IEC 61965:2000

(Main)Mechanical safety of cathode ray tubes

Mechanical safety of cathode ray tubes

Applicable to cathode ray tubes and cathode ray tube assemblies which are intended for use as components in apparatus and which have an integral protection with respect to the effects of implosion.

General Information

- Status

- Published

- Publication Date

- 28-Sep-2000

- Technical Committee

- TC 110 - Electronic displays

- Drafting Committee

- WG 2 - TC 110/WG 2

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 15-Jul-2003

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61965:2000 - Mechanical safety of cathode ray tubes (CRTs) - is an IEC component standard that specifies test methods, sampling and acceptance criteria for CRTs and CRT assemblies that include integral protection against implosion. It applies to tubes intended as components in apparatus (for example in televisions, information technology, medical and measurement equipment) and defines mechanical safety verification to protect users and service personnel from glass fragmentation and projectile hazards.

Key topics and requirements

- Scope and definitions: Applies to CRTs with built‑in implosion protection and covers both large and small CRT sizes (tables and size ranges are included in the standard).

- Test methods:

- Mechanical strength (ball impact) test to assess front‑face resistance to impact.

- Implosion tests using missile impact and thermal shock methods to verify devacuation/implosion protection systems.

- High‑energy impact tests to simulate severe mechanical abuse.

- Environmental conditioning: Requirements for standard atmospheric conditions, preconditioning and thermal conditioning prior to testing.

- Sampling and compliance: Detailed sampling plans and acceptance criteria are provided (Tables 1–6) for different CRT constructions (prestressed/banded, bonded‑frame, laminated).

- Test preparation: Guidance on scratch patterns, barriers, mounting, mounting position and cabinet set‑up for reproducible testing.

- Marking and documentation: Clause on required marking of CRTs and the information manufacturers must supply.

- Informative annexes: Background on test development and ballistic/statistical calculations (Annex A, Annex B) that underpin safety limits.

Applications and who uses this standard

IEC 61965 is primarily used by:

- CRT manufacturers and designers to verify mechanical safety and implosion protection for product development and type approval.

- Test laboratories and certification bodies to perform standardized mechanical and implosion tests.

- Compliance engineers and QA teams to implement sampling plans and ensure products meet safety requirements before integration into equipment.

- Equipment manufacturers and system integrators that use CRT components and need to confirm component-level mechanical safety for end products.

- Regulators and procurement officers who require objective test evidence for CRT safety.

Practical benefits include clearer acceptance criteria, harmonized test procedures for ball impact, missile and thermal‑shock implosion tests, and documented sampling plans tailored to CRT construction types.

Related standards

- IEC 60065 (equipment safety - historic clause on CRT mechanical tests)

- IEC 60050 (IEV terminology)

- IEC 60027, IEC 60417, IEC 60617 (symbols and letter symbols)

Keywords: IEC 61965, mechanical safety, cathode ray tube, CRT safety, implosion protection, ball impact test, thermal shock, sampling plan, high‑energy impact test.

Frequently Asked Questions

IEC 61965:2000 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Mechanical safety of cathode ray tubes". This standard covers: Applicable to cathode ray tubes and cathode ray tube assemblies which are intended for use as components in apparatus and which have an integral protection with respect to the effects of implosion.

Applicable to cathode ray tubes and cathode ray tube assemblies which are intended for use as components in apparatus and which have an integral protection with respect to the effects of implosion.

IEC 61965:2000 is classified under the following ICS (International Classification for Standards) categories: 31.100 - Electronic tubes. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61965:2000 has the following relationships with other standards: It is inter standard links to IEC 61965:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61965:2000 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD

First edition

2000-09

Mechanical safety of cathode ray tubes

Sécurité mécanique des tubes cathodiques

Reference number

Numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series.

Consolidated publications

Consolidated versions of some IEC publications including amendments are

available. For example, edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the

base publication, the base publication incorporating amendment 1 and the base

publication incorporating amendments 1 and 2.

Validity of this publication

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology.

Information relating to the date of the reconfirmation of the publication is available

in the IEC catalogue.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is to be found at the following IEC sources:

• IEC web site*

• Catalogue of IEC publications

Published yearly with regular updates

(On-line catalogue)*

• IEC Bulletin

Available both at the IEC web site* and as a printed periodical

Terminology, graphical and letter symbols

For general terminology, readers are referred to IEC 60050: International

Electrotechnical Vocabulary (IEV).

For graphical symbols, and letter symbols and signs approved by the IEC for

general use, readers are referred to publications IEC 60027: Letter symbols to be

used in electrical technology, IEC 60417: Graphical symbols for use on equipment.

Index, survey and compilation of the single sheets and IEC 60617: Graphical symbols

for diagrams.

* See web site address on title page.

INTERNATIONAL IEC

STANDARD

First edition

2000-09

Mechanical safety of cathode ray tubes

Sécurité mécanique des tubes cathodiques

IEC 2000 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission 3, rue de Varembé Geneva, Switzerland

Telefax: +41 22 919 0300 e-mail: inmail@iec.ch IEC web site http://www.iec.ch

Commission Electrotechnique Internationale

PRICE CODE

X

International Electrotechnical Commission

For price, see current catalogue

– 2 – 61965 © IEC:2000(E)

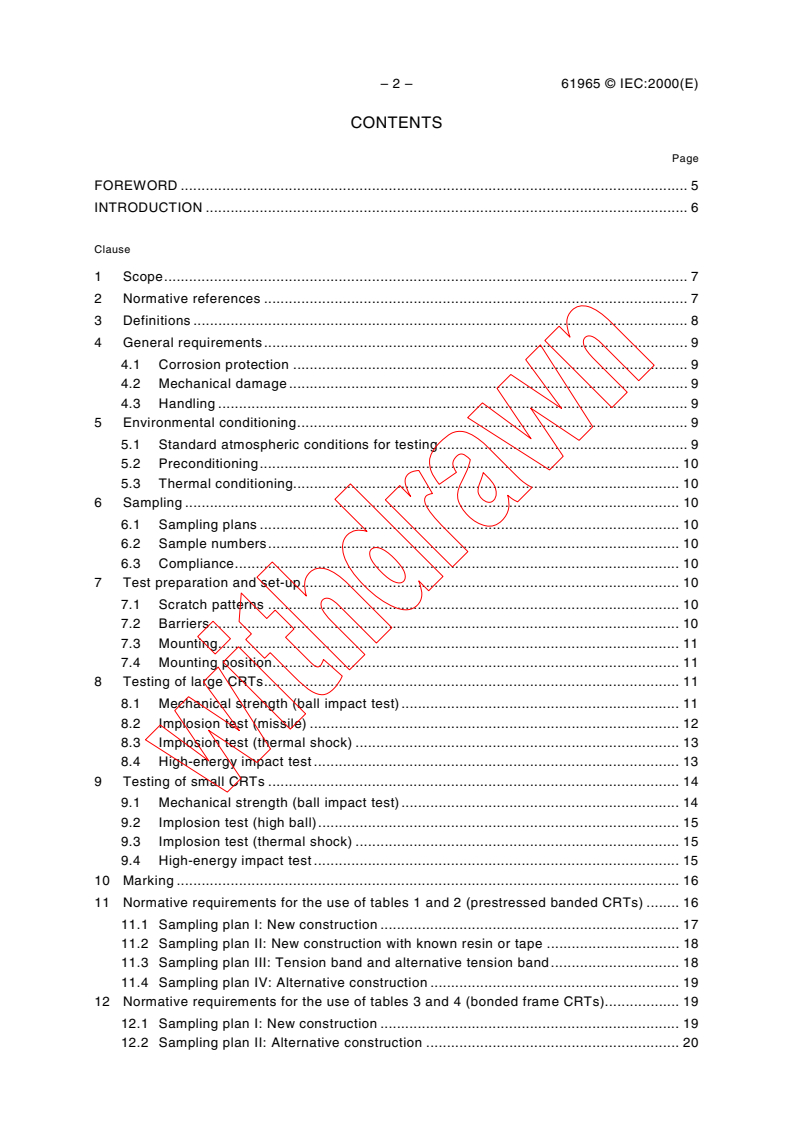

CONTENTS

Page

FOREWORD . 5

INTRODUCTION .6

Clause

1 Scope. 7

2 Normative references . 7

3 Definitions . 8

4 General requirements. 9

4.1 Corrosion protection . 9

4.2 Mechanical damage . 9

4.3 Handling . 9

5 Environmental conditioning. 9

5.1 Standard atmospheric conditions for testing. 9

5.2 Preconditioning. 10

5.3 Thermal conditioning. 10

6 Sampling .10

6.1 Sampling plans . 10

6.2 Sample numbers. 10

6.3 Compliance. 10

7 Test preparation and set-up. 10

7.1 Scratch patterns . 10

7.2 Barriers. 10

7.3 Mounting. 11

7.4 Mounting position. 11

8 Testing of large CRTs. 11

8.1 Mechanical strength (ball impact test). 11

8.2 Implosion test (missile) . 12

8.3 Implosion test (thermal shock) . 13

8.4 High-energy impact test . 13

9 Testing of small CRTs . 14

9.1 Mechanical strength (ball impact test). 14

9.2 Implosion test (high ball). 15

9.3 Implosion test (thermal shock) . 15

9.4 High-energy impact test . 15

10 Marking . 16

11 Normative requirements for the use of tables 1 and 2 (prestressed banded CRTs) . 16

11.1 Sampling plan I: New construction . 17

11.2 Sampling plan II: New construction with known resin or tape . 18

11.3 Sampling plan III: Tension band and alternative tension band . 18

11.4 Sampling plan IV: Alternative construction . 19

12 Normative requirements for the use of tables 3 and 4 (bonded frame CRTs). 19

12.1 Sampling plan I: New construction . 19

12.2 Sampling plan II: Alternative construction . 20

61965 © IEC:2000(E) – 3 –

Clause Page

13 Normative requirements for the use of tables 5 and 6 (laminated CRTs). 21

13.1 Sampling plan I: New construction . 21

13.2 Sampling plan II: Alternative construction . 21

Annex A (informative) Background to the development of this standard. 37

A.1 Mechanical strength test. 38

A.2 Implosion test. 38

A.3 Small CRTs (76 mm to 160 mm diagonal). 38

A.4 Evaluation time.38

Annex B (informative) Velocity and potential force of glass particles expelled

from a CRT subjected to a ball impact – Ballistic and statistical calculations . 39

B.1 Introduction . 39

B.2 Analysis without friction . 39

B.3 Analysis with friction. 45

B.4 Potential threat. 48

B.5 Conclusions. 48

Figure 1 – Example of a test cabinet . 27

Figure 2 – Example of a ball impact test. 28

Figure 3 – Example of a 2,3 kg steel missile. 29

Figure 4 – Missile impact area on a typical CRT . 30

Figure 5 – Example of a missile impact test. 31

Figure 6 – Options for scratch patterns for implosions by the thermal shock method . 32

Figure 7 – Example of high-energy impact test set-up . 33

Figure 8a – Example of steel pin for CRTs exceeding 160 mm face diagonal

used in high-energy impact test. 34

Figure 8b – Example of steel pin for CRTs from 76 mm to 160 mm diagonal

used in high-energy impact test. 34

Figure 9a – Example of 4,5 kg weight used in high-energy impact test on CRTs

exceeding 160 mm diagonal . 35

Figure 9b – Example of 0,45 kg weight used in high-energy impact test on CRTs

from 76 mm to 160 mm face diagonal. 35

Figure 10 – Example of 1,4 kg steel missile. 36

Figure B.1 – Height of the barriers and distances from the CRT face. 39

Figure B.2 – Example of the parabolic trajectory of a glass particle and the definition

of the distances. 40

Figure B.3 – Definition of the initial angle and initial velocity and the forces acting

on a particle . 41

Figure B.4 – Initial velocity required to pass over barriers at x = l (solid line)

or x = l (dashed line) as a function of the initial angle β. 43

– 4 – 61965 © IEC:2000(E)

Page

Figure B.5 – Trajectories for a glass particle for different initial angles and an initial velocity

of 4 m/s . 43

Figure B.6 – Definition of the forces acting on a particle. 45

Figure B.7 – Measurements of a typical glass particle . 46

Figure B.8 – Trajectory of a glass particle with an initial velocity of 2 m/s and

an initial angle of 45° without friction (dashed line) and with friction (solid line) . 47

Figure B.9 – Trajectories of a glass particle with an initial velocity of 2 m/s and an

initial angle of 45° for different values of the cross-sectional area . 48

Table 1 – Sampling and test programme for prestressed banded CRTs

exceeding 160 mm diagonal . 22

Table 2 – Sampling and test programme for prestressed banded CRTs

from 76 mm to 160 mm diagonal . 23

Table 3 – Sampling and test programme for bonded frame CRTs

exceeding 160 mm diagonal . 24

Table 4 – Sampling and test programme for bonded frame CRTs

from 76 mm to 160 mm diagonal . 24

Table 5 – Sampling and test programme for laminated CRTs exceeding 160 mm diagonal . 25

Table 6 – Sampling and test programme for laminated CRTs

from 76 mm to 160 mm diagonal . 25

Table 7 – CRT size and deflection angle ranges. 26

Table B.1 – Values of the distances . 40

Table B.2 – Upper and lower boundary values of the initial angle . 42

61965 © IEC:2000(E) – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MECHANICAL SAFETY OF CATHODE RAY TUBES

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International

Organization for Standardization (ISO) in accordance with conditions determined by agreement between the

two organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61965 has been prepared by IEC technical committee 39:

Electronic tubes.

The text of this standard is based on the following documents:

FDIS Report on voting

39/252/FDIS 39/255/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 3.

Annexes A and B are for information only.

The committee has decided that the contents of this publication will remain unchanged until 2004.

At this date, the publication will be

reconfirmed;

withdrawn;

replaced by a revised edition; or

amended.

A bilingual version of this publication may be issued at a later date.

– 6 – 61965 © IEC:2000(E)

INTRODUCTION

This International Standard sets forth test methods and limits for cathode ray tubes (CRTs).

Hitherto, the only IEC standard for the mechanical safety of CRTs has been contained within

clause 18 of the equipment standard IEC 60065. Whereas that standard has been accepted

and used by many countries, many others have not been able to implement its requirements

because of differing local needs. This new standard aims to provide the basis for wider

acceptance and use, and reflects the current IEC policy of producing separate component

standards to which equipment standards can refer.

Many years of experience had been built up in the use of both the IEC 60065 test and the

other commonly used national alternatives. During the development of this new standard,

extensive test programmes and ballistic and statistical calculations were carried out to verify

that the requirements of the standard give protection for users of CRTs when the tubes are

mounted in the equipment for which they are intended. This was also done to ensure that the

new standard maintains the stringent requirements of both IEC 60065 and the alternative

tests in common use. These tests and calculations also confirmed

a) the acceptability of one standard ball for the mechanical strength test, and

b) the need for the implosion test where it is not always possible to induce rapid devacuation

using the ball impact test.

As the impact tests in this standard are overstress tests, only the effect of rapid devacuation

is evaluated and not subsequent relaxation of mechanical stresses in the CRT from the

implosion protection system.

61965 © IEC:2000(E) – 7 –

MECHANICAL SAFETY OF CATHODE RAY TUBES

1 Scope

This International Standard is applicable to cathode ray tubes and cathode ray tube

assemblies (hereinafter referred to as CRTs) which are intended for use as components in

apparatus and which have integral protection with respect to the effects of implosion.

These requirements apply to CRTs intended for use in apparatus including electrical and

electronic measuring and testing equipment, information technology equipment, medical

equipment, telephone equipment, television equipment and other similar electronic apparatus.

This standard is intended to apply only to those CRTs in which the face of the CRT forms part

of the enclosure for the apparatus. The test methods do not apply to CRTs which are

protected by separate safety screens.

A CRT covered by this standard is intended to be installed in an enclosure designed both to

protect the rear of the CRT against mechanical or other damage under normal conditions of

operation and to protect the user against particles expelled in a backwards direction from the

CRT face in the event of implosion.

This standard contains requirements for CRTs of 76 mm diagonal and larger that incorporate

implosion protection systems providing protection against the hazards of particles expelled

forwards beyond the face. There is no intended protection against particles expelled in other

directions.

Compliance is tested by subjecting CRTs to the test procedures and criteria which are given

in clauses 8 (large CRTs) and 9 (small CRTs) of this standard. The definitions of large and

small CRTs are given in clause 3.

NOTE This set of requirements replaces the current requirements for the mechanical safety of cathode ray tubes

(CRTs) as described in IEC 60065 (clause 18), which will be modified accordingly.

2 Normative references

The following normative documents contain provisions which, through reference in this text,

constitute provisions of this International Standard. For dated references, subsequent

amendments to, or revisions of, any of these publications do not apply. However, parties to

agreements based on this International Standard are encouraged to investigate the possibility

of applying the most recent editions of the normative documents indicated below. For undated

references, the latest edition of the normative document referred to applies. Members of IEC

and ISO maintain registers of currently valid International Standards.

IEC 60065:1998, Audio, video and similar electronic apparatus – Safety requirements

IEC 60068-1:1988, Environmental testing – Part 1: General and guidance

Amendment 1 (1992)

IEC 60216-1, Guide for the determination of thermal endurance properties of electrical

insulating materials. Part 1: General guidelines for ageing procedures and evaluation of test

results

– 8 – 61965 © IEC:2000(E)

3 Definitions

For the purposes of this document the following definitions apply.

3.1

bonded frame

system employing a preformed metal frame that covers the periphery of the CRT rim area.

The space or void between the CRT rim and the metal frame is filled with resin or equivalent

3.2

CRT diagonal

nominal diagonal of the glass envelope at its maximum dimension (for example, mould-match

line) excluding any hardware

3.3

CRT envelope

structure consisting of a face or faceplate, funnel and neck assembly

3.4

devacuation

equalization of the pressure in a CRT relative to the ambient pressure

3.5

fracture

one or more cracks in the faceplate or funnel causing a rapid or slow devacuation of the

CRT envelope

3.6

glass particle

piece of glass that exceeds 0,025 g in weight

3.7

implosion

devacuation due to the rapid and sudden inward collapse of a CRT envelope, usually

accompanied by a loud report

3.8

laminated CRT

system that provides a separate external safety panel bonded to the face of the CRT

3.9

prestressed banded CRT

system that employs a metal tension band (located over the CRT rim area) that is tightened

by thermal shrinking, or other means, to a tensile load. The system may also include a metal

rim band located between the tension band and the CRT rim. The tension band or the rim

band or both may have an interlayer of tape, resin or the equivalent placed between the

mating parts

3.10

shaling

condition where the glassware splits into thin layers

61965 © IEC:2000(E) – 9 –

3.11

test cabinet

enclosure which is used to accommodate the CRT during tests

3.12

useful phosphor screen

a) colour CRT: the visible phosphored area of the CRT as viewed from the front

b) monochrome CRT: specified maximum useful phosphored area of the CRT

3.13

large CRT

CRT with diagonal dimension exceeding 160 mm

3.14

small CRT

rectangular CRT with a minor face dimension of at least 50 mm, a minimum diagonal

dimension of 76 mm and a maximum diagonal dimension of 160 mm; a round CRT of a

minimum diameter of 76 mm and a maximum diameter of 160 mm

3.15

common quality management system

quality management system described in documentation which is identical with systems used

in two or more plants and under one central control and management

4 General requirements

4.1 Corrosion protection

If corrosion of a metal part will contribute to a failure to meet the requirements of this

standard, then the part shall be adequately protected against corrosion.

4.2 Mechanical damage

To improve repeatability and reproducibility of test results, it should be verified that samples

submitted for test have no external visible scratching on the surface of the face plates.

4.3 Handling

Safety precautions should be addressed when handling test samples prior to, and after testing.

5 Environmental conditioning

5.1 Standard atmospheric conditions for testing

Unless otherwise specified, all tests and measurements shall be made under standard

atmospheric conditions for testing as given in 5.3 of IEC 60068-1:

– temperature: 15 °C to 35 °C;

– relative humidity: 25 % to 75 %;

– air pressure: 86 kPa to 106 kPa

– 10 – 61965 © IEC:2000(E)

5.2 Preconditioning

Before CRTs are subjected to thermal conditioning or to testing they will be allowed to stabilize

at standard atmospheric conditions for testing (see 5.1) for a minimum period of 16 h.

5.3 Thermal conditioning

Details of thermal conditioning are given in tables 1 to 6. After thermal conditioning has been

completed, the CRTs will be allowed to stabilize at standard atmospheric conditions for

testing (see 5.1) for a minimum period of 24 h.

6 Sampling

6.1 Sampling plans

Details are given in tables 1 to 6.

6.2 Sample numbers

The numbers of CRTs and the test programmes for prestressed banded CRTs are given in

tables 1 and 2, for bonded frame CRTs in tables 3 and 4 and for laminated CRTs in tables 5

and 6.

NOTE In addition to the quantities specified in the tables, additional samples shall be made available for use in

case of retest to satisfy the intent of the requirement.

6.3 Compliance

All CRTs in a test group shall comply with the test requirements for that group, except that, if

only one CRT from all the test groups does not comply with the requirements, acceptability

may be determined by subjecting a second test group to the set of tests during which

unacceptable results occurred. The construction is acceptable if all CRTs in the second test

group comply with the requirements.

7 Test preparation and set-up

7.1 Scratch patterns

As the form and depth of the scratch patterns may affect the force which is needed to obtain

implosion or devacuation of the CRT, it is recommended that the scratches be made using a

diamond- or carbide-tipped stylus, a glass cutter with a wheel of hardened steel or other

similar tools.

7.2 Barriers

Barriers as specified in the test procedures, each made of 10 mm to 20 mm thick material,

250 mm high and (2,00 ± 0,01) m long, shall be placed on the floor in front of the test

−3

cabinet at the specified locations, measured horizontally from the vertical plane of the centre

of the front surface of the CRT to the near surface of the barrier closest to the tube face. The

tolerance on the position of the barrier shall be ±10 mm, unless otherwise stated. The barriers

may be less than 2 m long provided that they extend to the walls of the test room

(see figures 2 and 5). A non-skid surface such as a blanket or rug may be placed on the floor.

NOTE A particle travelling past the plane of the front surface of the barrier shall be considered to have passed

the barrier.

61965 © IEC:2000(E) – 11 –

7.3 Mounting

The CRT shall be mounted in a test cabinet of rigid construction and of suitable dimensions

that does not permit a gap or opening wider than 6 mm around the CRT (see figure 1).

The mounting of the CRT in front of, or behind, the front panel of the test cabinet shall be in

accordance with the CRT manufacturer's specifications or intended application. When

mounting specifications are not available, the preferred mounting method shall be behind the

front panel unless design features do not allow this condition.

A hole of suitable area shall be provided at the top of the cabinet to allow access to the

funnel. This hole shall be covered during the impact test.

An opening having an area of not less than one-quarter of the area of the face of the CRT

or 0,02 m , whichever is the smaller, shall also be provided in the bottom or rear of the

cabinet for air intake in the event of an implosion.

The cabinet shall be firmly supported so as to prevent movement during the test.

7.4 Mounting position

The centre of the CRT shall be (1,00 ± 0,05) m above the floor.

8 Testing of large CRTs

8.1 Mechanical strength (ball impact test)

8.1.1 Test procedure

A solid smooth steel ball of (40 ± 1) mm diameter and mass of (260 ± 15) g, including the

hook, and a minimum C scale Rockwell hardness of 60, shall be suspended by suitable

means such as a fine wire or chain with a mass not exceeding 10 % of the mass of the ball

and the hook. It shall be allowed to fall freely as a pendulum from a calculated height and

strike the face of the CRT with an energy of (5,5 ± 0,1) J. The CRT shall be placed so that the

face is vertical and in the same vertical plane as the point of support of the pendulum.

A single impact shall be applied to any point on the CRT face at a distance of 40 mm or

greater from the edge of the useful phosphor screen.

NOTE The test laboratory should consider all their test set-up uncertainties to ensure this 40 mm minimum

position of the point of impact.

The barrier shall be placed 1,5 m from the plane of the centre of the face of the CRT

(see figure 2).

8.1.2 Glass throw criteria

A CRT is in compliance if the expulsion of glass within 5 s of the initial impact meets the

following requirements:

a) there shall be no glass particle (a single piece of glass having a mass greater than

0,025 g) past the 1,5 m barrier;

b) the total mass of all pieces of glass past the 1,5 m barrier shall not exceed 0,1 g.

– 12 – 61965 © IEC:2000(E)

8.2 Implosion test (missile)

8.2.1 Test procedure

The face of the CRT at the top and bottom shall be scratched (3 ± 1) mm from the screen or

phosphor edge into the viewing area. The scratches shall be horizontal lines (100 ± 5) mm long.

The impact object shall be a steel missile (see example in figure 3) with a mass of (2,3 ± 0,1) kg,

a minimum C scale Rockwell hardness of 60 and having one end rounded on a radius of

(25 ± 0,5) mm.

The CRT shall be subjected to a single impact, intending to cause rapid devacuation using the

minimum energy within the range. The impact object shall be swung through an arc of a

pendulum to obtain an impact of not less than 7,0 J and not more than 14,0 J to cause rapid

devacuation of the samples in the test group.

The impact area shall be the area bounded by two concentric circles where the radius of one

circle is one-sixth of the height of the useful phosphor screen and the second circle radius is

one-half of the height of the useful phosphor screen less 50 mm (see figure 4). In figure 4, if

R is less than R then the impact shall be applied to the circle specified in R .

2 1 1

NOTE Previous testing experience on a particular CRT design (obtained from the CRT manufacturer or the test

laboratory) should be considered when selecting the energy level within the range and the impact location.

The impact object travel shall be restricted so that the rounded end of the missile penetrates

the CRT face equal to, or less than 25 mm (see figure 5).

Barriers shall be placed 1,0 m and 1,5 m from the vertical plane of the centre of the face of

the CRT (see figure 5).

If no CRTs devacuate as a result of this test then the alternative implosion test (missile)

described in 8.2.3 shall be carried out.

8.2.2 Glass throw criteria

A CRT is in compliance if the expulsion of glass within 5 s of the initial impact meets the

following requirements:

a) there shall be no single piece of glass having a mass greater than 15 g between the 1,0 m

and 1,5 m barriers;

b) the total mass of all pieces of glass between the 1,0 m and 1,5 m barriers shall not exceed 45 g;

c) there shall be no single piece of glass having a mass greater than 1,5 g beyond the 1,5 m

barrier.

8.2.3 Alternative implosion test (missile)

This alternative test shall be used as an additional test when the test in 8.2.1 has devacuated

no CRTs, or may be used as an alternative to the test in 8.2.1 when it can be shown that

the 8.2.1 test is unlikely to devacuate at least one CRT of the sample group.

8.2.3.1 Test procedure

As in 8.2.1, except that the impact object will be a steel missile (see example in figure 10)

with a mass of (1,4 ± 0,1) kg, a minimum C scale Rockwell hardness of 60 and one end

rounded on a radius of (15 ± 0,5) mm.

61965 © IEC:2000(E) – 13 –

8.2.3.2 Glass throw criteria

As in 8.2.2. If no CRTs devacuate as a result of the test in 8.2.3.1, then the glass throw

requirements of 8.2.2 are deemed to have been satisfied.

8.3 Implosion test (thermal shock)

8.3.1 Test procedure

The CRT shall be mounted in the test cabinet which is described in 7.3 and 7.4. The barrier

shall be placed at (150 ± 2) mm from the vertical plane of the centre of the face of the CRT.

An area shall be scratched on the faceplate sidewall or face of the CRT using one of the

patterns illustrated in figure 6.

A thermal shock shall be applied using one of the following methods.

a) Liquid nitrogen

The scratched area shall be cooled using liquid nitrogen until a fracture occurs. A dam of

modelling clay or equivalent may be used to contain the liquid nitrogen.

b) Hot rod

The end of an ordinary flint glass rod, of suitable diameter (for example, 10 mm) shall be

heated until it is red hot and nearly fluid. The heated end of the rod shall be pressed firmly

on the scratched area of the CRT. If devacuation of the CRT does not occur within 10 s

then the rod shall be withdrawn and cold water poured slowly on the scratched area. If a

devacuation cannot be induced by repeated applications of the hot rod then the test shall

be carried out using liquid nitrogen (see 8.3.1a)).

8.3.2 Glass throw criteria

A CRT is in compliance if, within 5 s of the initial fracture, no glass particle is expelled through

the plane of the face beyond the 150 mm barrier.

8.4 High-energy impact test

CRTs which have a laminated implosion protection system shall be subjected to the following

high-energy impact test.

8.4.1 Test procedure

A (25 ± 1) mm diameter steel pin (see figure 8) shall be inserted through the hole at the top of

the test cabinet and placed on the CRT envelope (3 ± 1) mm behind the seal of the faceplate

and funnel. If the hardware extends back from the seal more than 3 mm so as to interfere with

the placement of the pin, then the pin shall be placed as close as possible to the hardware

without touching it. A weight (see figure 9a), having a mass of (4,5 ± 0,1) kg, shall be caused

to fall from a height so as to impact the pin at the end of its fall.

The height of the test mass shall be adjusted to limit the amount of energy to the minimum

required to produce fracturing of the glassware, but not less than 7 J.

If fracturing of the glass does not occur, the impact energy shall be increased in 7 J

increments to a maximum of 63 J using a new test sample each time until all the CRTs in the

test group have suffered rapid devacuation.

– 14 – 61965 © IEC:2000(E)

The impact energy shall not be so large as to cause the pin to punch a hole with little or no

cracking or shaling of the glassware. If this condition does occur then a lower impact energy

shall be selected so as to result in fracturing (7 J steps not necessary).

NOTE Previous testing experience on a particular CRT design (obtained from the CRT manufacturer or the test

laboratory) should be considered when selecting the energy level within the range.

The implosion pin shall be restricted so that its travel on impact shall be a maximum of 6 mm.

The pin travel restriction assembly shall be positioned so that its impact energy shall not be

transferred to the test cabinet. Figures 7, 8 and 9 give examples of equipment that may

be used.

Barriers shall be placed 1,0 m and 1,5 m from the plane of the centre of the face of the CRT.

8.4.2 Glass throw criteria

A CRT is in compliance if the expulsion of glass within 5 s of the initial impact meets the

following requirements:

a) there shall be no single piece of glass having a mass greater than 15 g between the 1,0 m

and 1,5 m barriers;

b) the total mass of all pieces of glass between the 1,0 m and 1,5 m barriers shall not exceed 45 g;

c) there shall be no single piece of glass having a mass greater than 1,5 g beyond the 1,5 m

barrier.

9 Testing of small CRTs

9.1 Mechanical strength (ball impact test)

9.1.1 Test procedure

A solid smooth steel ball of (40 ± 1) mm diameter and mass of (260 ± 15) g, including the

hook, and a minimum C scale Rockwell hardness of 60, shall be suspended by suitable

means such as a fine wire or chain with a mass not exceeding 10 % of the mass of the ball

and hook. It shall be allowed to fall freely as a pendulum from a calculated height and strike

the face of the CRT with an energy of (2,0 ± 0,1) J. The CRT shall be placed so that the face

is vertical and in the same vertical plane as the point of support of the pendulum. A single

impact shall be applied to any point on the CRT face at a distance of 25 mm or greater from

the edge of the useful screen.

NOTE The test laboratory should consider all their test set-up uncertainties to ensure this 25 mm minimum

position of the point of impact.

The barrier shall be placed 0,6 m from the plane of the centre of the face of the CRT

(see figure 2).

9.1.2 Glass throw criteria

A CRT is in compliance if the expulsion of glass within 5 s of the initial impact meets the

following requirements:

a) there shall be no glass particle (a single piece of glass having a mass greater than

0,025 g) past the 0,6 m barrier;

b) the total mass of all pieces of glass past the 0,6 m barrier shall not exceed 0,1 g.

61965 © IEC:2000(E) – 15 –

9.2 Implosion test (high ball)

If implosion or rapid devacuation does not occur when the CRT is tested as specified in 9.1

then a CRT having other than a laminated implosion protection system shall be subjected to

the following test.

9.2.1 Test procedure

The face of the CRT shall be scratched at the top and bottom edges (3 ± 1) mm from the

screen phosphor edge into the viewing area. The length of the scratches shall be 45 % to

55 % of the longest dimension/width of the face of the CRT.

Using a (40 ± 1) mm diameter steel ball having a mass of (260 ± 15) g and a minimum C scale

Rockwell hardness of 60, a CRT having other than a laminated implosion screen shall be

subject to additional impact tests during which the impact energy shall be increased in 0,7 J

increments until fracturing occurs. A new sample shall be used for each test until all CRTs in

the test group have been tested, with implosion or rapid devacuation occurring.

Barriers shall be placed 0,6 m and 1,2 m from the plane of the centre of the face of the CRT

(see figure 2).

9.2.2 Glass throw criteria

A CRT is in compliance if the expulsion of glass within 5 s of the initial impact meets the

following requirements:

a) there shall be no single piece of glass having a mass greater than 15 g between the 0,6 m

and 1,2 m barriers;

b) the total mass of all pieces of glass between the 0,6 m and 1,2 m barriers shall not exceed 45 g;

c) there shall be no single piece of glass having a mass greater than 1,5 g beyond the 1,2 m

barrier.

9.3 Implosion test (thermal shock)

9.3.1 Test procedure

As 8.3.1.

9.3.2 Glass throw criteria

As 8.3.2.

9.4 High-energy impact test

CRTs which have a laminated implosion protection system shall be subjected to the following

high-energy impact test.

9.4.1 Test procedure

A (9,5 ± 0,5) mm diameter steel pin shall be inserted through the hole in the top of the test

cabinet and placed directly on the envelope seal line. A weight (see figure 9b) having a mass

of (0,45 ± 0,02) kg, shall be caused to fall freely from a height so as to impact the pin at the

end of its fall.

– 16 – 61965 © IEC:2000(E)

The height of the test mass shall be adjusted to limit the amount of energy to the minimum

amount required to produce fracturing of the glassware, but not less than 2,7 J.

If fracturing of the glass does not occur, the impact energy shall be increased in 0,7 J

increments, using a new test sample each time, until all CRTs in the test group have been

tested with rapid devacuation.

The impact energy shall not be so large as to cause the pin to punch a hole with little or no

cracking or shaling of the glassware. If this condition does occur then a lower impact energy

shall be selected so as to result in fracturing (0,7 J steps not necessary).

NOTE Previous testing experience on a particular CRT design (obtained from the CRT manufacturer or the test

laboratory) should be considered when selecting the energy level within the range.

The impact pin shall be restricted so that its travel on impact shall be a maximum of 6 mm.

The pin travel restriction assembly shall be positioned so that impact energy shall not be

transferred to the test cabinet. Figures 7, 8 and 9 give examples of equipment that may

be used.

Barriers shall be placed 0,6 m and 1,2 m from the plane of the centre of the face of the CRT.

9.4.2 Glass throw criteria

A CRT is in compliance if the expulsion of glass within 5 s after the initial impact meets the

following requirements:

a) there shall be no single piece of glass having a mass greater than 15 g between the 0,6 m

and 1,2 m barriers;

b) the total mass of all pieces of glass between the 0,6 m and 1,2 m barriers shall not exceed 45 g;

c) there shall be no single piece of glass having a mass greater than 1,5 g beyond the 1,2 m

barrier.

10 Marking

Along with the CRT manufacturer’s name, trade name or identifying code, and a type number,

each CRT which meets the requirements of this standard shall be marked with the following

statement, or wording with a similar meaning. The marking shall be of a permanent and

legible type and in the appropriate language.

WARNING. This cathode ray tube employs integral implosion protection.

For continued safety it must be replaced with a cathode ray tube of the same or

equivalent type number.

11 Normative requirements for the use of tables 1 and 2

(prestressed banded CRTs)

Sampling and testing for new construction (sampling plan I), new construction with known

tape or resin (sampling plan II), tension band only (sampling plan III) and alternative

construction (sampling plan IV) will be used when any of the following new construction

features or variations in construction apply. Unique constructions may require a special

investigation.

61965 © IEC:2000(E) – 17 –

11.1 Sampling plan I: New construction

Applicable to first-time testing for a CRT manufacturer or a change in construction of a

previously tested CRT that employs any of the following nominal design changes:

11.1.1 Size

New CRT diagonal size range (see table 7).

11.1.2 Deflection angle

New deflection angle range for a particular CRT size range (see table 7).

11.1.3 Glassware shape

Glassware in a particular CRT size and deflection angle range, having the following shape

variations, is considered a new glassware shape.

a) front panel outside curvature – a change in height measurement from the Z point to the

centre of the face panel of more than ±10 % from a previously tested CRT for a

manufacturer;

b) aspect ratio – any change in the height-to-width ratio of the front panel from a previously

tested CRT for a manufacturer;

c) glassware thickness – a change in glassware thickness of more than ±20 % at any point,

other than the neck, from a previously t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...