IEC 61189-5-1:2016

(Main)Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 5-1: General test methods for materials and assemblies - Guidance for printed board assemblies

Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 5-1: General test methods for materials and assemblies - Guidance for printed board assemblies

IEC 61189-5-1:2016 is a catalogue of test methods representing methodologies and procedures that can be applied to test printed board assemblies. This part of IEC 61189 contains the types of content of the IEC 61189-5 series, as well as guidance documents and handbooks for printed board assemblies.

Méthodes d'essai pour les matériaux électriques, les cartes imprimées et autres structures d'interconnexion et ensembles - Partie 5-1: Méthodes d'essai générales pour les matériaux et les assemblages - Lignes directrices pour les assemblages de cartes à circuit imprimé

L'IEC 61189-5-1:2016 est un catalogue de méthodes d'essai qui représentent les méthodologies et les modes opératoires qui peuvent être appliqués aux assemblages de cartes à circuit imprimé. La présente partie de l'IEC 61189 récapitule le contenu de la série IEC 61189-5, ainsi que les documents et manuels avec les lignes directrices relatives aux assemblages de cartes à circuit imprimé.

General Information

- Status

- Published

- Publication Date

- 04-Jul-2016

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 3 - TC 91/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 05-Jul-2016

- Completion Date

- 15-Sep-2016

Overview

IEC 61189-5-1:2016 is an essential international standard published by the International Electrotechnical Commission (IEC) that provides comprehensive test methods for electrical materials, printed boards, and interconnection structures and assemblies. Specifically, Part 5-1 focuses on general test methods for materials and assemblies, offering detailed guidance tailored for printed board assemblies (PBAs). This standard serves as a foundational reference for manufacturers, engineers, and quality assurance professionals involved in the production, testing, and validation of printed circuit board assemblies.

The document catalogs scientifically approved methodologies and procedures designed to ensure uniformity, accuracy, and reproducibility in evaluating the physical and electrical integrity of PBAs. As a part of the IEC 61189 series, IEC 61189-5-1 also integrates relevant normative references and guidance materials that supplement industry best practices for testing PBAs.

Key Topics

- Scope and Application: Covers general test methods applicable to a wide range of electrical materials and assemblies used in the manufacture and assembly of printed boards.

- Accuracy, Precision, and Resolution: Defines statistical approaches, including the use of Student’s t-distribution and recommended uncertainty limits, to ensure reliable and reproducible test results.

- Catalogue of Approved Test Methods: Lists standardized testing techniques that evaluate various aspects of printed board assemblies, such as mechanical durability, electrical performance, and material stability.

- Guidance and Handbooks: References supplementary documents including industry handbooks and user guides that offer additional insights on cleanliness, soldering processes, and surface insulation resistance, enhancing the practical application of test methods.

- Integration with Related Standards: Harmonizes with other IEC standards and technical committee publications to provide a cohesive framework for testing PBAs.

Applications

IEC 61189-5-1:2016 is widely applicable in sectors where printed circuit board assembly reliability and quality are critical, including:

- Electronics Manufacturing: Enables manufacturers to assess the quality of materials and assemblies, ensuring compliance with international safety and performance standards.

- Quality Control and Assurance: Assists test technicians and engineers in systematically verifying solder joints, surface insulation, and mechanical strength of printed boards.

- Product Development: Supports design verification and failure analysis through established testing procedures that identify material weaknesses and assembly defects.

- Supply Chain Management: Aids OEMs and suppliers in maintaining consistent production standards across diverse manufacturing sites.

- Regulatory Compliance: Helps organizations align with international regulations and customer requirements by using recognized testing protocols.

Implementing IEC 61189-5-1 helps enhance product reliability, reduce failure rates, and optimize manufacturing processes by standardizing test methods for printed board assemblies.

Related Standards

IEC 61189-5-1 is part of the broader IEC 61189 series dedicated to test methods for electrical materials and printed boards, including:

- IEC 61189-5-2: Test methods for soldering flux used in printed board assemblies.

- IEC 61189-5-3: Test methods for soldering paste in printed board assemblies.

- IEC 61189-5-4: Covers additional materials and assembly test procedures.

This standard also complements IPC-related guidelines, such as IPC-J-STD-001 for assembly acceptability and IPC-9201 for surface insulation resistance, promoting comprehensive evaluation practices. Collaboration between IEC and other organizations like IPC strengthens the applicability of IEC 61189-5-1 across global electronic manufacturing communities.

By adopting the IEC 61189-5-1:2016 standard, professionals ensure adherence to internationally recognized test methods designed for the evolving challenges of printed circuit board assembly evaluation. This fosters enhanced reliability, quality, and global interoperability in electrical and electronic assembly manufacturing.

Buy Documents

IEC 61189-5-1:2016 - Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 5-1: General test methods for materials and assemblies - Guidance for printed board assemblies

Frequently Asked Questions

IEC 61189-5-1:2016 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 5-1: General test methods for materials and assemblies - Guidance for printed board assemblies". This standard covers: IEC 61189-5-1:2016 is a catalogue of test methods representing methodologies and procedures that can be applied to test printed board assemblies. This part of IEC 61189 contains the types of content of the IEC 61189-5 series, as well as guidance documents and handbooks for printed board assemblies.

IEC 61189-5-1:2016 is a catalogue of test methods representing methodologies and procedures that can be applied to test printed board assemblies. This part of IEC 61189 contains the types of content of the IEC 61189-5 series, as well as guidance documents and handbooks for printed board assemblies.

IEC 61189-5-1:2016 is classified under the following ICS (International Classification for Standards) categories: 31.180 - Printed circuits and boards. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61189-5-1:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61189-5-1 ®

Edition 1.0 2016-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Test methods for electrical materials, printed boards and other interconnection

structures and assemblies –

Part 5-1: General test methods for materials and assemblies – Guidance for

printed board assemblies

Méthodes d'essai pour les matériaux électriques, les cartes imprimées et autres

structures d'interconnexion et ensembles –

Partie 5-1: Méthodes d'essai générales pour les matériaux et les assemblages –

Lignes directrices pour les assemblages de cartes à circuit imprimé

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 15

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC 65 000 entrées terminologiques électrotechniques, en anglais

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 61189-5-1 ®

Edition 1.0 2016-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Test methods for electrical materials, printed boards and other interconnection

structures and assemblies –

Part 5-1: General test methods for materials and assemblies – Guidance for

printed board assemblies

Méthodes d'essai pour les matériaux électriques, les cartes imprimées et autres

structures d'interconnexion et ensembles –

Partie 5-1: Méthodes d'essai générales pour les matériaux et les assemblages –

Lignes directrices pour les assemblages de cartes à circuit imprimé

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.180 ISBN 978-2-8322-3506-5

– 2 – IEC 61189-5-1:2016 © IEC 2016

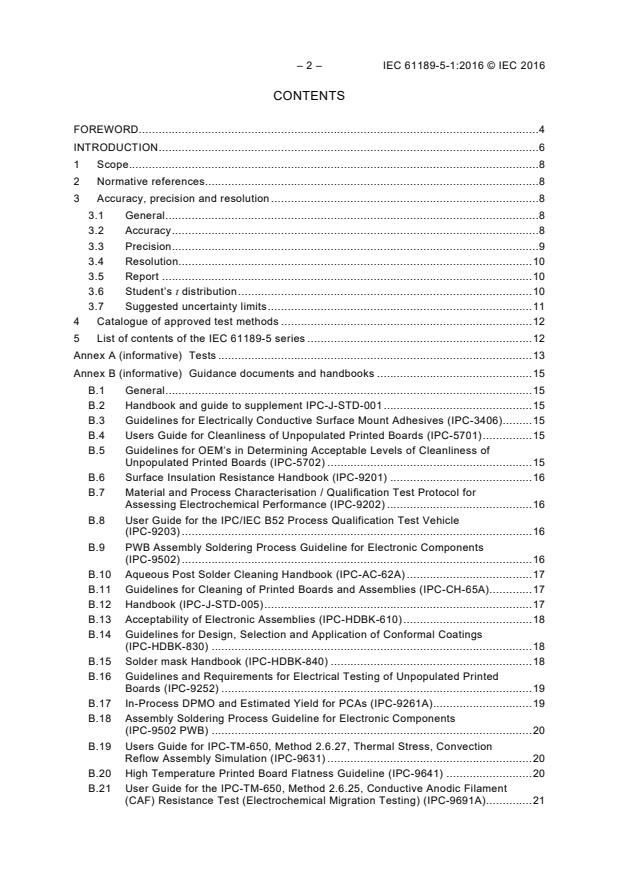

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 8

2 Normative references. 8

3 Accuracy, precision and resolution . 8

3.1 General . 8

3.2 Accuracy . 8

3.3 Precision . 9

3.4 Resolution. 10

3.5 Report . 10

3.6 Student’s t distribution . 10

3.7 Suggested uncertainty limits . 11

4 Catalogue of approved test methods . 12

5 List of contents of the IEC 61189-5 series . 12

Annex A (informative) Tests . 13

Annex B (informative) Guidance documents and handbooks . 15

B.1 General . 15

B.2 Handbook and guide to supplement IPC-J-STD-001 . 15

B.3 Guidelines for Electrically Conductive Surface Mount Adhesives (IPC-3406) . 15

B.4 Users Guide for Cleanliness of Unpopulated Printed Boards (IPC-5701) . 15

B.5 Guidelines for OEM’s in Determining Acceptable Levels of Cleanliness of

Unpopulated Printed Boards (IPC-5702) . 15

B.6 Surface Insulation Resistance Handbook (IPC-9201) . 16

B.7 Material and Process Characterisation / Qualification Test Protocol for

Assessing Electrochemical Performance (IPC-9202) . 16

B.8 User Guide for the IPC/IEC B52 Process Qualification Test Vehicle

(IPC-9203) . 16

B.9 PWB Assembly Soldering Process Guideline for Electronic Components

(IPC-9502) . 16

B.10 Aqueous Post Solder Cleaning Handbook (IPC-AC-62A) . 17

B.11 Guidelines for Cleaning of Printed Boards and Assemblies (IPC-CH-65A) . 17

B.12 Handbook (IPC-J-STD-005) . 17

B.13 Acceptability of Electronic Assemblies (IPC-HDBK-610) . 18

B.14 Guidelines for Design, Selection and Application of Conformal Coatings

(IPC-HDBK-830) . 18

B.15 Solder mask Handbook (IPC-HDBK-840) . 18

B.16 Guidelines and Requirements for Electrical Testing of Unpopulated Printed

Boards (IPC-9252) . 19

B.17 In-Process DPMO and Estimated Yield for PCAs (IPC-9261A) . 19

B.18 Assembly Soldering Process Guideline for Electronic Components

(IPC-9502 PWB) . 20

B.19 Users Guide for IPC-TM-650, Method 2.6.27, Thermal Stress, Convection

Reflow Assembly Simulation (IPC-9631) . 20

B.20 High Temperature Printed Board Flatness Guideline (IPC-9641) . 20

B.21 User Guide for the IPC-TM-650, Method 2.6.25, Conductive Anodic Filament

(CAF) Resistance Test (Electrochemical Migration Testing) (IPC-9691A) . 21

B.22 Mechanical Shock Test Guidelines for Solder Joint Reliability (IPC-JEDEC-

9703) . 21

B.23 Printed Circuit Assembly Strain Gage Test Guideline (IPC-JEDEC-9704A) . 22

Bibliography . 23

Table 1 – Student’s t distribution . 11

Table A.1 – General test methods for materials and assemblies . 13

– 4 – IEC 61189-5-1:2016 © IEC 2016

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

TEST METHODS FOR ELECTRICAL MATERIALS,

PRINTED BOARDS AND OTHER INTERCONNECTION

STRUCTURES AND ASSEMBLIES –

Part 5-1: General test methods for materials and assemblies –

Guidance for printed board assemblies

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61189-5-1 has been prepared by IEC technical committee 91:

Electronics assembly technology.

The text of this standard is based on the following documents:

CDV Report on voting

91/1273/CDV 91/1354/RVC

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 61189 series, published under the general title Test methods for

electrical materials, printed boards and other interconnection structures and assemblies, can

be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 61189-5-1:2016 © IEC 2016

INTRODUCTION

IEC 61189 relates to test methods for printed boards and printed board assemblies, as well as

related materials or component robustness, irrespective of their method of manufacture.

The standard is divided into separate parts, covering information for the designer and the test

methodology engineer or technician. Each part has a specific focus. Methods are grouped

according to their application and numbered sequentially as they are developed and released.

In some instances test methods developed by other technical committees (for example, TC

104) have been reproduced from existing IEC standards in order to provide the reader with a

comprehensive set of test methods. When this situation occurs, it will be noted on the specific

test method. If the test method is reproduced with minor revisions, those paragraphs that are

different are identified.

This part of IEC 61189 contains test methods for evaluating printed board assemblies as well

as materials used in the manufacture of electronic assemblies. The methods are self-

contained, with sufficient detail and description so as to achieve uniformity and reproducibility

in the procedures and test methodologies.

It was decided by TC 91 that the contents of IEC 61189-5 and IEC 61189-6 be merged into a

series of documents in the following way:

IEC 61189-5-1, Test methods for electrical materials, printed boards and other

interconnection structures and assemblies – Part 5-1: General test methods for materials and

assemblies – Guidance for printed board assemblies

IEC 61189-5-2:2015, Test methods for electrical materials, printed boards and other

interconnection structures and assemblies – Part 5-2: General test methods for materials and

assemblies – Soldering flux for printed board assemblies

IEC 61189-5-3:2015, Test methods for electrical materials, printed boards and other

interconnection structures and assemblies – Part 5-3: General test methods for materials and

assemblies – Soldering paste for printed board assemblies

IEC 61189-5-4:2015, Test methods for electrical materials, printed boards and other

interconnection structures and assemblies – Part 5-4: General test methods for materials and

assemblies – Solder alloys and fluxed and non-fluxed solid wire for printed board assemblies

IEC 61189-5-501:—, Test methods for electrical materials, printed boards and other

interconnection structures and assemblies – Part 5-501: General test methods for materials

and assemblies – Surface insulation resistance (SIR) testing of solder fluxes

IEC 61189-5-502:—, Test methods for electrical materials, printed boards and other

interconnection structures and assemblies – Part 5-502: General test methods for materials

and assemblies – SIR testing of assemblies

IEC 61189-5-503:—, Test methods for electrical materials, printed boards and other

interconnection structures and assemblies – Part 5-503: General test methods for materials

and assemblies – Conductive Anodic Filaments (CAF) testing of circuit boards

IEC 61189-5-504:—, Test methods for electrical materials, printed boards and other

interconnection structures and assemblies – Part 5-504: General test methods for materials

and assemblies – Process ionic contamination testing

____________

Under consideration.

The tests shown in this standard are grouped according to the following principles:

P: preparation/conditioning methods

V: visual test methods

D: dimensional test methods

C: chemical test methods

M: mechanical test methods

E: electrical test methods

N: environmental test methods

X: miscellaneous test methods including process control tests for the assembly process

To facilitate reference to the tests, to retain consistency of presentation and to provide for

future expansion, each test is identified by a number (assigned sequentially) added to the

prefix (group code) letter showing the group to which the test method belongs.

The test method numbers have no significance with respect to an eventual test sequence.

This responsibility rests with the relevant specification that calls for the method being

performed. The relevant specification, in most instances, also describes pass/fail criteria.

The letter and number combinations are for reference purposes to be used by the relevant

specification. Thus, "5-2C01" represents the first chemical test method described in

IEC 61189-5-2.

In short, in this example, 5-2 is the number of the part of IEC 61189, C is the group of

methods, and 01 is the test number.

A list of all test methods included in the above-mentioned documents, is given in Annex A.

This annex will be reissued whenever new tests are introduced.

– 8 – IEC 61189-5-1:2016 © IEC 2016

TEST METHODS FOR ELECTRICAL MATERIALS,

PRINTED BOARDS AND OTHER INTERCONNECTION

STRUCTURES AND ASSEMBLIES –

Part 5-1: General test methods for materials and assemblies –

Guidance for printed board assemblies

1 Scope

This part of IEC 61189 is a catalogue of test methods representing methodologies and

procedures that can be applied to test printed board assemblies.

This part of IEC 61189 contains the types of content of the IEC 61189-5 series, as well as

guidance documents and handbooks for printed board assemblies.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

There are no normative references in this document.

3 Accuracy, precision and resolution

3.1 General

Measurement errors and uncertainties are inherent in all measurement processes. The

information given below enables valid estimates of the amount of error and uncertainty to be

taken into account.

Test data serve a number of purposes which include

• monitoring of a process;

• enhancing of confidence in quality conformance;

• arbitration between customer and supplier.

In any of these circumstances, it is essential that confidence can be placed upon the test data

in terms of

• accuracy: calibration of the test instruments and/or system;

• precision: the repeatability and uncertainty of the measurement;

• resolution: the suitability of the test instrument and/or system.

3.2 Accuracy

The regime by which routine calibration of the test equipment is undertaken shall be clearly

stated in the quality documentation of the supplier or agency conducting the test and shall

meet the requirements of ISO 9001 or equivalent (see Bibliography).

The calibration shall be conducted by an agency having accreditation to a national or

international measurement standards institute. There should be an uninterrupted chain of

calibration to a national or international standard.

Where calibration to a national or international standard is not possible, round-robin

techniques may be used and documented to enhance confidence in measurement accuracy.

The calibration interval shall normally be one year. Equipment consistently found to be

outside acceptable limits of accuracy shall be subject to shortened calibration intervals.

Equipment consistently found to be well within acceptable limits may be subject to relaxed

calibration intervals.

A record of the calibration and maintenance history shall be maintained for each instrument.

These records should state the uncertainty of the calibration technique (in ±% deviation) in

order that uncertainties of measurement can be aggregated and determined.

A procedure shall be implemented to resolve any situation where an instrument is found to be

outside calibration limits.

3.3 Precision

The uncertainty budget of any measurement technique is made up of both systematic and

random uncertainties. All estimates shall be based upon a single confidence level, the

minimum being 95 %.

Systematic uncertainties are usually the predominant contributor and will include all

uncertainties not subject to random fluctuation. These include

• calibration uncertainties;

• errors due to the use of an instrument under conditions which differ from those under

which it was calibrated;

• errors in the graduation of a scale of an analogue meter (scale shape error).

Random uncertainties result from numerous sources but can be deduced from repeated

measurement of a standard item. Therefore, it is not necessary to isolate the individual

contributions. These may include

• random fluctuations such as those due to the variation of an influence parameter.

Typically, changes in atmospheric conditions reduce the repeatability of a measurement;

• uncertainty in discrimination, such as setting a pointer to a fiducial mark or interpolating

between graduations on an analogue scale.

Aggregation of uncertainties: Geometric addition (root-sum-square) of uncertainties may be

used in most cases. An interpolation error is normally added separately and may be accepted

as being 20 % of the difference between the finest graduations of the scale of the instrument.

2 2

U = ± (U + U ) + U

t s r i

where

U is the total uncertainty;

t

U is the systematic uncertainty;

s

U is the random uncertainty;

r

U is the interpolation error.

i

– 10 – IEC 61189-5-1:2016 © IEC 2016

Determination of random uncertainties: Random uncertainty can be determined by repeated

measurement of a parameter and subsequent statistical manipulation of the measured data.

The technique assumes that the data exhibits a normal (Gaussian) distribution.

t × σ

U =

r

n

where

U is the random uncertainty;

r

n is the sample size;

t is the percentage point of the t distribution as shown in Table 1;

σ is the standard deviation (σ ).

n–1

3.4 Resolution

It is paramount that the test equipment used is capable of sufficient resolution. Measurement

systems used should be capable of resolving 10 % (or better) of the test limit tolerance.

It is accepted that some technologies will place a physical limitation upon resolution (for

example, optical resolution).

3.5 Report

In addition to requirements detailed in the test specification, the report shall detail

a) the test method used;

b) the identity of the sample(s);

c) the test instrumentation;

d) the specified limit(s);

e) an estimate of measurement uncertainty and resultant working limit(s) for the test;

f) the detailed test results;

g) the test date and operators’ signature.

3.6 Student’s t distribution

Table 1 gives values of the factor t for 95 % and 99 % confidence levels, as a function of the

number of measurements.

Table 1 – Student’s t distribution

Sample t value t value Sample t value t value

size 95 % 99 % size 95 % 99 %

2 12,7 63,7 14 2,16 3,01

3 4,3 9,92 15 2,14 2,98

4 3,18 5,84 16 2,13 2,95

5 2,78 4,6 17 2,12 2,92

6 2,57 4,03 18 2,11 2,9

7 2,45 3,71 19 2,1 2,88

8 2,36 3,5 20 2,09 2,86

9 2,31 3,36 21 2,08 2,83

10 2,26 3,25 22 2,075 2,82

11 2,23 3,17 23 2,07 2,81

12 2,2 3,11 24 2,065 2,8

13 2,18 3,05 25 2,06 2,79

3.7 Suggested uncertainty limits

The following target uncertainties are suggested:

a) Voltage < 1 kV: ± 1,5 %

b) Voltage > 1 kV: ± 2,5 %

c) Current < 20 A: ± 1,5 %

d) Current > 20 A: ± 2,5 %

Resistance

e) Earth and continuity: ± 10 %

f) Insulation: ± 10 %

g) Frequency: ± 0,2 %

Time

h) Interval < 60 s: ± 1 s

i) Interval > 60 s: ± 2 %

j) Mass < 10 g: ± 0,5 %

k) Mass 10 g to 100 g: ± 1 %

l) Mass > 100 g: ± 2 %

m) Force: ± 2 %

n) Dimension < 25 mm: ± 0,5 %

o) Dimension > 25 mm: ± 0,1 mm

p) Temperature < 100 °C: ± 1,5 %

q) Temperature > 100 °C: ± 3,5 %

r) Humidity (30 – 75) % RH: ± 5 % RH

Plating thicknesses

s) Backscatter method: ± 10 %

– 12 – IEC 61189-5-1:2016 © IEC 2016

t) Microsection: ± 2 µm

u) Ionic contamination: ± 10 %

4 Catalogue of approved test methods

This standard provides specific test methods in complete detail to permit implementation with

minimal cross-referencing to other specific procedures. The use of generic conditioning

exposures is accomplished in the methods by reference, for example, to those described in

IEC 61189-1 and IEC 60068-1, and, when applicable, is a mandatory part of the test method

standard.

Each method has its own title, number and revision status to accommodate updating and

improving the methods as industry requirements change or demand new methodology. The

methods are organized in test method groups and individual tests.

5 List of contents of the IEC 61189-5 series

The types of content of existing and planned standards in the IEC 61189-5 series is described

in Annex A.

NOTE The details of the standards "under consideration" are not yet available.

Annex A

(informative)

Tests

Table A.1 gives a summary of the existing tests and of the tests under development.

Table A.1 – General test methods for materials and assemblies

IEC standard Designation Test

IEC 61189-5-2 C: Chemical test methods

5-2C01 Corrosion, flux

5-2C02 Determination of acid value of liquid soldering flux potentiometric and visual

titration methods

5-2C03 Acid number of rosin

5-2C04 Determination of halides in fluxes, silver chromate method

5-2C05 Solids content, flux

5-2C06 Quantitative determination of halide content in fluxes (chloride and bromide)

5-2C07 Qualitative analysis of fluorides and fluxes by spot test

5-2C08 Quantitative determination of fluoride concentration in fluxes

5-2C09 Specific gravity

5-2C10 Flux induced corrosion (copper mirror method)

X: Miscellaneous test methods

5-2X01 Liquid flux activity, wetting balance method

5-2X02 Spread test, liquid or extracted solder flux, solder paste and extracted cored

wires or preforms

5-2X03 Flux residues – Tackiness after drying

IEC 61189-5-3 X: Miscellaneous test methods

5-3X01 Paste flux viscosity – T-Bar spindle method

5-3X02 Spread test, extracted solder flux, paste flux and solder paste

5-3X03 Solder paste viscosity – T-Bar spin spindle method (applicable for 300 Pa•s to

1 600 Pa•s)

5-3X04 Solder paste viscosity – T-Bar spindle method (applicable to 300 Pa•s)

5-3X05 Solder paste viscosity – Spiral pump method (applicable for 300 Pa•s to

1 600 Pa•s)

5-3X06 Solder paste viscosity – Spiral pump method (applicable to 300 Pa•s)

5-3X07 Solder paste – Slump test

5-3X08 Solder paste – Solder ball test

5-3X09 Solder paste – Tack test

5-3X10 Solder paste – Wetting test

5-3X11 Determination of solder powder particle size distribution – Screen method for

types

5-3X12 Solder powder particle size distribution – Measuring microscope method

5-3X13 Solder powder particle size distribution – Optical image analyser method

5-3X14 Solder powder particle size distribution – Measuring laser diffraction method

5-3X15 Determination of maximum solder powder particle size

5-3X16 Solder paste metal content by weight

– 14 – IEC 61189-5-1:2016 © IEC 2016

IEC standard Designation Test

IEC 61189-5-4 C: Chemical test methods

5-4C01 Determination of the percentage of flux on/in flux-coated and/or flux-cored

solder

X: Mechanical test methods

5-4X01 Spread test, extracted cored wires or preforms

5-4X02 Spitting test of flux-cored wire solder

5-4X03 Solder pool test

IEC 61189-5-501 Under consideration

IEC 61189-5-502 Under consideration

IEC 61189-5-503 Under consideration

IEC 61189-5-504 Under consideration

Annex B

(informative)

Guidance documents and handbooks

B.1 General

The documents listed in Clauses B.2 to B.23 relate to the specific soldering materials or test

methods employed.

B.2 Handbook and guide to supplement IPC-J-STD-001

IPC-J-STD-001 and IPC-HDBK-001 do not exclude any acceptable process used to make the

electrical connections, as long as the methods used will produce completed solder joints

conforming to the acceptability requirements of the IPC-J-STD-001.

This handbook describes materials, methods, and verification criteria that, when applied as

recommended or required, will produce quality soldered electrical and electronic assemblies.

The intent of this handbook is to explain the ‘‘how-to,’’ the ‘‘why,’’ and fundamentals for these

processes, in addition to implementing control over processes rather than depending on end-

item inspection to determine product quality.

B.3 Guidelines for Electrically Conductive Surface Mount Adhesives (IPC-3406)

This document covers guidelines for selecting electrically conductive adhesives for use in

assembly of components to printed circuit boards (PCB) or similar wiring inter-connect

systems. The focus is on the use of adhesives as solder alternatives. The process discussion

attempts to stay within the bounds of the existing solder assembly infrastructure as much as

possible. Both major types of adhesives, isotropic (conducting equally in all directions) and

anisotropic (unidirectional conductivity), are covered. The two major divisions of polymer

adhesives, thermosets and thermoplastics, are described.

B.4 Users Guide for Cleanliness of Unpopulated Printed Boards (IPC-5701)

If you are in the electronics industry, sooner or later you have to, will, or should deal with the

issue of the cleanliness of the unpopulated printed circuit boards (bare boards). Residues on

circuit boards are directly related to the reliability of the produced hardware and can result in

serious failures if not monitored and controlled.

This document is the product of the IPC Bare Board Cleanliness Assessment Task Group and

was drafted to provide individuals who deal with these issues some guidance on how the

issues should be approached and specified in purchase documents.

B.5 Guidelines for OEM’s in Determining Acceptable Levels of Cleanliness of

Unpopulated Printed Boards (IPC-5702)

Every electronics manufacturer, whether an original equipment manufacturer (OEM) or

contract manufacturer (CM), will be faced with determining if the unpopulated printed boards

used in the finished assembly have an adequate level of cleanliness. The question of ‘‘how

clean is clean enough’’ has been asked repeatedly in the last decade in many IPC committees.

This is a very complex topic, with many critical considerations. For this reason there is not an

unique methodology that determines acceptability. This document was developed as guidance

for the individual(s) responsible for determining these criteria for their company.

– 16 – IEC 61189-5-1:2016 © IEC 2016

IPC-5701 covers many aspects of how cleanliness is measured on printed boards, as well as

many critical factors to consider when specifying board cleanliness in purchasing documents.

This reference, and associated technical papers, show the many inadequacies of current test

methodologies, as well as explaining why there are no ‘‘golden numbers’’ for cleanliness.

What is acceptably clean for one segment of the industry may be unacceptable for more

demanding segments of the industry (e.g., medical or aerospace).

B.6 Surface Insulation Resistance Handbook (IPC-9201)

This document is intended to cover the broad spectrum of temperature-humidity (TH) testing,

associated terminology, and suggested techniques for proper surface insulation resistance

testing as defined in IEC 61189-5-5, Test Methods 5E01 and 5E02.

B.7 Material and Process Characterisation / Qualification Test Protocol for

Assessing Electrochemical Performance (IPC-9202)

This material and process characterization/qualification test records changes in surface

insulation resistance (SIR) on a representative sample of a printed circuit assembly (PCA). It

quantifies any deleterious effects that might arise from solder flux or other process residues

left on external surfaces after soldering, which can cause unwanted electro-chemical

reactions that grossly affect reliability.

It uses test vehicles that are intended to be representative of the electronic circuits that are in

production. It is a test yielding both quantitative and qualitative data.

This test may be used for Process Qualification, demonstrating that a proposed manufacturing

process or process change can produce hardware with acceptable end-item performance

related to cleanliness. Changes may involve any assembly process step, or a change in the

printed board supplier, solder mask or metallization, soldering material supplier, conformal

coating, etc. The test vehicle construction will vary depending upon the type of change being

evaluated.

B.8 User Guide for the IPC/IEC B52 Process Qualification Test Vehicle

(IPC-9203)

The electronics manufacturing process is often very complex, with dozens of variables that

impact the quality and reliability of the manufactured assemblies in the end use environment.

Two of the important variables for consideration are the kinds of residues that remain on the

electronic assembly and the effects that these residues have on reliability. These two

variables are most often referred to in discussions on assembly “cleanliness”.

Whilst there are several different ways to measure residues and their effects on electrical

performance, the two most common approaches in the industry are ionic cleanliness testing,

for determination of ionic residues, and surface insulation resistance (SIR) testing, for the

evaluation of electrochemical failures in humid environments.

This document focuses on the IPC-B-52 standard test assembly and how it is used as an

evaluation tool for electronics manufacturing processes from a “cleanliness” perspective.

B.9 PWB Assembly Soldering Process Guideline for Electronic Components

(IPC-9502)

This document describes manufacturing solder process limits that components subjected to

IPC-9501, IPC-9503, IPC-9504 and J-STD-020 would survive. It does not include optimum

conditions for assembly, but rather guides to assure components are not damaged.

This document applies to both surface-mount (SM) and through-hole (TH) components that

are wave soldered, reflowed or hand soldered. This document is intended to complement

other industry documents, listed in applicable documents.

B.10 Aqueous Post Solder Cleaning Handbook (IPC-AC-62A)

This handbook addresses aqueous cleaning of electrical/electronic parts and application tools

after soldering.

The content of the text is intended to provide a basic understanding of the subject and to

serve as a guide to users or prospective users of aqueous cleaning technology, allowing

selection or improvement of aqueous cleaning processes.

B.11 Guidelines for Cleaning of Printed Boards and Assemblies (IPC-CH-65A)

This manual is a road map for current and developing cleaning issues, rather than to function

as a highly detailed document for all areas touched upon. In areas of cleaning where recent

detailed IPC manuals already exist, the relevant sections in IPC-CH-65A will contain only

sufficient information to make the reader reasonably knowledgeable. This guideline manual

refers the reader to appropriate existing IPC documents (where they exist) for in-depth

information on the particular subject. An example of such a reference IPC manual is IPC-AC-

62, Aqueous Cleaning Handbook. It is only where existing IPC documents are not available

that IPC-CH-65A will expand information beyond the basics in order to cover what is currently

known about the subject. A benefit of this approach is that the manual does not become

unwieldy and tends to foster a user-friendly environment.

Both bare board fabrication and assembly cleanliness issues are addressed. The fabrication

and assembly sections are separated for ease of access. In the original IPC-CH-65, these

sections were very much intertwined. However, it was recognized that for a subject such as

the required cleanliness of finished bare boards, basically redundant teachings are required

for both the fabrication and assembly sections.

B.12 Handbook (IPC-J-STD-005)

This handbook is a companion to the solder paste standard J-STD-005 and should be

considered to be a guide to help assess the applicability of a solder paste for its use in

surface-mount technology (SMT) processes. This document also suggests some test methods

that can help with designing and testing solder pastes. It is intended for use by both vendors

and users of solder paste.

Solder pastes are unique materials, whose performance in a surface-mount process depends

on a variety of variables, many of them interacting. J-STD-005 provides test methods for

classification of solder paste based on the use of a variety of testing techniques. However,

these solder paste classifications do not have a direct correlation to identify the type and

characteristics of a specific solder paste that is needed in any given SMT assembly process.

This document has been written as a guide to assess the applicability of a solder paste for a

specific process, given the tremendous number of permutations of different materials,

atmospheres and process variables currently available.

Where appropriate, references are given to papers and documents with further information.

Due to the sheer number of possible interacting factors, specific solder paste selection criteria

cannot be given. The solder paste selected and the assembly process used will need to form

solder connections that meet the requirements of industry standards such as J-STD-001

and/or IPC-A-610.

– 18 – IEC 61189-5-1:2016 © IEC 2016

B.13 Acceptability of Electronic Assemblies (IPC-HDBK-610)

This handbook is a companion reference to IPC-A-610C and IPC-A-610C Amendment 1 and

was prepared using them. The amendment provides additional criteria and clarification

statements. The amendment is included with this handbook following Appendix C and can be

downloaded free of charge from the IPC website at the following link:

http://www.ipc.org/TOC/IPC-HDBK-610-w-Amend-1.pdf.

The intent of this handbook is to explain the technical rationale for selected acceptability,

process indicator and defect criteria and to provide information regarding assembly

technology. Additional information is provided to give a broader understanding of the process

considerations needed for the production of accept

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...