the effect of stem reduction.

b

Preferred size of designation (e.g. L25 D stands for the L = linear, 25 = Inner cylinder diameter, D = double

acting).

NOTE For further sizing information please see Annex B.

6.2 Single acting version

Table 3 — Single acting selection chart

a

Actuator Inner cylinder diameter

Basic performances

b

designation

mm

L25S 25

L30S 30

L40S 40

L50S 50

L60S 60

L70S 70

L80S 80

L90S 90

—

L100S 100

L125S 125

L150S 150

L200S 200

L250S 250

L300S 300

L350S 350

L400S 400

a

For information regarding basic performances refer to Annex C.

b

Preferred size of designation (e.g. L25D stands for the L = linear, 25 = Inner

cylinder diameter, D = double acting).

6.3 Displacement volume

The manufacturer/supplier shall state the internal actuator displaced volumes for each direction,

including the dead volumes, for the maximum stroke without any external limitation.

Displacement volume should be expressed in litres.

6.4 Operating time

The actuator manufacturer/supplier shall state the minimum operating time in both directions, without

external load, at nominal pressure and without any significant external restriction on supply flow rate

and exhaust.

7 Basic design requirements

7.1 Safety requirements

Actuators shall be designed taking into account the technical principles and specifications for safety. For

maintenance purposes the design of the single acting (SA) actuators shall permit the safe

disassembly/reassembly of the whole unit including the spring unit or spring cartridge complying with

the manufacturer/supplier’s instructions.

7.2 Linear actuator attachment

Dimensions of attachment flange shall be according to EN ISO 5210:2017, Clause 5, Figure 2 and Table 2,

7.6 and Table 7.

Dimensions of output shaft shall be based on EN ISO 5210:2017, 7.6 with specific additional dimensions

according to Figure 1 and Table 4. A flat attach for fork wrench SW shall be provided as optional.

Figure 1 — Dimensions of output drive

Table 4 — Data and dimensions of output drive

Flange type

SW

EN ISO 5210 thrust rating

a

kN

EN ISO 5210 mm

F05 10 13

F07 20 17

F10 40 21

F12 70 27

F14 100 36

F16 150 46

F25 200 50

F30 325 55

F35 700 80

a

Different flange and/or coupling type may be used upon agreement between purchaser and

manufacturer/supplier.

The material of the output drive component (Table 4) shall be clearly indicated in the

manufacturer’s/supplier’s documentation.

7.3 Attachments size

Table 5 — Attachment sizes

Actuator Inner EN ISO 5210 flange based on thrust at Minimum stroke

d a, b c

cylinder

designation maximum allowable pressure H

diameter

(double/single bar

acting version)

mm

55 103 207 345

mm

L25D/L25S 25 F05 F05 F05 F07

L30D/L30S 30 F05 F05 F07 F10

L40D/L40S 40 F05 F07 F10 F12

L50D/L50S 50 F07 F07 F10 F12

L60D/L60S 60 F10 F10 F12 F14

L70D/L70S 70 F10 F10 F14 F16

Minimum stroke

L80D/L80S 80 F10 F10 F14 F25

according to

L90D/L90S 90 F10 F12 F16 F30

EN ISO 5210:2017,

L100D/L100S 100 F12 F14 F25 F30

7.6, Table 7 for

L125D/L125S 125 F12 F16 F30 F35

each flange type

L150D/L150S 150 F14 F25 F35 F35

L200D/L200S 200 F25 F30 F35 —

L250D/L250S 250 F30 F35 — —

L300D/L300S 300 F30 F35 — —

L350D/L350S 350 F35 — — —

L400D/L400S 400 F35 — — —

a

Actuator attachment dimensions according to 7.1.

b

Different flange type may be used upon agreement between purchaser and manufacturer/supplier.

c

Maximum stroke is provided by the manufacturer/supplier.

d

Preferred size of designation (e.g. L25D stands for the L = linear, 25 = Inner cylinder diameter,

D = double acting).

7.4 Nominal stroke

With respect to the basic performances stated in Clause 6 for each size of cylinder, linear actuator shall

provide an output stem movement, according to 3.1, specified by the manufacturer/supplier in a

tabulated form or based on agreement between the manufacturer/supplier and purchaser or valve

manufacturer. The stroke can be limited, around the spec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...