oSIST prEN IEC 62364:2026

(Main)Hydraulic machines - Guidelines for dealing with hydro-abrasive erosion in Kaplan, Francis and Pelton turbines

Hydraulic machines - Guidelines for dealing with hydro-abrasive erosion in Kaplan, Francis and Pelton turbines

Wasserturbinen - Leitfaden für den Umgang mit hydroabrasiver Erosion in Kaplan-, Francis und Pelton-Turbinen

Machines hydrauliques - Lignes directrices relatives au traitement de l'érosion hydroabrasive des turbines Kaplan, Francis et Pelton

Hidravlični stroji - Smernice za obravnavanje hidroabrazivne erozije pri Kaplanovih, Francisovih in Peltonovih turbinah

General Information

- Status

- Not Published

- Public Enquiry End Date

- 31-Mar-2026

- Technical Committee

- IEHT - Electrotechnics - Hydraulic turbins

- Current Stage

- 4020 - Public enquire (PE) (Adopted Project)

- Start Date

- 04-Feb-2026

- Due Date

- 24-Jun-2026

Relations

- Effective Date

- 14-Jan-2025

Overview

oSIST prEN IEC 62364:2026 is an international standard developed by CLC and IEC, providing comprehensive guidelines for addressing hydro-abrasive erosion in Kaplan, Francis, and Pelton turbines. Hydro-abrasive erosion, caused by the action of suspended abrasive particles in water, can significantly impact the efficiency and longevity of hydraulic turbines used in hydropower generation. This standard serves as a critical resource for hydroelectric power plant operators, designers, engineers, and equipment suppliers seeking to minimize erosion, optimize maintenance, and achieve reliable, long-term turbine performance.

Key Topics

- Hydro-abrasive Erosion Mechanisms: Explanation of how suspended particles like silt and sand lead to material loss in turbine components.

- Data Presentation: Guidelines for collecting and reporting erosion rates, covering various combinations of water quality, operating conditions, and material properties.

- Design Considerations: Recommendations for modifying hydraulic and mechanical designs to reduce erosion risks without sacrificing efficiency.

- Material Selection: Guidance on choosing materials and coatings with high resistance to hydro-abrasive wear, considering long-term maintainability.

- Operation and Maintenance: Strategies for turbine operation modes in particle-laden water to extend service intervals and reduce wear, as well as advice on regular inspection and repair.

- Monitoring and Sampling: Procedures for measuring particle concentrations, size distribution, and properties in water, with recommended sampling intervals and evaluation methods.

- Specification Development: Support for owners in drafting technical specifications that effectively communicate concerns about erosion and operational expectations to equipment suppliers.

Applications

This standard is highly relevant for:

- Hydroelectric Power Plants: Ensuring reliable operation of Kaplan, Francis, and Pelton turbines in rivers or reservoirs containing sediment or abrasive particles.

- Turbine Design and Manufacturing: Assisting engineers and manufacturers in developing turbine components and systems optimally resistant to abrasive wear.

- Plant Operation and Maintenance: Enabling owners to adopt best practices for monitoring, maintaining, and overhauling turbines, thereby reducing unscheduled downtime and optimizing performance.

- Specification and Procurement: Assisting project planners in drafting clear, achievable technical requirements for new installations or refurbishments.

- Research and Performance Evaluation: Supporting ongoing research into erosion mechanisms and the development of improved materials and coatings.

Key practical benefits include:

- Extended Turbine Life: Through reduction of material wear and improved maintenance guidelines.

- Lower Operating Costs: By minimizing downtime and optimizing overhaul intervals.

- Enhanced Efficiency: Keeping turbine surfaces smooth and design shapes intact for peak hydraulic performance.

- Improved Safety and Reliability: Reducing risk of sudden failures due to undetected or unchecked erosion.

Related Standards

For holistic implementation and enhanced compatibility, consider these related international standards:

- IEC 60193 – Hydraulic turbines, storage pumps, and pump-turbines – Model acceptance tests

- IEC 60609-2 – Hydraulic turbines, storage pumps, and pump-turbines – Cavitation pitting evaluation guide

- IEC TR 61364 – Terminology related to hydraulic turbines and their associated equipment

These standards complement prEN IEC 62364 by providing further detail on measurement methods, acceptance criteria, and terminology.

Keywords: hydraulic turbines, hydro-abrasive erosion, Kaplan turbines, Francis turbines, Pelton turbines, erosion-resistant materials, turbine maintenance, particle monitoring, hydropower standards, IEC 62364, turbine design, hydropower plant operation.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

oSIST prEN IEC 62364:2026 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Hydraulic machines - Guidelines for dealing with hydro-abrasive erosion in Kaplan, Francis and Pelton turbines". This standard covers: Hydraulic machines - Guidelines for dealing with hydro-abrasive erosion in Kaplan, Francis and Pelton turbines

Hydraulic machines - Guidelines for dealing with hydro-abrasive erosion in Kaplan, Francis and Pelton turbines

oSIST prEN IEC 62364:2026 is classified under the following ICS (International Classification for Standards) categories: 23.100.10 - Pumps and motors; 27.140 - Hydraulic energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

oSIST prEN IEC 62364:2026 has the following relationships with other standards: It is inter standard links to SIST EN IEC 62364:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

oSIST prEN IEC 62364:2026 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2026

Hidravlični stroji - Smernice za obravnavanje hidroabrazivne erozije pri

Kaplanovih, Francisovih in Peltonovih turbinah

Hydraulic machines - Guidelines for dealing with hydro-abrasive erosion in Kaplan,

Francis and Pelton turbines

Wasserturbinen - Leitfaden für den Umgang mit hydroabrasiver Erosion in Kaplan-,

Francis und Pelton-Turbinen

Machines hydrauliques - Lignes directrices relatives au traitement de l'érosion

hydroabrasive des turbines Kaplan, Francis et Pelton

Ta slovenski standard je istoveten z: prEN IEC 62364:2026

ICS:

23.100.10 Hidravlične črpalke in motorji Pumps and motors

27.140 Vodna energija Hydraulic energy engineering

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

4/538/CDV

COMMITTEE DRAFT FOR VOTE (CDV)

PROJECT NUMBER:

IEC 62364 ED3

DATE OF CIRCULATION: CLOSING DATE FOR VOTING:

2026-01-30 2026-04-24

SUPERSEDES DOCUMENTS:

4/515/RR

IEC TC 4 : HYDRAULIC TURBINES

SECRETARIAT: SECRETARY:

Canada Mrs Christine Geraghty

OF INTEREST TO THE FOLLOWING COMMITTEES: HORIZONTAL FUNCTION(S):

TC 114

ASPECTS CONCERNED:

Safety

SUBMITTED FOR CENELEC PARALLEL VOTING NOT SUBMITTED FOR CENELEC PARALLEL VOTING

Attention IEC-CENELEC parallel voting

The attention of IEC National Committees, members of

CENELEC, is drawn to the fact that this Committee Draft

for Vote (CDV) is submitted for parallel voting.

The CENELEC members are invited to vote through the

CENELEC online voting system.

This document is still under study and subject to change. It should not be used for reference purposes.

Recipients of this document are invited to submit, with their comments, notification of any relevant patent rights of

which they are aware and to provide supporting documentation.

Recipients of this document are invited to submit, with their comments, notification of any relevant “In Some

Countries” clauses to be included should this proposal proceed. Recipients are reminded that the CDV stage is the

final stage for submitting ISC clauses. (SEE AC/22/2007 OR NEW GUIDANCE DOC).

TITLE:

Hydraulic machines - Guidelines for dealing with hydro-abrasive erosion in Kaplan, Francis and

Pelton turbines

PROPOSED STABILITY DATE: 2028

NOTE FROM TC/SC OFFICERS:

download this electronic file, to make a copy and to print out the content for the sole purpose of preparing

National Committee positions. You may not copy or "mirror" the file or printed version of the document, or any part

of it, for any other purpose without permission in writing from IEC.

IEC CDV 62364 © IEC 2026

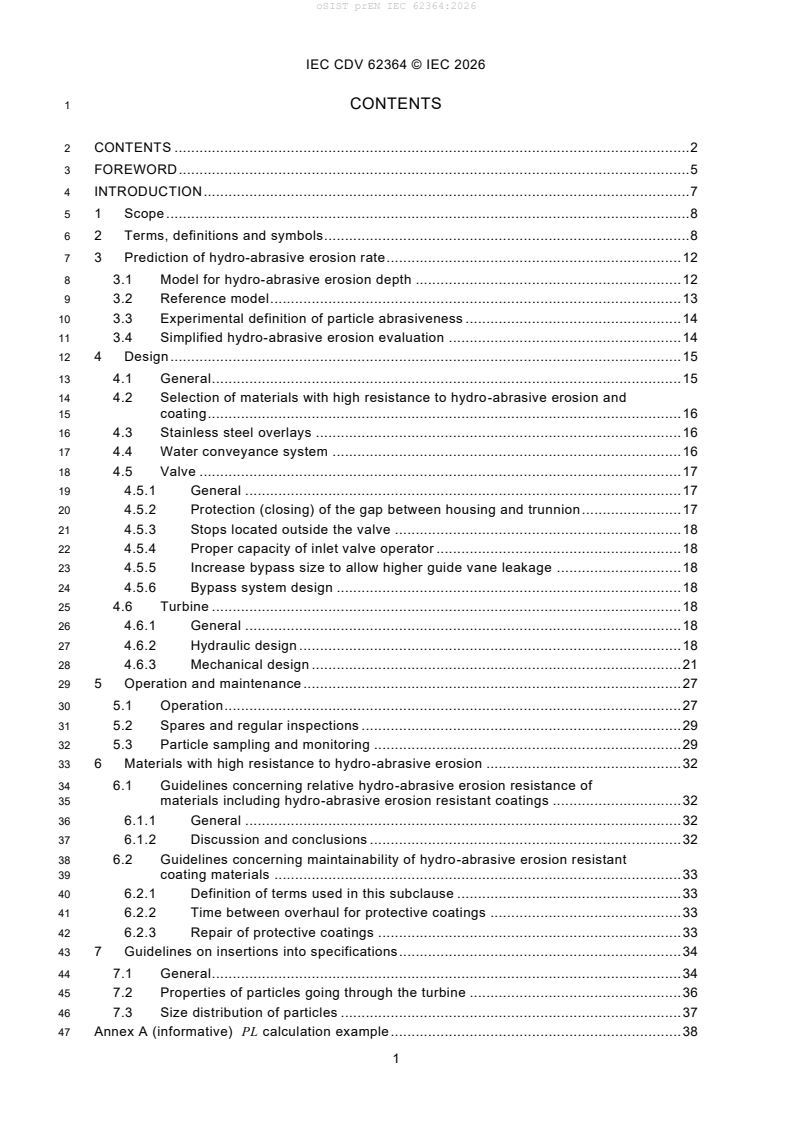

1 CONTENTS

2 CONTENTS . 2

3 FOREWORD . 5

4 INTRODUCTION . 7

5 1 Scope . 8

6 2 Terms, definitions and symbols. 8

7 3 Prediction of hydro-abrasive erosion rate . 12

8 3.1 Model for hydro-abrasive erosion depth . 12

9 3.2 Reference model . 13

10 3.3 Experimental definition of particle abrasiveness . 14

11 3.4 Simplified hydro-abrasive erosion evaluation . 14

12 4 Design . 15

13 4.1 General . 15

14 4.2 Selection of materials with high resistance to hydro-abrasive erosion and

15 coating . 16

16 4.3 Stainless steel overlays . 16

17 4.4 Water conveyance system . 16

18 4.5 Valve . 17

19 4.5.1 General . 17

20 4.5.2 Protection (closing) of the gap between housing and trunnion. 17

21 4.5.3 Stops located outside the valve . 18

22 4.5.4 Proper capacity of inlet valve operator . 18

23 4.5.5 Increase bypass size to allow higher guide vane leakage . 18

24 4.5.6 Bypass system design . 18

25 4.6 Turbine . 18

26 4.6.1 General . 18

27 4.6.2 Hydraulic design . 18

28 4.6.3 Mechanical design . 21

29 5 Operation and maintenance . 27

30 5.1 Operation . 27

31 5.2 Spares and regular inspections . 29

32 5.3 Particle sampling and monitoring . 29

33 6 Materials with high resistance to hydro-abrasive erosion . 32

34 6.1 Guidelines concerning relative hydro-abrasive erosion resistance of

35 materials including hydro-abrasive erosion resistant coatings . 32

36 6.1.1 General . 32

37 6.1.2 Discussion and conclusions . 32

38 6.2 Guidelines concerning maintainability of hydro-abrasive erosion resistant

39 coating materials . 33

40 6.2.1 Definition of terms used in this subclause . 33

41 6.2.2 Time between overhaul for protective coatings . 33

42 6.2.3 Repair of protective coatings . 33

43 7 Guidelines on insertions into specifications. 34

44 7.1 General . 34

45 7.2 Properties of particles going through the turbine . 36

46 7.3 Size distribution of particles . 37

47 Annex A (informative) PL calculation example . 38

IEC CDV 62364 © IEC 2026

48 Annex B (informative) Measuring and recording hydro-abrasive erosion damages . 40

49 B.1 Recording hydro-abrasive erosion damage . 40

50 B.2 Pelton runner without coating . 40

51 B.3 Needle tip and mouth piece without coating . 41

52 B.4 Pelton runner with hardcoating . 41

53 B.5 Needle tip, seat ring and nozzle housing with coating . 41

54 B.6 Francis runner and stationary labyrinth without coating . 42

55 B.7 Francis runner with coating and stationary labyrinth . 42

56 B.8 Guide vanes and facing plates without coating . 42

57 B.9 Guide vanes and facing plates with coating . 43

58 B.10 Stay vanes . 43

59 B.11 Francis labyrinth seals uncoated . 43

60 B.12 Kaplan uncoated . 43

61 B.13 Kaplan coated . 44

62 B.14 Sample data sheets . 44

63 B.15 Inspection record, runner blade inlet . 45

64 B.16 Inspection record, runner blade outlet . 46

65 B.17 Inspection record, runner band . 47

66 B.18 Inspection record, guide vanes . 48

67 B.19 Inspection record, facing plates and covers . 49

68 B.20 Inspection record, upper stationary seal . 50

69 B.21 Inspection record, upper rotating seal . 51

70 B.22 Inspection record, lower stationary seal . 52

71 B.23 Inspection record, lower rotating seal . 53

72 B.24 Inspection record, runner bucket . 54

73 B.25 Inspection record, Pelton runner splitter . 55

74 Annex C (informative) Monitoring of particle concentration and properties and water

75 sampling procedure . 56

76 C.1 General . 56

77 C.2 Sampling before building a power station . 56

78 C.3 Sampling in existing power stations . 57

79 C.4 Logging of samples . 57

80 Annex D (informative) Procedures for analysis of particle concentration, size,

81 hardness and shape . 58

82 D.1 General . 58

83 D.2 Particle concentration . 58

84 D.3 Particle size distribution . 58

85 D.4 Mineralogical composition . 58

86 D.5 Particle geometry . 58

87 Annex E (informative) Frequency of sediment sampling . 61

88 Annex F (informative) Typical criteria to determine overhaul time due to hydro-

89 abrasive erosion . 62

90 F.1 General . 62

91 F.2 Parameters which are observable while the unit is in operation . 62

92 F.3 Criteria that require internal inspection of the unit . 63

93 Annex G (informative) Example to calculate the hydro-abrasive erosion depth . 64

94 Annex H (informative) Examples to calculate the TBO in the reference model . 66

95 Annex I (informative) Background for hydro-abrasive erosion depth model . 69

IEC CDV 62364 © IEC 2026

96 I.1 Model background and derivation. 69

97 I.2 Introduction to the PL variable. 70

98 I.3 Calibration of the formula . 72

99 Annex J (informative) Quality control of thermal sprayed WC-CoCr . 74

100 J.1 Specification . 74

101 J.2 Quality control . 74

102 Bibliography . 75

104 Figure 1 – Estimation of the characteristic velocities in guide vanes, W , and runner,

gv

105 W , as a function of turbine specific speed . 14

run

106 Figure 2 – Simplified evaluation of risk of hydro-abrasive erosion for first assessment . 16

107 Figure 3 – Example of protection of transition area . 19

108 Figure 4 – Runner blade overhang in refurbishment project . 21

109 Figure 5 – Example of cavitation on runner band due to thicker blades . 22

110 Figure 6 – Example of design of guide vane trunnion seals . 23

111 Figure 7 – Example of fixing of facing plates from the dry side (bolt to the left) . 25

112 Figure 8 – Head cover balancing pipes with bends . 26

113 Figure 9 – Step labyrinth with optimized shape for hardcoating . 28

114 Figure 10 – Typical measurement ranges for continuous monitoring of suspended

115 particles . 31

116 Figure 11 – Sample plot of particle concentration versus time . 32

117 Figure D.1 – Typical examples of particle geometry . 61

118 Figure I.1 – Example of flow pattern in a Pelton injector at different load . 72

120 Table 1 – Values of K and p for various components . 14

f

121 Table 2 – relevant properties of suspended particles for hydroabrasive erosion . 30

122 Table 3 – comparison of measurement technologies for continuous monitoring of

123 suspended particles . 31

124 Table 4 – Overview over the feasibility for repair C on site . 35

125 Table 5 – Form for properties of particles going through the turbine . 37

126 Table 6 – Form for size distribution of particles . 38

127 Table A.1 – Example of documenting sample tests . 39

128 Table A.2 – Example of documenting sample results . 40

129 Table B.1 – Inspection record, runner blade inlet form . 46

130 Table B.2 – Inspection record, runner blade outlet form . 47

131 Table B.3 – Inspection record, runner band form . 48

132 Table B.4 – Inspection record, guide vanes form . 49

133 Table B.5 – Inspection record, facing plates and covers form . 50

134 Table B.6 – Inspection record, upper stationary seal form . 51

135 Table B.7 – Inspection record, upper rotating seal form . 52

136 Table B.8 – Inspection record, lower stationary seal form . 53

137 Table B.9 – Inspection record, lower rotating seal form . 54

138 Table B.10 – Inspection record, runner bucket . 55

139 Table B.11 – Inspection record, Pelton runner splitter . 56

140 Table G.1 – Calculations . 66

IEC CDV 62364 © IEC 2026

141 Table H.1 – Pelton turbine calculation example . 67

142 Table H.2 – Francis turbine calculation example . 68

143 Table I.1 – Analysis of the calibration constant K and p . 74

f

144 Table J.1 – Recommended items to include in HVOF inspection . 75

IEC CDV 62364 © IEC 2026

147 INTERNATIONAL ELECTROTECHNICAL COMMISSION

148 ____________

150 HYDRAULIC MACHINES –

151 GUIDELINES FOR DEALING WITH HYDRO-ABRASIVE

152 EROSION IN KAPLAN, FRANCIS, AND PELTON TURBINES

154 FOREWORD

155 1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

156 all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

157 international co-operation on all questions concerning standardization in the electrical and electronic fields. To

158 this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

159 Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

160 Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

161 in the subject dealt with may participate in this preparatory work. International, governmental and non -

162 governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

163 with the International Organization for Standardization (ISO) in accordance with conditions determined by

164 agreement between the two organizations.

165 2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

166 consensus of opinion on the relevant subjects since each technical committee has representation from all

167 interested IEC National Committees.

168 3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

169 Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

170 Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

171 misinterpretation by any end user.

172 4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

173 transparently to the maximum extent possible in their national and regional publications. Any divergence

174 between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

175 the latter.

176 5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

177 assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

178 services carried out by independent certification bodies.

179 6) All users should ensure that they have the latest edition of this publication.

180 7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

181 members of its technical committees and IEC National Committees for any personal injury, property damage or

182 other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

183 expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

184 Publications.

185 8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

186 indispensable for the correct application of this publication.

187 9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

188 patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

189 International Standard IEC 62364 has been prepared by IEC technical committee 4: Hydraulic

190 turbines.

191 This second edition cancels and replaces the first edition published in 2013. This edition

192 constitutes a technical revision.

193 This edition includes the following significant technical changes with respect to the previous

194 edition:

195 a) the formula for TBO in Pelton reference model has been modified;

196 b) the formula for calculating sampling interval has been modified;

197 c) the chapter in hydro-abrasive erosion resistant coatings has been substantially modified;

198 d) the annex with test data for hydro-abrasive erosion resistant materials has been removed;

199 e) a simplified hydro-abrasive erosion evaluation has been added.

IEC CDV 62364 © IEC 2026

200 The text of this International Standard is based on the following documents:

FDIS Report on voting

4/351/FDIS 4/366/RVD

202 Full information on the voting for the approval of this International Standard can be found in

203 the report on voting indicated in the above table.

204 This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

205 The committee has decided that the contents of this document will remain unchanged until the

206 stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

207 the specific document. At this date, the document will be

208 • reconfirmed,

209 • withdrawn,

210 • replaced by a revised edition, or

211 • amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

IEC CDV 62364 © IEC 2026

215 INTRODUCTION

216 The number of hydro power plants with hydro-abrasive erosion is increasing worldwide.

217 An overall approach is needed to minimize the impact of this phenomenon. Already at the

218 start of the planning phase an evaluation should be done to quantify the hydro-abrasive

219 erosion and the impact on the operation. For this, the influencing parameters and their impact

220 on the hydro-abrasive erosion have to be known. The necessary information for the evaluation

221 comprises among others the future design, the particle parameters of the water, which will

222 pass the turbine, the reservoir sedimentation and the power plant owner’s framework for the

223 future operation like availability or maximum allowable efficiency loss, before an overhaul

224 needs to be done.

225 Based on this evaluation of the hydro-abrasive erosion, an optimised solution can then be

226 found, by analysing all measures in relation to investments, energy production and

227 maintenance costs as decision parameters. Often a more hydro-abrasive erosion-resistant

228 design, instead of choosing the turbine design with the highest efficiency, will lead to higher

229 revenue. This analysis is best performed by the overall plant designer.

230 With regards to the machines, owners should find the means to communicate to potential

231 suppliers for their sites, their desire to have the particular attention of the designers at the

232 turbine design phase, directed to the minimization of the severity and effects of hydro-

233 abrasive erosion.

234 Limited consensus and very little quantitative data exists on the steps which the designer

235 could and should take to extend the useful life before major overhaul of the turbine

236 components when they are operated under severe hydro-abrasive erosion service. This has

237 led some owners to write into their specifications, conditions which cannot be met with known

238 methods and materials.

IEC CDV 62364 © IEC 2026

241 HYDRAULIC MACHINES –

242 GUIDELINES FOR DEALING WITH HYDRO-ABRASIVE

243 EROSION IN KAPLAN, FRANCIS, AND PELTON TURBINES

247 1 Scope

248 This document gives guidelines for:

249 a) presenting data on hydro-abrasive erosion rates on several combinations of water quality,

250 operating conditions, component materials, and component properties collected from a

251 variety of hydro sites;

252 b) developing guidelines for the methods of minimizing hydro-abrasive erosion by

253 modifications to hydraulic design for clean water. These guidelines do not include details

254 such as hydraulic profile shapes which are determined by the hydraulic design experts for

255 a given site;

256 c) developing guidelines based on “experience data” concerning the relative resistance of

257 materials faced with hydro-abrasive erosion problems;

258 d) developing guidelines concerning the maintainability of materials with high resistance to

259 hydro-abrasive erosion and hardcoatings;

260 e) developing guidelines on a recommended approach, which owners could and should take

261 to ensure that specifications communicate the need for particular attention to this aspect

262 of hydraulic design at their sites without establishing criteria which cannot be satisfied

263 because the means are beyond the control of the manufacturers;

264 f) developing guidelines concerning operation mode of the hydro turbines in water with

265 particle materials to increase the operation life.

266 It is assumed in this document that the water is not chemically aggressive. Since chemical

267 aggressiveness is dependent upon so many possible chemical compositions, and the

268 materials of the machine, it is beyond the scope of this document to address these issues.

269 It is assumed in this document that cavitation is not present in the turbine. Cavitation and

270 hydro-abrasive erosion can reinforce each other so that the resulting erosion is larger than

271 the sum of cavitation erosion plus hydro-abrasive erosion. The quantitative relationship of the

272 resulting hydro-abrasive erosion is not known and it is beyond the scope of this document to

273 assess it, except to suggest that special efforts be made in the turbine design phase to

274 minimize cavitation.

275 Large solids (e.g. stones, wood, ice, metal objects, etc.) traveling with the water can impact

276 turbine components and produce damage. This damage can in turn increase the flow

277 turbulence thereby accelerating wear by both cavitation and hydro-abrasive erosion. Hydro-

278 abrasive erosion resistant coatings can also be damaged locally by impact of large solids. It is

279 beyond the scope of this document to address these issues.

280 This document focuses mainly on hydroelectric powerplant equipment. Certain portions can

281 also be applicable to other hydraulic machines.

282 2 Terms, definitions and symbols

283 For the purposes of this document, the following terms and definitions apply.

284 ISO and IEC maintain terminological databases for use in standardization at the following

285 addresses:

IEC CDV 62364 © IEC 2026

286 • IEC Electropedia: available at http://www.electropedia.org/

287 • ISO Online browsing platform: available at http://www.iso.org/obp

288 NOTE 1 Terms and definitions are also based, where relevant, on IEC TR 61364.

289 NOTE 2 The International System of Units (S.I.) is adopted throughout this document but other systems are

290 allowed.

Sub- Term Definition Symbol Unit

clause

specific specific energy of water available between the high and

2.2.1 E J/kg

hydraulic low pressure reference sections 1 and 2 of the machine

energy of a

machine

Note 1 to entry: For full information, see IEC 60193.

acceleration local value of gravitational acceleration at the place of 2

2.2.2 g m/s

due to gravity testing

Note 1 to entry: For full information, see IEC 60193.

turbine head available head at hydraulic machine terminal

2.2.3 H m

pump head

H = E/g

reference reference diameter of the hydraulic machine

2.2.4 D m

diameter

Note 1 to entry: For Pelton turbines this is the pitch

diameter, for Kaplan turbines this is the runner chamber

diameter and for Francis and Francis type pump

turbines this is the blade low pressure section diameter

at the band

Note 2 to entry: See IEC 60193 for further information.

hub diameter the diameter of runner hub for Kaplan turbines

2.2.5 D mm

h

hydro-abrasive depth of material removed (measured perpendicular to

2.2.6 S mm

erosion depth the original surface) from a component due to hydro-

abrasive erosion

characteristic characteristic velocity defined for each machine

2.2.7 W m/s

velocity component and used to quantify hydro-abrasive erosion

damage

Note 1 to entry: See also 2.2.20 to 2.2.24.

particle mass concentration of particles, i.e. the mass of solid 3

2.2.8 C kg/m

concentration particles per volume of water-particle mixture

Note 1 to entry: In case the particle concentration is

expressed in parts per million (ppm) it is recommended

to use the mass of particles per volume of water, so that

1 000 ppm approximately corresponds to 1 kg/m .

particle load the integral of the modified particle concentration over

2.2.9 PL

kg h/m

time:

𝑇

𝑃𝐿 = ∫ 𝐶(𝑡) × 𝐴 (𝑡)𝑑𝑡

s

𝑁

(≈ ∑ 𝐶 × 𝐴 × 𝑇 )

𝑛 s,𝑛 𝑠,𝑛

𝑛=1

C(t) = 0 if no water is flowing through the turbine.

Note 1 to entry: For Francis turbines C(t) = 0 when

calculating PL for runner and labyrinth seals, if the unit

is at standstill with pressurized spiral case, but C(t) ≠ 0

when calculating PL for guide vanes and facing plates.

IEC CDV 62364 © IEC 2026

Sub- Term Definition Symbol Unit

clause

Abrasiveness

2.2.10 𝐴 = 𝐾 × 𝐾 × 𝐾 A

s

𝑠 size shape hardness

factor

size factor factor that characterizes how the hydro-abrasive erosion

2.2.11 K

size

relates to the size of the abrasive particles = median

particle size dP in mm

shape factor factor that characterizes how the hydro-abrasive erosion

2.2.12 K

shape

relates to the shape of the abrasive particles

Note 1 to entry: See Annex D.

hardness factor that characterizes how the hydro-abrasive erosion

2.2.13 K

hardness

factor relates to the hardness of the abrasive particles

for 13Cr4Ni stainless steel: K = fraction of

hardness

particles harder than Mohs 4,5.

for hard coated surfaces: K = fraction of particles

hardness

harder than Mohs 7,0.

material factor factor that characterizes how the hydro-abrasive erosion

2.2.14 K

m

relates to the material properties of the base material

flow coefficient coefficient that characterizes how the hydro-abrasive 3,4

2.2.15 K mm × s

f

erosion relates to the water flow around each

𝛼

kg × h × m

component

sampling time interval between two water samples taken to

2.2.16 T h

s

interval determine the concentration of abrasive particles in the

water

maximum maximum value of Cthe integrand in the PL integral 3

2.2.17 C Kg/m

max

concentration during a specified time interval, i.e. the maximum value

of the following expression

𝑇

Accumulated

2.2.18 S Kg

A

sediment

𝑆 = ∫ 𝐶(𝑡) × 𝑄(𝑡)𝑑𝑡

A

amount 0

particle median diameter of abrasive particles in a sample, i.e.

2.2.19 dP mm

median such diameter that the particles with size smaller than

diameter the value under consideration represent 50 % of the

total mass of particles in the sample

o

impingement angle between the particle trajectory and the surface of

2.2.20

angle the substrate

characteristic flow through unit divided by the minimum flow area at

2.2.21 W m/s

gv

velocity in the guide vane apparatus at best efficiency point

Francis guide

vanes

Q

characteristic

W =

gv

velocity in

a Z B

0 0

Kaplan guide

vanes

characteristic speed of the water flow at injector location

2.2.22 W m/s

inj

velocity in

Pelton injector

W = 2 E

inj

IEC CDV 62364 © IEC 2026

Sub- Term Definition Symbol Unit

clause

characteristic relative velocity between the water and the runner blade

2.2.23 W m/s

run

velocity in estimated with below formulas at best efficiency point

turbine runner

2 2

W = u + c

run 2 2

u = n D

Q 4

c = (Francis)

D

Q 4

c = (Kaplan)

(D − D )

h

characteristic relative velocity between the water and the runner

2.2.24 W m/s

run

velocity in bucket

Pelton runner

W = 0,5 2 E

run

discharge volume of water per unit time passing through any 3

2.2.25 Q m /s

section in the system

guide vane average shortest distance between adjacent guide

2.2.26 a m

opening vanes (at a specified section if necessary)

Note 1 to entry: For further information, see

IEC 60193.

number of total number of guide vanes in a turbine

2.2.27 z

guide vanes

distributor height of the distributor in a turbine

2.2.28 B m

height

rotational number of revolutions per unit time

2.2.29 n 1/s

speed

specific speed commonly used specific speed of a hydraulic machine

2.2.30 n rpm

s

60 n P

n =

s

5 / 4

H

P and H are taken in the rated operating point and given

in kW and m respectively

output output of the turbine in the rated operating point

2.2.31 P kW

hydro-abrasive estimated actual depth of metal that will be removed S

2.2.32 target mm

erosion depth from a component of the target turbine due to particle

of target unit

hydro-abrasive erosion

Note 1 to entry: For use with the reference model.

hydro-abrasive hydro-abrasive erosion depth of metal that has been S

2.2.33 ref mm

erosion depth removed from a component of the reference turbine due

of reference to hydro-abrasive erosion

unit

Note 1 to entry: For use with the reference model.

number of number of nozzles in a Pelton turbine z

2.2.34 jet

nozzles

bucket width bucket width in a Pelton runner B

2.2.35 2 mm

number of number of buckets in a Pelton runner z

2.2.36 2

buckets

time between time between overhaul for target unit TBO

2.2.37 target h

overhaul for

target unit

Note 1 to entry: For use with the reference model.

IEC CDV 62364 © IEC 2026

Sub- Term Definition Symbol Unit

clause

time between time between overhaul for reference unit TBO

2.2.38 ref h

overhaul for

reference unit

Note 1 to entry: For use with the reference model.

turbine reference size for calculation curvature dependent RS

2.2.39 m

reference size effects of hydro-abrasive erosion

Note 1 to entry: For Francis turbines, it is the

reference diameter, D (see 2.2.4).

Note 2 to entry: For Pelton turbines it is the inner

bucket width, B .

Note 3 to entry: For further information in the inner

bucket width, B , see IEC 60609-2.

size exponent exponent that describes the size dependant effects of p

2.2.40

hydro-abrasive erosion in evaluating RS

exponent numerical value of 0,4-p that balances units for K α

2.2.41 f

293 3 Prediction of hydro-abrasive erosion rate

294 3.1 Model for hydro-abrasive erosion depth

295 The following formula can be used to estimate the hydro-abrasive erosion depth in a Francis

296 turbine:

3,4 p

297 S = W PL K K / RS

m f

298 • The characteristic velocity, W, is defined in 2.2.20 to 2.2.23. If detailed data to calculate W

299 is not available it can be estimated based on Figure 1,

300 • PL, K and RS are defined in 2.2.9, 2.2.13 and 2.2.38 respectively,

m

301 • For uncoated components of Francis turbines K and p are taken from Table 1 below.

f

302 For additional information of the background for this formula please refer to Annex I. A sample

303 calculation is found in Annex G.

IEC CDV 62364 © IEC 2026

2,5

0,5

W = (0,25 + 0,003 n ) (2 g H)

run s

1,5

0,5

W = 0,55 (2 g H)

gv

0,5

0 100 200 300 400 500 600 700 800

Turbine specific speed, n (using m, kW)

s

304 IEC

305 NOTE Values of n and H in this figure refer to the rated operating point while the characteristic velocities are

s

306 given for the points noted in Clause 2.

307 Figure 1 – Estimation of the characteristic velocities in guide vanes, W ,

gv

308 and runner, W , as a function of turbine specific speed

run

309 Table 1 – Values of K and p for various components

f

Component K Exponent p

f

(for RS)

-6

Francis guide vanes 0,25

1,06 10

-6

Francis facing plates 0,86 10 0,25

-6

Francis labyrinth seals 0,38 10 0,75

-6

Francis runner inlet 0,25

0,90 10

-6

Francis runner outlet 0,75

0,54 10

311 3.2 Reference model

312 In the reference model presented in this document the TBO of two turbines are compared to

313 each other. To do this the TBO of one turbine (here called reference turbine) and the

314 differences in the influencing parameters to another turbine (here called target turbine) have

315 to be known to calculate the TBO of the target turbine. Note that the same overhaul criteria

316 have to be applied for both the target and reference turbines.

317 The aim of the reference model is not to calculate the hydro-abrasive erosion depth (S).

318 Therefore a calibrated model for the depth is not necessary. The criteria for the TBO can be

319 the relative amount of damage, the efficiency loss or some other criteria but has to be the

320 same for both turbines.

Characteristic velocity coefficient W , W

gv run

IEC CDV 62364 © IEC 2026

321 There are a few differences in the way the formula is built up between the reference model

322 and the absolute model as follows:

323 • since the reference model does not calculate the hydro-abrasive erosion depth of

324 individual components, constants valid for the whole turbine are used instead of different

325 constants for different components;

326 • a larger turbine can normally withstand more hydro-abrasive erosion depth than a small

327 turbine before it needs overhaul. For this reason the exponent for turbine reference size,

328 p, is chosen as 1 in the reference model;

329 • for Pelton turbines, it is assumed that the critical component for overhaul is the runner. In

330 addition to the factors described above, the K for Pelton runners is assumed to be

f

331 proportional to the number of nozzles and the speed and inversely proportional to the

332 number of buckets;

333 The TBO for the target turbine can be calculated as follows:

3,4 3,4

334 TBO / TBO = W / W PL / Pl K / K K / K

target ref ref target ref target m,ref m,target f,ref f,target

p p

335 RS / RS

target ref

336 In this equation, we use the following values for the relationships:

337 Pelton turbines: K / K = z z / (z z )

f, ref f, target jet,ref 2,target jet,target 2,ref

338 Francis and Kaplan turbines: K / K = 1

f,ref f,target

339 Size exponent: p = 1

340 The accuracy of the reference model might decrease when the differences between the

341 reference and target turbines become large.

342 The sensitivity of the calculated TBO value to variances in the input variables can also be

343 studied with the same formula. A sample calculation is found in Annex H.

344 3.3 Experimental definition of particle abrasiveness

345 The particle abrasiveness is calculated from three K-factors that can each be determined

346 inbdividually in the laboratory. This determination involves uncertainties for each of the

347 individual K-factors.In contrast, the overall influence of the factors can be determined using a

348 laboratory test stand. This method has the advantage that the abrasiveness, A , of the actual

s

349 sediment can be measured directly and under various influencing factors.

350 Depending on the geometry to be assessed, different test stands can be used to determine A

s

351 such as flow test stand or free jet test stands, etc.

352 Note that this method requires the calibration of the laboratory test stands and test

353 methodology against particles with known particle abrasiveness.

354 3.4 Simplified hydro-abrasive erosion evaluation

355 In addition to the formulas in 3.1 and 3.2 other methods to estimate hydro-abrasive erosion

356 have been proposed, such as in [15] and [22] . Each method may have its advantages and

357 disadvantages.

358 As a quick and easy rule of thumb to make a first assessment of the severity at a particular

359 site it is recommended to evaluate the following expression, which is shown graphically in

360 Figure 2.

______________

Numbers in square brackets refer to the Bibliography.

IEC CDV 62364 © IEC 2026

1,5

361 If C H ≤ 150 then the hydro-ab

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...