ISO 19434:2017

(Main)Mining — Classification of mine accidents

Mining — Classification of mine accidents

ISO 19434:2017 establishes a classification of mine accidents by their origin or causes, by the type of accident, and by their results or consequences. The latter includes only the accidents resulting into consequences on people, not equipment or machinery. Different categories of causes, types and consequences of mine accidents are briefly defined, and a 3-digit code is assigned to each category. These can be combined to ultimately allocate a unique 15-digit code to each type of mine accident. This code can then be used in statistical analysis. Similarly, an allocated code clearly shows to which categories of causes, type of accident and resulting consequences the mine accident belongs to. ISO 19434:2017 is applicable to all surface and underground mines. NOTE: Accidents can be classified in terms of other items than those given in ISO 19434:2017, especially in researches and in other classification schemes. These can be, e.g. classifications based on the level of financial damages; gender, age, professional skills, terms of service and academic degree of the personnel; days of week, month, year, hour of accident; area of site, etc. While these classifications can be useful to enable certain decisions to be taken by the health and safety executives, they are not considered in ISO 19434:2017.

Mines — Classification des accidents dans les mines

General Information

- Status

- Published

- Publication Date

- 24-Oct-2017

- Technical Committee

- ISO/TC 82 - Mining

- Drafting Committee

- ISO/TC 82 - Mining

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 29-Jan-2026

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 14-Aug-2021

Overview

ISO 19434:2017 - Mining - Classification of mine accidents defines a standardized system for classifying mine accidents by origin/causes, type of accident, and consequences for people. The standard assigns 3‑digit category codes (e.g., Code 1xx for causes, 2xx for types, 3xx/4xx/5xx for consequences) that can be combined to form a unique 15‑digit accident code suitable for consistent statistical analysis across surface and underground mines. The classification focuses on human consequences (injury, disability, death) and promotes comparability of accident records to support prevention and safety improvement.

Key topics and technical requirements

- Threefold classification model: origin/causes, accident type, and human consequences.

- Coded taxonomy: each category is given a 3‑digit code; combined codes produce a unique identifier for each accident scenario to enable database aggregation and analysis.

- Scope limitation: consequences relate only to people (not equipment or machinery).

- Applicability: intended for use in all surface and underground mining operations.

- Structured categories: the standard provides defined groups such as chemical, electrical, geomechanical, equipment-related and human‑error causes; contact, falls, exposure, fires/explosions as types; and disability, nature and location of injury as consequence classes.

- Use for statistics: designed to ensure uniformity and comparability in mine-accident reporting to enable pattern detection and correlation analysis.

Practical applications

- Standardized accident recording and reporting systems for mining companies and contractors.

- National and regional mining regulators compiling comparable safety statistics.

- Health & safety managers using coded data to identify high‑risk causes, recurring accident types, and priority areas for mitigation.

- Researchers and data analysts performing epidemiological or root‑cause studies of mining accidents.

- Insurers and risk assessors calculating exposure and trends based on harmonized accident classifications.

Who should use ISO 19434:2017

- Mine operators (surface and underground)

- Safety and risk management professionals in mining

- Government mining inspectors and regulators

- Occupational safety researchers and statisticians

- Developers of mining safety software and incident databases

Related standards and notes

- ISO 19434:2017 was developed by ISO/TC 82 (Mining). It complements broader occupational health and safety management practices and can be used alongside management standards and national reporting requirements.

- Note: other classification schemes (financial damage, demographics, time-of-incident, site area, etc.) exist and may be useful for specific analyses, but they are outside the scope of ISO 19434:2017.

Using ISO 19434:2017 helps organizations turn disparate accident reports into consistent, analyzable data-supporting better decision-making for mine safety and accident prevention.

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Chile

Bureau Veritas certification services in Chile.

Bureau Veritas Peru

Bureau Veritas certification services in Peru.

BVQI Peru

Bureau Veritas certification in Peru.

Sponsored listings

Frequently Asked Questions

ISO 19434:2017 is a standard published by the International Organization for Standardization (ISO). Its full title is "Mining — Classification of mine accidents". This standard covers: ISO 19434:2017 establishes a classification of mine accidents by their origin or causes, by the type of accident, and by their results or consequences. The latter includes only the accidents resulting into consequences on people, not equipment or machinery. Different categories of causes, types and consequences of mine accidents are briefly defined, and a 3-digit code is assigned to each category. These can be combined to ultimately allocate a unique 15-digit code to each type of mine accident. This code can then be used in statistical analysis. Similarly, an allocated code clearly shows to which categories of causes, type of accident and resulting consequences the mine accident belongs to. ISO 19434:2017 is applicable to all surface and underground mines. NOTE: Accidents can be classified in terms of other items than those given in ISO 19434:2017, especially in researches and in other classification schemes. These can be, e.g. classifications based on the level of financial damages; gender, age, professional skills, terms of service and academic degree of the personnel; days of week, month, year, hour of accident; area of site, etc. While these classifications can be useful to enable certain decisions to be taken by the health and safety executives, they are not considered in ISO 19434:2017.

ISO 19434:2017 establishes a classification of mine accidents by their origin or causes, by the type of accident, and by their results or consequences. The latter includes only the accidents resulting into consequences on people, not equipment or machinery. Different categories of causes, types and consequences of mine accidents are briefly defined, and a 3-digit code is assigned to each category. These can be combined to ultimately allocate a unique 15-digit code to each type of mine accident. This code can then be used in statistical analysis. Similarly, an allocated code clearly shows to which categories of causes, type of accident and resulting consequences the mine accident belongs to. ISO 19434:2017 is applicable to all surface and underground mines. NOTE: Accidents can be classified in terms of other items than those given in ISO 19434:2017, especially in researches and in other classification schemes. These can be, e.g. classifications based on the level of financial damages; gender, age, professional skills, terms of service and academic degree of the personnel; days of week, month, year, hour of accident; area of site, etc. While these classifications can be useful to enable certain decisions to be taken by the health and safety executives, they are not considered in ISO 19434:2017.

ISO 19434:2017 is classified under the following ICS (International Classification for Standards) categories: 73.020 - Mining and quarrying. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 19434:2017 has the following relationships with other standards: It is inter standard links to ISO 19434:2017/Amd 1:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 19434:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 19434

First edition

2017-10

Mining — Classification of mine

accidents

Mines — Classification des accidents dans les mines

Reference number

©

ISO 2017

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2017 – All rights reserved

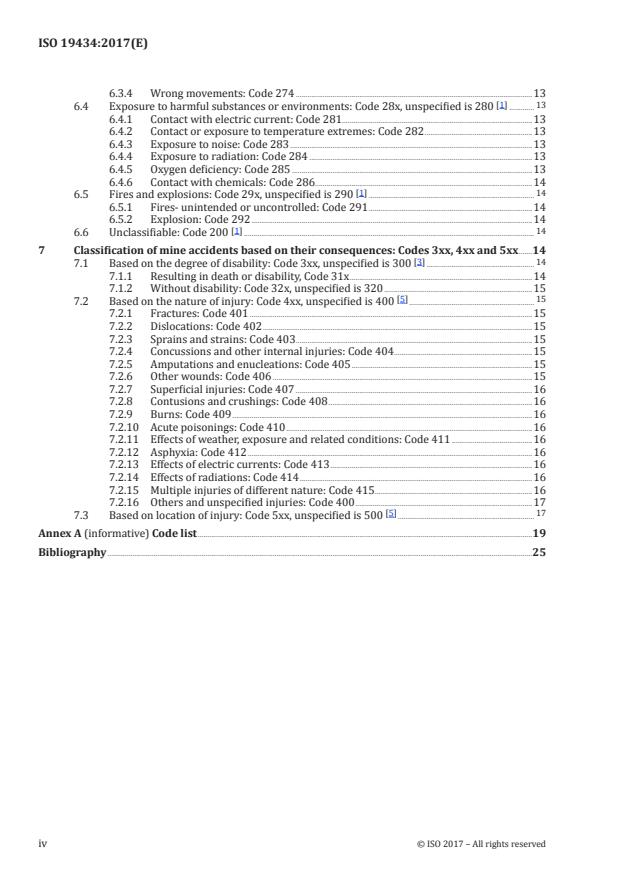

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Classification . 3

4.1 General . 3

4.2 Classification of mine accidents based on their origin or cause . 3

4.3 Classification of mine accidents based on type of accident . 4

4.4 Classification of mine accidents based on their consequences . 4

4.5 Coding . 4

5 Classification of mine accidents based on their origin or cause: Code 1xx .6

5.1 Chemical-based accidents: Code 10x, unspecified is 100 . 6

5.1.1 Explosives and accessories: Code 101 . 6

5.1.2 Chemical compounds: Code 102 . 6

5.1.3 Fire: Code 103 . 6

5.1.4 Chemical apparatus and material: Code 104 . 6

5.2 Electrical-based accidents: Code 110 . 6

5.3 Environmental-based accidents: Code 12x, unspecified is 120 . 6

5.3.1 Working environment: Code 121 . 6

5.3.2 Natural environment: Code 122 . 7

5.4 Geo-chemical-based accidents: Code 130 . 7

5.5 Geo-mechanical-based accidents: Code 140 . 7

5.6 Equipment-based accidents: Code 15x, unspecified is 150 . 7

5.6.1 Hand tools: Code 151 . 7

5.6.2 Non-powered haulage: Code 152 . 7

5.6.3 Powered haulage: Code 153 . 7

5.6.4 Hoisting: Code 154 . 7

5.6.5 Machinery: Code 155 . 8

5.7 Mechanical-based accidents: Code 160 . 8

[4] 8

5.8 Human errors-based accidents .

5.8.1 General. 8

[4] 8

5.8.2 Person-based errors: Code 17x, unspecified is 170 .

[4] 9

5.8.3 Situation-based errors: Code 18x, unspecified is 180 .

[4] 9

5.8.4 System-based errors: Code 19x, unspecified is 190 .

6 Classification of mine accidents based on type of accident: Code 2xx, unclassifiable

[1]

is 200 .10

6.1 Contact with objects and equipment: Codes 210 (for unspecified), 22x, 23x, 24x or

[1] 10

25x .

6.1.1 Struck against object: Code 22x, unspecified is 220 .10

6.1.2 Struck by object: Code 23x, unspecified is 230 .10

6.1.3 Caught in or compressed by equipment or objects: Code 24x, unspecified

is 240 .11

6.1.4 Caught in or crushed in collapsing materials: code 25x, unspecified is 250.12

[1] 12

6.2 Falls: Code 26x, unspecified is 260 .

6.2.1 Fall of person to lower level: Code 261 .12

6.2.2 Falls of persons on the same level: Code 262 .12

6.2.3 Fall of material or structures: Code 263 .12

[1] 13

6.3 Bodily reaction and exertion: Code 27x, unspecified is 270 .

6.3.1 Over-exertion in lifting objects: Code 271 .13

6.3.2 Over-exertion in pushing or pulling objects: Code 272 .13

6.3.3 Over-exertion in handling or throwing objects: Code 273 .13

6.3.4 Wrong movements: Code 274 .13

[1] 13

6.4 Exposure to harmful substances or environments: Code 28x, unspecified is 280 .

6.4.1 Contact with electric current: Code 281 .13

6.4.2 Contact or exposure to temperature extremes: Code 282 .13

6.4.3 Exposure to noise: Code 283 .13

6.4.4 Exposure to radiation: Code 284 .13

6.4.5 Oxygen deficiency: Code 285 .13

6.4.6 Contact with chemicals: Code 286 .14

[1] 14

6.5 Fires and explosions: Code 29x, unspecified is 290 .

6.5.1 Fires- unintended or uncontrolled: Code 291 .14

6.5.2 Explosion: Code 292 .14

[1] 14

6.6 Unclassifiable: Code 200 .

7 Classification of mine accidents based on their consequences: Codes 3xx, 4xx and 5xx .14

[3] 14

7.1 Based on the degree of disability: Code 3xx, unspecified is 300 .

7.1.1 Resulting in death or disability, Code 31x .14

7.1.2 Without disability: Code 32x, unspecified is 320 .15

[5] 15

7.2 Based on the nature of injury: Code 4xx, unspecified is 400 .

7.2.1 Fractures: Code 401 .15

7.2.2 Dislocations: Code 402 .15

7.2.3 Sprains and strains: Code 403 .15

7.2.4 Concussions and other internal injuries: Code 404.15

7.2.5 Amputations and enucleations: Code 405 .15

7.2.6 Other wounds: Code 406 .15

7.2.7 Superficial injuries: Code 407 .16

7.2.8 Contusions and crushings: Code 408 .16

7.2.9 Burns: Code 409 .16

7.2.10 Acute poisonings: Code 410 .16

7.2.11 Effects of weather, exposure and related conditions: Code 411 .16

7.2.12 Asphyxia: Code 412 .16

7.2.13 Effects of electric currents: Code 413 .16

7.2.14 Effects of radiations: Code 414 .16

7.2.15 Multiple injuries of different nature: Code 415 . .16

7.2.16 Others and unspecified injuries: Code 400 .17

[5] 17

7.3 Based on location of injury: Code 5xx, unspecified is 500 .

Annex A (informative) Code list .19

Bibliography .25

iv © ISO 2017 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 82, Mining.

Introduction

The primary purpose of this document on classification of mine accidents is to promote uniformity and

comparability of mine accidents statistics, which has as an ultimate goal to prevent accidents.

Although mine accidents are very complex realizations and many factors can contribute to their

occurrence, much thought has been given to the study of causes and consequences of the accidents and

many investigations have been carried out on the subject.

An accident, mishap or misadventure is an unforeseen and unplanned event or circumstance, often

with lack of intention or necessity. It usually implies a generally negative outcome which might have

been avoided or prevented.

A mine accident is an accident that occurs during the process of mining. Thousands of miners die from

mine accidents every year. And although safer modern mining methods have been introduced, mine

accidents are still the cause of casualties and financial losses.

Mine accidents can have a variety of causes, including leaks of poisonous gases such as hydrogen

sulphide or explosive natural gases, especially firedamp or methane, dust explosions, collapsing

of mine stopes, toxic gases arising from mine fires, mining-induced seismicity, flooding, or general

mechanical errors from improperly used or malfunctioning mining equipment. Mine accidents mainly

occur in the coal mining and underground mines sector. Initially, this document had a focus on coal and

underground mines risks, but it has been extended to cover all mining environments.

While available accident reports are very detailed, this International Standard provides a tool to look

at a broader picture. The advantage of the classification given in this International Standard is that

statistical methods can be used to gain more insight into mine accident causation and probable results.

By analysing a multitude of mine accidents and applying this standardized classification scheme, the

users of this International Standard will be able to both detect patterns for the development of mine

accidents and to derive correlations.

vi © ISO 2017 – All rights reserved

INTERNATIONAL STANDARD ISO 19434:2017(E)

Mining — Classification of mine accidents

1 Scope

This document establishes a classification of mine accidents by their origin or causes, by the type of

accident, and by their results or consequences. The latter includes only the accidents resulting into

consequences on people, not equipment or machinery.

Different categories of causes, types and consequences of mine accidents are briefly defined, and a

3-digit code is assigned to each category. These can be combined to ultimately allocate a unique 15-digit

code to each type of mine accident. This code can then be used in statistical analysis. Similarly, an

allocated code clearly shows to which categories of causes, type of accident and resulting consequences

the mine accident belongs to.

This document is applicable to all surface and underground mines.

NOTE Accidents can be classified in terms of other items than those given in this document, especially in

researches and in other classification schemes. These can be, e.g. classifications based on the level of financial

damages; gender, age, professional skills, terms of service and academic degree of the personnel; days of week,

month, year, hour of accident; area of site, etc. While these classifications can be useful to enable certain decisions

to be taken by the health and safety executives, they are not considered in this document

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

accident

unplanned event that can result in injury or ill health of people, and/or damage to or loss of property,

plants, materials, machinery, processes or the environment, and business opportunity

3.2

accident cause

factor or factors that act together to produce an accident

3.3

air blast

airborne shock wave or acoustic transient generated by an explosion

3.4

backfilling

filling in again of a place from which the rock or ore has been removed

3.5

blocking

obstruction of the ore passes by ore material or rock that refuses to pass

3.6

brattice curtain

line brattice

line canvas

line curtain

fire-resistant fabric or plastic partition used in a mine passage to confine the air and force it into the

working place

3.7

detonation

explosion where the shock waves are supersonic

Note 1 to entry: Detonation involves a supersonic exothermic front accelerating through a medium that eventually

drives a shock front propagating directly in front of it.

Note 2 to entry: Detonations are observed in both conventional solid and liquid explosives, as well as in reactive

gases. The velocity of detonations in solid and liquid explosives is higher than that in gaseous ones, which allows

the wave system to be measured with greater detail.

3.8

dust

fine particles of a solid that can remain suspended in air with a particle size larger than that of a fume

Note 1 to entry: Dusts are produced by mechanical action, such as grinding.

Note 2 to entry: Some dusts can be harmful to an employee’s health.

3.9

dust explosion

fast combustion of dust particles suspended in the air in an enclosed location

Note 1 to entry: Coal dust explosions are a frequent hazard in underground coal mines, but dust explosions can

occur where any powdered combustible material is present in an enclosed atmosphere or, in general, in high

enough concentrations of dispersed combustible particles in atmosphere or other suitable gaseous medium such

as molecular oxygen.

3.10

explosive

chemical which detonates after introduction of a stimulus appropriate initiation, so that the reaction

front moves through the explosive at a higher speed than the sonic velocity of the material

Note 1 to entry: Upon detonation, an explosive releases large volumes of gaseous products and energy on the

surrounding rock, which causes fragmentation, shattering, or shearing.

Note 2 to entry: The ingredients of an explosive, which are combinations of fuels and oxidizers, are converted to

high pressure, high temperature gases upon detonation.

3.11

face

exposed area of a working place from which a mineral, rock, ore or coal is being extracted

3.12

failure

rock instability occurring when applied force exceeds maximum rock strength

3.13

failure

state or condition of not meeting a desirable or intended objective

3.14

fly rock

fugitive rock fragments propelled from the blast area by the force of an explosion

2 © ISO 2017 – All rights reserved

3.15

injury

damage to a biological organism caused by physical harm

3.16

noise

unwanted sound that can lead to hearing loss or stress, or to interfere with the ability to hear other

sound or to communicate

3.17

outburst

violent evolution of combustible gases (usually together with large quantities of coal dust) from a

working face

Note 1 to entry: The occurrence is violent and can overwhelm the workings and fill the entire district with

gaseous mixtures.

Note 2 to entry: Roadways advancing into virgin and stressed areas of coal are particularly prone to outbursts in

certain seams and faults often intersect in the area.

3.18

rock burst

sudden and often violent breaking of a mass of rock from the walls of a tunnel, mine, or deep quarry,

caused by failure of highly stressed rock and the rapid or instantaneous release of accumulated

strain energy

3.19

roof fall

mine cave-in, especially in permanent areas such as entries

3.20

spalling

violent formation of slabs which separate from a strained surface

Note 1 to entry: If the force is sufficient for the slab to be ejected from the surface this would constitute one form

of strainburst.

3.21

stowing

debris of a vein thrown back from a continuous miner machine and which supports the roof or hanging

wall of the excavation

4 Classification

4.1 General

This document defines three major categories to classify mine accidents. As shown in Figure 1, one

category is the origin or cause of mine accidents, the second one is the type of accidents and the third

one is their resulting consequences. In this regard, all mine accidents can be placed into the categories,

given in 4.2 to 4.4.

4.2 Classification of mine accidents based on their origin or cause

This category comprises the following mutually exclusive sub-categories:

— Chemical-based accidents (see 5.1)

— Electrical-based accidents (see 5.2)

— Environmental-based accidents (see 5.3)

— Geo-chemical-based accidents (see 5.4)

— Geo-mechanical-based accidents (see 5.5)

— Equipment-based accidents (see 5.6)

— Mechanical-based accidents (see 5.7)

— Human errors-based accidents (see 5.8)

4.3 Classification of mine accidents based on type of accident

This category comprises the following mutually exclusive sub-categories:

— Contact with objects and equipment (see 6.1)

— Falls (see 6.2)

— Bodily reaction and exertion (see 6.3)

— Exposure to harmful substances or environments (see 6.4)

— Fires and explosions (see 6.5)

— Unclassifiable (see 6.6)

4.4 Classification of mine accidents based on their consequences

This category comprises the following mutually inclusive sub-categories:

— Degree of disability (see 7.1)

— Nature of injury (see 7.2)

— Location of injury (see 7.3)

4.5 Coding

A unique combined code in the form of “1xx.2xx.3xx.4xx.5xx” can then be allocated to any accident, where:

“1xx” is for the origin or cause of the accident.

“2xx” is for the type of accident.

“3xx” is for its consequences by degree of disability.

“4xx” is for its consequences by nature of injury.

“5xx” represents its consequences by part of the body injured.

EXAMPLE Code “194.292.311.409.517” shows that the origin of the accident is “Errors caused by violating

procedures, instructions and regulations”, type of accident is “Explosion”, degree of disability is “Death”, the

nature of injury is “Burns” and location of injury is “Head, multiple locations”.

Clause 5 describes the codes for the origin or cause of the accident, Clause 6 describes the codes for the

type of accident, and Clause 7 describes the codes for the consequences of the accident by degree of

disability (7.1), by nature of injury (7.2) and by part of the body injured (7.3). Annex A gives a complete

list of the codes.

4 © ISO 2017 – All rights reserved

Figure 1 — Classification of mine accidents

5 Classification of mine accidents based on their origin or cause: Code 1xx

5.1 Chemical-based accidents: Code 10x, unspecified is 100

5.1.1 Explosives and accessories: Code 101

Accidents involving the detonation of manufactured explosives that can cause unbalancing oxygen,

flying debris, fly rock, concussive forces and fumes are included in this category.

These accidents can occur during blasting operations, charging, handling and withdrawing charges.

5.1.2 Chemical compounds: Code 102

In this category, chemical compounds such as acids and alkalis are most directly tied to the resulting

accident and injury.

5.1.3 Fire: Code 103

Accidents classified in this group are caused by fire accidents. Fires include:

a) Open fires, which result from friction, welding, firing, gas explosion and cable short circuiting.

b) Spontaneous combustion: in this process, charcoal temperature increases due to oxygen surface

absorption and causes an increase in chemical reactions and the production of carbon monoxide,

carbon dioxide, methane, hydrogen and various carbohydrates. In case of oxygen sufficiency and

lack of an efficient ventilation system to transmit the resulted heat, spontaneous combustion and

eventually fire occur in the mine. The events relating to spontaneous combustions are classified in

subclause 5.4.

5.1.4 Chemical apparatus and material: Code 104

The events classified in this group are caused by defective or broken equipment and chemicals used in

mines, such as: failure of the brattice curtain (plastic and canvas) and catalytic heating equipment and

damage of rubber/plastic/fibreglass/fabric material.

5.2 Electrical-based accidents: Code 110

In this category, electric current (DC or AC) is most directly responsible for the resulting accident.

Electrical energy is used in mines in four settings: lighting (lights), power distribution network (cables),

electrical mining machines such as ventilation machines, and electric shot firing. Accidents occurring in

these four settings are classified in this group.

5.3 Environmental-based accidents: Code 12x, unspecified is 120

Mining accidents in this group occur due to working and natural environment conditions.

5.3.1 Working environment: Code 121

Conditions occurring due to mining operations and construction activities, such as inrush of water and

mud, audio contamination, slippery surfaces or geographical topology such as ponds and lakes or stuck

in facilities.

Conditions related to the environmental situation of the workplace such as temperature and pressure,

diesel particulate matter (DPM), fog, disturbing animals, and light intensity.

6 © ISO 2017 – All rights reserved

5.3.2 Natural environment: Code 122

Conditions occurring due to natural disasters, such as earthquakes, floods, lightning, and volcanic

eruptions among others.

5.4 Geo-chemical-based accidents: Code 130

Accidents of this group are associated to changes in the elemental particles of the materials available in

the mines, such as radioactivity materials, charcoal spontaneous combustion, dispersion and explosion

of mine gases.

5.5 Geo-mechanical-based accidents: Code 140

Accidents of this group are relevant to soil and rock mechanical behaviour and are mainly caused

by instability of mine segments such as wall, surface mining or underground mine, roof, floor, face

or galleries, manifested as collapse, rock burst, outburst, roof fall, floor heave up, subsidence, run of

materials, stowing, backfilling and spalling.

Some of the collapses cause accidents directly and some other through generation of windblast, air

blast or blocking.

NOTE Many of the geo-mechanical aspects are overlapped with geo-technical engineering related aspects

such as landslide. In this document, seismology, continuum mechanics, fracture mechanics and mechanics of

non-continuous environments are included in geo-mechanics.

5.6 Equipment-based accidents: Code 15x, unspecified is 150

This category comprises the mine accidents resulting from equipment (light and heavy) that performs

mining functions in both surface and underground mines. This category should only be used for

classifying accidents caused by, and during, the operation of the mining equipment.

These accidents are classified as per the sub-categories given in 5.6.1 to 5.6.5.

5.6.1 Hand tools: Code 151

Accidents related to non-powered tools when being used as hand tools. Do not include electric tools or

[2]

air-powered tools .

5.6.2 Non-powered haulage: Code 152

Accidents related to motion of non-powered haulage equipment. Included are accidents involving

[2]

wheelbarrows, manually pushed mine cars and trucks, etc.

5.6.3 Powered haulage: Code 153

Haulage includes motors and rail cars, conveyors, belt feeders, longwall conveyors, bucket elevators,

vertical manlifts, self-loading scrapers or pans, shuttle cars, haulage trucks, front-end loaders, load-

haul-dumps, forklifts, cherry pickers, mobile cranes if travelling with a load, etc. The accident is caused

by the motion of the haulage unit. Include accidents that are caused by an energized or moving unit or

failure of component parts. If a car dropper suffers an injury as a result of falling from a moving car,

[2]

charge the accident to haulage .

5.6.4 Hoisting: Code 154

Damage to hoisting equipment in a shaft or slope which endangers an individual or interferes with use

of the equipment for more than 30 min. Hoisting may also be the classification where a victim was

[2].

injured by hoisting

5.6.5 Machinery: Code 155

Accidents that result from the action or motion of machinery or from failure of component parts.

Included are autonomous or tele-operated machines, all electric and air-powered tools and mining

machinery such as drills, raise climbers, tuggers, slushers, draglines, power shovels, loading machines,

compressors, etc. Include derricks and cranes except when they are used in shaft sinking (see hoisting,

[2]

5.6.4) or mobile cranes travelling with a load (see powered haulage, 5.6.3) .

5.7 Mechanical-based accidents: Code 160

Accidents of this group are caused by mechanical factors such as abrasion, strike and pressure, and

affect the effective lifetime and performance of machines and equipment.

Torn cables, blown tanks and pressurized pipes, technical defects of machinery, unwanted release of

mechanical or stored energy and equipment body depreciation or lost mechanical protection of the

same are amongst the issues that occur due to mechanical factors, resulting in accidents.

[4]

5.8 Human errors-based accidents

5.8.1 General

This classification is partly based on the occurrence of human errors. Humans naturally make mistakes,

but there are certain reasons leading to errors which are not directly controlled by the one who

commits such errors, and understanding these reasons can help prevent the errors from occurring.

Therefore, the human errors-based accidents are classified in the following three groups: person-based

(5.8.2, code 17x), situation-based (5.8.3, code 18x), and system-based (5.8.4, code 19x) errors.

[4]

5.8.2 Person-based errors: Code 17x, unspecified is 170

[4]

5.8.2.1 Unintentional errors: Code 171

These errors occur against one’s will and unintentionally and notwithstanding the fact that one is

decisive to do the job correctly. Such errors sometimes occur due to real time negligence (internal

factors) and sometimes due to distraction (external factors). These errors often occur in routine duties.

[4]

5.8.2.2 Errors caused by habit: Code 172

These errors occur when a repetitive action that is made frequently is replaced with another action.

EXAMPLE A worker is used to apply a recurrent suite of actions, but these need to be exceptionally altered.

[4]

5.8.2.3 Identification errors: Code 173

These errors occur when something is identified wrongly. In a study conducted at refineries, 75 % of

the human errors have been reported to be the result of defects in labels of equipment and eventually

errors in identifying the equipment.

[4]

5.8.2.4 Errors resulting from the impossibility of fulfilment of job duties: Code 174

Some of the job duties are quite complex, difficult and even impossible to fulfil. Therefore, shortcuts are

used to fulfil those. In case such shortcuts are not examined well, they may result in the occurrence of

errors. The more complex and difficult a job duty is, the more likely the occurrence of error will be. For

instance, the high mental load is seen as a complexity, as one may focus on a certain issue at a certain

time and, in case excessive information is simultaneously received, this may result in errors.

EXAMPLE Lighting several alarms in the control panel which gives too much information to the operator

and eventually results in confusion.

8 © ISO 2017 – All rights reserved

[4]

5.8.2.5 Errors resulting from a wrong perception: Code 175

In this type of error the information entered into the system for decision making is perceived and

interpreted wrongly.

[4]

5.8.2.6 Errors resulting from a lack of knowledge: Code 176

The regular course of this type of error is a defect in acquiring proper information from other individuals

or organizations which caused insufficient information (especially under non normal conditions) and

eventually the operator may act in terms of own assumptions which may be wrong and cause errors.

[4]

5.8.2.7 Errors resulting from expectations and habits: Code 177

It is a certain type of error resulting from the expectations and habits. Inherently, humans fulfil their

tasks in terms of their habits and this is sometimes problematic. In many cases, what we see is what we

expect, even if there are evidences to neglect the same. This error is known as the daily habits error as

well. It is more likely to occur under limited time and stressful conditions.

[4]

5.8.2.8 Reasoning errors: Code 178

These errors occur when one acquires correct information for decision making and acting, while fails

to do correct analysis and conclusion. Lack of training and experience intensifies the occurrence of

such errors.

5.8.2.9 Errors resulting from a lack of compliance between the employee and the job: Code 179

[4]

These errors are mainly the result of human factors, where one is not suitable for the job assigned.

EXAMPLE The height of the operator is not appropriate for driving the relevant vehicle.

[4]

5.8.3 Situation-based errors: Code 18x, unspecified is 180

[4]

5.8.3.1 Environment: Code 181

Occurrence of the errors depends on environmental factors.

EXAMPLES Lack of work space, high temperatures, weak light, strong light, etc. can cause such errors.

[4]

5.8.3.2 Stress: Code 182

Decision making under stressful conditions can cause errors; some references indicate that human-

[4]

based error potential under stressful conditions reaches 50 % .

[4]

5.8.3.3 Time: Code 183

Some of the errors occur due to time limitations. Limited time results in that one does a certain action

and/or makes a certain decision resulting in errors and/or no action is taken at all within such limited

period of time.

[4]

5.8.4 System-based errors: Code 19x, unspecified is 190

These errors are intensified by system elements. They comprise the errors in 5.8.4.1 to 5.8.4.4.

[4]

5.8.4.1 Errors resulting from others’ actions: Code 191

Many of the errors are in fact a chain of errors triggered by a fundamental error. This issue is the result

of uncontrolled accepting of the information, action of others, etc.

[4]

5.8.4.2 Errors resulting from incorrect equipment design: Code 192

EXAMPLE In a control board, the pressure gauge is located at a 3 m distance from the left hand of the

operator’s seat and the thermometer is on the right side and within a 2 m distance. The operator reads the two

figures at the same time and registers them in the report. Therefore, this incorrect design can cause errors.

[4]

5.8.4.3 Instructions-based errors: Code 193

Sometimes the instructions are wrong and are not suitable to the work being conducted. Such

instructions result in confusion of the operator and errors.

[4]

5.8.4.4 Errors caused by violating procedures, instructions and regulations: Code 194

Violating regulations are intentional errors and are defined as failing to accept the regulations. These

errors occur when people feel the procedures, and/or regulations, are not relevant for them.

6 Classification of mine accidents based on type of accident: Code 2xx,

[1]

unclassifiable is 200

The type of accident relates to the manner in which the object or substance causing the injury comes

into contact with the injured person, or to the movement of the person which resulted in the injury.

6.1 Contact with objects and equipment: Codes 210 (for unspecified), 22x, 23x, 24x

[1]

or 25x

Codes in this division apply to injuries produced by contact between the injured person and the source

of injury except when contact is due to falls, fires and explosions. Contact may be denoted by a statement

that the injured person struck or was struck by an object, was caught in an object, rubbed against an

object, or by words such as “hit by,” or “hit,” “bumped into,” “crushed by,” or “banged”.

6.1.1 Struck against object: Code 22x, unspecified is 220

The “struck against” codes apply to injuries produced by forcible contact or impact between the injured

person and the source of injury when the motion producing the contact is primarily that of the injured

person. This major group includes bumping into objects, stepping on objects, kicking objects, and being

pushed or thrown into or against objects. If a person strikes against an object due to falling, the injury

is classified in subclause 6.2, Falls.

6.1.1.1 Stepped on object: Code 221

6.1.1.2 Struck against stationary object: Code 222

6.1.1.3 Struck against moving object: Code 223

6.1.2 Struck by object: Code 23x, unspecified is 230

The “struck by” codes apply to injuries produced by forcible contact or impact between the injured

person and the source of injury when the motion producing the contact is primarily that of the source

of injury rather than the person.

6.1.2.1 Struck by falling object: Code 231

Struck by falling object should be selected when the source of injury is falling from an elevation to a

lower level. This includes instances where the injured person is crushed, pinned, or caught under a

falling object, other than collapsing material or structures.

10 © ISO 2017 – All rights reserved

6.1.2.2 Struck by flying object: Code 232

Struck by flying object codes should be selected when the source of injury has been thrown, hurled, or

is being propelled across space.

6.1.2.2.1 Struck by dislodged flying object or particle: Code 233

Struck by dislodged flying object or particle includes instances when a piece of material separates from

a tool, machine or other equipment, for example, a piece of a drill bit breaks off, striking a worker.

6.1.2.2.2 Struck by discharged object or substance: Code 234

Struck by discharged objects or substance refers to instances where the object is ejected under power

by a tool or equipment usually designed for that purpose. Examples include a nail discharged from a

nail gun, water discharged from a pressure cleaner and a staple from a staple gun.

6.1.2.3 Struck by swinging or slipping objects: Code 235

Struck by swinging or slipping object refers to objects which are not free standing; that is, they are

attached at some point or are being held by the worker.

6.1.2.3.1 Struck by or slammed in swinging door or gate: Code 236

6.1.2.3.2 Struck by slipping hand-held object: Code 237

Struck by slipping hand-held objects includes cases where the worker is holding a tool or other

instrument that slips and injures the worker.

6.1.2.4 Struck by rolling, sliding objects on floor or ground level: Code 238

Struck by rolling, sliding objects on floor or ground level (Code 238

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...