IEC 60068-2-69:2017/COR1:2018

(Corrigendum)Corrigendum 1 - Environmental testing - Part 2-69: Tests - Test Te/Tc: Solderability testing of electronic components and printed boards by the wetting balance (force measurement)

Corrigendum 1 - Environmental testing - Part 2-69: Tests - Test Te/Tc: Solderability testing of electronic components and printed boards by the wetting balance (force measurement)

Corrigendum 1 - Essais d'environnement - Partie 2-69: Essais - Essai Te/Tc: Essai de brasabilité des composants électroniques et cartes imprimées par la méthode de la balance de mouillage (mesure de la force)

General Information

Relations

Standards Content (Sample)

IEC 2018

INTERNATIONAL ELECTROTECHNICAL COMMISSION

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

IEC 60068-2-69 IEC 60068-2-69

Edition 3.0 2017-03 Édition 3.0 2017-03

ENVIRONMENTAL TESTING – ESSAIS D'ENVIRONNEMENT –

Part 1: 2-69: Tests – Test Te/Tc: Solderability Partie 2-69: Essais – Essai Te/Tc: Essai de

testing of electronic components and brasabilité des composants électroniques et

printed boards by the wetting balance cartes imprimées par la méthode de la balance

(force measurement) de mouillage (mesure de la force)

CORRIGENDUM 1

Corrections to the French version appear after the English text.

Les corrections à la version française sont données après le texte anglais.

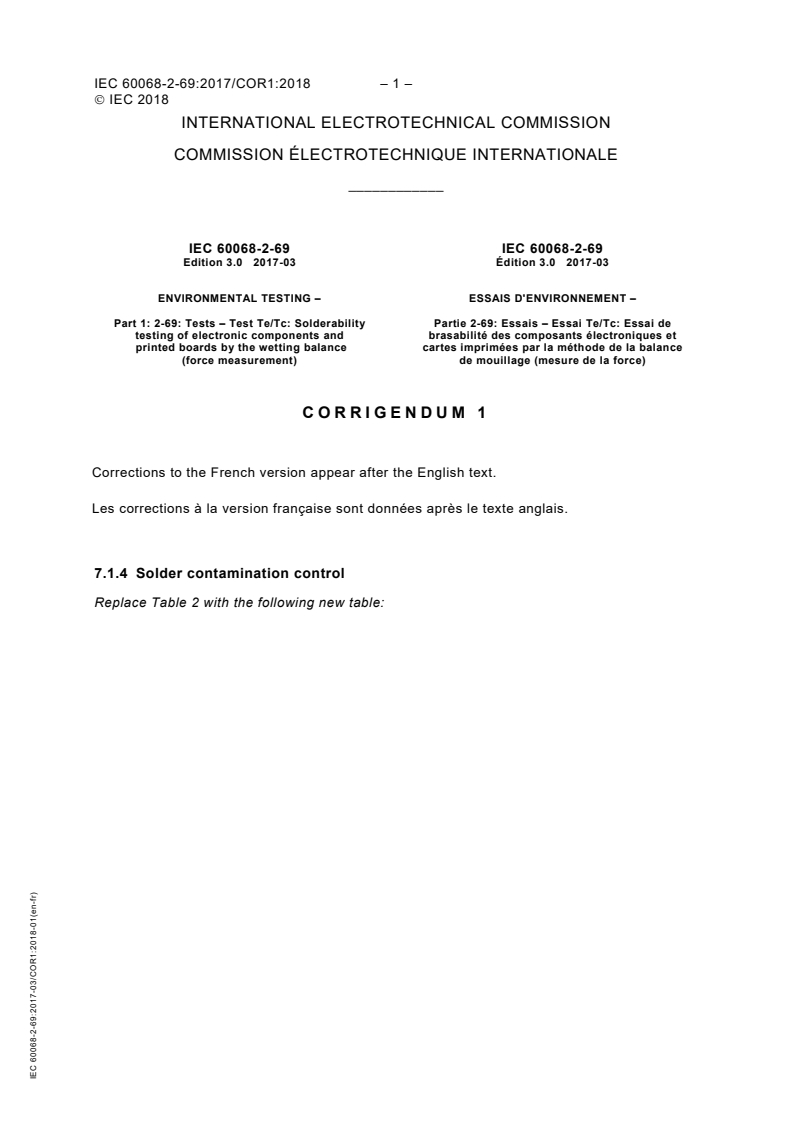

7.1.4 Solder contamination control

Replace Table 2 with the following new table:

IEC 60068-2-69:2017-03/COR1:2018-01(en-fr)

– 2 – IEC 60068-2-69:2017/COR1:2018

IEC 2018

Table 2 – Maximum limits of solder bath contaminants

Contaminant Maximum mass fraction contaminant limit

a b c d

, ,

SnPb alloys Lead-free alloys

% %

Copper 0,300 1,100

Gold 0,200 0,200

Cadmium 0,005 0,005

Zinc 0,005 0,005

Aluminium 0,006 0,006

Antimony 0,500 0,200

Iron 0,020 0,020

Arsenic 0,030 0,030

Bismuth 0,250 0,250

Silver 0,100 4,000

Nickel 0,010 0,050

Lead N/A 0,100

a

The tin content of the solder shall be maintained within ±1,5 % of the nominal alloy being used. Tin content

shall be tested at the same frequency as testing for copper/gold contamination. The balance of the bath shall

be lead and/or the items listed above.

b

The total of copper, gold, cadmium, zinc, and aluminium contaminants shall not exceed 0,4 %. Not

applicable to lead-free alloys.

c

The tin content of the solder shall be maintained within ±1 % of the nominal alloy being used. Tin content

shall be tested at the same frequency as testing for copper/silver concentration. The balance of the bath

shall be the items listed above.

d

Maximum contamination limits are applicable for Sn96,5Ag3Cu,5. Other lead-free solder alloy contamination

limits may be used upon agreement between user and vendor.

8.2.2 Solder bath wetting balance procedure

rd

Replace the 3 paragraph to Table 5 with the following new paragraph:

The recommended immersion speed for all components is between 1 mm/s and 5 mm/s,

except for leaded non-SMD where between 5 mm/s and 20 mm/s is recommended.

8.2.4.2 Procedure

st

In the 1 paragraph, replace "7.2.3" with "7.2.1".

10 Information to be given in the relevant specification

In the list item e), replace "8.2.2" with "8.2.3".

In the list item l), replace with the following text and replace "9.2" with "8.2.2, 8.2.3":

Areas to be visually examined for wetting and de-wetting

IEC 2018

B.5 Test flux

st

In the 1 paragraph, replace "8.1.2" with "8.2.2".

B.7.2.1 Stiffness of the spring (see Clause A.1 d))

In the title, replace "A.1 d)" with "A.1 e)".

B.7.2.2 Noise level (see Clause A.1 e))

In the title, replace "A.1 e)" with "A.1 c)".

B.7.4.1 Choice of test criteria

Replace "8.2 with "9.2".

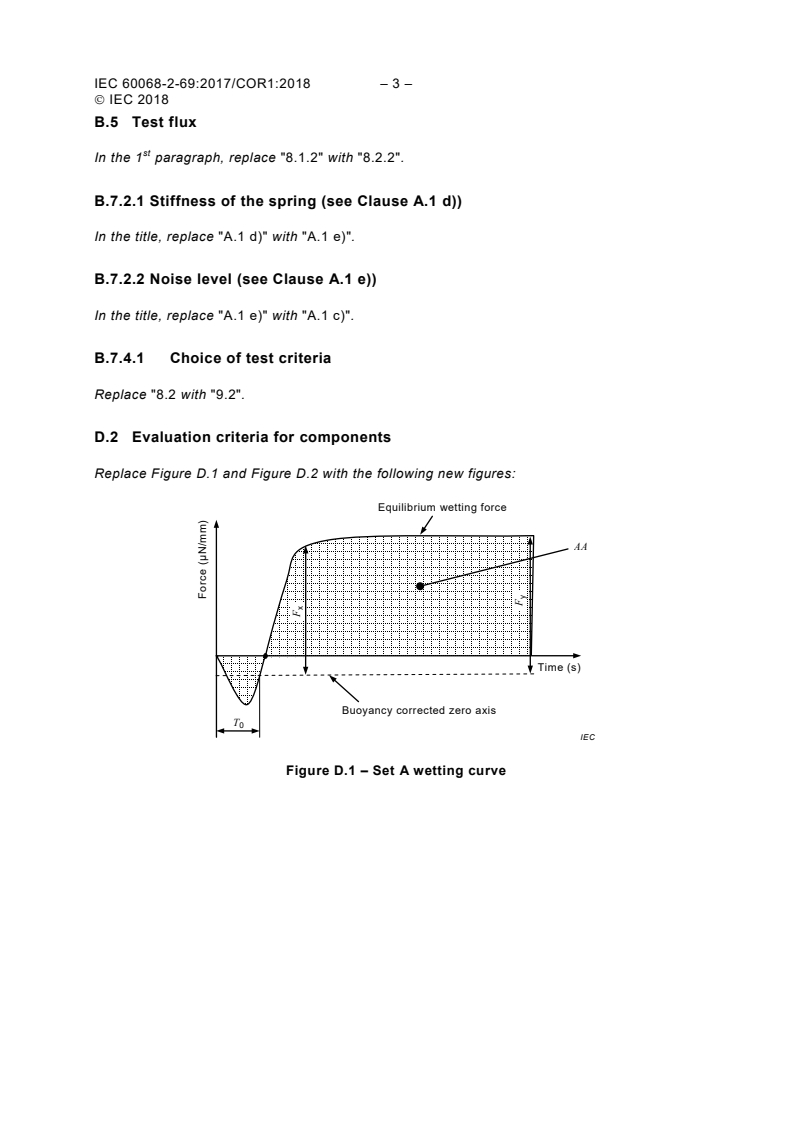

D.2 Evaluation criteria for components

Replace Figure D.1 and Figure D.2 with the following new figures:

Equilibrium wetting force

AA

Time (s)

Buoyancy corrected zero axis

T

IEC

Figure D.1 – Set A wetting curve

Force (μN/mm)

F

x

F

y

– 4 – IEC 60068-2-69:2017/COR1:2018

IEC

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...