SIST EN 1265:2000+A1:2009

(Main)Safety of machinery - Noise test code for foundry machines and equipment

Safety of machinery - Noise test code for foundry machines and equipment

This noise test code specifies all the information necessary to carry out efficiently and under standardized conditions the determination, declaration and verification of the noise emission values of several groups of foundry machinery. It specifies noise measurement methods that are available and operating and mounting conditions that shall be used for the test.

Noise emission values include emission sound pressure levels at work stations and the sound power level. The determination of these quantities is necessary for:

- manufacturers to declare the noise emitted;

- comparing the noise emitted by machines in the group concerned;

- purposes of noise control at the source at the design stage.

The use of this standard ensures the reproducibility of the determination of the !noise emission values" within specified limits determined by the grade of accuracy of the basic noise measurement method used. Noise measurement methods allowed by this standard are engineering methods (grade 2) and survey methods (grade 3).

This standard has a main body giving general requirements common to the foundry machines family. Six normative Annexes give requirements specific to the groups of foundry machinery listed below:

- core making machines (EN 710);

- moulding machines (EN 710);

- knock-out grids and knock-out trays (EN 710);

- dry abrasive blasting equipment (not restricted to foundry application) (EN 1248);

- air blasting equipment (EN 1248);

- diecasting machines (EN 869);

and six informative Annexes giving guidance for the definition of specific operating conditions.

The main body of this standard also gives guidance for the measurement of the noise emission of foundry machines not dealt with in the Annexes.

This standard does not cover the computation of personnel daily noise exposure.

Sicherheit von Maschinen - Geräuschmessverfahren für Gießereimaschinen und -anlagen

Sécurité des machines - Code d'essai acoustique pour machines et équipements de fonderie

Le présent code d'essai spécifie toutes les informations qui sont nécessaires pour effectuer d'une manière efficace et dans des conditions normalisées la détermination, la déclaration et la vérification des valeurs d'émission sonore de plusieurs familles de machines de fonderie. Il spécifie les méthodes de mesurage qui sont disponibles ainsi que les conditions de fonctionnement et de montage qui doivent être utilisées pour l'essai."

Les grandeurs caractéristiques de l'émission sonore sont le niveau de pression acoustique d'émission à la position de l'opérateur ainsi que le niveau de puissance acoustique. La détermination de ces quantités est nécessaire pour :

les fabricants en vue de la déclaration des valeurs d'émission sonore ;

la comparaison des valeurs d'émission sonore de familles spécifiques de machines et d'équipements ;

la réduction du bruit à la source au stade de la conception.

L'emploi de ce code d'essai garantit la reproductibilité de la détermination des valeurs d’émission sonore dans les limites fixées par la classe de précision de la norme de base employée pour le mesurage. Ce code d'essai permet l’emploi de méthodes de classe 2 (expertise) et de classe 3 (contrôle).

La présente norme comprend une partie principale donnant des spécifications générales communes aux machines de fonderie et six annexes normatives spécifiques aux familles de machines de fonderie dont la liste suit :

machines pour noyautage (EN 710) ;

machines pour le moulage (EN 710) ;

grilles de décochage et tables de décochage (EN 710) ;

machines de grenaillage par turbine (sans restriction au domaine de la fonderie) (!EN 1248") ;

machines de grenaillage par air comprimé (!EN 1248") ;

machines à coulée sous pression (EN 869).

Six annexes informatives donnent des informations concernant la détermination des conditions de fonctionnement spécifiques.

Varnost strojev - Postopki za merjenje hrupa livarskih strojev in opreme

General Information

- Status

- Published

- Publication Date

- 20-Nov-2008

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 17-Nov-2008

- Due Date

- 22-Jan-2009

- Completion Date

- 21-Nov-2008

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 01-Jan-2009

Overview

EN 1265:1999+A1:2008 - Safety of machinery: Noise test code for foundry machines and equipment - is a CEN noise test code that specifies the information and standardized conditions required to determine, declare and verify the noise emission values of foundry machinery. It covers both emission sound pressure levels at work stations and sound power levels, and defines permitted measurement methods, operating and mounting conditions to ensure reproducible results across manufacturers and test laboratories.

Key topics and technical requirements

- Scope and purpose

- Enables manufacturers to declare noise emissions, compare machines within the same family, and support noise control at the design stage.

- Does not cover computation of personnel daily noise exposure.

- Permitted measurement methods

- Engineering methods (grade 2) and survey methods (grade 3) are allowed. Grade 2 is preferred where practicable.

- Sound power may be determined using EN ISO 3743-1, EN ISO 3744, EN ISO 3746, EN ISO 9614-1 and EN ISO 9614-2.

- Emission sound pressure at workstations follows EN ISO 11201, EN ISO 11202 or EN ISO 11204 as appropriate.

- Operating and mounting conditions

- The standard prescribes operating states and mounting/installation conditions to be recorded and used during tests so results are comparable and reproducible.

- When using enveloping surface methods, a rectangular parallelepiped surface is recommended and a 1 m measuring distance is preferred.

- Declaration and uncertainty

- Introduces the declared dual-number value (L + K): the measured A-weighted level (L) plus its uncertainty (K), rounded per the standard rules.

- Measurement uncertainty and reporting requirements are specified to allow verification and consistent declaration.

- Annex structure

- Main body gives general requirements; six normative Annexes specify test details for specific foundry groups:

- coremaking machines, moulding machines, knock-out grids/trays, dry abrasive blasting, air blasting, high-pressure diecasting

- Six informative Annexes provide guidance and data-sheet templates for operating conditions.

- Main body gives general requirements; six normative Annexes specify test details for specific foundry groups:

Applications and who uses it

- Manufacturers - declare noise emission values for product data sheets and design quieter equipment.

- Test laboratories and acoustical consultants - perform standardized noise measurements and verification testing.

- OEMs, purchasers and safety managers - compare machine noise performance across suppliers for procurement and workplace risk reduction.

- Design engineers - use test code results to guide noise-at-source control during product development.

Related standards

- EN 710, EN 1248, EN 869 (foundry machine family safety references)

- EN ISO 3743-1, EN ISO 3744, EN ISO 3746, EN ISO 9614-1/2 (sound power)

- EN ISO 11201, EN ISO 11202, EN ISO 11204 (emission sound pressure)

- EN ISO 12001, EN ISO 4871 (noise test code rules and declaration)

Keywords: EN 1265, noise test code, foundry machines, sound power level, emission sound pressure, noise measurement methods, CEN, noise declaration, measurement uncertainty.

Frequently Asked Questions

SIST EN 1265:2000+A1:2009 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Safety of machinery - Noise test code for foundry machines and equipment". This standard covers: This noise test code specifies all the information necessary to carry out efficiently and under standardized conditions the determination, declaration and verification of the noise emission values of several groups of foundry machinery. It specifies noise measurement methods that are available and operating and mounting conditions that shall be used for the test. Noise emission values include emission sound pressure levels at work stations and the sound power level. The determination of these quantities is necessary for: - manufacturers to declare the noise emitted; - comparing the noise emitted by machines in the group concerned; - purposes of noise control at the source at the design stage. The use of this standard ensures the reproducibility of the determination of the !noise emission values" within specified limits determined by the grade of accuracy of the basic noise measurement method used. Noise measurement methods allowed by this standard are engineering methods (grade 2) and survey methods (grade 3). This standard has a main body giving general requirements common to the foundry machines family. Six normative Annexes give requirements specific to the groups of foundry machinery listed below: - core making machines (EN 710); - moulding machines (EN 710); - knock-out grids and knock-out trays (EN 710); - dry abrasive blasting equipment (not restricted to foundry application) (EN 1248); - air blasting equipment (EN 1248); - diecasting machines (EN 869); and six informative Annexes giving guidance for the definition of specific operating conditions. The main body of this standard also gives guidance for the measurement of the noise emission of foundry machines not dealt with in the Annexes. This standard does not cover the computation of personnel daily noise exposure.

This noise test code specifies all the information necessary to carry out efficiently and under standardized conditions the determination, declaration and verification of the noise emission values of several groups of foundry machinery. It specifies noise measurement methods that are available and operating and mounting conditions that shall be used for the test. Noise emission values include emission sound pressure levels at work stations and the sound power level. The determination of these quantities is necessary for: - manufacturers to declare the noise emitted; - comparing the noise emitted by machines in the group concerned; - purposes of noise control at the source at the design stage. The use of this standard ensures the reproducibility of the determination of the !noise emission values" within specified limits determined by the grade of accuracy of the basic noise measurement method used. Noise measurement methods allowed by this standard are engineering methods (grade 2) and survey methods (grade 3). This standard has a main body giving general requirements common to the foundry machines family. Six normative Annexes give requirements specific to the groups of foundry machinery listed below: - core making machines (EN 710); - moulding machines (EN 710); - knock-out grids and knock-out trays (EN 710); - dry abrasive blasting equipment (not restricted to foundry application) (EN 1248); - air blasting equipment (EN 1248); - diecasting machines (EN 869); and six informative Annexes giving guidance for the definition of specific operating conditions. The main body of this standard also gives guidance for the measurement of the noise emission of foundry machines not dealt with in the Annexes. This standard does not cover the computation of personnel daily noise exposure.

SIST EN 1265:2000+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 17.140.20 - Noise emitted by machines and equipment; 25.120.30 - Moulding equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1265:2000+A1:2009 has the following relationships with other standards: It is inter standard links to SIST EN 1265:2000. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1265:2000+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC, EUR-PUB; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1265:2000+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Varnost strojev - Postopki za merjenje hrupa livarskih strojev in opremeSicherheit von Maschinen - Geräuschmessverfahren für Gießereimaschinen und -anlagenSécurité des machines - Code d'essai acoustique pour machines et équipements de fonderieSafety of machinery - Noise test code for foundry machines and equipment25.120.30Livarska opremaMoulding equipment17.140.20Emisija hrupa naprav in opremeNoise emitted by machines and equipmentICS:Ta slovenski standard je istoveten z:EN 1265:1999+A1:2008SIST EN 1265:2000+A1:2009en01-januar-2009SIST EN 1265:2000+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1265:1999+A1

November 2008 ICS 17.120.20; 25.120.30 Supersedes EN 1265:1999English Version

Safety of machinery -Noise test code for foundry machines and equipment

Sécurité des machines - Code d'essai acoustique pour machines et équipements de fonderie

Sicherheit von Maschinen - Geräuschmessverfahren für Gießereimaschinen und -anlagen This European Standard was approved by CEN on 2 July 1999 and includes Amendment 1 approved by CEN on 5 October 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2008 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1265:1999+A1:2008: ESIST EN 1265:2000+A1:2009

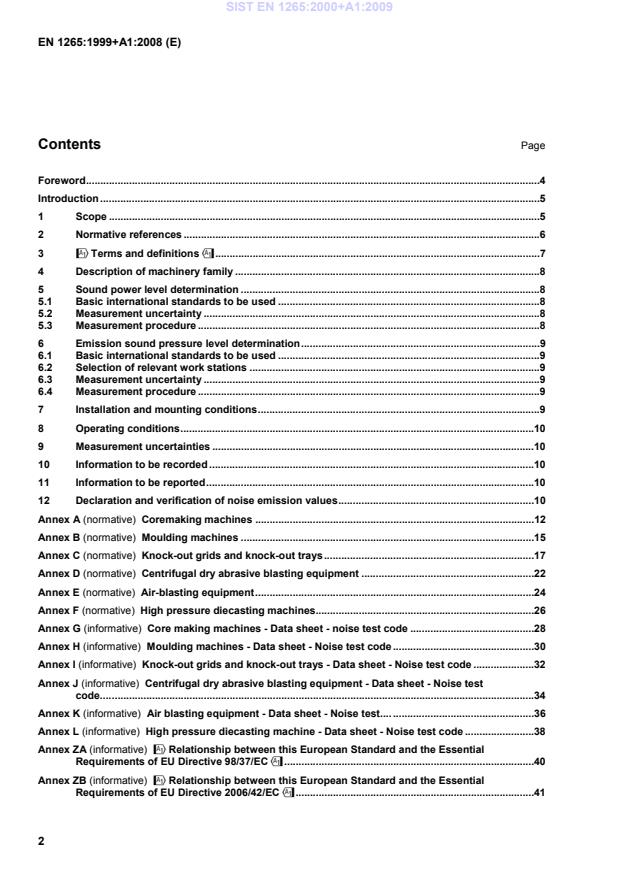

Coremaking machines.12 Annex B (normative)

Moulding machines.15 Annex C (normative)

Knock-out grids and knock-out trays.17 Annex D (normative)

Centrifugal dry abrasive blasting equipment.22 Annex E (normative)

Air-blasting equipment.24 Annex F (normative)

High pressure diecasting machines.26 Annex G (informative)

Core making machines - Data sheet - noise test code.28 Annex H (informative)

Moulding machines - Data sheet - Noise test code.30 Annex I (informative)

Knock-out grids and knock-out trays - Data sheet - Noise test code.32 Annex J (informative)

Centrifugal dry abrasive blasting equipment - Data sheet - Noise test code.34 Annex K (informative)

Air blasting equipment - Data sheet - Noise test.36 Annex L (informative)

High pressure diecasting machine - Data sheet - Noise test code.38 Annex ZA (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC".40 Annex ZB (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC".41 SIST EN 1265:2000+A1:2009

Figure title Figure C.1 — Reference box, measuring surface and position of measuring points in case of knock-out grid for sound power level determination according to the surface enveloping method.20 Figure C.2 — Reference box, measuring surface and measuring positions in case of knock-out tray for sound power level determination according to the surface enveloping method.21 "

(ISO 3746:1995) EN ISO 4871:1996, Acoustics — Declaration and verification of noise emission values of machinery and equipment (ISO 4871:1996) EN ISO 9614-1:1995, Acoustics — Determination of sound power levels of noise sources using sound intensity — Part 1: Measurement at discrete points (ISO 9614-1:1993) EN ISO 9614-2:1996, Acoustics — Determination of sound power levels of noise sources using sound intensity — Part 2: Measurement by scanning (ISO 9614-2:1996) EN ISO 11201:1995, Acoustics — Noise emitted by machinery and equipment — Measurement of emission sound pressure levels at a work station and at other specified positions — Engineering method in an essentially free field over a reflecting plane (ISO 11201:1995) EN ISO 11202:1995, Acoustics — Noise emitted by machinery and equipment — Measurement of emission sound pressure levels at a work station and at other specified positions — Survey method in situ (ISO 11202:1995) EN ISO 11204:1995, Acoustics — Noise emitted by machinery and equipment — Measurement of emission sound pressure levels at a work station and at other specified positions — Method requiring environmental corrections (ISO 11204:1995) EN ISO 12001:1996, Acoustics — Noise emitted by machinery and equipment — Rules for the drafting and presentation of a noise test code (ISO 12001:1996) EN ISO 12100-1:2003, Safety of machinery — Basic concepts, general principles for design — Part 1: Basic terminology, methodology (ISO 12100-1:2003) EN ISO 12100-2:2003, Safety of machinery — Basic concepts, general principles for design — Part 2: Technical principles (ISO 12100-2:2003)" SIST EN 1265:2000+A1:2009

DECLARED

DUAL-NUMBER

NOISE

EMISSION

VALUES

MEASURED A-WEIGHTED EMISSION SOUND PRESSURE LEVEL

AT THE WORK STATION: LpA (re 20 µPa) in decibels ____ Uncertainty KpA in decibels ____

MEASURED A-WEIGHTED SOUND POWER LEVEL: LWA (re 1 pW) in decibels ____ Uncertainty KWA in decibels ____

Values determined according to noise test code EN 1265, Annex xx and noise measurement standards EN xxxxx and EN xxxxx

NOTE The sum of a measured noise emission value and its associated uncertainty factor represents an upper bound of the range of values which can occur in the measurements." SIST EN 1265:2000+A1:2009

Coremaking machines The clause numbering in this normative Annex corresponds to that in the main body. A.4 Description of machinery group This Annex applies to manually or automatically controlled coremaking machines as defined in EN 710. A hydraulic or vacuum device being integrated in the coremaking machine is considered to be part of it. The sand feeding device is an integral part of the machine. A.5 Sound power level determination A.5.3 Measurement procedure The A-weighted sound power level is determined over the complete working cycle outlined in clause 8. The total cycle time TC contains a time TH for hardening whose duration depends on sand and core type and during which practically no noise is produced. For this reason the A-weighted sound power level which was determined for the cycle, LWAc, is corrected for a normalised hardening time of 10 s for cold setting and 120 s for hot setting using the following formulas for cold setting: LWAc,10 = LWAc + 10 lg 10s+T-TT H CC dB for hot setting: LWAc,120 = LWAc + 10 lg 120s+T-TT

HCC dB with LWAc,10:

A-weighted sound power level with normalised hardening time for cold setting LWAc,120: A-weighted sound power level with normalised hardening time for hot setting. The final result shall be the arithmetic average of at least five separate measurements of one complete cycle. The normalised values shall be used for declaration purposes. SIST EN 1265:2000+A1:2009

HCC dB

for hot setting: LpAc,120 = LpAc + 10 lg 120s+T-TT

HCC dB with LpAc,10:

A-weighted sound pressure level with normalised hardening time for cold setting LpAc,120:

A-weighted sound pressure level with normalised hardening time for hot setting. The final result shall be the arithmetic average of at least five measurements over one complete cycle. The normalised values shall be used for declaration purposes. In the case of automatically controlled machines the emission sound pressure level shall be the average on an energy basis of the measured values at the specified positions using LpAc = 10 lg()++3,2,1,1,01,01,010101031pAcpAcpAcxLxLxL with LpAc,1 to 3: the emission sound pressure level at positions 1 to 3. The C-weighted peak emission sound pressure level shall be controlled at the work station(s). If the value exceeds 130 dB it shall be recorded and reported. SIST EN 1265:2000+A1:2009

Moulding machines The clause numbering in this normative Annex corresponds to that in the main body. B.4 Description of machinery group This Annex applies to moulding machines which are installed as a single machine or are part of a moulding production line as defined in EN 710. There are different subgroups of moulding machines which are determined by their compaction principle. The measuring object is the operating moulding machine with the product. If the moulding machine is part of a moulding line, the noise emission of the machine alone shall be determined. B.5 Sound power level determination B.5.1 Basic international Standards to be used In some cases the noise emission of the moulding machine cannot be separated from that of the other components of the production line. In this case it is not always

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...