SIST EN 17267:2019

(Main)Energy measurement and monitoring plan - Design and implementation - Principles for energy data collection

Energy measurement and monitoring plan - Design and implementation - Principles for energy data collection

This document specifies the requirements and principles for the design and implementation of an energy measurement and monitoring plan for an organization in order to improve its energy performance. The measurement and monitoring plan defines a measurement system for monitoring and analysing the energy performance of an organization, taking into account its influencing factors.

This document applies to all forms of energy, to all energy uses and to all types of organizations. It does not apply to domestic dwellings.

Plan für die Energiemessung und -überwachung für Organisationen - Gestaltung und Umsetzung

Dieses Dokument legt die Anforderungen und Grundsätze für die Gestaltung und Umsetzung eines Plans für die Energiemessung und -überwachung für eine Organisation fest, um deren energiebezogene Leistung zu verbessern. Der Mess- und Überwachungsplan definiert ein Messsystem für die Überwachung und Analyse der energiebezogenen Leistung einer Organisation unter Berücksichtigung ihrer Einflussfaktoren.

Dieses Dokument gilt für sämtliche Energiearten, für sämtliche Energieeinsätze sowie für sämtliche Orga-nisationstypen. Es gilt nicht für Wohngebäude.

Plan de mesure et de surveillance de l'énergie - Conception et mise en oeuvre - Principes pour la collecte des données énergétiques

Le présent document spécifie les exigences et la méthodologie de conception et de mise en oeuvre d’un plan de mesure et de surveillance de l’énergie pour permettre à un organisme d’améliorer sa performance énergétique. Le plan de mesure et de surveillance de l’énergie définit un système de mesure pour la surveillance et l’analyse de la performance énergétique d’un organisme, en tenant compte des facteurs qui influent sur son fonctionnement.

Le présent document s’applique à toutes les formes d’énergie, à tous les usages énergétiques et à tous les types d’organisme. Elle ne s'applique pas aux locaux d'habitation.

Načrt za merjenje in nadzorovanje energije - Načrtovanje in izvajanje - Načela za zbiranje podatkov o energiji

Ta standard določa zahteve in metodologijo za načrtovanje ter izvajanje načrta za merjenje energije za organizacijo, da se izboljša njena energetska učinkovitost. Načrt določa merilni sistem za nadzorovanje in analiziranje energetske učinkovitosti organizacije, pri tem pa upošteva dejavnike, ki vplivajo na njeno delovanje.

Ta standard se uporablja za vse oblike energije, vse rabe energije in vse vrste organizacij. Ne uporablja se za stanovanjske zgradbe.

General Information

- Status

- Published

- Public Enquiry End Date

- 31-Aug-2018

- Publication Date

- 12-Sep-2019

- Technical Committee

- I11 - Imaginarni 11

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 06-Sep-2019

- Due Date

- 11-Nov-2019

- Completion Date

- 13-Sep-2019

Overview

EN 17267:2019 - "Energy measurement and monitoring plan - Design and implementation - Principles for energy data collection" (CEN) specifies requirements and principles for designing and implementing an energy measurement and monitoring plan. The standard defines how to set up a measurement system to monitor and analyse an organisation’s energy performance, taking into account influencing factors (relevant variables and static factors). It applies to all forms of energy and energy uses across all types of organisations (except domestic dwellings).

Key Topics

- Purpose and scope of a measurement and monitoring plan within an Energy Management System (EnMS).

- Definitions and terminology: measurement system, measurement point, metering, monitoring, EnPI (energy performance indicator), EnB (energy baseline), influencing factors.

- Measurement system components: measuring devices, time-stamped recording, data utilisation and information architecture (see annexes).

- Design and lifecycle stages: the standard structures the plan into stages (define context/objectives, assess existing situation, prioritise improvements, implement, use data, maintain the system).

- Data quality and metrology: concepts of measurement accuracy, repeatability, precision and metrological maintenance (informative annexes).

- Topological and functional considerations: zoning, levels of measurement, examples for sectors, and recommended information flows.

- Integration with energy performance management: how measurement supports EnPIs, EnBs and decision-making for energy performance improvement.

Applications

EN 17267:2019 is practical guidance for organisations seeking reliable energy data to:

- Establish or improve an energy measurement and monitoring plan.

- Support ISO 50001 EnMS requirements for data collection, EnPIs and EnBs.

- Ensure data quality for energy audits, measurement & verification (M&V) and energy efficiency services.

Who uses it:

- Energy managers and EnMS teams

- Facility and operations managers

- Energy consultants, auditors and auditors conducting EN 16247 energy audits

- ESCOs and energy services providers

- Instrumentation and building automation integrators

Related Standards

- ISO 50001:2018 (Energy management systems) - referenced for EnMS context.

- ISO 50006:2014 (EnPI/EnB guidance) - related guidance on baselines and indicators.

- ISO 50015:2014 (Measurement & verification) - M&V processes that rely on measurement plans.

- EN 16247-1 and EN 15900 - energy audits and energy efficiency services where measurement plans support data needs.

EN 17267:2019 is a practical, CEN-approved resource for organisations and professionals implementing robust energy data collection and measurement systems to drive validated energy performance improvements.

Frequently Asked Questions

SIST EN 17267:2019 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Energy measurement and monitoring plan - Design and implementation - Principles for energy data collection". This standard covers: This document specifies the requirements and principles for the design and implementation of an energy measurement and monitoring plan for an organization in order to improve its energy performance. The measurement and monitoring plan defines a measurement system for monitoring and analysing the energy performance of an organization, taking into account its influencing factors. This document applies to all forms of energy, to all energy uses and to all types of organizations. It does not apply to domestic dwellings.

This document specifies the requirements and principles for the design and implementation of an energy measurement and monitoring plan for an organization in order to improve its energy performance. The measurement and monitoring plan defines a measurement system for monitoring and analysing the energy performance of an organization, taking into account its influencing factors. This document applies to all forms of energy, to all energy uses and to all types of organizations. It does not apply to domestic dwellings.

SIST EN 17267:2019 is classified under the following ICS (International Classification for Standards) categories: 03.100.01 - Company organization and management in general; 27.010 - Energy and heat transfer engineering in general. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 17267:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2019

Načrt za merjenje in nadzorovanje energije - Načrtovanje in izvajanje - Načela za

zbiranje podatkov o energiji

Energy measurement and monitoring plan - Design and implementation - Principles for

energy data collection

Plan für die Energiemessung und -überwachung für Organisationen - Gestaltung und

Umsetzung

Plan de mesure et de surveillance de l'énergie - Conception et mise en oeuvre -

Principes pour la collecte des données énergétiques

Ta slovenski standard je istoveten z: EN 17267:2019

ICS:

03.100.01 Organizacija in vodenje Company organization and

podjetja na splošno management in general

27.010 Prenos energije in toplote na Energy and heat transfer

splošno engineering in general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN 17267

NORME EUROPÉENNE

EUROPÄISCHE NORM

August 2019

ICS 27.010

English version

Energy measurement and monitoring plan - Design and

implementation - Principles for energy data collection

Plan de mesure et de surveillance de l'énergie - Plan für die Energiemessung und -überwachung für

Conception et mise en oeuvre - Principes pour la Organisationen - Gestaltung und Umsetzung

collecte des données énergétiques

This European Standard was approved by CEN on 12 May 2019.

CEN and CENELEC members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for

giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical

references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to

any CEN and CENELEC member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN and CENELEC member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN and CENELEC members are the national standards bodies and national electrotechnical committees of Austria, Belgium,

Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy,

Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North Macedonia, Romania, Serbia,

Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

CEN-CENELEC Management Centre:

Rue de la Science 23, B-1040 Brussels

© 2019 CEN/CENELEC All rights of exploitation in any form and by any means Ref. No. EN 17267:2019 E

reserved worldwide for CEN national Members and for

CENELEC Members.

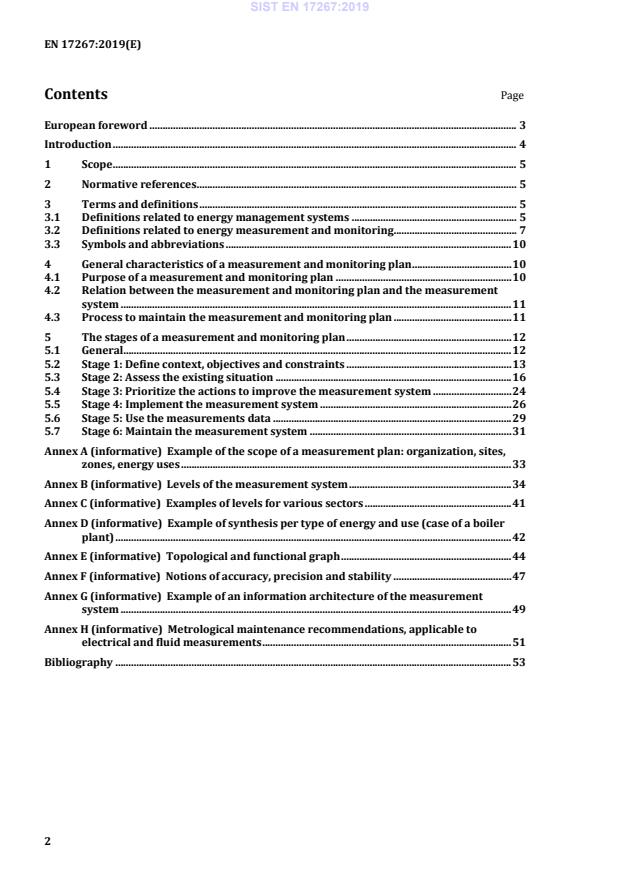

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

3.1 Definitions related to energy management systems . 5

3.2 Definitions related to energy measurement and monitoring . 7

3.3 Symbols and abbreviations . 10

4 General characteristics of a measurement and monitoring plan . 10

4.1 Purpose of a measurement and monitoring plan . 10

4.2 Relation between the measurement and monitoring plan and the measurement

system . 11

4.3 Process to maintain the measurement and monitoring plan . 11

5 The stages of a measurement and monitoring plan . 12

5.1 General. 12

5.2 Stage 1: Define context, objectives and constraints . 13

5.3 Stage 2: Assess the existing situation . 16

5.4 Stage 3: Prioritize the actions to improve the measurement system . 24

5.5 Stage 4: Implement the measurement system . 26

5.6 Stage 5: Use the measurements data . 29

5.7 Stage 6: Maintain the measurement system . 31

Annex A (informative) Example of the scope of a measurement plan: organization, sites,

zones, energy uses . 33

Annex B (informative) Levels of the measurement system . 34

Annex C (informative) Examples of levels for various sectors . 41

Annex D (informative) Example of synthesis per type of energy and use (case of a boiler

plant) . 42

Annex E (informative) Topological and functional graph . 44

Annex F (informative) Notions of accuracy, precision and stability . 47

Annex G (informative) Example of an information architecture of the measurement

system . 49

Annex H (informative) Metrological maintenance recommendations, applicable to

electrical and fluid measurements . 51

Bibliography . 53

European foreword

This document (EN 17267:2019) has been prepared by CEN/CLC/JTC 15 “Energy measurement plan for

organizations”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by January 2020, and conflicting national standards shall

be withdrawn at the latest by January 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands,

Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

the United Kingdom.

Introduction

Existing energy management standards often refer to the measurement of energy as an important

improvement of energy performance, but do not detail how a measurement and monitoring plan should

be designed and implemented:

— EN 16247-1:2012, Energy audits: in specific cases an energy audit requires to get specific data

measurement (§ 5-2 b) 5-3, 5-5). An energy measurement plan has to be set up in order to collect

this data. But there are no guidelines given on how to design or implement an energy measurement

plan: The future standard will help to fulfil this step;

— EN 15900:2010, Energy Efficiency Services: the energy efficiency service has to be based on collected

data (4-1 b). If there is not available or reliable data an energy measurement plan is needed;

— ISO EN 50001:2018 states in 6-6: "The organization shall define and implement an energy data

collection plan appropriate to its size, its complexity, its resources and its measurement and

monitoring equipment. The plan shall specify the data necessary to monitor the key characteristics

and state how and at what frequency the data shall be collected and retained." EN 17267 provides

principles for the design and implementation of an energy data collection plan;

— ISO 50006:2014, "Energy management systems — Measuring energy performance using energy

baselines (EnB) and energy performance indicators (EnPI) — General principles and guidance",

provides some recommendation related to measurement (§ 4.2.6.2);

— ISO EN 50015:2014, describes the process of "Measurement and verification" (M & V) to help

organizations determine and validate in a systematic way the improvement of its energy

performance, within specified boundaries. As can be seen in Clause 5.2 [h) k) l) m)], the M&V process

relies upon a number of measurements, without giving the methodology on how to organize the

measurement. To ensure the quality of these measurements (reliability, accuracy as well as

appropriateness) a "measurement plan" is needed.

The measurement and monitoring plan should be considered as a tool to facilitate the operational

implementation of those cited standards.

1 Scope

This document specifies the requirements and principles for the design and implementation of an energy

measurement and monitoring plan for an organization in order to improve its energy performance. The

measurement and monitoring plan defines a measurement system for monitoring and analysing the

energy performance of an organization, taking into account its influencing factors.

This document applies to all forms of energy, to all energy uses and to all types of organizations. It does

not apply to domestic dwellings.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 50001:2018, Energy management systems — Requirements with guidance for use

ISO 50006:2014, Energy management systems — Measuring energy performance using energy baselines

(EnB) and energy performance indicators (EnPI) — General principles and guidance

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 Definitions related to energy management systems

3.1.1

energy management system

EnMS

set of interrelated or interacting elements of an organization to establish an energy policy, objectives,

energy targets, action plans, and process(es) to achieve the objectives and energy targets

[SOURCE: ISO 50001:2018]

3.1.2

energy performance indicator

EnPI

measure or unit of energy performance, as defined by the organization

Note 1 to entry: EnPI(s) can be expressed by using a simple metric, ratio, or a model.

Note 2 to entry: See ISO 50006 for additional guidance.

[SOURCE: ISO 50001:2018]

3.1.3

energy performance improvement

improvement in measurable results of energy efficiency, or energy consumption related to energy use,

compared to the energy baseline

[SOURCE: ISO 50001:2018]

3.1.4

energy baseline

EnB

quantitative reference(s) providing a basis for comparison of energy performance

Note 1 to entry: An energy baseline is based on data from a specified period of time and/or conditions, as defined

by the organization.

Note 2 to entry: One or more energy baselines are used for determination of energy performance improvement, as

a reference before and after, or with and without implementation of energy performance improvement actions.

Note 3 to entry: See ISO 50015 for additional information on measurement and verification of energy performance.

Note 4 to entry: See ISO 50006 for additional information on EnPIs and EnBs.

3.1.5

energy management team

person(s) with responsibility and authority for effective implementation of an energy management

system and for delivering energy performance improvement

[SOURCE: ISO 50001:2018 modified:note 1 was deleted]

3.1.6

relevant variable

quantifiable factor that impacts energy performance and routinely changes

EXAMPLE Weather condition, operating condition (indoor temperature, light level), working hours,

production throughput.

[SOURCE ISO 50001:2018]

3.1.7

static factor

identified factor that impacts energy performance and doesn’t routinely change

EXAMPLE 1 Examples of static factors can include facility size, design of installed equipment. To be completed.

EXAMPLE 2 A example of a change in static factor could be a change in a manufacturing process raw material

from aluminium to plastic and may lead to a non-routine adjustment.

[SOURCE ISO 50001:2018]

3.1.8

influencing factor

factor that has an influence on energy performance, either a relevant variable or a static factor

3.1.9

boundary

physical or site limits and/or organizational limits as defined by the organization

[SOURCE: ISO 50001:2018]

3.1.10

significant energy use

energy use accounting for substantial energy consumption and/or offering considerable potential for

energy performance improvement

[SOURCE ISO 50001:2018]

3.2 Definitions related to energy measurement and monitoring

3.2.1

measurement

process that consists in physically obtaining one or more values which can be reasonably assigned to a

quantity

Note 1 to entry: Measurements do not apply to qualitative properties.

Note 2 to entry: A measurement implies the comparison of quantities, including the counting of entities.

[SOURCE: ISO/IEC GUIDE 99:2007, modified. Deletion of the NOTE 3]

3.2.2

device

material element or assembly of such elements intended to perform a required function

Note 1 to entry: to entry: A device may form part of a larger device.

[SOURCE: ISO/IEC GUIDE 99:2007]

3.2.3

measuring device

device intended to be used for taking measurements, alone or combined with one or more auxiliary

devices

[SOURCE: ISO/IEC GUIDE 99:2007]

3.2.4

measurement point

location of the sensing function(s) of a measuring device

3.2.5

measurement system

set of measuring devices, means of reading and recording time-stamped values resulting from the

measurement, and the means of utilizing these values

[SOURCE: ISO/IEC GUIDE 99:2011, modified. Deletion of the qualifier “complete”. Replacement of

“measuring instruments” by “measuring devices”. Replacement of “other equipment” by “means of

time-stamped reading and recording and means of utilizing these values”]

3.2.6

measurement and monitoring plan

all tasks organized in time including the design, setting up, utilization, maintenance and improvement of

a measurement system and its monitoring functions

3.2.7

metering

continuous integration of quantities measured as a function of time

Note 1 to entry: The integration can be carried out on a measurement of active or reactive electrical power, flow of

fluid, number of parts, etc.

3.2.8

monitoring

determining the status of a system, a process or an activity

Note 1 to entry: To determine the status, there can be a need to check, supervise or critically observe.

Note 2 to entry: In an energy management system monitoring can be a review of energy data.

[SOURCE: ISO 50001:2018]

3.2.9

installation monitoring

continuous assessment of the installation in order to ensure availability and reliability of energy flows as

well as the performance and the durability of the installation

Note 1 to entry: Installation monitoring can reveal malfunctions that affect energy performance. To facilitate

monitoring, thresholds and alarms can be put in place on the parameters to be monitored.

EXAMPLES In the case of steam production: outgoing pressure, quality of the make-up water, etc. or to monitor

an electrical installation: power factor, voltage, and harmonics, etc.

Note 2 to entry: This technical concept is complementary to the concept of monitoring as defined in ISO 50001 (see

3.2.8)

3.2.10

parameter to monitor

parameter that is not directly related to energy but which can influence the energy distribution and

energy performance in an installation

EXAMPLE Level of harmonics or power factor in an electrical installation, outgoing pressure and dryness

fraction for a steam production plant, etc.

3.2.11

zone

geographical or functional space defining a part of the organization

Note 1 to entry: Examples: a zone can be a kitchen (function), or a storage area of 5 000 m (surface area) or a

building of 10 000 m (volume space).

3.2.12

measurement accuracy

closeness of agreement between a measured quantity value and a true quantity value of a measurand

Note 1 to entry: The concept "measurement accuracy" is not a quantity and is not given a numerical quantity value.

A measurement is said to be more accurate when it offers a smaller measurement error.

Note 2 to entry: The term “measurement accuracy” should not be used for measurement trueness and the term

measurement precision should not be used for ‘measurement accuracy’, which, however, is related to both these

concepts.

Note 3 to entry: "Measurement accuracy" is sometimes understood as closeness of agreement between measured

quantity values that are being attributed to the measurand.

[SOURCE: ISO/IEC GUIDE 99:2011]

3.2.13

repeatability (of results of measurements)

closeness of agreement between the results of successive measurements of the same measurand, carried

out under the same conditions of measurement, i.e.:

— by the same measurement procedure;

— by the same observer;

— with the same measuring instruments, used under the same conditions;

— in the same laboratory;

— at relatively short intervals of time

Note 1 to entry: The concept of "measurement procedure" is defined in VIM 2.5.

[SOURCE IEV 311-06-06]

3.2.14

stability

ability of a measuring instrument to keep its performance characteristics unchanged during a specified

time interval, all other conditions being the same

[SOURCE IEV 311-06-12]

3.2.15

durability,

ability to perform as required, under given conditions of use and maintenance, until the end of useful life

[SOURCE IEV 192-01-21]

3.2.16

uncertainty

non-negative parameter characterizing the dispersion of the quantity values being attributed to a

measurand, based on the information used

[SOURCE: ISO/IEC GUIDE 99:2007]

3.2.17

sensitivity

quotient of the change in an indication of a measuring system and the corresponding change in a value of

a quantity being measured

Note 1 to entry: Sensitivity of a measuring system can depend on the value of the quantity being measured.

Note 2 to entry: The change considered in a value of a quantity being measured shall be large compared with the

resolution.

[SOURCE: ISO/IEC GUIDE 99:2007]

3.3 Symbols and abbreviations

COP Coefficient of Performance

EnMs Energy management system

EnPI Energy Performance Indicator

M&V Measurement and verification

EnB Energy baseline

PF Power Factor

THD Total harmonic distortion

U voltage

U voltage unbalance

nb

Toe ton of oil equivalent

f frequency

4 General characteristics of a measurement and monitoring plan

4.1 Purpose of a measurement and monitoring plan

The purpose of the measurement and monitoring plan is to design, apply, use and maintain the

measurement system which enables the organization to:

— measure the energy performance to ascertain that it complies with the targets;

— analyse the causes of potential drifts in energy consumption;

— monitor the relevant parameters of the installation;

— sustain the energy performance gains made over time;

— identify potential improvements.

The measurement and monitoring plan may be used on its own. It also provides practical principles and

guidance on how to collect data for ISO 50001, in line with the requirements stated in its 6-6 section (“The

organization shall define and implement an energy data collection plan appropriate to its size, its

complexity, its resources and its measurement and monitoring equipment. The plan shall specify the data

necessary to monitor the key characteristics and state how and at what frequency the data shall be

collected and retained.").

4.2 Relation between the measurement and monitoring plan and the measurement

system

Figure 1 brings together the elements of a measurement system, to be adapted according to the needs of

the organisation:

Figure 1 — Description of a measurement system

4.3 Process to maintain the measurement and monitoring plan

The implementation of the measurement and monitoring plan is an iterative process.

The organization shall put in place a periodic review of its plan in order to reach its objectives.

5 The stages of a measurement and monitoring plan

5.1 General

The organization shall carry out the stages 1 to 6 defined in 5.2 to 5.7 when putting in place a

measurement and monitoring plan, as described in the following figure:

Figure 2 — The stages of a measurement and monitoring plan

The figure doesn’t imply a linear approach and users of the standard may loop back to a stage in an

iterative process.

5.2 Stage 1: Define context, objectives and constraints

5.2.1 Objectives

— Ensure that the motivations, implications and objectives of organization are clearly defined;

— ensure that the key characteristics of operations that determine energy performance are measured,

analysed and monitored at planned intervals;

— ensure that the organizational, technical and financial contexts will allow the creation and

maintenance of a measurement and monitoring plan.

5.2.2 Context of the measurement and monitoring plan

The measurement and monitoring plan is meant as a tool to help organizations to improve and monitor

their energy performance and support the verification of the savings.

The measurement and monitoring plan should be used for the implementation of an ISO 50001 energy

management system:

— an energy management system in ISO 50001 requires that the key characteristics of energy

performance are measured, monitored and analysed at regular intervals, as part of an energy data

collection plan;

— “measurement and verification” (M&V) methods, as defined in ISO 50015, help the organization

determine and validate in a systematic way the improvement of its energy performance, within

specified boundaries. The M&V process relies upon a number of measurements. To ensure the quality

of these measurements (reliability, accuracy as well as appropriateness) a “measurement and

monitoring plan” is therefore needed.

The measurement and monitoring plan may support the use of other standards relative to energy

management, such as:

— energy audits (as described in EN 16247): an energy audit requires to get specific data measurement;

— energy efficiency services (as described in EN 15900): an energy efficiency service has to be based

on collected data.

However, an organization wishing to deploy a measurement and monitoring plan faces a number of

obstacles, including:

— the design of the plan, defining its content according to the needs and objectives;

— the evaluation of the cost/benefits of implementing the plan, acting as a decision-aid;

— the technical difficulties associated with the implementation of the plan.

5.2.3 Motivations of the organization

The organization shall design its measurement and monitoring plan such that it contributes to the

improvement of its energy performance.

By putting in place a plan, the organization obtains benefits such as:

— improve the monitoring of energy consumption;

— detect anomalies or drifts;

— facilitate operation and maintenance;

— implement a proactive approach to improving energy performance;

— meet the legal requirements and other requirements relative to energy;

— implement the recommendations of the energy audits.

5.2.4 Boundaries of the measurement and monitoring plan

The organization shall define the boundaries of the measurement and monitoring plan, and more

specifically the sites and the zones.

NOTE 1 See Annex A for an explanation on the notion of zones.

NOTE 2 For electrical applications, another way to define boundaries is using the notion of mesh

(see IEC 60364-8-1)

5.2.5 End purpose of measurements

The organization shall define the end-purpose of each measurement within the measurement and

monitoring plan, such as:

— calculate an Energy Performance Indicator (EnPI) (as specified in ISO 50006) and follow its

development over time;

— establish an energy baseline (as specified in ISO 50006);

— verify the savings;

— monitor the energy performance of an equipment, a process or an installation.

Additional measurements of influencing factors are in the scope of the standard, to complete the

information provided by energy meters. Yet it shall be verified that all the measuring points included in

the measurement and monitoring plan are intended to improve the energy performance of the

organization. Parameter measurements that have no direct or indirect influence on energy consumption

are not included in the boundaries of the energy measurement and monitoring plan.

5.2.6 Users of the plan

The organization shall identify the specific needs of each type of user of a measurement and monitoring

plan, including but not limited to:

— top management: defines the organization objectives relative to energy management in general and

energy measurement and monitoring in particular including the budget and priorities;

— energy management team: provides expertise related to energy management, at site or

organizational level. The measurement and monitoring plan is one of the tools he uses to implement

an efficient energy management system. The energy management team is responsible for making

sure the scope of measured data are consistent with energy management objectives;

— operating and maintenance staff: tasked with using the measurement system to check and ensure

efficient operation by taking corrective measures in the event of deviations in energy performance,

by eliminating energy losses and performing corrective and preventive maintenance to reduce

deterioration in energy performance. The operating and maintenance personnel can use the

measurement and monitoring plan for the equipment, process or installation under their

responsibility;

— end-users: these users can include other corporate departments, business experts, contract

managers, EnMS auditors, customers, suppliers, regulating organizations, architects, facility

managers or any other user interested into the energy related data;

— installers and system integrators: are responsible for the design and setup of the measurement

system. They shall make sure the measurement system is working as expected by the plan. They may

be internal or external.

5.2.7 Budget

The organization shall define the budget allocated to the measurement and monitoring plan according to

its objectives and the energy issues at stake. The plan shall be validated by the financial sponsors in the

organization, to whom energy management team shall report on the progress of its practical

implementation.

5.2.8 Planning

The energy performance measurement plan may be implemented in steps according to priorities in order

to meet the organization's budgetary constraints and mitigate the project risks.

The organization shall put in place a schedule for the implementation of the measurement plan, including

the most important milestones of the project.

5.2.9 Resources

The organization shall identify the human and material resources necessary for the implementation of

the measurement plan, related to:

— design;

— installation;

— metrology;

— acquisition system or resources necessary for manual reading if necessary;

— storage and use of data;

— maintenance.

The organization shall clearly identify a responsible team for the measurement and monitoring plan and

ensure that it is competent and available.

The organization shall identify and verify the skills necessary for the application of the measurement and

monitoring plan by its personnel or its service providers.

5.2.10 Criteria to asset the levels of the measurement system

The organization shall assess the appropriateness of its measurement system with respect to its needs

and in order to identify its potential improvements. An example of a qualitative assessment of a

measurement system is defined in Annex B, where three levels (base, medium, high) are suggested. The

levels shall be assessed in accordance with the following six criteria:

— criterion 1: the ability to quantify the energy consumption by zone and by energy use;

NOTE 1 The majority of the sites have consumption measurements at the points of delivery. These

measurements are used essentially for billing. Having sub-measurement by zone or by energy use allows finer

analysis and monitoring of energy consumption and performance.

— criterion 2: the ability to acquire measuring points and relevant variables at a regular frequency;

NOTE 2 To analyse the trend of energy consumption, the measuring point readings can be taken regularly. The

measuring points can be read manually by operators or automatically by remote reading. Remote reading generally

allows a larger number of measuring points to be read at a higher frequency while controlling costs.

NOTE 3 The identification and quantification of the influencing factors improves and refines the analysis of

variations in energy consumption and therefore in energy performance.

— criterion 3: the ability to transfer the measurement and relevant variables data;

NOTE 4 The time-stamped recording of the readings taken at regular intervals from the different measuring

points allows the detection of variations in energy consumption over time.

— criterion 4: the ability to store measurement and influencing factors data;

— criterion 5: the ability to analyse the collected data;

NOTE 5 Installation monitoring can reveal malfunctions that affect energy performance. To facilitate installation

monitoring, thresholds and alarms can be put in place on the parameters to be monitored. The levels of the

measurement system on a zone, on an energy use or even a measuring point can differ according to the energy

issues at stake, the technical and economic constraints and its energy performance objectives.

— criterion 6: the ability to visualize data and the results from the analysis.

Annex C provides examples of assessment according to the six above-mentioned criteria.

5.2.11 Deliverables

The organization shall provide a note summarizing its objectives and constraints, the organizational

structure adopted and the implementation schedule and budgets allocated to the measurement and

monitoring plan.

5.3 Stage 2: Assess the existing situation

5.3.1 Objectives

— Draw up the functional inventory (the needs, the data that shall be collected and why);

— draw up the technical inventory (the available data, tools, measurement devices and equipment).

5.3.2 Preliminary analysis

The organization shall conduct a preliminary analysis of the existing information available in order to

define the energy issues at stake. The organization may carry this study via the collect and analysis of:

— energy bills;

— energy audits;

— buildings or plant design documentation (e.g. energy rating of the building);

— simulations (e.g. thermal simulation for a new building);

— existing measurement system documentation;

— or any other document that it may see fit for that purpose.

5.3.3 Zones

The organization shall determine the useful zones depending on its activity, such as:

— workshops (e.g. in the industry);

— rooms (e.g. in a hotel);

— floor (e.g. in a building).

5.3.4 List of energy consumption

The organization shall carry out a list of energy consumption by the installations in each zone, in

accordance with Table 1.

Table 1— Example of list of energy consumption

Type of energy Type of Unit of Conversion Energy Measurement

used within zone 1 measurement measure factor measurement frequency

unit

Electricity Active, reactive kWh, - kWh, kvarh e.g 15 min

energy kvarh

Natural gas Flow rate Nm /h, GCV kWh, MJ, toe e.g 1 h

Sm /h

Fuel oil Flow rate kWh, MJ, toe

LPG Flow rate kWh, MJ, toe

Coal Weight kWh, MJ, toe

Wood Weight kWh, MJ, toe

Biomass Weight kWh, MJ, toe

Compressed air Flow rate, kWh, MJ, toe

Pressure

Steam Flow rate, kWh, MJ, toe

Temperature

Secondary coolant Flow rate kWh, MJ, toe

fluids

Other energy kWh, MJ, toe

carriers

TOTAL

NOTE 1 Toe means ton of oil equivalent.

NOTE 2 GCV means gross calorific value and can be either a direct measurement from a chromatograph or a

static factor.

NOTE 3 For organizations which are producing their own energy a similar table with local produced energy or

exported energy may be set up.

NOTE 4 To fill out the table, the organization may use the results of energy audits or energy review

(see Annex D, Figure D.1).

NOTE 5 Energy carrier can be water, fluid, etc.

5.3.5 Energy uses

The organization shall determine its energy uses, for example:

— HVAC (heating, ventilation and air-conditioning);

— lighting;

— connectors for electrical devices (computers, printers, etc.);

— manufacturing, process (motors, machines, etc.);

— transportation;

— processes and production lines.

The organization shall list its energy uses in each zone and characterize them by a measured or estimated

energy consumption in accordance with Table 2.

Table 2 — Example of inventory of the energy uses

Energy use in zone 1 Unit of Value Significant Evaluation method (unknown /

measure Energy Use? estimated / measured)

Lighting kWh Yes Measured

HVAC kWh Yes Measured

Other uses kWh No Estimated

TOTAL

NOTE 1 To fill out Table 2, the organization may use the results of energy audits or energy review

(see Annex D, Figure D.2).

NOTE 2 The organization focuses in priority on its significant energy uses.

NOTE 3 In case the evaluation method is estimated, the organization also provides an explanation on the

methodology used.

5.3.6 Relevant variables

The organization shall identify the relevant variables influencing the energy consumption of each chosen

use, such as:

— production activity, for instance:

— a number, a volume or a weight of parts produced or equivalent (turnover, etc.) in the industry;

— a number of persons present per time period (occupancy rate, etc.) for buildings;

— factors on local production of energy if relevant;

— climatic conditions, such as:

— outside air temperature;

— outside relative humidity;

— degree days;

NOTE 1 Degree Day is a derived parameter designed to quantify the demand of energy needed to

heat (HDD) or to cool (CDD) a building. Degree Days are defined relative to an indoor base temperature

adequate for human comfort and type of building – home, businesses, hospital, etc. HDDs depend on outside

air temperature and are calculated by algorithms computing only the positive differences between the

reference indoor temperatures and the actual outdoor temperature on daily or hourly/semi-hourly basis. CDDs

are related to outside air temperature too, but in continental and Mediterranean areas they strongly depend

on relative humidity and solar radiation and other weather parameters. CDDs are calculated subtracting the

reference temperature from apparent temperature (combined effect of air temperature and relative humidity

and other weather parameters).

— solar radiation;

— atmospheric pressure;

— natural light;

— hygrometry;

— wind speed and direction:

— comfort of the occupant (indoor temperature, relative humidity, radiant heat, light, etc.);

— other processes, such as air quality (particle matters, etc.).

The organization shall produce a synthesis of relevant variables in each zone and for each energy use and

the impact of each variable on achieving the objectives, in accordance with Table 3.

Table 3 — Example of inventory of the relevant variables

Energy use: air conditioning in zone 1

Relevant factor Measurement method Storage Impact with respect to objectives

frequency

outside daily aligning energy consumption with

the closest weather

real needs

station

air temperature

outside relative humidity sensor daily real time monitoring of anomalies

with solar shield on site and drifts of thermal plants

relative humidity

indoor air temperature sensor hourly optimize energy consumption while

inside the office taking comfort of users into account

air temperature

NOTE 2 In a measurement chain aimed at evaluating derived energy parameter (e.g EnPI, baselines, etc.) the

quality of the final result is dependent on the least accurate measurement.

The organization shall identify which relevant variables are already being measured. The organization

may include external data sources whenever it is relevant, such as the closest weather station in Table 3.

5.3.7 Static factors

The organization shall define the static factors for each zone and for each energy use, such as:

— building occupancy rate;

— facility size (surface or volume);

— building envelope characteristics;

— opening times;

— level of services provided by the energy use;

— temperature setting;

— context of operations (processing sequence, product quality, legal or other requirements, etc.);

— operating conditions (manual or automatic modes, etc.);

— availability of the equipment (in operation or not).

Depending on the situation, some of the listed static factors may be considered as relevant variables. For

instance the operating conditions may change regularly within industrial plants, opening times can

change between summer and winter, etc.

5.3.8 Installation parameters to monitor

5.3.8.1 General

The organization shall list the quantities that are or should be used to characterize the performance of

the installation.

5.3.8.2 Monitoring the electrical installation

Table 4 below describes the influence of certain electrical energy-related parameters on the energy

performance of the installation, as described more thoroughly in IEC 60364-8-1.

Table 4 — Example of electrical parameters to monitor

Electrical Impact on the energy Impact on the performance

parameter Abbreviation performance of the of the installation

installation

Power factor PF Energy losses are generated in The cables need to be

(cos phi) the cables. The supplier bills oversized

penalties

Total THD , U The negative sequence Premature failure of certain

u h

harmonic harmonics (u2) slow down devices, particularly motors

THD , I

i h

distortion, the motors, the zero sequence

Harmonic, harmonics (u0) cause energy

voltage and losses

current

Constant or U The electrical devices work Premature failure of certain

frequent outside their specifications devices, particularly motors

voltage and will overconsume,

deviations particularly motors

Voltage U Energy losses are generated in Premature failure of certain

nb

unbalance motors devices, particularly motors

Voltage dips, U –- Process stoppages with

dip

voltage financial impact

U

int

interruptions

Frequency F –- Change in speed of rotating

machines

NOTE The organisation should check the relevancy of the given parameters in terms of economic

effort and monitorability.

5.3.8.3 Monitoring the fluids installation

For fluids installations (boiler room, compressed air plant, refrigerating plant, water treatment

plant, etc.), some other parameters may be important and subject to installation monitoring.

For example:

— steam production plant: the outgoing pressure from the plant, the quality of the make-up water and

the condensate returns (conductivity, pH, etc.), the condensates return rate, the dryness fraction;

— compressed air plant: the pressure, hygrometry, the head losses of the filtration system, the

compressor suction temperature;

— refrigerating plant: the high pressure, low pressure, the temperature difference between the

outgoing and return line of the refrigerant system, monitoring of heat exchanger fouling, the oil

temperature of lubricated machines;

— water, waste water and sludge treatment plant: the inlet and outlet quality of the fluid.

Some of these parameters should be monitored as part of corrective and preventive maintenance to

ensure the reliability, durability and optimum performance of the equipment.

5.3.8.4 Existing measuring devices

The organization shall draw up an inventory of the existing measuring devices for each installation:

— electrical energy meters;

— power meters (for monitoring the electrical installation);

— gas meters;

— fluid meters;

— measuring devices related to the relevant variables.

The organization shall explain their current use and make a synthesis of the existing measurements per

zone or per use.

The organization shall characterize the measuring devices (brand, reference) and their location. The

organization shall verify that the reading frequency of each measuring device is appropriate for the

quantity measured and its variability.

5.3.8.5 Mapping of energy flows

The organization shall identify the energy distribution or generation networks within th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...