ISO 8066-3:2020

(Main)Rubber and plastics hoses and hose assemblies for automotive air conditioning — Specification — Part 3: Refrigerant 1234yf

Rubber and plastics hoses and hose assemblies for automotive air conditioning — Specification — Part 3: Refrigerant 1234yf

This document specifies the requirements for rubber or thermoplastic hoses and hose assemblies used for circulating liquid and gaseous R1234yf (tetrafluoropropene) in the air-conditioning systems of automobiles. The hoses and hose assemblies are designed in such a way as to restrict losses of refrigerant and contamination of the system. The operational temperature range is −40 °C to +125 °C. Due to the critical relationship between the hose and coupling for this application, a requirement that the coupling to be used in service be used for testing has been laid down.

Tuyaux et flexibles en caoutchouc et en plastique pour climatisation des automobiles — Spécifications — Partie 3: Réfrigérant 1234yf

General Information

- Status

- Published

- Publication Date

- 13-Aug-2020

- Technical Committee

- ISO/TC 45/SC 1 - Rubber and plastics hoses and hose assemblies

- Drafting Committee

- ISO/TC 45/SC 1/WG 2 - Automotive hoses

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 27-Jun-2025

- Completion Date

- 12-Feb-2026

Overview

ISO 8066-3:2020 specifies requirements for rubber and thermoplastic hoses and hose assemblies used to circulate liquid and gaseous R1234yf (tetrafluoropropene) in automotive air‑conditioning systems. The standard focuses on minimizing refrigerant loss and system contamination, and defines an operational temperature range of −40 °C to +125 °C. Because hose performance depends critically on the mating coupling, ISO 8066-3 requires that the coupling intended for service be used during testing.

Key topics and technical requirements

ISO 8066-3 covers classification, dimensions, testing and performance criteria for hoses and assemblies for R1234yf:

- Classification by construction type (examples in the standard: Type A–F: rubber textile‑reinforced, wire‑reinforced, barrier, thermoplastic, veneer types).

- Pressure classes, moisture‑ingression grades, and refrigerant‑permeation grades.

- Dimensional controls (inside diameters, wall thickness variation).

- Extensive testing and performance requirements, including:

- Leakage tests (Method A for type/production, Method B for routine)

- Refrigerant permeation and related test procedures

- Ageing, low‑temperature, vacuum resistance

- Bursting pressure, proof pressure, and length change under pressure

- Extraction by R1234yf, ozone resistance, hose cleanliness

- Impulse test, moisture ingression, and coupling integrity (sealability)

- Marking, test report content, and recommendations for packaging and storage.

- Normative annexes detail methods for permeation, low‑temperature testing, extraction, impulse testing, moisture ingression, coupling sealability, and test frequency.

Practical applications and users

ISO 8066-3 is essential for stakeholders involved with automotive A/C refrigerant systems using R1234yf:

- Hose and hose‑assembly manufacturers - design, material selection, production testing and quality control.

- Automotive OEMs and suppliers - specifying compliant hoses for vehicle HVAC systems and validating supplier claims.

- Testing laboratories and certification bodies - performing leakage, permeation, impulse and durability tests per the standard.

- Quality and compliance managers - ensuring supplier contracts, incoming inspection, and regulatory traceability.

- Design engineers - selecting hose types (rubber vs thermoplastic, barrier layers) according to performance classes.

Related standards

ISO 8066-3 references and complements other standards used in testing and specification, including:

- ISO 8066 series (other parts)

- ISO 8330 (vocabulary)

- ISO 1402 (hydrostatic testing)

- ISO 4671 (dimension measurement)

- ISO 7326 (ozone resistance)

- ISO 23529 and ISO/TR 11340 (conditioning and leakage classification)

Keywords: ISO 8066-3, R1234yf hoses, automotive air conditioning hoses, refrigerant permeation, hose assemblies, coupling integrity, thermoplastic hoses, rubber hoses.

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Smithers Quality Assessments

US management systems and product certification.

Sponsored listings

Frequently Asked Questions

ISO 8066-3:2020 is a standard published by the International Organization for Standardization (ISO). Its full title is "Rubber and plastics hoses and hose assemblies for automotive air conditioning — Specification — Part 3: Refrigerant 1234yf". This standard covers: This document specifies the requirements for rubber or thermoplastic hoses and hose assemblies used for circulating liquid and gaseous R1234yf (tetrafluoropropene) in the air-conditioning systems of automobiles. The hoses and hose assemblies are designed in such a way as to restrict losses of refrigerant and contamination of the system. The operational temperature range is −40 °C to +125 °C. Due to the critical relationship between the hose and coupling for this application, a requirement that the coupling to be used in service be used for testing has been laid down.

This document specifies the requirements for rubber or thermoplastic hoses and hose assemblies used for circulating liquid and gaseous R1234yf (tetrafluoropropene) in the air-conditioning systems of automobiles. The hoses and hose assemblies are designed in such a way as to restrict losses of refrigerant and contamination of the system. The operational temperature range is −40 °C to +125 °C. Due to the critical relationship between the hose and coupling for this application, a requirement that the coupling to be used in service be used for testing has been laid down.

ISO 8066-3:2020 is classified under the following ICS (International Classification for Standards) categories: 43.040.60 - Bodies and body components; 83.140.40 - Hoses. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 8066-3:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 8066-3

First edition

2020-08

Rubber and plastics hoses and

hose assemblies for automotive air

conditioning — Specification —

Part 3:

Refrigerant 1234yf

Tuyaux et flexibles en caoutchouc et en plastique pour climatisation

des automobiles — Spécifications —

Partie 3: Réfrigérant 1234yf

Reference number

©

ISO 2020

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

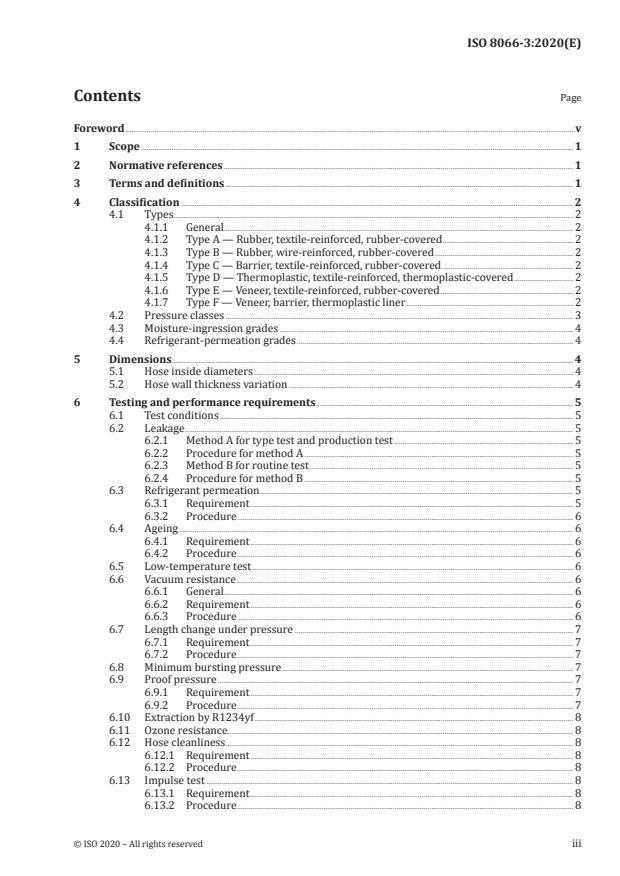

Contents Page

Foreword .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Classification . 2

4.1 Types. 2

4.1.1 General. 2

4.1.2 Type A — Rubber, textile-reinforced, rubber-covered . 2

4.1.3 Type B — Rubber, wire-reinforced, rubber-covered . 2

4.1.4 Type C — Barrier, textile-reinforced, rubber-covered . 2

4.1.5 Type D — Thermoplastic, textile-reinforced, thermoplastic-covered . 2

4.1.6 Type E — Veneer, textile-reinforced, rubber-covered . 2

4.1.7 Type F — Veneer, barrier, thermoplastic liner . 2

4.2 Pressure classes . 3

4.3 Moisture-ingression grades . 4

4.4 Refrigerant-permeation grades . 4

5 Dimensions . 4

5.1 Hose inside diameters . 4

5.2 Hose wall thickness variation . 4

6 Testing and performance requirements . 5

6.1 Test conditions . 5

6.2 Leakage . 5

6.2.1 Method A for type test and production test . 5

6.2.2 Procedure for method A . 5

6.2.3 Method B for routine test . 5

6.2.4 Procedure for method B . 5

6.3 Refrigerant permeation . 5

6.3.1 Requirement . 5

6.3.2 Procedure . 6

6.4 Ageing . 6

6.4.1 Requirement . 6

6.4.2 Procedure . 6

6.5 Low-temperature test . 6

6.6 Vacuum resistance . 6

6.6.1 General. 6

6.6.2 Requirement . 6

6.6.3 Procedure . 6

6.7 Length change under pressure . 7

6.7.1 Requirement . 7

6.7.2 Procedure . 7

6.8 Minimum bursting pressure. 7

6.9 Proof pressure . 7

6.9.1 Requirement . 7

6.9.2 Procedure . 7

6.10 Extraction by R1234yf . 8

6.11 Ozone resistance. 8

6.12 Hose cleanliness . 8

6.12.1 Requirement . 8

6.12.2 Procedure . 8

6.13 Impulse test . 8

6.13.1 Requirement . 8

6.13.2 Procedure . 8

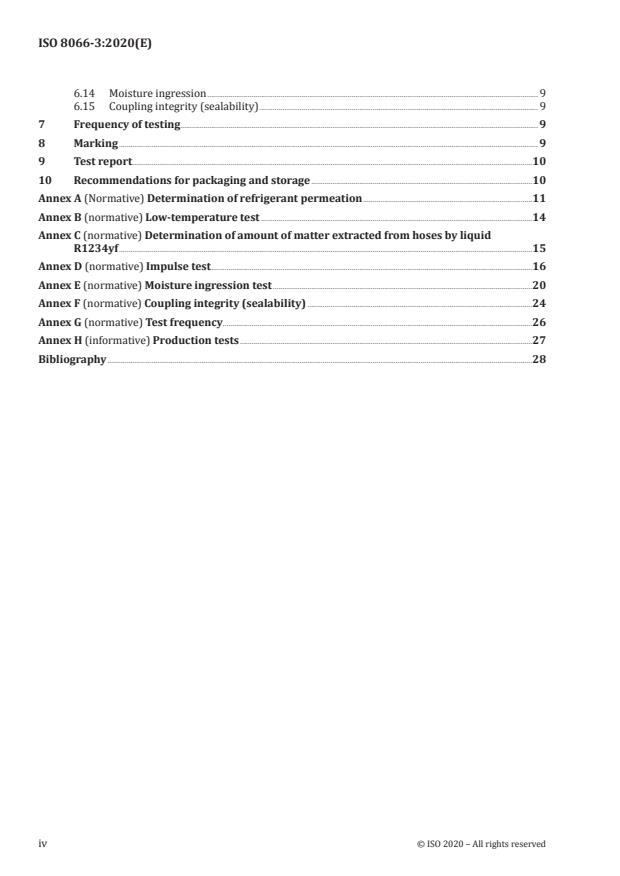

6.14 Moisture ingression . 9

6.15 Coupling integrity (sealability) . 9

7 Frequency of testing . 9

8 Marking . 9

9 Test report .10

10 Recommendations for packaging and storage .10

Annex A (Normative) Determination of refrigerant permeation .11

Annex B (normative) Low-temperature test .14

Annex C (normative) Determination of amount of matter extracted from hoses by liquid

R1234yf .15

Annex D (normative) Impulse test .16

Annex E (normative) Moisture ingression test .20

Annex F (normative) Coupling integrity (sealability) .24

Annex G (normative) Test frequency.26

Annex H (informative) Production tests .27

Bibliography .28

iv © ISO 2020 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

w w w . is o . or g / is o/ f or ewor d . ht m l .

This document was prepared by Technical Committee ISO/TC 45, Rubber and rubber products,

Subcommittee SC 1, Rubber and plastics hoses and hose assemblies.

A list of all parts in the ISO 8066 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

INTERNATIONAL STANDARD ISO 8066-3:2020(E)

Rubber and plastics hoses and hose assemblies for

automotive air conditioning — Specification —

Part 3:

Refrigerant 1234yf

WARNING — Persons using this document should be familiar with normal laboratory practice.

This document does not purport to address all of the safety problems, if any, associated with its

use. It is the responsibility of the user to establish appropriate health and safety practices and to

ensure compliance with any national regulatory conditions.

1 Scope

This document specifies the requirements for rubber or thermoplastic hoses and hose assemblies

used for circulating liquid and gaseous R1234yf (tetrafluoropropene) in the air-conditioning systems

of automobiles. The hoses and hose assemblies are designed in such a way as to restrict losses of

refrigerant and contamination of the system. The operational temperature range is −40 °C to +125 °C.

Due to the critical relationship between the hose and coupling for this application, a requirement that

the coupling to be used in service be used for testing has been laid down.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 1402, Rubber and plastics hoses and hose assemblies — Hydrostatic testing

ISO 4671:2007, Rubber and plastics hoses and hose assemblies — Methods of measurement of the

dimensions of hoses and the lengths of hose assemblies

ISO 7326:2016, Rubber and plastics hoses — Assessment of ozone resistance under static conditions

ISO 8330, Rubber and plastics hoses and hose assemblies — Vocabulary

ISO 23529, Rubber — General procedures for preparing and conditioning test pieces for physical test methods

ISO/TR 11340, Rubber and rubber products — Hydraulic hose assemblies — External leakage classification

for hydraulic systems

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 8330 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http:// www .electropedia .org/

— ISO Online browsing platform: available at https:// www .iso .org/ obp

4 Classification

4.1 Types

4.1.1 General

Including, but not limited to the following.

4.1.2 Type A — Rubber, textile-reinforced, rubber-covered

The hose shall be built having a suitable seamless synthetic rubber tube. The reinforcement shall

consist of textile yarn, cord, or fabric adhered to the tube and cover. The outer cover shall be heat- and

ozone-resistant synthetic rubber.

4.1.3 Type B — Rubber, wire-reinforced, rubber-covered

The hose shall be built having a suitable seamless synthetic rubber tube. The reinforcement shall

consist of steel wire adhered to the rubber tube. The cover shall consist of a heat-resistant textile yarn

impregnated with a synthetic rubber cement.

4.1.4 Type C — Barrier, textile-reinforced, rubber-covered

The hose shall have a suitable thermoplastic barrier between rubber layers. The reinforcement shall

consist of suitable textile yarn, cord, or fabric adhered to the tube and cover. The outer cover shall be

heat- and ozone-resistant synthetic rubber.

4.1.5 Type D — Thermoplastic, textile-reinforced, thermoplastic-covered

The hose shall have a suitable thermoplastic tube. The reinforcement shall consist of a suitable textile

yarn, cord, or fabric adhered to the tube and cover. The outer cover shall be heat- and ozone-resistant

synthetic elastomer.

4.1.6 Type E — Veneer, textile-reinforced, rubber-covered

The hose shall have a suitable thermoplastic veneer lining with a rubber tube outer layer. The

reinforcement shall consist of a textile yarn, cord, or fabric adhered to the tube and cover. The cover

shall be heat- and ozone-resistant synthetic rubber.

4.1.7 Type F — Veneer, barrier, thermoplastic liner

The hose shall have a suitable thermoplastic veneer liner with a thermoplastic barrier between

elastomeric layers. The reinforcement shall consist of a suitable textile yarn, cord, or fabric adhered to

the tube and cover. The cover shall be heat- and ozone-resistant elastomer.

Table 1 gives the figure and applicable pressure class for each type.

2 © ISO 2020 – All rights reserved

Table 1 — Figure and applicable pressure class

Applicable pressure class

Type Figure

High Low

A X X

B X N/A

C X X

D X N/A

E X X

F X X

Key

1 rubber 4 wire X = Applicable

2 cover 5 thermoplastic resin N/A = Not applicable

3 textile

4.2 Pressure classes

4.2.1 High — Discharge and liquid applications.

4.2.2 Low — Suction application.

Working pressures are given in Table 2.

Table 2 — Working pressure

Pressure class Working pressure

MPa (bar)

High 3,28 (32,8)

Low 1,06 (10,6)

4.3 Moisture-ingression grades

4.3.1 ML — Low moisture ingression hose as defined in 6.14.

4.3.2 Mm — Medium moisture ingression hose as defined in 6.14.

4.4 Refrigerant-permeation grades

4.4.1 RU — Ultra low refrigerant permeation hose as defined in 6.3.2.

4.4.2 RL — Low refrigerant permeation hose as defined in 6.3.2.

4.4.3 Rm — Medium refrigerant permeation hose as defined in 6.3.2.

5 Dimensions

5.1 Hose inside diameters

Standard dimensions are given in Table 3, but not limited to the following.

Table 3 — Typical inside diameters

Nominal size Mean inside diameter

mm

8 (5/16) 8

10 (13/32) 10,3

11 11

13 (1/2) 12,7

14 14

15 15

16 (5/8) 15,9

19 (3/4) 19

25 (1) 25,4

NOTE Nominal size in parenthesis is in inches.

5.2 Hose wall thickness variation

When the wall thickness is measured in accordance with method 2 of ISO 4671:2007, the variation in

the wall thickness shall not exceed the values given in Table 4.

4 © ISO 2020 – All rights reserved

Table 4 — Wall thickness variation

Type A, B, C and E Type D and F

Nominal size Maximum departure Nominal size Maximum departure

from concentricity from concentricity

mm mm

Up to and including 13 0,6

Up to and including 19 1,0

Over 13 and including 19 0,8

Over 19 1,3 Over 19 1,0

6 Testing and performance requirements

6.1 Test conditions

The testing room shall be kept at standard temperature in accordance with ISO 23529. The temperature

of the hoses or hose assemblies shall be stabilized for 24 h before testing.

6.2 Leakage

6.2.1 Method A for type test and production test

When determined in accordance with the procedure given in 6.2.2, the loss in mass of refrigerant shall

be no greater than 10 % of the initial mass of the refrigerant and there shall be no visible deterioration

in the hoses or hose assemblies.

6.2.2 Procedure for method A

Test three test pieces. Fill each test piece with R1234yf containing (10 ± 1) % refrigerant compatible

lubrication oil. Maintain each test piece with the pressure listed in Table 2 for 24 h at a temperature of

80 °C ± 2 °C.

This test can be carried out separately or during the 24 h pre-conditioning period for the refrigerant

loss test (see 6.3) at 80 °C ± 2 °C. When the test is carried out separately from 6.3, use the procedure

described in Annex A.

6.2.3 Method B for routine test

When determined in accordance with the procedure given in 6.2.4, there shall be no leak and no

visible deterioration in the hoses or hose assemblies. When pricked hose is tested, gas bubbles which

form on the surface of the hose and decrease gradually after pressurizing may be observed but not be

considered as a leak.

6.2.4 Procedure for method B

Immerse the test assembly in the water bath. Apply gas (air or inert gases) pressure and maintain the

pressure listed in Table 2 for 5 min. Also, a gas leak detector, snoop liquid leak detector may be applied

to check leakage under the pressure listed in Table 2 for 5 min.

6.3 Refrigerant permeation

6.3.1 Requirement

When determined in accordance with the procedure described in 6.3.2, the loss of refrigerant from the

hoses or hose assemblies shall be no greater than the values given in Table 5.

6.3.2 Procedure

Test the hoses or hose assemblies in accordance with the procedure described in Annex A at 80 °C ± 2 °C.

Table 5 — Refrigerant permeation

Refrigerant-permeation grade Maximum allowable loss of refrigerant

kg/m /year

RU 1,5

RL 5

Rm 18

6.4 Ageing

6.4.1 Requirement

When tested in accordance with 6.4.2, there shall be no leak and no cracks in a test hose or hose

assembly.

6.4.2 Procedure

Wind a hose or hose assembly, of length between 300 mm and 1 000 mm, on to a mandrel having a

diameter eight times the outside diameter of the hose. Place the mandrel and hose or hose assembly in a

circulating-air oven for 168 h at 125 °C ± 2 °C.

Take the mandrel and hose or hose assembly out of the oven, allow to cool to ambient temperature,

unwind the hose or hose assembly and examine it externally for any cracks, disintegration or other

defects. Then test the hose or hose assembly in accordance with the procedure given in 6.2.3 and 6.2.4.

6.5 Low-temperature test

When tested in accordance with the method described in Annex B, there shall be no leak or loss due to

cracks or splits.

6.6 Vacuum resistance

6.6.1 General

A hose or hose assembly shall be subjected, consecutively, to the vacuum test, then the length variation

test (6.7), then the burst test (6.8).

6.6.2 Requirement

The decrease in the outside diameter of the hose shall not exceed 20 % of the initial outside diameter

and there shall be no obstruction of flow caused by the hose collapse when the hose or hose assembly

is subjected to a reduced internal pressure (vacuum) of 1,33 kPa ± 0,66 kPa (absolute) for 2 min in

accordance with 6.6.3.

6.6.3 Procedure

The test hose or hose assembly shall have a free length of from 610 mm to 1 000 mm. Bend the hose into

a U shape, whereby the internal radius of the base of the U shall be five times the mean outside diameter

of the hose. Measure the minor axis, d , at the base of the U. Apply a vacuum of 1,33 kPa ± 0,66 kPa

(absolute) to the bent hose for 2 min. At the end of this period and while the vacuum is still being

6 © ISO 2020 – All rights reserved

applied, measure the minor axis, d at the base of the U. The ratio of the decrease in outside diameter R

2 d

shall be calculated as below:

R = (d – d )/d (×100 %)

d 1 2 1

6.7 Length change under pressure

6.7.1 Requirement

When subjected to a pressure listed in Table 2, a hose or hose assembly shall not contract by more than

4 % or extend by more than 2 %.

6.7.2 Procedure

Subject the hose or hose assembly, in a horizontal position, to an internal hydrostatic pressure of 7 kPa

(0,07 bar) and measure the length. Increase the pressure to the prescribed value and measure the

length once again within the following minute. Express the length as a percentage of the length at 7 kPa

(0,07 bar).

Refer to ISO 1402 for additional information.

6.8 Minimum bursting pressure

When determined in accordance with the method described in ISO 1402, using test pieces that have

been subjected to the test for refrigerant loss described in 6.3, the minimum bursting pressure shall be

the value listed in Table 6.

Table 6 — Minimum burst pressure

Pressure class Minimum burst pressure

MPa (bar)

High 13,12 (131,2)

Low 4,24 (42,4)

6.9 Proof pressure

6.9.1 Requirement

When tested in accordance with the procedure described in 6.9.2, a hose or hose assembly shall exhibit

no leakage, cracking, abrupt distortion (indicating irregularity in materials or manufacture) or other

signs of failure.

6.9.2 Procedure

Hydrostatically pressurize a hose or hose assembly to the value listed in Table 7 and hold the pressure

for 2 min ± 30 s. During and after the proof pressure hold period, examine the hose.

Table 7 — Proof pressure

Pressure class Proof pressure

MPa (bar)

High 6,56 (65,6)

Low 2,12 (21,2)

6.10 Extraction by R1234yf

When determined in accordance with Annex C, the quantity of matter extracted from the lining of the

hose by the R1234yf shall not exceed 118 g/m .

NOTE The substances extracted will be of an oily or greasy nature.

6.11 Ozone resistance

This requirement applies only to rubber covered hoses.

Bend the hose around a mandrel with a diameter equal to eight times the mean outside diameter of the

hose and carry out the test in accordance with method 1 of ISO 7326:2016 using an ozone concentration

of 50 mPa ± 5 mPa.

The hose cover shall exhibit no visible cracks when viewed under ×7 magnification.

6.12 Hose cleanliness

6.12.1 Requirement

The tube of the hose shall be dry and clean. When determined in accordance with 6.12.2, the mass of

insoluble matter shall be a maximum of 270 mg/m based on the internal surface area of the hose.

6.12.2 Procedure

Take a hose test piece having a minimum length of 300 mm. Bend the hose into a U-shape, with the legs

of the U of equal length. Place the hose in a vertical position and fill the hose with a suitable solvent.

Immediately empty the hose, filtering the solvent through a prepared Gooch crucible, a sintered-glass

crucible or a 0,4 mm filter of known mass.

After drying the filter and residue at approximately 70 °C for 20 min, determine the mass of insoluble

matter by difference.

6.13 Impulse test

6.13.1 Requirement

When tested in accordance with 6.13.2, hoses or hose assemblies shall not leak or fail prior to

150 000 cycles.

6.13.2 Procedure

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...