SIST EN 13023:2004+A1:2010

(Main)Noise measurement methods for printing, paper converting, paper making machines and auxiliary equipment - Accuracy grades 2 and 3

Noise measurement methods for printing, paper converting, paper making machines and auxiliary equipment - Accuracy grades 2 and 3

This standard specifies all the information necessary to carry out efficiently and under standardized conditions the determination, declaration and verification of airborne noise emission from printing and paper converting machines covered by the EN 1010 series and from paper making and finishing machines covered by the EN 1034 series. It specifies noise measurement methods and installation and operating conditions to be used for the test.

This standard applies to those machines listed in the normative annexes A to J. The principles of this noise test code should be applied as far as possible also for the determination of noise emission of machines and machine parts not listed in the normative annexes A to J. In such cases, all information relating to assembly, installation and operating conditions as well as the arrangement of work stations should be recorded and reported in the test report.

Noise emission characteristics include emission sound pressure levels at work stations and the sound power level. Declared noise emission values permit comparison of printing and paper machines on the market.

The use of this noise test code ensures the reproducibility of the determination of the characteristic noise emissions within specific limits. These limits are determined by the accuracy grade of the noise measuring method used. Noise measurements specified by this standard are carried out by the engineering method (accuracy grade 2) and the survey method (accuracy grade 3).

Geräuschmessverfahren für Druck- und Papierverarbeitungs-, Papierherstellungs- und Ausrüstungsmaschinen - Genauigkeitsklassen 2 und 3

Diese Norm enthält alle Festlegungen, die erforderlich sind, um die Ermittlung, Kennzeichnung und Nachprüfung

von Luftschallemissionen an den durch die Reihe EN 1010 abgedeckten Druck- und Papierverarbeitungsmaschinen

und den durch die Reihe EN 1034 abgedeckten Maschinen der Papierherstellung

und Ausrüstung effektiv und unter einheitlichen Voraussetzungen durchführen zu können. Die Norm

beschreibt die Lärmmessverfahren sowie die Betriebs- und Installationsbedingungen für die Geräuschmessung.

Diese Norm bezieht sich auf die Maschinen, die in den normativen Anhängen A bis J aufgeführt sind. Auch

zur Bestimmung der Geräuschemission von Maschinen oder Maschinenteilen, die nicht in den normativen

Anhängen A bis J aufgeführt sind, sollten die Grundsätze dieser Geräuschmessvorschrift so weit wie möglich

angewendet werden. In diesem Fall sollten alle Informationen über Aufstellungs-, Befestigungs- und

Betriebsbedingungen und die Anordnung der Arbeitsplätze dokumentiert und im Ergebnisbericht angegeben

werden.

Zu den charakteristischen Geräuschemissionswerten gehören Emissons-Schalldruckpegel am Arbeitsplatz

sowie der Schallleistungspegel. Die angegebenen Geräuschwerte ermöglichen den Vergleich der am Markt

befindlichen Druck- und Papiermaschinen.

Die Anwendung dieser Geräuschmessvorschrift gewährleistet die Reproduzierbarkeit der Bestimmung der

charakteristischen Geräuschemissionswerte innerhalb genau festgelegter Grenzen. Diese Grenzen werden

durch die Genauigkeitsklasse des Geräuschmessverfahrens festgelegt. Geräuschmessungen nach dieser

Norm entsprechen der Genauigkeitsklasse 2 oder der Genauigkeitsklasse 3.

Méthodes de mesurage du bruit émis par les machines d'impression, de transformation, de fabrication et de finition du papier - Classes de précision 2 et 3

La présente Norme spécifie toutes les informations nécessaires pour procéder efficacement et dans des conditions normalisées à la détermination, la déclaration et la vérification des émissions sonores aériennes des machines destinées à l'impression et à la transformation du papier qui font l'objet des séries EN 1010 ainsi que des machines destinées à la fabrication et à la finition du papier traitées par les séries EN 1034. La Norme spécifie les méthodes de mesurage des émissions sonores, ainsi que les conditions de fonctionnement et de montage qui doivent être utilisées lors de l'essai.

La présente Norme s’applique aux machines énumérées dans les annexes normatives A à J. Pour les machines non énumérées dans ces annexes, l’émission sonore doit être autant que possible déterminée selon les principes de ces prescriptions de mesurage du bruit. Dans ce cas, toutes les informations relatives aux conditions d’installation, de montage et de fonctionnement ainsi que l’emplacement des postes de travail doivent être relevées et consignées dans le rapport d’essai.

Les valeurs d'émission sonore comprennent le niveau de pression acoustique d'émission aux postes de travail et le niveau de puissance acoustique. Les valeurs d’émission sonore déclarées permettent de comparer les différentes machines graphiques et papetières en présence sur le marché.

L'utilisation de ce code d'essai acoustique garantit la reproductibilité de la détermination des valeurs d'émission sonore caractéristiques dans des limites spécifiées. Ces limites sont déterminées par la classe de précision de la méthode utilisée pour le mesurage de l'émission sonore. Les méthodes de mesurage acoustique spécifiées par la présente norme sont des méthodes d'expertise (classe 2) et des méthodes de contrôle (classe 3).

Metode za merjenje hrupa pri strojih za tiskanje, obdelavo in izdelavo papirja in dodatni opremi - Razreda točnosti 2 in 3

Ta standard opredeljuje vse informacije, ki so potrebne za učinkovito izvajanje pod opredeljenimi pogoji določevanja, deklariranja in preverjanja emisij hrupa, ki se prenašajo po zraku, pri strojih za tiskanje in obdelavo papirja, ki jih zajema serija EN 1010, ter strojih in opremi za izdelavo papirja, ki jih zajema serija EN 1034. Opredeljuje metode meritve hrupa ter pogoje namestitve in obratovanja, ki se uporabljajo pri preskusu. Ta standard velja za stroje, navedene v normativnih dodatkih od A do J. Načela preskusne kode hrupa je treba uporabljati, kolikor je to mogoče, tudi za določevanje emisij hrupa strojev in delov strojev, ki niso našteti v normativnih dodatkih od A do J. V takih primerih je vse informacije, ki se nanašajo na pogoje sestavljanja, namestitve in obratovanja, kot tudi ureditev delovnih postaj, treba evidentirati in o njih poročati v poročilu o preskusu. Značilnosti emisij hrupa vključujejo ravni emisije zvočnega tlaka na delovnih postajah in raven zvočne moči. Nazivne vrednosti emisij hrupa omogočajo primerjavo strojev za tiskanje in papir na trgu. Uporaba te preskusne kode hrupa zagotavlja obnovljivost določevanja značilnih emisij hrupa znotraj posebnih omejitev. Te omejitve so določene z razredom točnosti uporabljene metode merjenja hrupa. Meritve hrupa, opredeljene v tem standardu, se izvajajo z inženirsko metodo (razred točnosti 2) in metodo analize (razred točnosti 3).

General Information

- Status

- Published

- Publication Date

- 08-Apr-2010

- Technical Committee

- GRT - Graphical technology

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 22-Mar-2010

- Due Date

- 27-May-2010

- Completion Date

- 09-Apr-2010

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 01-May-2010

- Effective Date

- 01-May-2010

Overview

EN 13023:2003+A1:2010 is a CEN noise test code that defines standardized noise measurement methods for printing, paper converting, paper making machines and auxiliary equipment. The standard sets out the information, installation and operating conditions, and reporting requirements needed to determine, declare and verify airborne noise emission for machines covered by the EN 1010 and EN 1034 series. Its scope covers machines listed in normative annexes A–J and recommends applying the same principles to comparable machines not listed.

Key topics

- Noise characteristics measured

- Emission sound pressure levels at work stations

- Sound power level of the machine

- Measurement accuracy grades

- Accuracy grade 2 - engineering method (higher accuracy)

- Accuracy grade 3 - survey method (survey-level measurements)

- Test conditions

- Standardized assembly, installation and operating conditions

- Work-station arrangement and operating points must be recorded

- Data handling

- Information to be recorded during tests and reported in test reports

- Declaration and verification procedures for published noise values

- Measurement uncertainty

- Requirements to determine and state uncertainty limits consistent with the chosen accuracy grade

- Normative annexes A–J

- Detailed machine categories (e.g., printing presses, finishers, converting machines) and machine-specific guidance

Applications

EN 13023 is practical for stakeholders who need reliable, comparable noise data for printing and paper industry equipment:

- Manufacturers and OEMs - to declare machine noise levels for product data sheets and compliance

- Test laboratories and acoustic consultants - for reproducible field and laboratory noise measurements

- Plant engineers and safety officers - to assess workplace noise exposure and plan controls

- Purchasing and specification teams - to compare machines on the market using declared noise emission values

- Regulators and conformity assessors - to verify declared values and support machinery safety directives

Benefits include consistent, reproducible noise data, transparent reporting, and a basis for comparing machines on noise emission performance.

Related standards

- EN 1010 series - printing and paper converting machines (machine safety)

- EN 1034 series - paper making and finishing machines

- Normative references in EN 13023 include standards such as EN ISO 3740 (sound power determination) and EN ISO 216 (paper sizes) where applicable

- Informative annexes link the standard to EU machinery directives (see Annex ZA/ZB)

Keywords: EN 13023, noise measurement, printing machines, paper converting, paper making, sound power level, emission sound pressure level, accuracy grade 2, accuracy grade 3, CEN.

Frequently Asked Questions

SIST EN 13023:2004+A1:2010 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Noise measurement methods for printing, paper converting, paper making machines and auxiliary equipment - Accuracy grades 2 and 3". This standard covers: This standard specifies all the information necessary to carry out efficiently and under standardized conditions the determination, declaration and verification of airborne noise emission from printing and paper converting machines covered by the EN 1010 series and from paper making and finishing machines covered by the EN 1034 series. It specifies noise measurement methods and installation and operating conditions to be used for the test. This standard applies to those machines listed in the normative annexes A to J. The principles of this noise test code should be applied as far as possible also for the determination of noise emission of machines and machine parts not listed in the normative annexes A to J. In such cases, all information relating to assembly, installation and operating conditions as well as the arrangement of work stations should be recorded and reported in the test report. Noise emission characteristics include emission sound pressure levels at work stations and the sound power level. Declared noise emission values permit comparison of printing and paper machines on the market. The use of this noise test code ensures the reproducibility of the determination of the characteristic noise emissions within specific limits. These limits are determined by the accuracy grade of the noise measuring method used. Noise measurements specified by this standard are carried out by the engineering method (accuracy grade 2) and the survey method (accuracy grade 3).

This standard specifies all the information necessary to carry out efficiently and under standardized conditions the determination, declaration and verification of airborne noise emission from printing and paper converting machines covered by the EN 1010 series and from paper making and finishing machines covered by the EN 1034 series. It specifies noise measurement methods and installation and operating conditions to be used for the test. This standard applies to those machines listed in the normative annexes A to J. The principles of this noise test code should be applied as far as possible also for the determination of noise emission of machines and machine parts not listed in the normative annexes A to J. In such cases, all information relating to assembly, installation and operating conditions as well as the arrangement of work stations should be recorded and reported in the test report. Noise emission characteristics include emission sound pressure levels at work stations and the sound power level. Declared noise emission values permit comparison of printing and paper machines on the market. The use of this noise test code ensures the reproducibility of the determination of the characteristic noise emissions within specific limits. These limits are determined by the accuracy grade of the noise measuring method used. Noise measurements specified by this standard are carried out by the engineering method (accuracy grade 2) and the survey method (accuracy grade 3).

SIST EN 13023:2004+A1:2010 is classified under the following ICS (International Classification for Standards) categories: 17.140.20 - Noise emitted by machines and equipment; 37.100.10 - Reproduction equipment; 85.100 - Equipment for the paper industry. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13023:2004+A1:2010 has the following relationships with other standards: It is inter standard links to SIST EN 13023:2004, SIST EN 13023:2004/kFprA1:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13023:2004+A1:2010 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13023:2004+A1:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Geräuschmessverfahren für Druck- und Papierverarbeitungs-, Papierherstellungs- und Ausrüstungsmaschinen - Genauigkeitsklassen 2 und 3Méthodes de mesurage du bruit émis par les machines d'impression, de transformation, de fabrication et de finition du papier - Classes de précision 2 et 3Noise measurement methods for printing, paper converting, paper making machines and auxiliary equipment - Accuracy grades 2 and 385.100Oprema za papirno industrijoEquipment for the paper industry37.100.10Reprodukcijska opremaReproduction equipment17.140.20Emisija hrupa naprav in opremeNoise emitted by machines and equipmentICS:Ta slovenski standard je istoveten z:EN 13023:2003+A1:2010SIST EN 13023:2004+A1:2010en,fr01-maj-2010SIST EN 13023:2004+A1:2010SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13023:2003+A1

March 2010 ICS 17.140.20; 37.100.10; 85.100 Supersedes EN 13023:2003English Version

Noise measurement methods for printing, paper converting, paper making machines and auxiliary equipment - Accuracy grades 2 and 3

Méthodes de mesurage du bruit émis par les machines d'impression, de transformation, de fabrication et de finition du papier - Classes de précision 2 et 3

Geräuschmessverfahren für Druck- und Papierverarbeitungs-, Papierherstellungs- und Ausrüstungsmaschinen - Genauigkeitsklassen 2 und 3 This European Standard was approved by CEN on 25 March 2003 and includes Amendment 1 approved by CEN on 7 February 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13023:2003+A1:2010: ESIST EN 13023:2004+A1:2010

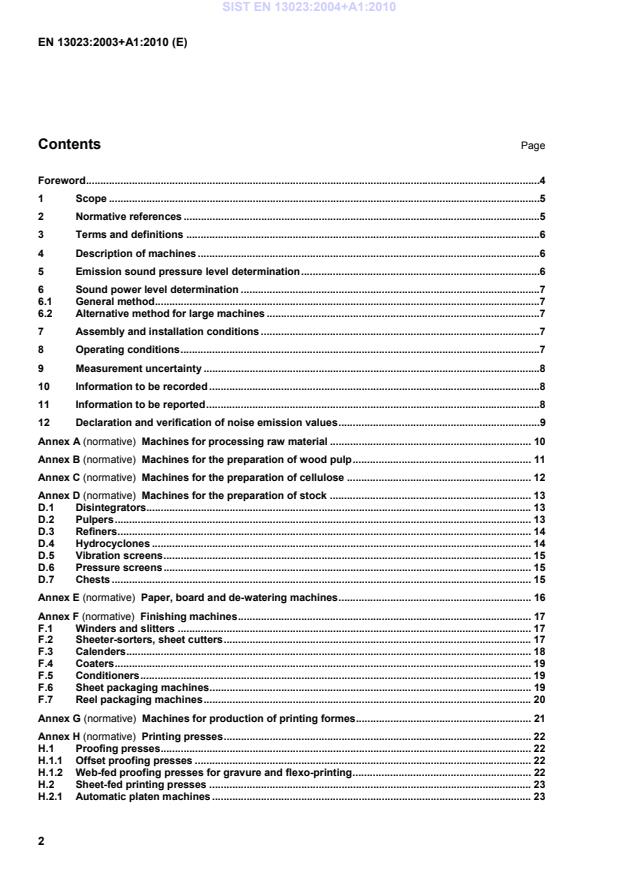

Machines for processing raw material . 10Annex B (normative)

Machines for the preparation of wood pulp . 11Annex C (normative)

Machines for the preparation of cellulose . 12Annex D (normative)

Machines for the preparation of stock . 13D.1Disintegrators . 13D.2Pulpers . 13D.3Refiners . 14D.4Hydrocyclones . 14D.5Vibration screens . 15D.6Pressure screens . 15D.7Chests . 15Annex E (normative)

Paper, board and de-watering machines . 16Annex F (normative)

Finishing machines . 17F.1Winders and slitters . 17F.2Sheeter-sorters, sheet cutters . 17F.3Calenders . 18F.4Coaters . 19F.5Conditioners . 19F.6Sheet packaging machines . 19F.7Reel packaging machines . 20Annex G (normative)

Machines for production of printing formes . 21Annex H (normative)

Printing presses . 22H.1Proofing presses. 22H.1.1Offset proofing presses . 22H.1.2Web-fed proofing presses for gravure and flexo-printing . 22H.2Sheet-fed printing presses . 23H.2.1Automatic platen machines . 23SIST EN 13023:2004+A1:2010

Paper converting machines . 26J.1Bundling machines . 26J.2Bending and folding machines . 27J.2.1Bending, scoring and creasing machines rotary bending, grooving and buckling machines, scoring and creasing machines . 27J.2.2Sheet-fed folding machines . 27J.2.3Folding machines for sanitary items (web-fed) . 29J.3Binding and finishing machines . 29J.3.1Stitching, corner staying and inserting machines . 29J.3.2Collating, web joining and inserting machines . 30J.4Gluing machines and equipment . 32J.4.1Gluing machines, gluing equipment and auxiliary equipment for paper converting . 32J.4.2Gluing machines, gluing equipment and auxiliary equipment for cardboard processing . 33J.4.3Gluing machines, gluing equipment and auxiliary equipment for book production. 33J.5Paper bag, sack and envelope making machines for paper and foil . 34J.6Presses . 36J.6.1Presses for book binding . 36J.6.2Forming presses for paper, board and foil . 36J.7Cutting machines . 37J.7.1Sheet-fed cutting machines . 37J.7.2Rotary cutters . 38J.7.3Toilet paper winding machine, tissue winding machine . 38J.7.4Cutting machines for book making and paper, cardboard and foil processing . 39J.8Punching machines . 40J.8.1Punching machines for book production . 40J.8.2Punching machines for paper and cardboard converting . 40J.9Coating, finishing and drying equipment for paper, board and foil . 47J.9.1Coating and finishing machines . 47J.9.2Continuous flow dryers for paper, board and foil . 48J.10Corrugated board production machines . 49J.11Auxiliary equipment . 50J.11.1Pile processing machines . 50J.11.2Tube processing and finishing machines . 50J.11.3Jogging machines . 51J.11.4Bridging machines . 51J.11.5Back rounding machines . 52J.11.6Paper drills . 52J.12Production lines and equipment for production of school and office stationery . 53J.12.1Exercise book production lines . 53J.13Shredders for paper and cardboard . 53Annex ZA (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC" . 54Annex ZB (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC" . 55Bibliography . 56 SIST EN 13023:2004+A1:2010

This standard applies to those machines listed in the normative annexes A to J. The principles of this noise test code should be applied as far as possible also for the determination of noise emission of machines and machine parts not listed in the normative annexes A to J. In such cases, all information relating to assembly, installation and operating conditions as well as the arrangement of work stations should be recorded and reported in the test report. Noise emission characteristics include emission sound pressure levels at work stations and the sound power level. Declared noise emission values permit comparison of printing and paper machines on the market. The use of this noise test code ensures the reproducibility of the determination of the characteristic noise emissions within specific limits. These limits are determined by the accuracy grade of the noise measuring method used. Noise measurements specified by this standard are carried out by the engineering method (accuracy grade 2) and the survey method (accuracy grade 3). 2 Normative references !The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies." !deleted text" !EN ISO 216:2007, Writing paper and certain classes of printed matter — Trimmed sizes — A and B series, and indication of machine direction (ISO 216:2007)" !EN ISO 3740:2000, Acoustics — Determination of sound power levels of noise sources — Guidelines for the use of basic standards (ISO 3740:2000)" EN ISO 3744:1994, Acoustics — Determination of sound power levels of noise sources using sound pressure — Engineering method in an essentially free field over a reflecting plane (ISO 3744:1994) EN ISO 3746:1995, Acoustics — Determination of sound power levels of noise sources using sound pressure — Survey method using an enveloping measurement surface over a reflecting plane for accuracy grade 3 (ISO 3746:1995) EN ISO 4871:1996, Acoustics — Declaration and verification of noise emission values of machinery and equipment (ISO 4871:1996) EN ISO 9614-1:1995, Acoustics — Determination of sound-power levels of noise sources using sound intensity — Part 1: Measurement at discrete points (ISO 9614-1:1993) EN ISO 9614-2:1996, Acoustics — Determination of sound-power levels of noise sources using sound intensity — Part 2: Measurement by scanning (ISO 9614-2:1996) EN ISO 11200:1995, Acoustics — Noise emitted by machinery and equipment — Guidelines for the use of basic standards for the determination of emission sound pressure levels at a work station and at other specified positions (ISO 11200:1995) SIST EN 13023:2004+A1:2010

(ISO 11203:1995) EN ISO 11204:1995, Acoustics — Noise emitted by machinery and equipment — Measurement of emission sound pressure levels at a work station and at other specified positions — Method requiring environmental corrections (ISO 11204:1995) 3 Terms and definitions For the purposes of this Error! Reference source not found., the following term and definition applies in addition to the definitions given in the basic standards for the determination of emission sound pressure levels at work stations and other specified positions (EN ISO 11200:1995, EN ISO 11202:1995, EN ISO 11203:1995 and EN ISO 11204:1995) and in the basic standards for the determination of sound power levels (EN ISO 3740:2000, EN ISO 3744:1995, EN ISO 3746:1995 and EN ISO 9614-1:1995 and ISO 9614-2:1996). 3.1 large machines large machines within the meaning of this standard are machines where the greatest linear dimension exceeds 15 m 4 Description of machines The machines described in this standard include the equipment or parts covered by the normative annexes A to J or as described in the measurement reports, which contribute significantly to noise emission. For machines not listed in the normative annexes A to J, a description of auxiliary devices shall be provided where these devices are required for the correct operation of the machines and are therefore subject to the noise measurement methods. 5 Emission sound pressure level determination The measuring points for determining the emission sound pressure level at work stations and other specified positions are defined in the normative annexes A to J. All microphone positions are at a height of 1,6 m above the floor or access level.

Emission sound pressure levels shall be determined in accordance with EN ISO 11204 (with accuracy grade 2). Where this standard is not applicable, EN ISO 11204 (with accuracy grade 3) or EN ISO 11202:1995 shall be applied. The test report shall state the reasons why it was not possible to apply a grade 2 method. Where measuring is made difficult due to strong environmental influences such as sound reflections from walls and high levels of noise from other sources, EN ISO 11203 (with accuracy grades 2 or 3) may be applied if the sound power level has been determined in accordance with EN ISO 9614-1 or EN ISO 9614-2. Where emission sound pressure levels are determined in frequency bands, EN ISO 11204 shall be applied. The work station should preferably be used as the measuring point or, if this cannot be defined, the point with the highest sound pressure level measured at a distance of 1 m from the machine surface and at a height of 1,6 m above the floor or access level. !The C-weighted peak emission sound pressure level (LpCpeak) shall be determined where this exceeds 63 Pa (130 dB in relation to 20 µPa)." SIST EN 13023:2004+A1:2010

Such measuring points are specified along a path around the machine at a height of 1,6 m above the floor or access level and at a distance of 1 m from the machine. They shall be spaced so that the difference in emission sound pressure levels between adjacent points does not exceed 5 dB(A). NOTE Where the emission sound pressure levels around the machine vary by less than 5 dB e.g. when the sound radiation is very uniform, measurements should be made at 4 characteristic positions at least. For determining the emission sound pressure level, the method described in clause 5 shall be used.

7 Assembly and installation conditions The machine shall be assembled and installed in accordance with the manufacturer's instructions. If the conditions of installation are not known or if several modes of installation are possible, the type of installation used for noise measurement shall be specified in the test report. The assembly and installation conditions of the machine shall be identical for determining both sound power levels and also emission sound pressure levels at the measuring points specified in the normative annexes A to J.

Care shall be taken that any electrical connections, piping or air ducts connected to the machine do not significantly increase noise emission. 8 Operating conditions Operating conditions with significant noise emission are stipulated in the normative annexes A to J. Operating conditions shall be identical for determining both the emission sound pressure level at the specified measuring points and also the sound power level. Where there are no operating conditions defined in the normative annexes A to J, it is understood that operating conditions with significance for noise emission do not exist. If the operating conditions specified in the annexes cannot be adhered to partly or completely, the operating conditions that differ shall be recorded and documented in the test report. There are basically two different types of operating conditions: a) Where the normal running of the machine leads to a constant noise emission, this operating condition shall be used for noise measurements. b) For variable operating conditions, either one or more typical operating conditions or one characteristic work cycle comprising, amongst other things, the time required for converting and finishing the product (printed sheet, folded box, book block etc.) shall be defined. SIST EN 13023:2004+A1:2010

a) type, classification and technical data, dimensions, as well as manufacturer, machine serial number and year of manufacture of the machine tested; b) any installation and operating conditions relevant to noise emission during the test (see clauses 7 and 8) that are not specified in the normative annexes A to J; c) basic standards applied for the determination of the noise emission (see clauses 5 and 6), giving, where applicable, reasons for not using accuracy grade 2 methods; d) measurement results emission sound pressure level at work station LpA and other specified positions if required, A-weighted sound power level LWA or emission sound pressure level LpA on a measuring path according to 6.2 if required, impulse noise index according to EN ISO 11204 at measuring points if required, LpCpeak at measuring points if required, emission sound pressure level in frequency bands when work cycles are split into subcycles, measuring results shall be provided for each subcycle. SIST EN 13023:2004+A1:2010

f) place, date and person responsible for test. 12 Declaration and verification of noise emission values The declaration of the noise emission values is the sole responsibility of the manufacturer or his appointed representative. The method for noise declaration described in EN ISO 4871 shall be applied using the dual number declaration (see annex B.2 of EN ISO 4871:1996). If machine-specific values for the uncertainty K are unavailable, respective values shall be taken from A 2.2 of EN ISO 4871:1996, i.e. KpA = KWA = 2,5 dB for grade 2 and KpA = KWA = 4 dB for grade 3 measurements. The noise declaration shall mention explicitly the fact that the noise emission values have been obtained in accordance with the machine-specific noise test code and indicate which standards have been used. Any deviation from the noise test code shall be clearly indicated in the declaration. The method used and the grade of accuracy attained shall be stated. The noise designation shall contain the following information: the term "noise test " the EN number the letters and numbers identifying the relevant normative annex applied the grade of accuracy attained ("grade" 2 or 3). EXAMPLE Designation for a noise test carried out in accordance with this standard, annex H.2.2, accuracy grade 2: Noise test EN 13023 H.2.2 – Grade 2 Verification shall be carried out as far as possible using the same assembly and installation and operating conditions and with the machine in a condition comparable to the one used for the initial determination of noise emission values. It shall be carried out in accordance with EN ISO 4871. NOTE Additional noise emission data such as sound power levels in octave bands may also be given in the noise declaration. In this case, care should be taken to present additional noise emission data in such a form as to prevent confusion with the declared noise emission values. SIST EN 13023:2004+A1:2010

Machines for processing raw material Barking drums Operating condition of machine Filling degree Position of outlet weir with 60 % to 70 % of front side Measuring point(s) at work station(s) and other specified positions Arrangement Delivery side: 3 m from centre of front side (fixed work station not defined) Additional technical data Machine data — length in m and

— diameter in mm and — inclination angle of drum in ° — type of drum bearing: steel rollers and/or

rubber rollers otherwise: to be specified — barking drums type of barking drums and arrangement of barking drums — speed in rev/min with above filling degree Material processed — type and length of logs — diameter range of logs

Machines for the preparation of wood pulp Wood grinders Operating condition of machine Tool Sharpening of grinding tool: optimum Water jet pressure 10 bar Measuring point(s) at work station(s) and other specified positions Arrangement — press grinder: 1 m in front of charging point — continuous grinder: 1 m from centre of discharging point Additional technical data Machine data — stone dimensions diameter in m and width in m — circumferential speed in m/s — specification of wood density — power specification — date of last sharpening of stone Material processed — type of wood SIST EN 13023:2004+A1:2010

Machines for the preparation of cellulose Pulp digesters with chip inlet Operating condition of machine Performance Nominal performance Measuring point(s) at work station(s) and other specified positions Arrangement 1 m in front of charging point Additional technical data Machine data — volume of digester in m3 — type of charging unit — specification of individual blow-in vapour throughput in tonnes per hour — charging time in min

Machines for the preparation of stock D.1 Disintegrators Operating condition of machine Performance Nominal performance Material processed Type of fibres: as required Measuring point(s) at work station(s) and other specified positions Arrangement 1 m in front of centre of charging point Additional technical data Machine data — type of digester single-shaft digester or double-shaft digester — nominal throughput in tonnes per day — individual power input rate in kW at nominal throughput — stock density (percentage of dry fibres)

D.2 Pulpers Operating condition of machine Performance Nominal performance Material processed Type of fibres: as required

Measuring point(s) at work station(s) and other specified positions Arrangement Measuring points: 1 m in front of centre of charging point and 1 m in front of centre of control desk Additional technical data Machine data — type of shredding: horizontal or vertical — nominal volume in m3 — diameter of vessel in m — type of operation: continuous or intermittent — throughput in tonnes per day — stock density (discharge density) (percentage of dry fibres)

D.4 Hydrocyclones Operating condition of machine Performance Nominal performance Measuring point(s) at work station(s) and other specified positions Arrangement 1 m in front of charging head Additional technical data Machine data — number of hydrocyclone units — head diameter in mm — nominal throughput in l/min — type of trash discharge open or closed and continuous or intermittent — input and output pressure difference — type of stock

— stock density (percentage of dry fibres)

D.6 Pressure screens Operating condition of machine Performance Nominal performance Measuring point(s) at work station(s) and other specified positions Arrangement 1 m from housing (fixed workstation not defined) Additional technical data Machine data — type of screen revolving screen and/or revolving wings — speed in rev/min under nominal load — nominal throughput in tonnes per day

D.7 Chests Operating condition of machine Filling degree — 60 % to 80 % of usable capacity — operation of circulating unit under nominal load Material processed Type of fibres: as required Measuring point(s) at work station(s) and other specified positions Arrangement 1 m in front of mover drive Additional technical data Machine data — usable capacity in m3 — type of chest steel or concrete or wood — type of circulation number of wings and diameter of wing circle and speed in rev/min under nominal load SIST EN 13023:2004+A1:2010

Paper, board and de-watering machines Operating condition of machine Operating conditions as agreed between manufacturer and user Measuring point(s) at work station(s) and other specified positions Arrangement Measuring path according to 5.2 Additional technical data Sheet production — wire width in mm — de-watering elements of wire section foils or suction units or guide rollers Sheet delivery Pick-up Press section — number of presses — type of presses — type of felt conditioning Drier section — type of drive — number of drying cylinders — number of smoothing cylinders — smoothing unit Size press — number of scrapers — type of ventilation Winding section — centre-driven roller — pope reeler Machine data — machine speed m/min maximum and minimum — weight that can be produced in g/m² maximum and minimum SIST EN 13023:2004+A1:2010

Finishing machines F.1

Winders and slitters Operating condition of machine Speed 80 % of maximum speed Web width Maximum Remarks Trim suction in operation Measuring point(s) at work station(s) and other specified positions Arrangement 1 m in front of machine frame on the longitudinal centre line and 1 m in front of centre of control desk Additional technical data Machine data — type of drive electric or hydraulic — maximum width of web in mm — maximum operating speed in m/min — type of trim suction — surface of supporting rollers — type of unwinding unit — type of rewinding unit — type of slitting unit — number of slitting operations

F.2

Sheeter-sorters, sheet cutters Operating condition of machine Speed 80 % of maximum speed Format size — maximum web width — variable format machines: format length approx 2/3 of the maximum format length Tool — knives sharpened — knife adjustment: optimum Remarks Trim suction in operation Measuring point(s) at work station(s) and other specified positions Arrangement Operator's side: 1 m in front of front side of cross knives and 1 m in front of centre of control desk and 1 m in front of centre of sheet delivery unit SIST EN 13023:2004+A1:2010

F.3

Calenders Operating condition of machine Speed 80 % of maximum speed Web width Maximum Remarks Condition of rollers: optimum Measuring point(s) at work station(s) and other specified positions Arrangement 1 m in front of centre of control desk Additional technical data Machine data — maximum operating speed in m/min — maximum width of web in mm — type of drive — number of rollers — roller material — type of unwinding unit — type of rewinding unit

Coaters Operating condition of machine Operating conditions as agreed between manufacturer and user Measuring point(s) at work station(s) and other specified positions Arrangement Measuring path according to 5.2 Additional technical data Machine data — maximum operating speed in m/min — type of drive

— maximum width of web in mm — type of coating system — number of coating units — type of drying unit — type of unwinding unit — type of rewinding unit

F.5

Conditioners Operating condition of machine Speed 80 % of maximum speed Web width Maximum Measuring point(s) at work station(s) and other specified positions Arrangement 1 m in front of centre of rewinding station Additional technical data Machine data — maximum operating speed in m/min — maximum width of web in mm

F.6

Sheet packaging machines Operating condition of machine Performance — maximum format at maximum operating speed Measuring point(s) at work station(s) and other specified positions Arrangement 1 m in front of centre of packaging table Additional technical data Machine data — type of feeding and delivery units: semi-automatic or fully automatic — operating speed

Reel packaging machines Operating condition of machine Performance Supporting rollers in operation Measuring point(s) at work station(s) and other specified positions Arrangement 1 m in front of centre of reel Additional technical data Machine data — maximum reel diameter in mm — maximum width of web in mm — maximum packaging capacity in reels/h for maximum reel diameter SIST EN 13023:2004+A1:2010

Machines for production of printing formes Embossing and vulcanising presses Operating condition of machine Speed 80 % of maximum speed

Format size Maximum Embossing pressure Maximum Measuring point(s) at work station(s) and other specified positions Arrangement Centre of control desk; 0,5 m in front of control desk SIST EN 13023:2004+A1:2010

Printing presses H.1 Proofing presses H.1.1 Offset proofing presses Operating condition of machine Speed 80 % of maximum speed Size of substrate Maximum Printing forme — text and pictures — maximum format

Remarks — all inking units running — auxiliary equipment in operation Measuring point(s) at work station(s) and other specified positions Arrangement Centre of control desk; 0,5 m in front of control desk

H.1.2 Web-fed proofing presses for gravure and flexo-printing Operating condition of machine Speed 80 % of maximum speed Size of substrate At least 80 % of maximum web width Remarks — all auxiliary equipment in operation — all inking units under ink running Measuring point(s) at work station(s) and other specified positions Arrangement Unwinding unit: centre of unwinding unit; 0,5 m in front of max. reel diameter Control desk: centre of control desk; 0,5 m in front of control desk Delivery unit: centre of delivery unit; 0,5 m behind delivery unit

— text and pictures Remarks All auxiliary equipment in operation Measuring point(s) at work station(s) and other specified positions Arrangement Centre of machine; 0,5 m in front of machine

H.2.2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...