IEC PAS 61189-3-913:2011

(Main)Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 3-913: Test methods for interconnection structures (printed boards) - Electronic circuit board for high-brightness LEDs

Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 3-913: Test methods for interconnection structures (printed boards) - Electronic circuit board for high-brightness LEDs

IEC/PAS 61189-3-913:2011(E) specifies the test methods of the electronic circuit board for high-brightness LEDs.

General Information

- Status

- Replaced

- Publication Date

- 30-Jan-2011

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 10 - TC 91/WG 10

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 05-Jan-2016

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

IEC PAS 61189-3-913:2011 - Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 3-913: Test methods for interconnection structures (printed boards) - Electronic circuit board for high-brightness LEDs Released:1/31/2011

Frequently Asked Questions

IEC PAS 61189-3-913:2011 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 3-913: Test methods for interconnection structures (printed boards) - Electronic circuit board for high-brightness LEDs". This standard covers: IEC/PAS 61189-3-913:2011(E) specifies the test methods of the electronic circuit board for high-brightness LEDs.

IEC/PAS 61189-3-913:2011(E) specifies the test methods of the electronic circuit board for high-brightness LEDs.

IEC PAS 61189-3-913:2011 is classified under the following ICS (International Classification for Standards) categories: 31.180 - Printed circuits and boards. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC PAS 61189-3-913:2011 has the following relationships with other standards: It is inter standard links to IEC 61189-3-913:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC PAS 61189-3-913:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC/PAS 61189-3-913 ®

Edition 1.0 2011-01

PUBLICLY AVAILABLE

SPECIFICATION

PRE-STANDARD

colour

inside

Test methods for electrical materials, printed boards and other interconnection

structures and assemblies –

Part 3-913: Test methods for interconnection structures (printed boards) –

Electronic circuit board for high-brightness LEDs

IEC/PAS 61189-3-913:2011(E)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC/PAS 61189-3-913 ®

Edition 1.0 2011-01

PUBLICLY AVAILABLE

SPECIFICATION

PRE-STANDARD

colour

inside

Test methods for electrical materials, printed boards and other interconnection

structures and assemblies –

Part 3-913: Test methods for interconnection structures (printed boards) –

Electronic circuit board for high-brightness LEDs

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

X

ICS 31.180 ISBN 978-2-88912-343-8

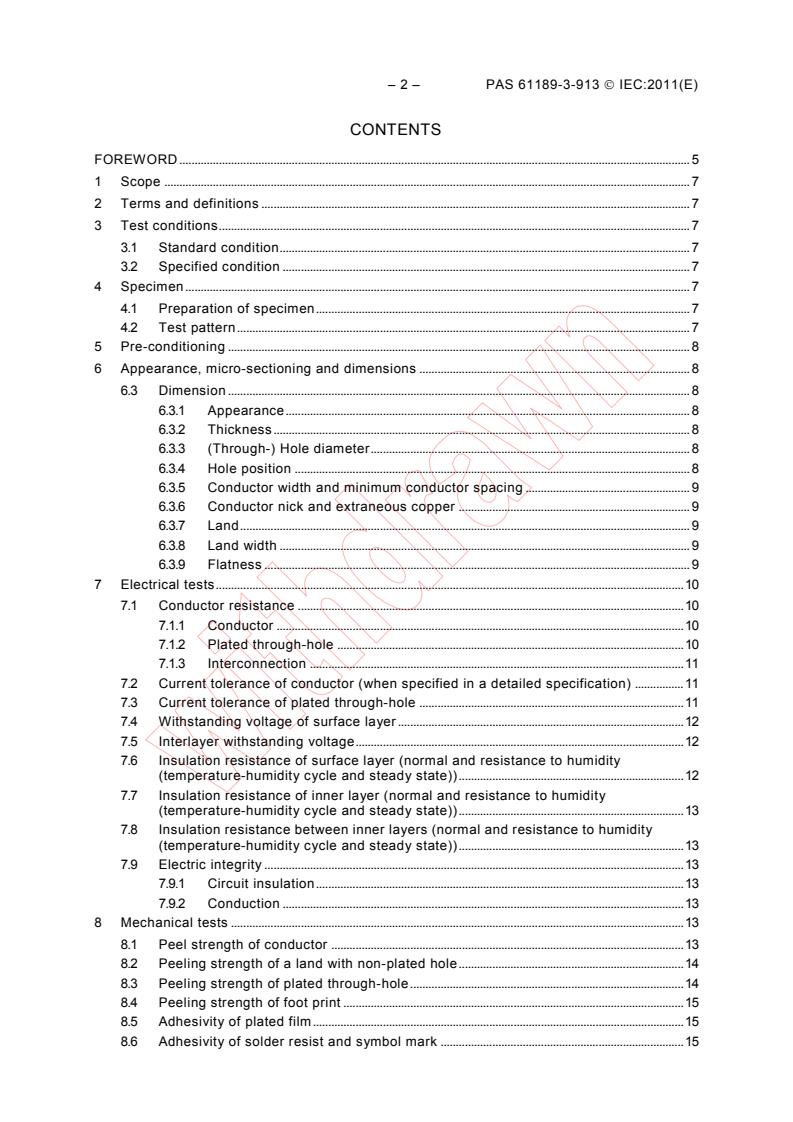

– 2 – PAS 61189-3-913 IEC:2011(E)

CONTENTS

FOREWORD . 5

1 Scope . 7

2 Terms and definitions . 7

3 Test conditions . 7

3.1 Standard condition. 7

3.2 Specified condition . 7

4 Specimen . 7

4.1 Preparation of specimen . 7

4.2 Test pattern . 7

5 Pre-conditioning . 8

6 Appearance, micro-sectioning and dimensions . 8

6.3 Dimension . 8

6.3.1 Appearance . 8

6.3.2 Thickness . 8

6.3.3 (Through-) Hole diameter . 8

6.3.4 Hole position . 8

6.3.5 Conductor width and minimum conductor spacing . 9

6.3.6 Conductor nick and extraneous copper . 9

6.3.7 Land . 9

6.3.8 Land width . 9

6.3.9 Flatness . 9

7 Electrical tests . 10

7.1 Conductor resistance . 10

7.1.1 Conductor . 10

7.1.2 Plated through-hole . 10

7.1.3 Interconnection . 11

7.2 Current tolerance of conductor (when specified in a detailed specification) . 11

7.3 Current tolerance of plated through-hole . 11

7.4 Withstanding voltage of surface layer . 12

7.5 Interlayer withstanding voltage . 12

7.6 Insulation resistance of surface layer (normal and resistance to humidity

(temperature-humidity cycle and steady state)) . 12

7.7 Insulation resistance of inner layer (normal and resistance to humidity

(temperature-humidity cycle and steady state)) . 13

7.8 Insulation resistance between inner layers (normal and resistance to humidity

(temperature-humidity cycle and steady state)) . 13

7.9 Electric integrity . 13

7.9.1 Circuit insulation . 13

7.9.2 Conduction . 13

8 Mechanical tests . 13

8.1 Peel strength of conductor . 13

8.2 Peeling strength of a land with non-plated hole . 14

8.3 Peeling strength of plated through-hole . 14

8.4 Peeling strength of foot print . 15

8.5 Adhesivity of plated film . 15

8.6 Adhesivity of solder resist and symbol mark . 15

PAS 61189-3-913 IEC:2011(E) – 3 –

8.6.1 Tape peeling strength . 15

8.6.2 Grid line test (see JIS K 5600, 5 and 6). 16

8.6.3 Scratch test using pencil . 16

8.7 Resistance to bending . 17

9 Environmental tests . 18

9.1 Temperature cycle . 18

9.2 Thermal shock (low and high temperatures) (see JIS C 0025) . 18

9.3 Thermal shock (immersion in high temperature) . 19

9.4 Resistance to humidity (temperature/humidity cycle) (see JIS C 60068-2-78) . 19

9.5 Resistance to humidity (steady state) (see JIS C 60068-2-78) . 20

10 Other tests . 20

10.1 Flammability. 20

10.2 Resistance to chemical solvent . 21

10.3 Solderability . 21

10.4 Resistance to soldering heat . 22

10.4.1 Solder float method . 22

10.4.2 Reflow soldering . 22

10.5 Resistance to heat of solder resist and symbol mark . 22

10.5.1 Solder floating method . 22

10.5.2 Reflow soldering method . 23

10.6 Thermal conductivity. 23

10.6.1 Measurement of thermal resistance on the plane . 23

10.6.2 Thermal conductivity in the direction of thickness . 24

10.7 Reflectivity . 25

10.8 Wire bond strength . 25

11 Normative references . 25

Annex A (informative) Figures . 27

Annex B (informative) Reflectivity . 46

Annex C (informative) Connection strength of wire bonding . 47

Annex D (informative) Additional information to IEC/PAS 61189-3-913 . 48

Bibliography . 49

Figure 1 – Land width . 9

Figure 2 – Warpage . 10

Figure 3 – Twist . 10

Figure 4 – Electrode arrangement for resistance measurement . 10

Figure 5 – Electrode arrangement for resistance measurement of a plated through-hole . 11

Figure 6 – Electrode arrangement for resistance measurement of interconnection

measurement . 11

Figure 7 – An example of cutter knife blade (mm) . 16

Figure 8 – Use of a cutter knife . 16

Figure 9 – Use of a pencil . 17

Figure 10 – An example of bending machine . 18

Figure 11 – Flammability test (mm) . 21

Figure A.1a – Composite test pattern for single- and double-sided electronic board (front

surface) . 28

– 4 – PAS 61189-3-913 IEC:2011(E)

Figure A.1b – Composite test pattern for double-sided electronic board (back surface) . 29

Figure A.1 – Composite test pattern . 29

Figure A.2.1 – Complex test patterns of multi-layer electronics board (perspective) . 31

Figure A.2.2a – Electrode patterns of each specimen (Part 1) . 32

Figure A.2.2b – Electrode patterns of each specimen (Part 2) . 33

Figure A.2.2c – Electrode patterns of each specimen (Part 3) . 34

Figure A.2.2d – Electrode patterns of each specimen (Part 4) . 35

Figure A.2.2e – Electrode patterns of each specimen (Part 5) . 36

Figure A.2.2f – Electrode patterns of each specimen (Part 6) . 37

Figure A.2.2g – Electrode patterns of each specimen (Part 7) . 38

Figure A.2.2 – Electrode pattern of each specimen . 38

Figure A.3 – Temperature rise according to conductor thickness, width and current . 39

Figure A.4a – Insulation resistance (normal, resistance to

humidity-temperature/humidity cycle and steady state) . 40

Figure A.4b – Insulation resistance of inner layers (normal, resistance to

humidity-temperature/humidity cycle and steady state) . 40

Figure A.4c – Insulation resistance between inner layers (normal, resistance to

humidity-temperature/humidity cycle and steady state) . 41

Figure A.4 – Insulation resistance . 41

Figure A.5 – Specimen for resistance to bending test . 41

Figure A.6 – Temperature – humidity cycle . 42

Figure A.7 – Test pattern for resistance to soldering heat test (for information only) . 43

Figure A.8 – Temperature profile of reflow furnace (for information only) . 43

Figure A.9 – Illustration of thermal conductivity test (for information). Arrange the

heating TEG (test equipment group) to the center of the cabinet . 44

Figure A.10 – Surface layer specimen pattern for thermal conductivity test . 44

Figure A.11 – Test equipment for thermal resistance to the thickness direction . 45

Table 1 – Examples of test current . 12

Table 2 – Land, hole and lead wire . 14

Table 3 – Temperature cycle conditions . 18

Table 4 – Thermal shock conditions . 19

Table 5 – Test condition . 19

Table 6 – Heating of specimen . 24

Table 7 – Heating of specimen . 25

PAS 61189-3-913 IEC:2011(E) – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

TEST METHODS FOR ELECTRICAL MATERIALS, PRINTED BOARDS

AND OTHER INTERCONNECTION STRUCTURES AND ASSEMBLIES –

Part 3-913: Test methods for interconnection structures (printed boards) –

Electronic circuit board for high-brightness LEDs

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and in

addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and expenses

arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

A PAS is a technical specification not fulfilling the requirements for a standard, but made

available to the public.

IEC-PAS 61189-3-913 was submitted by the JPCA (Japan Electronics Packaging and Circuits

Association) and has been processed by IEC technical committee 91: Electronics assembly

technology.

– 6 – PAS 61189-3-913 © IEC:2011(E)

It is based on JPCA-TMC-LED02T-2010. It is published as a double-logo IEC/ JPCA PAS.

The text of this PAS is based on the This PAS was approved for publication by

following document: the P-members of the committee concerned

as indicated in the following document

Draft PAS Report on voting

91/928/PAS 91/943A/RVD

Following publication of this PAS, which is a pre-standard publication, the technical committee

or subcommittee concerned may transform it into an International Standard.

This PAS shall remain valid for an initial maximum period of 3 years starting from the publication

date. The validity may be extended for a single period up to a maximum of 3 years, at the end of

which it shall be published as another type of normative document, or shall be withdrawn.

A list of all the parts in the IEC 61189 series, under the general title Test methods for electrical

materials, printed boards and other interconnection structures and assemblies, can be found on

the IEC website.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

PAS 61189-3-913 IEC:2011(E) – 7 –

TEST METHODS FOR ELECTRICAL MATERIALS, PRINTED BOARDS

AND OTHER INTERCONNECTION STRUCTURES AND ASSEMBLIES –

Part 3-913: Test methods for interconnection structures (printed boards) –

Electronic circuit board for high-brightness LEDs

1 Scope

This standard specifies the test methods of the electronic circuit board for high-brightness LEDs

(hereafter described as electronic circuit board).

NOTE Reference documents to this standard are listed in Clause 11 Normative references and in the Bibliography.

2 Terms and definitions

For the purpose of this document, the terms used in this PAS shall be in accordance with

JPCA-TD01, JIS C 60068-1 and JIC C 5603.

3 Test conditions

3.1 Standard condition

Tests shall be made unless otherwise specified in a specific standard under the standard

condition specified in JIS C 60068-1, 5.3.1, Standard atmospheric condition (standard

o o

condition), temperature of 15 C to 35 C, relative humidity of 25 % to 75 % and atmospheric

pressure of 86 kPa to 106 kPa. Condition specified in 3.1 shall be used in case there is any doubt

to the experimental results or in case required by a specific standard.

3.2 Specified condition

The specified condition as specified in JIS C 60068-1, 5.2, Standard atmospheric condition

o o

(specified condition), is a temperature of 20 C ± 2 C, a relative humidity of 60 % to 70 % and an

atmospheric pressure of 86 kPa to 106 kPa.

4 Specimen

4.1 Preparation of specimen

Specimen shall be prepared as in (1) or (2) below. The surface of a specimen shall not be

contaminated by oil/grease, sweat and others.

1) Specimen by sampling: the specimen shall be sampled from the electronic circuit boards to

be used in production. The specimen shall be cut to the defined size if its shape and size are

defined in a specific standard. A test coupon may used as the specimen when such coupons

are prepared.

2) Specimen using a test pattern: a specimen shall be prepared using the test pattern shown in

4.2 using the same materials and method to produce products.

4.2 Test pattern

The test pattern with the shape and dimension shown in Figures A.1 and A.2 shall be used

depending on the type of the electronic circuit board.

– 8 – PAS 61189-3-913 IEC:2011(E)

5 Pre-conditioning

Pre-conditioning described in (1) or (2) below shall be made in accordance to the specific

standard.

1) Leave a specimen for 24 h in the standard condition.

o

2) Leave a specimen for 60 min in a thermostat chamber at 85 C and then leave the specimen

for 24 h ± 4 h in the standard atmospheric condition.

6 Appearance, micro-sectioning and dimensions

6.1 Appearance

Appearance check shall be made by naked eyes or using a magnifying glass for appearance of

the specimen, finish and conductor pattern according to its detailed specification. Use a

micrograph of 250X to check a micro-section of a specimen by cutting it and polishing the cutting

face of a specimen embedded usually in epoxy resin or polyester resin.

6.2 Micro-sectioning

Inside of a plated through-hole, conductor or electronic circuit board shall be checked by

micro-sectioning to see its cross section.

1) Equipment: the equipment for the test is a micrograph capable of measuring a thickness of

plated film with an accuracy of better than 0,001 mm, or equivalent.

2) Material: the materials needed are as follows: release agent, embedding resin, polishing

cloth (#180, #400, #1000 and alike), polishing paper (#180, #400, #1000 and alike), and

polishing powder (alumina, chromium oxide, etc.).

3) Specimen: the specimen shall be cut to an appropriate size not to make any damage to the

observing face and embedded in resin. The cut specimen shall be polished using polishing

cloth/paper from coarse to fine particle and then polish using a rotating disc with felt cloth

o o

and polishing powder. The polished surface shall be within 85 to 95 to the board layer.

The diameter of the micro-sectioned hole for measurement of plated film on a through-hole

shall be larger than 90 % of the diameter of the hole measured beforehand. If necessary,

etch the polished surface to identify layer boundaries of a specimen.

4) Test: observe the polished surface of a specimen according to the requirement of specific

standard using a micrograph of the specified magnification.

6.3 Dimension

6.3.1 Appearance

1) Equipment: use a slide caliper specified in JIS B 7507 or equivalent accuracy.

2) Measurement: measure its length and width with an accuracy of 0,01 mm.

6.3.2 Thickness

1) Equipment: use a micrometer specified in JIS B 7502 or equivalent accuracy.

2) Measurement: measure the thickness of a board or total thickness if multilayer board with an

accuracy of 0,01 mm.

6.3.3 (Through-) Hole diameter

1) Equipment: use a magnifying glass with reading scale with an accuracy of 0,01 mm.

2) Measurement: measure the diameter of the specified hole.

6.3.4 Hole position

1) Equipment: use a coordination measuring instrument or a microscope with an accuracy of

0,01 mm, or an equivalent instrument.

PAS 61189-3-913 IEC:2011(E) – 9 –

2) Measurement

a) Measurement of the position of a hole on a grid shall be made by measuring the X and Y

coordinate distances by holding the specimen board in an appropriate method.

b) Measurement of the position of a hole from an arbitrary hole shall be made by measuring

the distance of the measuring hole from that reference hole by holding the specimen

board in an appropriate method.

6.3.5 Conductor width and minimum conductor spacing

1) Equipment: use a coordination measuring instrument or a microscope with an accuracy of

0,01 mm, or an equivalent instrument.

2) Measure the conductor width and conductor spacing by holding the specimen board in an

appropriate method.

6.3.6 Conductor nick and extraneous copper

1) Equipment: use the equipment specified in 6.3.3 (1) or 6.3.4 (1).

2) Measurement: measure the size of a conductor nick or of a extraneous copper of the length

and width in the direction of the conductor.

6.3.7 Land

1) Equipment: use the equipment specified in 6.3.4 (1).

2) Measurement: observe the land to be measured from above and measure its maximum size.

6.3.8 Land width

1) Equipment: use the equipment specified in 6.3.4 (1).

2) Measurement: measure the distance (w) from the edge of a land and a hole.

(1) Non-plated through-hole (2) Plated through-hole

Figure 1 – Land width

6.3.9 Flatness

6.3.9.1 Warpage

1) Equipment: use the height-gauge specified in JIS B 7517 or an equipment with better

accuracy.

2) Measurement: place the specimen as shown in Figure 2 on a precision base with its convex

face upward. Measure the warpage as the maximum gap between the board and base (h )

B

to an accuracy of 0,1 mm.

6.3.9.2 Twist

1) Equipment: Use the regular class gap gauge specified in JIS B 7524 or a height-gauge

specified in JIS B 7517 or an equipment with better accuracy.

2) Measurement: place the specimen as shown in Figure 3 on a precision base with its convex

face upward with three corners of the board in touch with the base. Measure the twist as the

maximum gap between the remaining floating edge of the board and base (h ) to an

T

accuracy of 0,1 mm.

– 10 – PAS 61189-3-913 IEC:2011(E)

Printed board

Printed board

Precision surface plate

Precision surface plate

Figure 2 – Warpage Figure 3 – Twist

7 Electrical tests

7.1 Conductor resistance

7.1.1 Conductor

1) Equipment: equipment is for the voltage-drop method (four-terminal method), or equivalent.

The current used in the measurement is d.c.

2) Specimen: the specimen shall be a conductor long and narrow as much as possible, and

shall comply with the detailed specification.

3) Pre-conditioning: the pre-conditioning shall be as specified in Clause 5.

4) Test: care shall be made to avoid influences caused by contact method of probe and of

heating caused by the measuring current. Measure the resistance as shown in Figure 4 to an

accuracy of ± 5 % using the equipment described in (1) above.

Current terminal Voltage terminal

Insulation material

Figure 4 – Electrode arrangement for resistance measurement

7.1.2 Plated through-hole

1) Equipment: use the equipment specified in 7.1.1 (1).

2) Specimen: specimen is the specified part of a board or a test coupon or with the specified

composite test pattern as shown in Figure A.1.

PAS 61189-3-913 IEC:2011(E) – 11 –

3) Pre-conditioning: the pre-conditioning shall be as specified in Clause 5.

4) Test: care shall be made to avoid influences caused by contact method of probe and of

heating caused by the measuring current. Measure the resistance as shown in Figure 5 to an

accuracy of ± 5 % using the equipment described in (1).

Current terminal Voltage terminal

Insulation material

Current terminal Voltage terminal

Figure 5 – Electrode arrangement for resistance measurement of a plated through-hole

7.1.3 Interconnection

1) Equipment: use the equipment specified in 7.1.1 (1).

2) Specimen: specimen is the specified part of a board or a test coupon or with the specified

composite test pattern as shown in the Figure A.1.

3) Pre-conditioning: the pre-conditioning shall be as specified in Clause 5.

4) Test: care shall be made to avoid influences caused by contact method of probe and of

heating caused by the measuring current. Measure the contact resistance as shown in

Figure 6 to an accuracy of ± 5 % using the equipment described in (1).

Current terminal

Voltage terminal

Insulation material

Figure 6 – Electrode arrangement for resistance measurement of interconnection

measurement

7.2 Current tolerance of conductor (when specified in a detailed specification)

1) Equipment: equipment shall be a d.c. or an a. c. power supply capable of supplying the test

current specified in 7.2.4), an ammeter and a temperature measuring instrument.

2) Specimen: the specimen shall be an electronic circuit board with the specified composite test

pattern (select the pattern in reference to Figure A.2).

3) Pre-conditioning: the pre-conditioning shall be as specified in Clause 5.

4) Test: test shall be made by supplying the specified d.c. or a.c. current to the specimen for a

specified time and measure the temperature rise of the specimen (see Figure A.3 for the

current). This test shall be performed only when current tolerance is required.

7.3 Current tolerance of plated through-hole

1) Equipment: equipment shall be a d.c. or an a. c. power supply capable of supplying the test

current specified in 7.2.3), and an ammeter.

– 12 – PAS 61189-3-913 IEC:2011(E)

2) Specimen: the specimen shall be an electronic circuit board or a test coupon with the

specified composite test pattern with a plated through-hole.

3) Pre-conditioning: the pre-conditioning shall be as specified in Clause 5.

4) Test: test shall be made by supplying the specified current to the plated through-hole for 30s

and check if there is any anomaly. Examples of test current are shown in Table 1.

Table 1 – Examples of test current

Hole diameter, mm 0,6 0,8 1,0 1,3 1,6 2,0

Test current, A 8 9 11 14 16 20

This test shall be made only when current tolerance is required.

7.4 Withstanding voltage of surface layer

1) Equipment: equipment shall be an current breaker specified in JIS C 2110-2, 8.1 or

equivalent.

2) Specimen: the specimen shall be the specified section of an electronics circuit board with the

specified composite test pattern (as shown in Figures A.1 and A.2, E). The damaged

specimen in this test such as mechanical damage, flush over, spark over or breakdown shall

be used in other test.

3) Pre-conditioning: the pre-conditioning shall be as specified in Clause 5.

4) Test: test shall be made by the specified d.c. voltage or 50 H or 60 H a.c. voltage with a peak

voltage specified in the detailed specification. The applying voltage shall be increased to the

specified voltage in 5 s and keep at the voltage for 1 min. Damages such as mechanical

damage, flush over, spark over or breakdown shall be checked.

7.5 Interlayer withstanding voltage

1) Equipment: equipment shall be as specified in 7.4.1).

2) Specimen: the specimen shall be the specified section of an electronics circuit board with the

specified composite test pattern (as shown in Figure A.2.1, M).

3) Pre-conditioning: the pre-conditioning shall be as specified in Clause 5.

4) Test: test shall be as specified in 7.4.4).

7.6 Insulation resistance of surface layer (normal and resistance to humidity

(temperature-humidity cycle and steady state))

1) Equipment: equipment shall be as the insulation tester as specified in JIS C 1302, or a

standard resistance, universal shunt and a galvanometer calibrated to an accuracy of ±10 %.

2) Specimen: the specimen shall be a solder resist coated test coupon as specified in Figure

A.3 (1).

3) Pre-conditioning: the pre-conditioning shall be as follows for each condition.

o o

a) Normal: specimen shall be left in a thermostat chamber at 85 C ± 2 C for 4 h and then

o o

leave it at temperature 20 C ± 2 C and relative humidity of 60 ± 10 % for 24 h ± 4 h.

b) Resistance to humidity (temperature-humidity cycle): specimen shall be conditioned for

o o

10 cycles (9.4) and then measure the resistance in an environment of 20 C ± 2 C and

relative humidity of 60 % ± 10 % within 30 min to 60 min after conditioning.

c) Resistance to humidity (steady state): specimen shall be conditioned for 96 h with the

o o

condition of an environment of 40 C ± 2 C and relative humidity of 90 % ± 95 % and

o o

then measure the resistance in an environment of 20 C ± 2 C and relative humidity of

60 % ± 10 % within 30 min to 60 min after conditioning.

4) Test: measurement shall be made for insulation resistance after applying a voltage to the

specimen for 1 min of a voltage as specified in the detailed specification of either 10 V ± 1 V,

100 V ± 15 V, 500 V ± 50 V.

PAS 61189-3-913 IEC:2011(E) – 13 –

7.7 Insulation resistance of inner layer (normal and resistance to humidity

(temperature-humidity cycle and steady state))

1) Equipment: equipment shall be as specified in 7.6 (1).

2) Specimen: the specimen shall be a coupon with a comb pattern as shown in Figure A.3 (2).

The conductor spacing of the specimen shall be the minimum spacing of actual production

board.

3) Pre-conditioning: the pre-conditioning shall be as in 7.6 (4).

4) Test: test shall be as described in 7.6 (4).

7.8 Insulation resistance between inner layers (normal and resistance to humidity

(temperature-humidity cycle and steady state))

1) Equipment: equipment shall be as specified in 7.6 (1).

2) Specimen: the specimen shall be a coupon with a comb pattern as shown in Figure A.3(3).

The diameter of the hole, φ, shall be 10 mm, nominal hole diameter of through holes for

interconnections to inner layers shall be 0,8 mm and nominal land diameter shall be 2 mm.

3) Pre-conditioning: the pre-conditioning shall be as in 7.6 (3).

4) Test: measurement shall be made for insulation resistance after applying a d.c. voltage to

the specimen for 1 min of a voltage as specified in detailed specification of either 100 V ± 15

V, or 500 V ± 50 V.

7.9 Electric integrity

7.9.1 Circuit insulation

1) Equipment: equipment shall consist of a power supply which can supply the test voltage to a

specimen, resistance meter and probes which can contact to the measuring points.

2) Specimen: specimen shall be a product or the specified part of a test coupon.

3) Pre-conditioning: preconditioning shall be as specified in Clause 5.

4) Test: measurement shall be made to confirm that no electric contacts exists to unintended

section of the specimen in the intended specification (art-work, computer generated test

data, or detailed specification). Apply the specified test voltage to the specified part of the

test pattern and measure the resistance. Insulation shall be confirmed when the resistance

is above the specified minimum resistance. The applied voltage and applying time, and the

minimum allowed resistance shall be specified in detailed specification.

7.9.2 Conduction

1) Equipment: equipment shall consist of a power supply which can supply the test current to a

specimen, resistance meter and probes which can contact to the measuring points.

2) Specimen: specimen shall be the specified part of a product.

3) Pre-conditioning: preconditioning shall be as specified in Clause 5.

4) Test: measurement shall be made to confirm that no electric contacts exists to unintended

section of the specimen in the intended specification (art-work, computer generated test

data, or detailed specification). Apply the specified test voltage to the specified part of the

test pattern and measure the resistance. Insulation shall be confirmed when the resistance

is above the specified minimum resistance. The applied voltage and applying time, and the

minimum allowed resistance shall be specified in detailed specification.

8 Mechanical tests

8.1 Peel strength of conductor

1) Equipment: the instrument shall be a testing machine which can keep the pulling speed of

the cross head to 50 mm/min. The accuracy shall be within ± 1 % of the indication within its

effective measuring range and the pulling force shall be within 15 % to 85 % of the capability

o

of the testing machine. Use a jig to hold the specimen to keep the peeling angle to 90 to the

s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...