SIST EN 13547:2014

(Main)Industrial valves - Copper alloy ball valves

Industrial valves - Copper alloy ball valves

This European Standard applies to copper alloy ball valves for general use having, flanged, threaded, capillary or compression or loose nut/union body ends.

This European Standard does not apply to copper alloy ball valves for drinking water applications.

This European Standard specifies the design and performance requirements including materials, pressure/temperature ratings for the shell and body seats, dimensions, test procedures and marking.

For some specific fields of application, for example gas, valves to this European Standard can be used provided the requirements of the relevant performance standards are met. Approval by the relevant regulatory body may be required.

The range of nominal sizes is DN 6 to DN 300 and of nominal diameters 6 mm to 110 mm.

The range of pressure designations covered is PN 6 ; PN 10 ; PN 16 ; PN 20 ; PN 25 ; PN 32 ; PN 40 ; PN 63 ; Class 150 and Class 300.

For the applicability of each nominal size/diameter and each pressure designation to the different types of valve end, see 4.1.

Industriearmaturen - Kugelhähne aus Kupferlegierungen

Diese Europäische Norm gilt für Kugelhähne aus Kupferlegierungen für allgemeine Anwendungsfälle mit Flansch-, Gewinde-, Kapillarlöt- oder Klemmanschluss oder Gehäusen mit losen Einschraubenden/Verschraubungen.

Diese Europäische Norm gilt nicht für Kugelhähne aus Kupferlegierungen für Trinkwasseranwendungen.

Diese Europäische Norm legt die Anforderungen an die Konstruktion und Funktion fest, einschließlich Werkstoffen, Druck/Temperatur-Zuordnungen für das drucktragende Gehäuse und Gehäusesitze, Maßen, Prüfverfahren und Kennzeichnung.

Für einige bestimmte Anwendungsfälle, z. B. Gas, können Armaturen nach diesem Dokument angewendet werden, wenn die Anforderungen der entsprechenden Gebrauchtauglichkeitsnormen erfüllt sind. Eine Genehmigung der zuständigen Behörde kann erforderlich sein.

Der Nennweitenbereich umfasst DN 6 bis DN 300 und der Nenndurchmesserbereich 6 mm bis 110 mm.

Der Druckbereich umfasst PN 6; PN 10; PN 16; PN 20; PN 25; PN 32; PN 40; PN 63; Class 150 und Class 300.

Die für die verschiedenen Anschlussarten geltenden Nennweiten, Nenndurchmesser und Druckbezeich-nungen sind in 4.1 angegeben.

Robinetterie industrielle - Robinets à tournant sphérique en alliage de cuivre

La présente norme Européenne s’applique aux robinets à tournant sphérique en alliage de cuivre à usage général, dont les extrémités peuvent être à brides, filetées, à braser par capillarité ou à compression, ou être des extrémités à écrous prisonniers/extrémités de corps union.

La présente norme Européenne ne s’applique pas aux robinets à tournant sphérique en alliage de cuivre pour des applications à l’eau potable.

La présente norme Européenne spécifie les exigences de conception et de performance s’appliquant notamment aux matériaux, aux relations pression/température pour les sièges de l’enveloppe et du corps, aux dimensions, aux modes opératoires d’essai et au marquage.

Les appareils de robinetterie conformes à la présente norme Européenne peuvent être utilisés pour certains domaines d’application spécifiques, comme par exemple le gaz, sous réserve du respect des exigences des normes de performance correspondantes. L’agrément de l’instance réglementaire correspondante peut être exigé.

La gamme des dimensions nominales est comprise entre DN 6 et DN 300, et celle des diamètres nominaux entre 6 mm et 110 mm.

La gamme de désignations de pression comprend les PN 6, PN 10, PN 16, PN 20, PN 25, PN 32, PN 40, PN 63, Class 150 et Class 300.

Pour l’applicabilité de chaque dimension/diamètre nominal(e) et de chaque désignation de pression aux différents types d’extrémités d’appareils de robinetterie, voir 4.1.

Industrijski ventili - Krogelni ventili iz bakrovih zlitin

Ta evropski standard se uporablja za krogelne ventile iz bakrovih zlitin za splošno uporabo, ki imajo prirobne, navojne, kapilarne, kompresijske ali proste zaključke telesa matice/cevne spojke. Ta evropski standard se ne uporablja za krogelne ventile iz bakrovih zlitin za uporabo s pitno vodo. Ta evropski standard določa zahteve za zasnovo in delovanje, vključno z materiali, vrednostmi tlaka/temperature za sedeže lupine in telesa, dimenzije, preskusne postopke in oznake. Za nekatera posebna področja uporabe, na primer za plin, se lahko uporabljajo ventili iz tega evropskega standarda, če so izpolnjene zahteve iz ustreznih standardov za lastnosti. Zahteva se lahko dovoljenje ustreznega regulatornega organa. Razpon nazivnih velikosti je od DN 6 do DN 300, razpon nazivnih premerov pa od 6 mm do 110 mm. Razpon zajetih oznak tlaka je PN 6; PN 10; PN 16; PN 20; PN 25; PN 32; PN 40; PN 63; razred 150 in razred 300. Za uporabnost vsake nazivne velikosti/premera in vsake oznake tlaka za različne vrste zaključkov ventilov.

General Information

- Status

- Published

- Publication Date

- 01-Dec-2013

- Technical Committee

- TLP - Pressure vessels

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 25-Nov-2013

- Due Date

- 30-Jan-2014

- Completion Date

- 02-Dec-2013

Relations

- Effective Date

- 01-Jan-2014

Overview

EN 13547:2013 - Industrial valves - Copper alloy ball valves is a CEN European Standard that defines design, materials, performance and testing requirements for copper-alloy ball valves used in general industrial applications. It covers valves with flanged, threaded, capillary, compression, loose nut or union body ends, in sizes from DN 6 to DN 300 (nominal diameters 6 mm to 110 mm) and pressure designations PN 6, 10, 16, 20, 25, 32, 40, 63 and Class 150 / Class 300. The standard explicitly excludes copper-alloy ball valves intended for drinking water applications.

Key topics and technical requirements

- Scope & classification

- Applicable body ends, nominal sizes/diameters and PN/Class designations for each end type.

- Two valve series: Series A (shells in copper‑aluminium and copper‑tin alloys for higher pressure/temperature ratings) and Series B (shells in copper‑zinc‑lead or complex copper‑zinc alloys with lower allowable pressures at elevated temperatures).

- Materials

- Materials for shell, seats and other components are specified (see Annex A and normative references such as EN 1092‑3, EN 1982).

- Design requirements

- Full‑bore and reduced‑bore configurations allowed.

- Shaft design: anti‑blow‑out requirement; shaft end must clearly indicate ball-port position.

- Manufacturer responsibility for safe design and appropriate safety margins.

- Pressure/temperature ratings

- Ratings linked to material series and flange standards (see Annex B and referenced flange standards).

- Testing & inspection

- Mandatory production pressure testing, seat leakage rate tests and functional tests in line with EN 12266‑1.

- Angular movement test for operating element (type test in Annex C).

- Marking, documentation & storage

- Marking requirements, declaration of compliance and instructions for protection, transportation and storage are specified.

Practical applications and users

- Typical users:

- Valve manufacturers, design engineers, purchasing/specification teams, testing labs and compliance officers in industrial sectors.

- Typical applications:

- General industrial fluid systems (hydraulic, oil, some gas services where additional approval is obtained), HVAC, process plants and pipeline assemblies using copper‑alloy components.

- Important notes:

- Not for potable water supply installations.

- For gas or other regulated fields, additional performance standards and regulatory approvals may be required.

Related standards

- EN 12266‑1 (valve testing), EN 1092‑3 / EN 1759‑3 (copper alloy flanges), EN 1254 series (capillary/compression fittings), EN 19 (valve marking), EN ISO 5211 (actuator attachments) - all frequently referenced by EN 13547:2013.

Keywords: EN 13547:2013, copper alloy ball valves, industrial valves, pressure/temperature ratings, DN 6–DN 300, PN 6–PN 63, Class 150, valve testing, anti‑blow‑out shaft, valve materials.

Frequently Asked Questions

SIST EN 13547:2014 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Industrial valves - Copper alloy ball valves". This standard covers: This European Standard applies to copper alloy ball valves for general use having, flanged, threaded, capillary or compression or loose nut/union body ends. This European Standard does not apply to copper alloy ball valves for drinking water applications. This European Standard specifies the design and performance requirements including materials, pressure/temperature ratings for the shell and body seats, dimensions, test procedures and marking. For some specific fields of application, for example gas, valves to this European Standard can be used provided the requirements of the relevant performance standards are met. Approval by the relevant regulatory body may be required. The range of nominal sizes is DN 6 to DN 300 and of nominal diameters 6 mm to 110 mm. The range of pressure designations covered is PN 6 ; PN 10 ; PN 16 ; PN 20 ; PN 25 ; PN 32 ; PN 40 ; PN 63 ; Class 150 and Class 300. For the applicability of each nominal size/diameter and each pressure designation to the different types of valve end, see 4.1.

This European Standard applies to copper alloy ball valves for general use having, flanged, threaded, capillary or compression or loose nut/union body ends. This European Standard does not apply to copper alloy ball valves for drinking water applications. This European Standard specifies the design and performance requirements including materials, pressure/temperature ratings for the shell and body seats, dimensions, test procedures and marking. For some specific fields of application, for example gas, valves to this European Standard can be used provided the requirements of the relevant performance standards are met. Approval by the relevant regulatory body may be required. The range of nominal sizes is DN 6 to DN 300 and of nominal diameters 6 mm to 110 mm. The range of pressure designations covered is PN 6 ; PN 10 ; PN 16 ; PN 20 ; PN 25 ; PN 32 ; PN 40 ; PN 63 ; Class 150 and Class 300. For the applicability of each nominal size/diameter and each pressure designation to the different types of valve end, see 4.1.

SIST EN 13547:2014 is classified under the following ICS (International Classification for Standards) categories: 23.060.20 - Ball and plug valves. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13547:2014 has the following relationships with other standards: It is inter standard links to SIST-TS CEN/TS 13547:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13547:2014 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU, 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13547:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Industrijski ventili - Krogelni ventili iz bakrovih zlitinIndustriearmaturen - Kugelhähne aus KupferlegierungenRobinetterie industrielle - Robinets à tournant sphérique en alliage de cuivreIndustrial valves - Copper alloy ball valves23.060.20Zapirni ventili (kroglasti in pipe)Ball and plug valvesICS:Ta slovenski standard je istoveten z:EN 13547:2013SIST EN 13547:2014en,fr,de01-januar-2014SIST EN 13547:2014SLOVENSKI

STANDARDSIST-TS CEN/TS 13547:20071DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13547

October 2013 ICS 23.060.20 Supersedes CEN/TS 13547:2006English Version

Industrial valves - Copper alloy ball valves

Robinetterie industrielle - Robinets à tournant sphérique en alliage de cuivre

Industriearmaturen - Kugelhähne aus Kupferlegierungen This European Standard was approved by CEN on 29 August 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13547:2013: ESIST EN 13547:2014

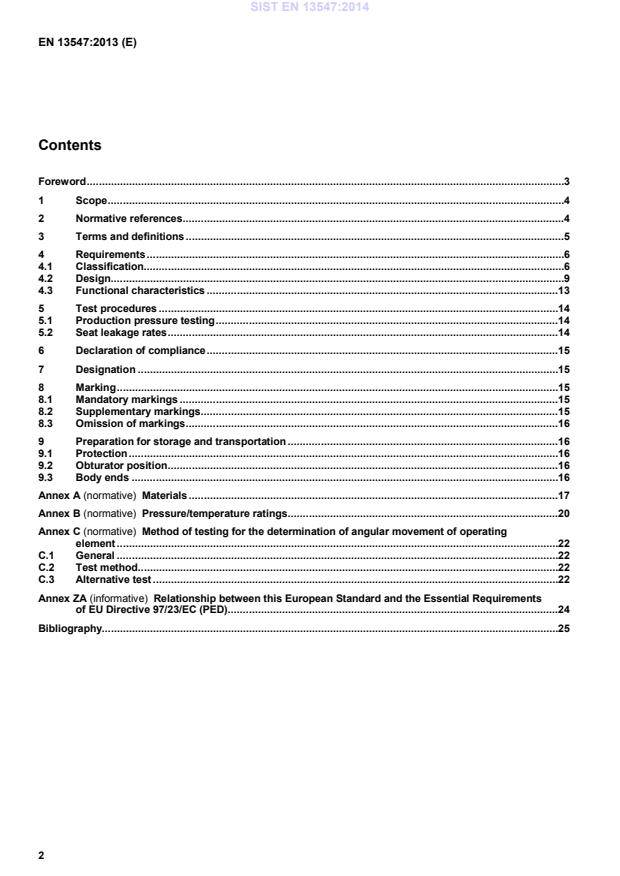

Materials . 17 Annex B (normative)

Pressure/temperature ratings . 20 Annex C (normative)

Method of testing for the determination of angular movement of operating element . 22 C.1 General . 22 C.2 Test method . 22 C.3 Alternative test . 22 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 97/23/EC (PED) . 24 Bibliography. 25

X = other European tube or pipe outside diameters.

4.1.2 Nominal size relationship The relationship between nominal size, DN and body end type shall be as given in Table 3. SIST EN 13547:2014

DN DN 6 6 - 1/8 - 6 8 DN 8 8 - ¼ - 8 ; 10 10 DN 10 10 - 3/8 10 12 ; 14 12 ; 14 DN 15 15 ½ ½ 15 14,7 ; 15 ; 16 ; 18 14,7 ; 15 ;16 ;18 DN 20 20 ¾ ¾ 20 21 ; 22 20 ; 21 ; 22 DN 25 25 1 1 25 25 ; 27,4 ; 28 25 ; 27,4 ; 28 DN 32 32 1¼ 1¼ 32 34 ; 35 32 ; 34 DN 40 40 1½ 1½ 40 40 ; 40,5 ; 42 40 ; 40,5 DN 50 50 2 2 50 53,6 ; 54 50 ; 53,6 DN 65 65 2½ 2½ - 64 ; 66,7 ; 70 ; 76,1 63 ; 75 DN 80 80 3 3 - 80 ; 88,9 90 DN 100 100 4 4 - 108 110 DN 125 125 5 - - - - DN 150 150 6 - - - - DN 200 200 8 - - - - DN 250 250 10 - - - - DN 300 300 12 - - - -

4.1.3 PN and Class designations The PN and Class designations applicable to valves having flanged or threaded body ends shall be as specified in Table 4. NOTE 1 PN 20 and PN 32 are established PN designations for threaded end copper alloy valves and are additional to the list of PN designations given in EN 1333. Valves with capillary or compression ends are not designated by PN or Class. NOTE 2 EN 1254-1, EN 1254-2, EN 1254-3 and EN 1254-5 which give details of the body ends for capillary and compression end valves in this document, do not use the PN designation system given in EN 1333. If PN designations are allocated to capillary or compression end valves, it is the responsibility of the manufacturer to provide information on any pressure and/or temperature limitations in service. SIST EN 13547:2014

4.1.4 Valve series Two series of valves are specified: series A for flanged and threaded end valves and series B for flanged, threaded, capillary, compression and loose nut/union end valves. Series A valves have the shell components constructed from the restricted range of copper-aluminium and copper-tin alloys (see Table A.1) specified in EN 1092-3 and EN 1759-3, and are suitable for the pressure/temperature ratings given in these two flange standards. Additional copper-aluminium and copper-tin alloys are specified in Table A.1 for series A valves and the pressure/temperature ratings for valves in these materials are the same as given in EN 1092-3 and EN 1759-3. Series B valves have the shell components constructed from copper-zinc-lead or complex copper-zinc alloys (see Table A.2) and have lower allowable pressures at elevated temperatures than series A valves. 4.2 Design 4.2.1 Construction 4.2.1.1 General Valves shall be properly designed incorporating appropriate safety margins and taking all relevant operating factors into account in order to ensure that they will be safe throughout their intended life. The construction details shall be the responsibility of the manufacturer. 4.2.1.2 Patterns Valves shall be full bore or reduced bore (see Figure 1). NOTE The construction details given in Figure 1 are examples; other designs are possible.

Figure 1a — Full bore Figure 1b — Reduced bore Key 1 nominal size Figure 1 — Valve bore configurations 4.2.1.3 Body The body may be of one-piece or multi-piece construction. SIST EN 13547:2014

EN 13547:20

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...