SIST EN 15080-8:2009

(Main)Extended application of results from fire resistance tests - Part 8: Beams

Extended application of results from fire resistance tests - Part 8: Beams

This Part of EN 15080 identifies the parameters and factors that affect the fire resistance of beams and need to be taken into account when considering extended application of results of beams tested in accordance with EN 1365-3. It also gives the methodology to be used when preparing an extended application, including rules and calculation methods which can be applied to establish the resultant influence of a variation in one or more parameters and to determine the field of extended application.

Erweiterter Anwendungsbereich der Ergebnisse aus Feuerwiderstandsprüfungen - Teil 8: Balken

In diesem Teil der Normenreihe EN 15080 werden die Parameter und Faktoren festgestellt, die die Feuer-widerstandsfähigkeit von Balken beeinflussen und die in Betracht gezogen werden müssen, um den erweiterten Anwendungsbereich auf Basis der Prüfergebnisse von Balken nach EN 1365 3:1999 ermitteln zu können. Dieser Teil beinhaltet auch die anzuwendende Methodologie, wenn ein erweiterter Anwendungs-bereich vorbereitet wird, einschließlich der Regeln und Berechnungsverfahren, die angewandt werden können, um die aufgrund von Änderungen in einem oder mehreren Parameter(n) resultierenden Einflüsse zu ermitteln und den erweiterten Anwendungsbereich zu bestimmen.

Application étendue des résultats des essais de résistance au feu - Partie 8 : Poutres

La présente partie de l’EN 15080 identifie les paramètres et facteurs qui affectent la résistance au feu des poutres et qui doivent être pris en compte si l’on considère l’application étendue des résultats des poutres soumises à un essai conformément à l’EN 1365-3. Elle fournit également la méthodologie à utiliser lors de l’élaboration d’une application étendue, notamment les règles et les méthodes de calcul qui peuvent être appliquées pour établit l’influence résultant d’une variation dans un ou plusieurs paramètres mais aussi pour déterminer le champ de l’application étendue.

Razširjena uporaba rezultatov preskusov požarne odpornosti - 8. del: Nosilci

General Information

- Status

- Published

- Publication Date

- 17-Nov-2009

- Technical Committee

- POZ - Požarna varnost

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 22-Oct-2009

- Due Date

- 27-Dec-2009

- Completion Date

- 18-Nov-2009

- Directive

- 89/106/EEC - Construction products

Overview

EN 15080-8:2009 - Extended application of results from fire resistance tests - Part 8: Beams (CEN) gives the framework, rules and calculation methods for extending the outcome of fire resistance tests (performed to EN 1365-3) to other beam configurations or use-cases. The standard identifies the parameters that affect beam fire performance and prescribes a methodology to assess how variations (span, loads, materials, protection, etc.) influence fire resistance and the resulting classification or design decisions.

Key topics

- Scope and purpose: Defines when an extended application analysis is required (i.e., when a beam’s use is outside the direct field of application in the test/classification report).

- Methodology: Step‑by‑step approach for preparing an extended application, including:

- Thermal and structural analysis methods (basic thermal analysis; basic structural analysis).

- Use of a modelling factor derived from reference tests to adjust predictive models.

- Calculation of calculated structural resistance, effective structural resistance, and relative resistance.

- Critical parameters: Lists common thermal, mechanical and constructional parameters that influence fire resistance (load level, span, material properties, cross-section, applied fire protection, connections and restraint).

- Specific beam types: Guidance for concrete, steel, timber, mechanically jointed and composite steel–concrete beams-plus rules when beams have applied fire protection.

- Failure modes and limits: Consideration of mode changes (bending to shear or connection failure), deflection limits and criteria for classification.

- Reporting: Requirements for documenting the extended application analysis and its assumptions.

- Informative annexes: Worked examples and guidance for steel, timber, composite and concrete beams to support practical application.

Applications and users

EN 15080-8:2009 is intended for:

- Structural and fire safety engineers performing structural fire engineering assessments.

- Manufacturers and product developers seeking to extend test results to product ranges.

- Fire test laboratories and certification bodies preparing classification reports.

- Building designers, consultants and regulators who need to verify compliance with fire resistance requirements or to justify variations from tested specimens.

Typical uses:

- Demonstrating that a beam with modified dimensions, load or protection still meets a target fire resistance class.

- Reducing the need for additional full-scale tests by using validated calculation procedures.

- Supporting product certification and documentation for building approvals.

Related standards

- EN 1365-3 (fire resistance tests - beams)

- EN 1363-1 (general fire resistance test requirements)

- EN 13501-2 (fire classification using test data)

- Material standards referenced (EN 338, EN 1194, EN 10025, etc.)

Keywords: EN 15080-8:2009, fire resistance, beams, extended application, EN 1365-3, structural fire engineering, CEN, fire resistance tests.

Frequently Asked Questions

SIST EN 15080-8:2009 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Extended application of results from fire resistance tests - Part 8: Beams". This standard covers: This Part of EN 15080 identifies the parameters and factors that affect the fire resistance of beams and need to be taken into account when considering extended application of results of beams tested in accordance with EN 1365-3. It also gives the methodology to be used when preparing an extended application, including rules and calculation methods which can be applied to establish the resultant influence of a variation in one or more parameters and to determine the field of extended application.

This Part of EN 15080 identifies the parameters and factors that affect the fire resistance of beams and need to be taken into account when considering extended application of results of beams tested in accordance with EN 1365-3. It also gives the methodology to be used when preparing an extended application, including rules and calculation methods which can be applied to establish the resultant influence of a variation in one or more parameters and to determine the field of extended application.

SIST EN 15080-8:2009 is classified under the following ICS (International Classification for Standards) categories: 13.220.50 - Fire-resistance of building materials and elements; 91.060.99 - Other elements of buildings. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 15080-8:2009 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/117. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 15080-8:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Razširjena uporaba rezultatov preskusov požarne odpornosti - 8. del: NosilciErweiterter Anwendungsbereich der Ergebnisse aus Feuerwiderstandsprüfungen - Teil 8: BalkenApplication étendue des résultats des essais de résistance au feu - Partie 8 : PoutresExtended application of results from fire resistance tests - Part 8: Beams91.060.99Drugi stavbni elementiOther elements of buildings13.220.50Požarna odpornost gradbenih materialov in elementovFire-resistance of building materials and elementsICS:Ta slovenski standard je istoveten z:EN 15080-8:2009SIST EN 15080-8:2009en,de01-december-2009SIST EN 15080-8:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15080-8

October 2009 ICS 13.220.50; 91.060.99 English Version

Extended application of results from fire resistance tests - Part 8: Beams

Application étendue des résultats des essais de résistance au feu - Partie 8 : Poutres

Erweiterter Anwendungsbereich der Ergebnisse aus Feuerwiderstandsprüfungen - Teil 8: Balken This European Standard was approved by CEN on 10 February 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15080-8:2009: ESIST EN 15080-8:2009

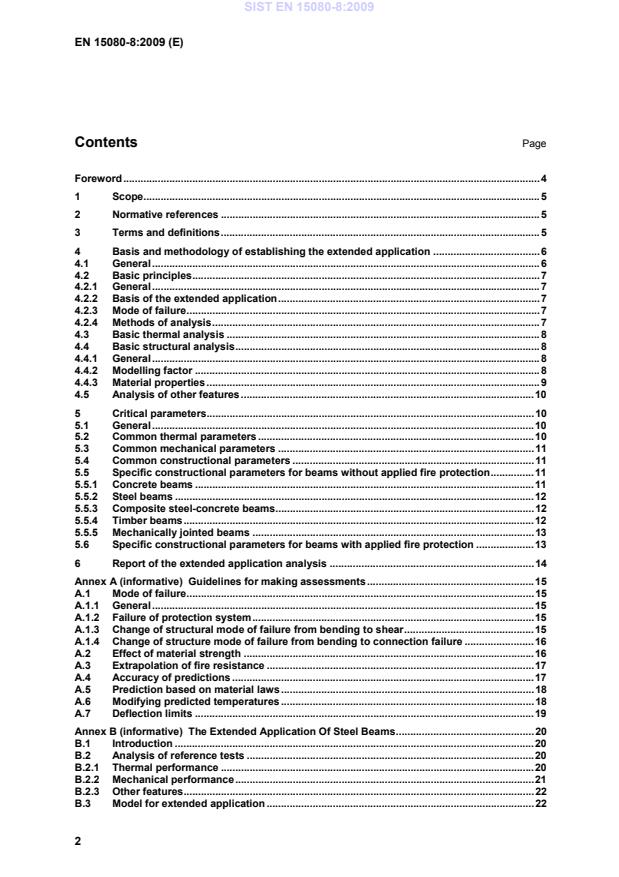

Guidelines for making assessments . 15 A.1 Mode of failure . 15 A.1.1 General . 15 A.1.2 Failure of protection system . 15 A.1.3 Change of structural mode of failure from bending to shear . 15 A.1.4 Change of structure mode of failure from bending to connection failure . 16 A.2 Effect of material strength . 16 A.3 Extrapolation of fire resistance . 17 A.4 Accuracy of predictions . 17 A.5 Prediction based on material laws . 18 A.6 Modifying predicted temperatures . 18 A.7 Deflection limits . 19 Annex B (informative)

The Extended Application Of Steel Beams . 20 B.1 Introduction . 20 B.2 Analysis of reference tests . 20 B.2.1 Thermal performance . 20 B.2.2 Mechanical performance . 21 B.2.3 Other features . 22 B.3 Model for extended application . 22 SIST EN 15080-8:2009

The Extended Application Of Timber Beams . 24 C.1 Introduction . 24 C.2 Extended application in the load domain (increase of load-bearing capacity) . 24 C.2.1 Increasing of load-bearing capacity by higher strength class . 24 C.2.2 Increasing of load-bearing capacity by increasing beam dimensions (braced beams) 25 C.2.3 Increasing of load-bearing capacity by decreasing the fire resistance . 26 C.3 Extended application in the time domain: Increasing fire resistance by applied fire protection . 30 Annex D (informative)

The Extended Application of a Composite Steel Concrete Beam . 32 D.1 Introduction . 32 D.1.1 General . 32 D.1.2 Reference test 1 . 33 D.1.3 Reference test 2 . 33 D.2 Analysis of reference tests . 34 D.2.1 Thermal performance . 34 D.2.2 Reference test 1 . 34 D.2.3 Reference test 2 . 35 D.2.4 Structural performance . 36 D.2.5 Bending resistance . 36 D.2.6 Assessment of reference test 1 . 36 D.2.7 Assessment of reference test 2 . 37 D.2.8 Conclusions of structural performance . 38 D.2.9 Model for extended application . 38 D.2.10 Extended application . 38 Annex E (informative)

The extended application of concrete beams . 41 E.1 Introduction . 41 E.2 Failure modes . 41 E.3 Examples . 41 E.3.1 Possible change of failure mode . 41 E.3.2 Change of cross section . 42 E.3.3 Change of material strength . 42 E.3.4 Axial and rotational restraint . 43 Bibliography . 44

If more than one reference test is available, all the tests may be used for the extended application provided that the tests all have the same mechanical boundary conditions and have all been carried out using the same fire curve. NOTE It is possible that in the classification report all reference beams are classified with the same classification “Rref” although the actual test results (tref,fi) given in the test reports may differ.

4.2 Basic principles 4.2.1 General It is assumed that extended application is made by appropriately qualified and experienced persons in the field of structural fire design. The reference test(s) shall be well documented, i.e. an insight into the performance of the test specimen(s) and the mode of failure, leading to Rref, are available.

Three analyses (described in 4.3, 4.4 and 4.5) should be carried out where appropriate. It shall be decided whether: field of application can be extended, maintaining the classification Rref or changing the classification and if so, by how much; extension is not possible (new tests are required). Any predicted increase in fire resistance shall not exceed the lesser of 15 min and 20 % of the target classification.

NOTE This is illustrated in A.3. 4.2.2 Basis of the extended application An adequate understanding of the structural and thermal performance, as well as an understanding of other relevant features, shall be achieved based on the scope of the required extended application. For minor or obvious extensions to the reference test, the depth of analysis required may be reduced. 4.2.3 Mode of failure Any assessment shall consider the possibility that the mode or cause of failure, such as structural collapse in bending or failure of a fire protection system, might change and that the mode or cause of failure in a fire test may no longer be critical if one or more parameters are changed.

If a change of failure mode is expected, then extended application is not possible unless additional information is available. NOTE For additional information see A.1. 4.2.4 Methods of analysis When analysing the reference test(s), the rules given in the Eurocodes shall be used if applicable. Additional rules are given in this standard. These are also applicable in cases where the Eurocodes do not fully cover the construction to be assessed. Other calculation models, as well as empirical rules, shall be validated on the basis of similar tests as the reference test(s). Historic data and ad hoc tests may be used to supplement to the information of the reference test(s). SIST EN 15080-8:2009

Boundary conditions. Material properties versus temperature. NOTE 2 As an illustration of the depth of structural analysis required, the report on the analysis for the vertical shear check on a steel beam might simply say, “The shear is low enough to have no influence on the bending strength - no check required”. 4.4.2 Modelling factor Any assessment shall take into account the accuracy of the structural model used. Models which overestimate the load resistance of the reference test(s), shall have a modelling factor applied when used to make an assessment for extended application. In making any assessment, the effective structural resistance shall be determined as follows: effmfRRk=× (1) where Reff

is the effective structural resistance; SIST EN 15080-8:2009

is the calculated structural resistance; kmf

is the modelling factor. For a single reference test, the modelling factor is defined as: mfFkR=

but not greater than 1,0 (2) where F is the applied load or moment in the reference test. For more than one reference test: imfi1FknR=∑ but not greater than 1,0 (3) where Fi is the applied load or moment in the reference test I; Ri is the calculated structural resistance of test i calculated using the measured temperature distribution;

n is the number of tests. and with each individual value: (Fi / Ri ) ≤ 1,3

If the value of (Fi / Ri) exceeds 1,3 then that test should not be used as part of the assessment of extended application. NOTE 1 If the measured temperature distribution is not sufficiently comprehensive to allow the structural resistance to be adequately predicted then it may be supplemented with computed temperatures. NOTE 2 If the value of (Fi / Ri) exceeds 1,3, there may be something wrong with the test data or with some aspect of the engineering model being used so the particular test may be considered unreliable. 4.4.3 Material properties The reference test(s) should be assessed using measured material strength. If the actual material strength is not available then the strength should be taken from Table 1. In making any assessment of extended application, mean material properties shall be assumed. If the actual mean value is unknown, then values for the mean strength should be taken from Table 1. NOTE The values in Table 1 are conservative values for the mean strength. For additional information see A.1. SIST EN 15080-8:2009

Table 1 — Conservative values for mean strength MaterialMean strength(a) Concrete compressive strength fck + 8 N/mm2 Reinforcement steel to EN 10080 for concrete

fsk

× 1,1 Prestressing steel to EN 10138-1 for concrete fpk × 1,1 Hot rolled structural steel to EN 10025 parts 1 and 2 fy

× 1,1 Timber

- Structural timber, strength classes C14 to C40 to EN 338 fk × 1,5

- glued laminated timber, all strength classes to EN 1194 fk × 1,3

- LVL

fk × 1,25 Other materials to be estimated (a) fi k

and fy are the characteristic strength values (5 % fractile). 4.5 Analysis of other features Where relevant phenomena not assessed in 4.3 and 4.4 shall be taken into account. NOTE These may include such things as the stickability of fire protection materials and spalling of concrete. For spalling of concrete, reference should be made to EN 1992-1-2:2004, subclauses 4.5 and 6.2. The stickability of fire protection materials should be either: assessed using the methods given in ENV 13381, or be based on clear evidence of the performance of the material and fixing system in at least two fire tests. 5 Critical parameters 5.1 General The parameters listed in 5.2 to 5.6 may affect the fire performance, i.e. the value of Rref, and shall be taken into account when preparing an extended application. The specific constructional parameters vary depending upon the nature of the beam being considered.

NOTE 1 The list in this section is not definitive; in special cases other parameters may also be appropriate. NOTE 2 The review in Annex A of parameters and of corresponding factor and factor influences, is only given for the common thermal, common mechanical and common constructional parameters.

5.2 Common thermal parameters 1) Nominal gas temperature time curves. 2) Number of exposed faces. SIST EN 15080-8:2009

g) Concrete cover to reinforcement. h) Amount and position of the shear reinforcement. i) Minimum dimensions, the level of compressive stresses, moisture content and other parameters possible relevant for spalling. j) Other parameters which may effect spalling. 5.5.2 Steel beams

The following specific parameters can be distinguished: 1) Steel specification. 2) Section factor. 3) Classification of cross section (see EN 1993-1-2). 4) Web stiffeners. 5.5.3 Composite steel-concrete beams

In addition to the items listed in 5.5.1 and 5.5.2, the following parameters may apply: 1) Degree of shear connection. 2) Number of shear connectors. 3) Type of shear connectors. 4) Type of concrete slab. NOTE This could include a consideration of whether the slab is flat or composite with profiled steel sheeting. 5) Thickness of the concrete slab. 5.5.4 Timber beams The following parameters apply, where relevant, to timber beams made of solid timber, glued laminated timber and LVL (laminated veneer lumber) or other engineered wood products: a) Timber specification NOTE This will normally include: 1) Material (timber or wood based materials). 2) Species of timber. 3) Strength class of solid or glued laminated timber (including characteristic values of strength and stiffness parameters and density). 4) Strength. 5) Stiffness. SIST EN 15080-8:2009

T-shape, composed of several parts connected by mechanical fasteners with flanges and/or webs made of solid or glued laminated timber, wood-based panels and LVL or other engineered wood products. In addition, the following parameters may apply: 1) Type of fastener. 2) Spacing of fasteners. 3) Edge distances of fasteners. 5.6 Specific constructional parameters for beams with applied fire protection In addition to the parameters given in 5.5, the following parameters may apply: 1) Surface treatment of the beam (i.e. grit blasted, primer). 2) Type of protection material (generic or proprietary). 3) Thermal characteristics of the protection (thermal conductivity and specific heat). 4) Density of the protection. 5) Thickness of the protection. 6) Number of layers of the applied fire protection. 7) Position and geometry of joints in the applied fire protection. 8) All details of method of fixing of the fire protection (type of fasteners, spacing and edge distances; including reinforcement where relevant). 9) Surface treatment of the fire protection. 10) Position of the fire protection (vertical, horizontal sides; one or more sides may be unprotected). SIST EN 15080-8:2009

Guidelines for making assessments A.1 Mode of failure A.1.1 General Care should be taken to ensure that any change in the mode of failure should be taken into account when assessing an extended application. For a simple beam the effect is shown diagrammatically in Figure A.1 and Figure A.2. The two modes might be bending and shear.

Key

Relative resistance t Time 1 Failure mode 1 2 Failure mode 2

Key

Relative resistance t Time 1 Failure mode 1 2 Failure mode 2 Figure A.1 — Member resistance as a function of time for a single mode of failure Figure A.2 — Member resistance as a function of time for a changing mode of failure

Other examples of a change in the mode of failure. A.1.2 Failure of protection system A beam achieves t = 52 min. If the applied loading is reduced R60 may be possible. However, large cracks were observed in the protection system at the end of the test which may indicate a potential stickability failure of the protection system. It is important to take into account the stickability of any protection system as it will affect the heating rate of the beam. The stickability may be affected by any increase in thickness of fire protection. A.1.3 Change of structural mode of failure from bending to shear A fabricated steel beam containing a large service opening is tested. A load-bearing failure occurs caused by bending at mid-span. Calculations indicate that the web of the beam could be reduced in SIST EN 15080-8:2009

As the strength of reinforcement is normally the dominant parameter in calculating the strength of the beam, a false impression of how well the beam performed in the test may be obtained. The actual bending strength could have been 117 % (585/500) of the strength based on characteristic reinforcement strength. Although the mean rate at which strength was lost was about 1,2 % per min, beams do not lose strength linearly with time in a fire resistance test so, during the last 15 min, the rate was probably about 3 % per min. The extra 17 % of strength might therefore represent about 6 min. A beam with only characteristic material properties might therefore only achieve t = 76 min (= 82 - 6). In view of the effect of material properties on fire resistance, it is recommended in 4.4.3 that tests are assessed using measured values for all material properties. It follows that if it is known a test is going to be used as a reference test for extended application then the material properties should be measured. Alternatively, if material properties are not known, it is recommended that mean values should be assumed. Subsequent predictions for an extended application should be made assuming mean material properties. For the common structural materials, these are presented in Table 1. For structural steel, reinforcement and concrete is it not possible to give definitive values for mean material strength as the product standards do not specify mean strength. For these materials, the mean strength values given in Table 1 are conservative estimates. For timber, the product standards do specify mean strength values and these are reproduced in Table 1. For materials not included in the table a conservative estimate of mean strength should be used. SIST EN 15080-8:2009

Relative resistance t, θ Time or temperature 1 Test result 2 Prediction 3 Error in terms of relative resistance 4 Error in terms of time or temperature

Figure A.3 — Illustration of types of error in predictions SIST EN 15080-8:2009

The curve describing the material law is drawn in terms of the strength retention factor against temperature. The test point is then plotted with the applied load converted to a fraction of normal strength and the temperature at that of the critical element. This point will normally be above the curve for the material law. The material law curve is then moved vertically until it passes through the test point. This modified curve may be used to estimate the load carrying capacity of the beam relative to the temperature of the critical element, assuming that the mode of failure does not change (see A.1).

Key

Relative resistance t, θ Time or temperature 1 Test result 2 Material law 3 Curve drawn by moving the Material Law vertically 4 Prediction Figure A.4 — Illustration of prediction based on material model A.6 Modifying predicted temperatures Computer modelling of the temperature distribution may not always accurately predict the temperature of certain key elements of the beam but may often predict the relative values of temperature reasonably well. A useful technique to obtain a temperature distribution that can be used in an assessment is to logically adjust the predicted temperatures so that they align with the key measured temperatures. The adjusted predicted temperature distribution is then be used. This is illustrated in Figure A.5. Any adjustment should take account of the effect of errors on the structural resistance. The temperature of a reinforcement bar towards the bottom of a beam will be structurally much more important than the temperature of a concrete element at the top of a beam. SIST EN 15080-8:2009

Key

θ Temperature 1 Beam cross section 2 Measured temperatures

3 Predicted temperatures 4 Adjusted prediction ∆θ Temperature adjustment

Figure A.5 — Illustration of adjusted temperature distribution A.7 Deflection limits Deformation criteria do not normally need to be considered separately in the EXAP assessment. Where fire protection of the beam contributes to the fire resistance of the beam, it shall be verified that the fire protection remains cohesive and coherent when subjected to the strain and temperature, which result from any change in the parameters. NOTE The main reason to introduce deformation limits into EN 1365-3 is to protect people carrying out fire tests from the effect of a sudden beam collapse into the furnace and to limit potential damage to the furnace, rather than avoiding problems in the end use situation. In the fire parts of the Eurocodes a similar approach is adopted. For example, Eurocode 3: Design of steel structures, Part 1.2: General rules, Structural fire design, states: 2 Basis of design 2.1 Requirements 2.1.1 Basic requirements (1) Where mechanical resistance in the case of fire is required, steel structures shall be designed and constructed in such a way that they maintain their load bearing function during the relevant fire exposure. (2) Deformation criteria shall be applied where the protection aims, or the design criteria for separating elements, require consideration of the deformation of the load bearing structure. (3)

Except from (2) consideration of the deformation of the load bearing structure is not

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...