ISO 21413:2005

(Main)Manual methods for the measurement of a groundwater level in a well

Manual methods for the measurement of a groundwater level in a well

ISO 21413:2005 develops procedures and prescribes the minimum accuracy required of water-level measurements made in wells using graduated steel tapes, electric tapes and air lines. Procedures and accuracy requirements for measuring water levels in a flowing well are also included, as are procedures required to establish a permanent measuring point. ISO 21413:2005 discusses the advantages and limitations of each method and requirements for recording the data. ISO 21413:2005 does not include methods that use automated electrical or mechanical means to measure and record water levels.

Méthodes manuelles pour le mesurage du niveau de l'eau souterraine dans un puits

General Information

- Status

- Published

- Publication Date

- 16-Oct-2005

- Technical Committee

- ISO/TC 113/SC 8 - Ground water

- Drafting Committee

- ISO/TC 113/SC 8 - Ground water

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 11-Jul-2025

- Completion Date

- 13-Dec-2025

Overview

ISO 21413:2005 - "Manual methods for the measurement of a groundwater level in a well" - specifies standardized procedures and minimum accuracy requirements for manual groundwater level measurement in wells. The standard covers three manual methods - graduated steel tape, electric tape, and air-line - plus procedures for measuring flowing (overflowing) wells and for establishing a permanent measuring point. ISO 21413:2005 explicitly excludes automated electrical or mechanical logging systems.

Key topics and requirements

- Measurement methods: Detailed procedures for the graduated steel tape (wetted-tape), electric tape (contact-sensor), and air-line (pressurized tube) methods.

- Flowing well procedures: Techniques and accuracy considerations for measuring water levels in wells that discharge at the ground surface.

- Permanent measuring point (MP): Steps to establish and document a stable reference point on the well casing and relate it to land-surface datum.

- Accuracy requirements:

- Independent steel tape measurements should agree within ±1.0 cm for depths < 60 m.

- For depths between 60 m and 150 m, agreement within ±2.0 cm is required.

- Guidance on deep-well corrections (thermal expansion, tape stretch) is provided in Annex A; Annex B covers air-line corrections.

- Calibration & maintenance: Steel tapes should be calibrated at least annually against a reference tape; records of calibration and maintenance must be kept.

- Data recording: The standard prescribes minimum data recording elements (measuring point, MP correction to land-surface datum, raw readings, method used, and notes on assumptions or corrections).

- Advantages and limitations: Discussion of method-specific pros/cons (e.g., steel tape accuracy vs. susceptibility to condensation; air-line use for inaccessible wells).

- Assumptions: Clear listing of assumptions such as plumbness of casing, availability of prior measurements, and condition of measuring devices.

Applications

ISO 21413:2005 is practical for:

- Groundwater monitoring programs (routine water-level surveys)

- Environmental site assessments and remediation monitoring

- Hydrogeological investigations and well inventory surveys

- Water utilities and well owners needing standardized manual measurement protocols

Using ISO 21413 ensures consistent, comparable water-level data, facilitates quality control, and documents measurement uncertainty for regulatory reporting, research and long-term monitoring.

Who should use it

- Hydrogeologists and field technicians

- Environmental consultants and regulators

- Water-resource managers and utilities

- Well contractors and monitoring program coordinators

Related standards and context

ISO 21413 was prepared by ISO/TC 113 (Hydrometry), Subcommittee SC 8 (Groundwater). For a broader hydrometry framework, consider other ISO hydrology/hydrometry documents produced by the same technical committee.

Keywords: ISO 21413, groundwater level measurement, water-level measurement in wells, manual water-level methods, graduated steel tape, electric tape, air-line method, flowing well measurement, well monitoring standards.

Frequently Asked Questions

ISO 21413:2005 is a standard published by the International Organization for Standardization (ISO). Its full title is "Manual methods for the measurement of a groundwater level in a well". This standard covers: ISO 21413:2005 develops procedures and prescribes the minimum accuracy required of water-level measurements made in wells using graduated steel tapes, electric tapes and air lines. Procedures and accuracy requirements for measuring water levels in a flowing well are also included, as are procedures required to establish a permanent measuring point. ISO 21413:2005 discusses the advantages and limitations of each method and requirements for recording the data. ISO 21413:2005 does not include methods that use automated electrical or mechanical means to measure and record water levels.

ISO 21413:2005 develops procedures and prescribes the minimum accuracy required of water-level measurements made in wells using graduated steel tapes, electric tapes and air lines. Procedures and accuracy requirements for measuring water levels in a flowing well are also included, as are procedures required to establish a permanent measuring point. ISO 21413:2005 discusses the advantages and limitations of each method and requirements for recording the data. ISO 21413:2005 does not include methods that use automated electrical or mechanical means to measure and record water levels.

ISO 21413:2005 is classified under the following ICS (International Classification for Standards) categories: 07.060 - Geology. Meteorology. Hydrology; 17.060 - Measurement of volume, mass, density, viscosity. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 21413:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 21413

First edition

2005-10-15

Manual methods for the measurement

of a groundwater level in a well

Méthodes manuelles pour le mesurage du niveau de l'eau souterraine

dans un puits

Reference number

©

ISO 2005

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2005

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2005 – All rights reserved

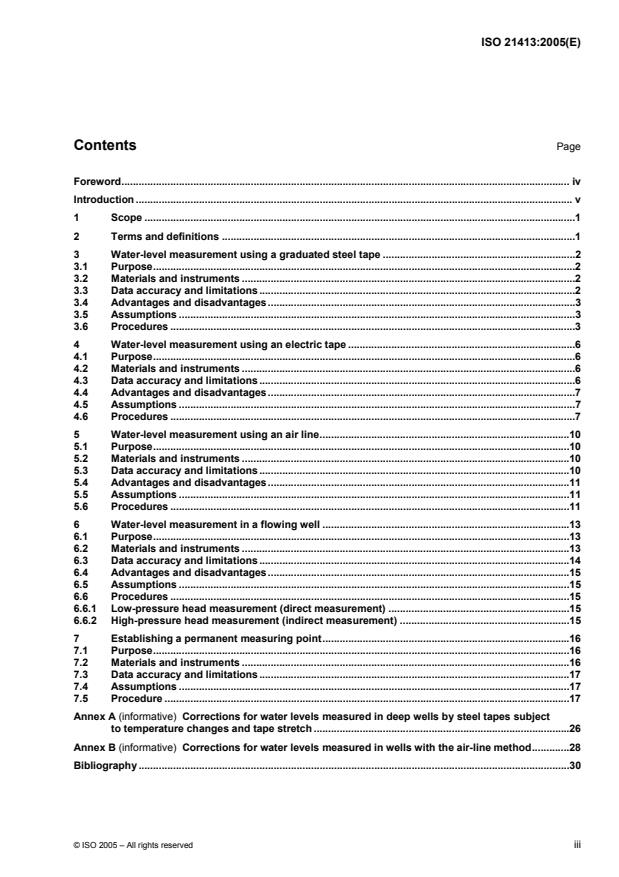

Contents Page

Foreword. iv

Introduction . v

1 Scope.1

2 Terms and definitions .1

3 Water-level measurement using a graduated steel tape .2

3.1 Purpose.2

3.2 Materials and instruments .2

3.3 Data accuracy and limitations.2

3.4 Advantages and disadvantages.3

3.5 Assumptions .3

3.6 Procedures.3

4 Water-level measurement using an electric tape .6

4.1 Purpose.6

4.2 Materials and instruments .6

4.3 Data accuracy and limitations.6

4.4 Advantages and disadvantages.7

4.5 Assumptions .7

4.6 Procedures.7

5 Water-level measurement using an air line.10

5.1 Purpose.10

5.2 Materials and instruments .10

5.3 Data accuracy and limitations.10

5.4 Advantages and disadvantages.11

5.5 Assumptions .11

5.6 Procedures.11

6 Water-level measurement in a flowing well .13

6.1 Purpose.13

6.2 Materials and instruments .13

6.3 Data accuracy and limitations.14

6.4 Advantages and disadvantages.15

6.5 Assumptions .15

6.6 Procedures.15

6.6.1 Low-pressure head measurement (direct measurement) .15

6.6.2 High-pressure head measurement (indirect measurement) .15

7 Establishing a permanent measuring point.16

7.1 Purpose.16

7.2 Materials and instruments .16

7.3 Data accuracy and limitations.17

7.4 Assumptions .17

7.5 Procedure.17

Annex A (informative) Corrections for water levels measured in deep wells by steel tapes subject

to temperature changes and tape stretch .26

Annex B (informative) Corrections for water levels measured in wells with the air-line method.28

Bibliography .30

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 21413 was prepared by Technical Committee ISO/TC 113, Hydrometry, Subcommittee SC 8, Ground

water.

iv © ISO 2005 – All rights reserved

Introduction

The measurement of a water level in a well constitutes a data-collection process that provides fundamental

information about the status of a groundwater system. Accordingly, measured water levels should be

sufficiently accurate and reproducible to meet the needs of most data-collection and monitoring programs.

Several manual methods commonly used to collect water-level data in wells employ relatively simple

measuring devices such as graduated steel tapes, electric tapes, and air lines. In some cases, water-level

measurements are required in flowing wells. The procedures associated with each of these methods are

intrinsically different and subject to varying limitations and accuracies. Standardization of these methods

would ensure that the procedures and associated equipment used by the international community to collect

water-level data in a well are consistent, and that the results can be compared with minimal concern about the

relative accuracies and/or the procedures use in collecting the data.

INTERNATIONAL STANDARD ISO 21413:2005(E)

Manual methods for the measurement of a groundwater level in

a well

1 Scope

This International Standard develops procedures and prescribes the minimum accuracy required of water-

level measurements made in wells using graduated steel tapes, electric tapes and air lines. Procedures and

accuracy requirements for measuring water levels in a flowing well are also included, as are procedures

required to establish a permanent measuring point. This International Standard discusses the advantages and

limitations of each method and requirements for recording the data. This International Standard does not

include methods that use automated electrical or mechanical means to measure and record water levels.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply:

2.1

air line

water-level measuring device consisting of a small diameter open-ended tube fixed in position that is

accessible from the top of the casing and extends to below the water level in a well where pressurized air

measurements can be used to determine the depth to water

2.2

casing (well casing)

tubular retaining structure, which is installed in a drilled borehole or excavated well, to maintain the borehole

opening. Plain (unscreened) casing prevents the entry of water and fine material into the well, while open

(screened) casing allows water ingress but should exclude fines

2.3

electric tape

water-level measuring device that uses an electrical signal, sent through a cable with fixed distance marks, to

determine the water level relative to a fixed reference point. The electrical signal, which is induced when the

sensor makes contact with the water surface, activates an indicator (typically a light, buzzer or needle)

2.4

flowing well (or overflowing well)

well from which groundwater is discharged at the ground surface without the aid of pumping

NOTE A deprecated term for this definition is an artesian well.

2.5

graduated steel tape

water-level measuring device consisting of a flat measuring tape with permanently fixed distance marks that

can be wound on a reel

2.6

groundwater

water within the saturated zone

2.7

land surface datum

average altitude of land surface at a referenced well

2.8

measuring point

permanent reference marked on well casing

2.9

static water level (or static head)

height, relative to an arbitrary reference level, of a column of water that can be supported by the static

pressure at a given point

2.10

well

hole sunk into the ground for abstraction of water or for observation purposes

3 Water-level measurement using a graduated steel tape

3.1 Purpose

The purpose of this method is to measure the depth to the water surface (level) below a measuring point using

the graduated steel tape (wetted-tape) method.

3.2 Materials and instruments

The following materials and instruments are required.

3.2.1 Steel tape graduated in metres and centimetres.

A black tape is preferred to a chromium-plated tape because the wetted chalk mark is easier to read against a

black tape. A break-away weight should be attached to the ring on the end of the tape with wire strong enough

to hold the weight, but not as strong as the tape, so that if the weight becomes lodged in the well, the tape can

still be pulled free. The weight should be made of brass, stainless steel or iron.

3.2.2 Coloured chalk.

3.2.3 Clean cloth.

3.2.4 Pencil and eraser.

3.2.5 Steel tape calibration and maintenance equipment log book.

3.2.6 Water-level measurement field form (see the example in Figure 6).

3.2.7 Equipment to gain access to the well (wrenches, crow bars, manhole keys, etc.).

3.2.8 Common household chlorine bleach or other suitable disinfectant.

3.3 Data accuracy and limitations

The following data accuracy and limitations apply.

a) Independent graduated steel tape measurements of static water levels should agree within ± 1,0 cm for

depths of less than 60 m;

2 © ISO 2005 – All rights reserved

b) For depths between 60 m and 150 m, independent measurements using the same tape should agree

within ± 2,0 cm. When measuring deep water levels (i.e. greater than 300 m), errors due to the effects of

thermal expansion and of stretch produced by the suspended weight of the tape and plumbing weight

warrant consideration (see Reference [2], p. 3). An example of correcting a deep water level for thermal

expansion and stretch of a steel tape is given in Annex A. However, because the equipment required to

measure temperatures at land surface and down the well may not always be readily available, the

corrections described in Annex A are not required for the purposes of this International Standard, though

the practitioner shall note on the water-level field form (see the example in Figure 6) whether or not any

such corrections were applied.

c) At least once every twelve months, the steel tape should be calibrated against another steel tape that is

dedicated as a calibration tape and is not used in the field. If the steel tape does not meet test criteria,

then it must be removed from service. Records of these tests shall be kept.

d) If the well casing is angled, instead of vertical, the depth to water will have to be corrected. If the casing

angle is unknown and a correction is not feasible, this should be noted in water-level measurement field

form (see the example in Figure 6).

3.4 Advantages and disadvantages

The graduated steel tape method is easy to use and is considered to be the most accurate method for

measuring the water level in nonflowing wells of moderate depth. However, it may be impossible to get

reliable results if water is dripping into the well or condensing on the well casing. Also, the method is not

recommended for measuring pumping levels in wells.

3.5 Assumptions

The following assumptions apply in the use of the graduated steel tape method.

a) An established measuring point (MP) exists and the distance from the MP to land-surface datum (LSD) is

known (see the example in Figure 6). See the technical procedure described in Clause 7 for establishing

a permanent MP.

b) The MP is clearly marked and described so that all measurements will be taken from the same point.

c) The results from previous water-level measurements made at the well are available for estimating the

length of the required tape.

d) The steel tape will retain the chalk.

e) The well is free of obstructions. Well obstructions, if present, could cause errors in the measurement if the

obstructions affect the plumbness of the steel tape.

3.6 Procedures

The following procedures for measuring water levels in a well with a graduated steel tape shall be observed.

a) Apply the coloured chalk to the lower metre of the tape by pulling the tape across the chalk. The wetted

chalk mark will identify that part of the tape that was submerged.

b) Lower the weight and tape into the well until the lower end of the tape is submerged below the water

(more than one attempted measurement may be needed to determine the length of tape required to

submerge the weight). Once the end of the tape is submerged, continue to lower the tape into the well

until the next whole metre graduation mark is opposite the MP. This whole number shall be recorded in

the “MP HOLD” (Figure 1) column of the water-level measurements field form (see the example in

Figure 6).

c) Pull the tape back to the surface before the wetted chalk mark dries and becomes difficult to read. Record

the number of the wetted chalk mark (sometimes referred to as the cut) in the “WETTED CHALK MARK”

(Figure 1) column of the water-level measurements field form (see the example in Figure 6).

d) Subtract the wetted chalk mark number from the number held to the MP, and record this number in the

“DEPTH TO WATER FROM MP” (Figure 1) column of the water-level measurements field form (see the

example in Figure 6). The difference between these two readings is the depth to water below the MP.

e) Apply the MP correction to get the depth to water below or above land-surface datum (LSD). If the MP is

above land surface (see the example in Figure 6), the distance between the MP and land surface datum

is subtracted from the depth to water from the MP (see the example in Figure 6) to obtain the depth to

water below land surface. If the MP is below land surface, precede the MP correction value with a minus

(−) sign and subtract the distance between the MP and land surface datum from the depth to water from

the MP to obtain the depth to water below land surface. Record this number in the “DEPTH TO WATER

FROM LSD” (Figure 1) column of the water-level measurements field form (see the example in Figure 6).

If the water level is above LSD, record the depth to water above land surface as a negative number.

f) Make a check measurement by repeating steps a) through e). The check measurement shall be made

using a different MP hold value (see the example in Figure 6) than that used for the original measurement.

If the check measurement does not agree with the original measurement to the nearest centimetre,

continue to make check measurements until the reason for the lack of agreement is determined or until

the results are shown to be reliable. If more than two readings are taken, the observer shall select the

reading considered the most reliable. This reading shall be recorded to the nearest centimetre.

g) After completing the well measurements, disinfect the steel tape and weight by pouring a small amount of

common household chlorine bleach or other suitable disinfectant on a clean cloth and wiping down the

part of the tape that was submerged below the water surface. This will avoid possible contamination of

other wells.

h) The tape shall be maintained in good working condition by periodically checking the tape for rust, breaks,

kinks and possible stretch due to the suspended weight of the tape and the tape weight.

All calibration and maintenance data associated with the steel tape being used shall be recorded in its

calibration and maintenance equipment log book. All water-level data shall be recorded on the water-level

measurements field form (see the example in Figure 6) to the nearest centimetre.

In some contaminated or pumped wells, a layer of oil may be floating on the surface of the water. In such

cases, if the thickness of the oil layer is several centimetres or less, the tape reading made at the top of the oil

mark can be used as the water-level measurement. The associated error in this case should be relatively

small because the level of the oil surface would differ only slightly from the level of the water surface that

would be measured if no oil were present. If a meter of more of oil is present, however, or if it is deemed

necessary to ascertain the thickness of the oil layer, a commercially-available water-detection paste, originally

developed to detect water in gasoline storage tanks, is available to do so. The paste can be applied to the end

of the measuring tape that is lowered into the well. The top of the oil layer will be reflected as a wet line on the

tape, while the top of the water will be shown by a distinct colour change. In either event, whether the oil layer

is greater than or less than a few millimetres in thickness, its presence should be noted on the water-level

measurements field form (see the example in Figure 6). A specialized interface probe is also commercially

available for measuring the interface.

In the event no water is encountered in the well, this shall be duly noted under “REMARKS” on the field form,

along with the distance between the MP and the bottom of the well.

4 © ISO 2005 – All rights reserved

Dimensions in metres

Key

1 measuring point (MP)

2 MP hold

3 land surface datum (LSD)

4 water level

5 depth to water from LSD = 12,86

6 depth to water from MP = 13,71

7 wetted chalk mark

Figure 1 — Water-level measurements using a graduated steel tape

4 Water-level measurement using an electric tape

4.1 Purpose

The purpose of this method is to measure the depth to the water surface below a measuring point using the

electric tape method.

Electric tapes fall into two categories:

⎯ Type 1 those that have fixed graduations lacking a suitable frequency (e.g. 1 m graduation) that would

enable readings to be made at a sufficient accuracy without the use of additional graduated measures

(e.g. tapes calibrated in centimetres). Type 1 tapes are referred to as “partially graduated” tapes in the

rest of this clause; and

⎯ Type 2 those with fixed graduations which are spaced at lengths equal to or smaller than the accuracy

required for the readings. Type 2 tapes are referred to as “fully graduated” tapes in the rest of this clause.

4.2 Materials and instruments

The following materials and instruments are required.

4.2.1 Electric tape of various wiring arrangements or configurations, that would include flat parallel or

co-axial conductive wires, graduated in metres and/or centimetres. Electric tapes are commonly mounted on a

hand-cranked supply reel that contains space for the batteries and some device for signalling when the circuit

is closed (Figure 2).

4.2.2 Electric tape calibration and maintenance equipment log book.

4.2.3 Pencil and eraser.

4.2.4 Water-level measurement field form (Tables 2 and 3).

4.2.5 Equipment to gain access to the well (wrenches, crow bars, manhole keys, etc.).

4.2.6 Common household chlorine bleach, and, for measurements made with Type 1, electric tapes.

4.2.7 Steel tape graduated in metres and centimetres.

4.2.8 Spare batteries.

4.3 Data accuracy and limitations

The following data accuracy and limitations apply.

a) Independent electric tape measurements of static water levels using the same tape should agree within

± 1,0 cm for depths of less than 60 m.

b) For depths of about 150 m, the maximum difference of independent measurements using the same tape

should agree within ± 3,0 cm.

c) For depths in the 500 m range, the repeatability of measurements using the same tape should agree

within ± 15 cm (see Reference [2], p. 11).

6 © ISO 2005 – All rights reserved

4.4 Advantages and disadvantages

The electric tape method is superior to the graduated steel tape method when

a) water is dripping into the well or condensing on the inside of casing walls which may make it very difficult

to get a good water mark on the chalked tape,

b) wells are being pumped and the splashing of the water surface makes chalked measurements virtually

impossible, and

c) a series of measurements are needed in quick succession, such as in aquifer tests, because the electric

tape does not have to be removed from the well for each reading.

Also, the electric tape method is safer to use in pumping wells because the water is sensed as soon as the

probe reaches the water surface and there is less danger of lowering the tape into the pump impellers.

Electric tape measurements are generally less accurate than are measurements made with graduated steel

tapes. Electric tapes are also harder to keep calibrated than are steel tapes and electric connections need to

be maintained in good order. Also, the insulation around the conductor cables may be severed when being

drawn across sharp edges of metal pipes at the top of a borehole. In addition, the presence of hydrocarbons

on the water surface that may result from oil leaks during drilling operations may coat the sonde, resulting in a

failure to complete the electrical circuit. Finally, a stilling pipe may be required to avoid inaccurate readings

where water is cascading down the borehole during pumping (aquifer) tests.

In general, fully graduated tapes are preferred to partially graduated tapes. Fully graduated tapes are easier to

use and there are fewer opportunities for errors in measurement, particularly when the time intervals between

measurements are small such as during pumping tests.

4.5 Assumptions

Application of the electric tape method assumes

a) that an established measuring point (MP) exists; and

b) if the water level is to be referenced to land surface, that the distance between the MP and land-surface

datum (LSD) is known (see the example in Figure 7).

See the technical procedure described in Clause 7 for establishing a permanent MP.

Also, the MP should be clearly marked and described so that all measurements will be taken from the same

point.

If the MP of record cannot be located, the use of data for assessing long-term trends may be compromised. In

such cases, a new MP should be established and the date of change should be indicated on the record sheet.

4.6 Procedures

The following procedures for measuring water levels in a well with an electric tape shall be observed.

a) Prior to using an electric tape in the field, calibrate it by comparing the total length of the electric tape

against the length of an acceptable steel tape. An acceptable steel tape is one that has a fixed graduation

of a centimetre (or less) and that is maintained in the office for the sole purpose of calibrating electric

tapes. Also, check the accuracy of the position of each 1 m interval metal band to make sure that the

bands have not moved. This is especially important if the electric tape has been used for a long time or

after it has been pulled hard in attempting to free the line. If the field tape fails to meet test criteria, then it

must be removed from service. Records of these tests shall be kept.

b) Before lowering the probe into the well, check the circuitry of the electric tape by dipping the probe into

water and observe if the indicator (needle, light, or buzzer) is operating correctly as the circuit closes.

Note the position the indicator needle deflects during the circuitry check.

c) Lower the electrode probe slowly into the well until contact with the water surface causes the circuit to

close, activating the indicator (Figure 2). Slightly raise and then lower the electrode again to identify just

where the electrode first comes into contact with the surface of the water. Once the indicator needle

deflects to the point chosen during the circuitry check, place the nail of the index finger on the insulated

wire at the MP.

d) For fully graduated tapes, partly withdraw the electric tape from the well and record the depth to water to

the nearest centimetre or less if, in the opinion of the observer, the instrumentation is capable of greater

precision. Record in the “DEPTH TO WATER FROM MP” column of the water-level measurements field

form (see the example in Figure 7).

For partially graduated tapes, partly withdraw the electric tape from the well and record the metre mark of

the nearest 1-metre tape band below the MP in the “NEAREST 1-metre TAPE BAND BELOW MP”

column of the water-level measurements field form (see the example in Figure 8). Then measure the

distance from the MP mark on the insulated wire to the nearest 1-metre tape band that is below the MP

mark with a graduated steel tape and record that distance, to the nearest centimetre, in the

“DIFFERENCE BETWEEN MP MARK AND NEAREST 1-metre TAPE BAND BELOW MP” column of the

water-level measurements field form (see the example in Figure 8). The depth to water below MP is then

obtained by adding the distance between the MP mark and the next lowest 1-metre tape band to the

value of the next lowest tape band. Record this number in the “DEPTH TO WATER FROM MP” column of

the water-level measurements field form (see the example in Figure 8).

e) Apply the MP correction to get the depth to water below or above LSD. If the MP is above land surface,

its height is subtracted from the water level to obtain the depth to water below land surface. If the MP is

below land surface, precede the MP correction value with a minus (-) sign and subtract its height from the

water level to obtain the depth to water below land surface. Subtract the MP correction (Table 2 or

Table 3) from the depth to water from MP (Table 2 or Table 3) and record this number in the “DEPTH TO

WATER CORRECTED FOR LSD” column of the water-level measurements field form (Table 2 or

Table 3). If the water level is above LSD, enter the water level in centimetres above land surface

preceded by a minus sign (−).

f) Make a check measurement by repeating steps d) through f). If the check measurement does not agree

within the accuracy given in 4.3 under “Data accuracy and limitations”, continue to make check

measurements until the reason for the lack of agreement is determined. If more than two measurements

are taken, the observer shall select the reading considered the most reliable. This reading shall be

recorded to the nearest centimetre.

g) After completing the well measurement, disinfect the electric tape by pouring a small amount of common

household chlorine bleach or other suitable disinfectant on a clean cloth and then wipe down that part of

the tape that was submerged below the water surface. This will avoid possible contamination of other

wells.

h) Maintain the tape in good working condition by periodically checking the tape for breaks, kinks, and

possible stretch due to the suspended weight of the tape and the tape weight. Do not let the tape rub

across the top of the casing because the 1-metre metal bands can become displaced; consequently,

placement of the bands should be checked frequently with a steel tape.

8 © ISO 2005 – All rights reserved

Key

1 light indicator

2 reel

3 casing

4 electric cable

5 electrode(s)

6 water

Figure 2 — Water-level measurements using an electric tape (adapted from Reference [1], Figure 16.12)

Because an electric tape will not respond to oil floating on water in a well, the liquid level determined by an

electric tape will be different than that determined by a steel tape, with the difference depending on the

thickness of the oil layer. In cases where this is of concern, a miniature float-driven switch can be put on a

two-conductor electric tape that will allow detection of the oil surface.

All calibration and maintenance data associated with the electric tape being used shall be recorded in its

calibration and maintenance equipment log book. All data shall be recorded in the water-level measurements

field form (see the example in Figure 6) to the appropriate accuracy (4.3) for the depth being measured.

In the event no water is encountered in the well, this shall be duly noted under “REMARKS” on the field form,

along with the distance between the MP and the bottom of the well.

5 Water-level measurement using an air line

5.1 Purpose

The purpose of this method is to measure the depth to the water surface below a measuring point using a

submerged air line.

5.2 Materials and instruments

The following materials and instruments are required.

5.2.1 Seamless copper tubing, brass tubing, or galvanized pipe, preferably 3 mm to 6 mm in diameter

with a suitable pipe tee for connecting an altitude or pressure gauge.

Flexible plastic tubing can also be used, but is less desirable.

5.2.2 Altitude or pressure gauge.

5.2.3 Tyre valve stem and tyre pump.

5.2.4 Small open end wrench.

5.2.5 Wire or electrician’s tape.

5.2.6 Steel tape graduated in metres and centimetres.

5.2.7 Blue carpenter's chalk.

5.2.8 Clean rag.

5.2.9 Field notebook, pencil and eraser.

5.2.10 Water-level measurements field form (see the example in Figure 9).

5.3 Data accuracy and limitations

The following data accuracy and limitations apply.

a) Water-level measurements using an altitude gauge should be accurate to within 3 cm.

b) Water-level measurements using a pressure gauge are more approximate and should not be considered

accurate to more than 30 cm.

10 © ISO 2005 – All rights reserved

c) As in all pressure-dependent methods, fluid density should be considered when measuring water levels

by the air-line method, because the conversion constant of 0,102 m of water per kilopascal (referenced

later in 5.6) is valid only for distilled water at 20 °C. Fluid density is affected primarily by the temperature

and dissolved solids content of the water. An example of correcting a water level measured by an air line

for temperature and dissolved solids content is given in Annex B. However, because the equipment

required to measure the temperature and/or dissolved solids content of the groundwater is not always

readily available, the corrections described in Annex B are not required for the purposes of this

International Standard, though the practitioner shall note on the water-level field form (see the example in

Figure 10) whether or not any such corrections were applied.

5.4 Advantages and disadvantages

The air-line method is especially useful in pumped wells where water turbulence may preclude using a more

precise method. The method can be used while the well is being pumped, when splashing of water renders

the wetted tape method useless. Bends or spirals in the air line do not influence the accuracy of this method

as long as the position of the tubing is not appreciably changed. However, the method is less accurate than

the wetted tape or the electric tape methods and requires time to install the air line and equipment.

5.5 Assumptions

The following assumptions apply in the use of the air-line method.

a) An established measuring point (MP) exists. See the technical procedure described in Clause 7 for

establishing an MP.

b) The MP is clearly marked and described so that all measurements will be taken from the same point.

5.6 Procedures

Figure 3 shows a typical installation for measuring water levels by the air-line method.

The following procedures for measuring water levels in a well with an air line shall be observed.

a) Install an air-line pipe or tube in the well. The air line can be installed by either lowering it into the annular

space between the pump column and casing after the pump has been installed in the well, or by securing

it to sections of the pump and pump column with wire or tape as it is lowered into the well.

b) The air line shall be extended far enough below the water level such that the lower end remains

submerged during pumping of the well.

c) Attach a pipe tee to the top end of the air line. On the opposite end of the pipe tee, attach a tyre valve

stem.

d) Connect an altitude gauge that reads in meters, or a pressure gauge that reads pressure in kilopascals

(kPa), to the fitting on top of the pipe tee with a wrench. If an altitude gauge is used, read the gauge to the

nearest centimetre. For pressure gauges with kilopascal (kPa) units, read the gauge to the nearest

kilopascal (kPa) and multiply by 0,102 m/kPa to convert to meters of water.

e) Connect a tyre pump to the tire valve stem fitting on the pipe tee.

f) As the water level in the well changes, h and d (Figure 3) must change in a manner such that their sum

remains the same. Their sum is a constant (k), which is determined at the same time as a simultaneous

wetted-steel tape and air gauge measurement is made.

Key

a b

1 altitude or pressure gauge

2 tyre pump

3 pipe tee

4 well casing

5 water level

6 air line

7 pump line or column

a

For the altitude gauge:

d = k ⋅ h,

where

d is the measured depth to water level, in metres;

h is the height of water displaced from the air line, in metres; and

b

For the pressure gauge:

d = k ⋅(1,04p) and h = 0,104p,

where

p is the pressure reading in kilopascals; and

d, h and k are in metres.

Figure 3 — Typical installation for measuring water levels by the air-line method and relation of

measured depth to water level, height of water displaced from air line, and depth to bottom of air line

12 © ISO 2005 – All rights reserved

g) To calibrate the air line and gauge, make an initial depth to water-level measurement (d) with a

wetted-steel tape, and an initial air gauge reading (h). Add d and h to determine the constant value for k.

Use a tyre pump to pump compressed air into the air line until all the water is expelled from the line. Once

all water is displaced from the air line, record the maximum gauge reading.

EXAMPLE 1 Using an altitude gauge. The initial measured depth to the water level, d, is 7,88 m; the initial altitude

gauge reading, h, is 23,02 m. Then the constant k = 7,88 m + 23,02 m = 30,90 m (see the example in Figure 9).

EXAMPLE 2 Using a pressure gauge. The initial measured depth to the water level, d, is 26,17 m; the initial pressure

gauge reading, h, is 190 kPa. Then the constant k = 26,17 m + (190 kPa × 0,102 m/kPa) = 26,17 m + 19,38 m = 45,55 m

(see the example in Figure 10).

h) Calibrate the air line and gauge as indicated in g) above.

i) To measure the water-level depth in a well with an air line, subsequent air line readings are subtracted

from the constant k to determine the depth to the water level below the MP. Use a tyre pump to pump

compressed air into the air line until all the water is expelled from the line, and record the maximum

gauge reading.

EXAMPLE 3 Depth to the water level in a well using an altitude gauge with a constant k of 30,90 m. During a later

pumping period, the maximum altitude gauge h reads 15,24 m; therefore, the water level,

d = 30,90 m − 15,24 m = 15,66 m (see the example in Figure 9).

EXAMPLE 4 Depth to the water level in a well using a pressure gauge with a constant k of 45,55 m. During a later

pumping period, the maximum pressure gauge h reads 122 kPa; therefore, the water level,

d = 45,55 m − (122 kPa × 0,102 m/kPa) = 45,55 m − 12,44 m = 33,11 m (see the example in Figure 10).

j) Measure the water-level depth as indicated in i) above.

k) Apply the MP correction to get the depth to water below or above land-surface datum.

l) Record water-level data in the field notebook and on the water-level measurements field form (Table 4 or

Table 5).

6 Water-level measurement in a flowing well

6.1 Purpose

The purpose of this method is to measure low-pressure or high-pressure water-level heads in flowing wells.

6.2 Materials and instruments

The following materials and instruments are required.

6.2.1 Low-pressure head measurements

6.2.1.1 Transparent plastic tubing, of suitable length and diameter.

6.2.1.2 Ladder, if pressure head is more than 2 m to 3 m.

6.2.1.3 Hose clamps.

6.2.1.4 Measuring scale.

6.2.1.5 Pencil and eraser.

6.2.1.6 Calibration and maintenance log book.

6.2.1.7 Water-level measurements field form (see the example in Figure 11).

6.2.2 High-pressure head measurements

6.2.2.1 Flexible hose with a 3-way valve.

6.2.2.2 Hose clamps.

6.2.2.3 Altitude or pressure gauge.

6.2.2.4 Small open-end wrench.

6.2.2.5 Soil-pipe test plug, also known as a sanitary seal, available from most plumbing-supply stores in

sizes that will fit 5 cm to 25 cm diameter pipes.

Soil-pipe test plugs consist of a length of small-diameter pipe, generally less than 3 cm, surrounded by a

rubber packer. The packer can be expanded by an attached wing nut to fit tightly against the inside of the well

casing or discharge pipe. The small-diameter pipe is threaded so that it can be attached to a valve, hose, or

altitude/pressure gauge.

6.2.2.6 Pencil and eraser.

6.2.2.7 Calibration and maintenance log book.

6.2.2.8 Water-level measurement field form (see the example in Figure 11).

6.3 Data accuracy and limitations

The following data accuracy and limitations apply.

a) Low-pressure head measurements can be measured to an accuracy of 3,0 cm.

b) High-pressure head measurements using a pressure-gauge are probably not accurate to within less than

3,0 cm, although the measurements themselves can be read at finer resolutions.

c) The pressure in the well shall not exceed the limit of the altitude/pressure gauge. Pressure gauges are

generally most accurate in the middle third of the gauge range.

d) The measuring gauge shall not be connected to a well that uses a booster pump in the system, because

the pump could start automatically and the resulting pressure surge may ruin the gauge.

e) When a flowing well is closed or opened by a valve or test plug, it should be done gradually. If pressure is

applied or released suddenly, the well could be permanently damaged by the “water-hammer effect” with

subsequent caving of the aquifer material, breakage of the well casing, or damage to the distribution lines

or gauges. To reduce the possibility of a water-hammer effect, a pressure-snubber should be installed

ahead of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...