IEC TR 62866:2014

(Main)Electrochemical migration in printed wiring boards and assemblies - Mechanisms and testing

Electrochemical migration in printed wiring boards and assemblies - Mechanisms and testing

IEC TR 62866:2014 describes the history of the degradation of printed wiring boards caused by electrochemical migration, the measurement method, observation of the failure and remarks to testing in detail.

Migration électrochimique dans les cartes à circuits imprimés et assemblages - Mécanismes et essais

IEC TR 62866:2014 décrit dans le détail l'histoire de la dégradation des cartes à circuits imprimés provoquée par la migration électrochimique, la méthode de mesure, l'observation de la défaillance et les remarques relatives aux essais.

General Information

- Status

- Published

- Publication Date

- 06-May-2014

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 10 - TC 91/WG 10

- Current Stage

- PPUB - Publication issued

- Start Date

- 07-May-2014

- Completion Date

- 15-May-2014

Overview

IEC TR 62866:2014 is a technical report published by the International Electrotechnical Commission (IEC) focused on electrochemical migration (ECM) in printed wiring boards (PWBs) and assemblies. The report provides a comprehensive review of the mechanisms that cause ECM, the history of related insulation degradation, and detailed testing methodologies to identify and evaluate these failures. It serves as an essential reference for professionals involved in the reliability and quality assurance of electronic assemblies, guiding effective diagnosis and prevention of insulation breakdown caused by electrochemical processes.

Key Topics

Electrochemical Migration Mechanisms: The report explains how ECM leads to operational failure in electronic and electrical equipment, describing the chemical and physical processes that degrade insulation on printed wiring boards.

Degradation History and Naming: IEC TR 62866 covers the evolution of terminology and concepts related to ECM and associated insulation failures, offering clarity to standardize communication in the industry.

Testing Procedures: Detailed test conditions, including specimen design, preparation, and storage, are outlined. Various test types such as steady state temperature and humidity tests, temperature-humidity cyclic tests, highly accelerated temperature and humidity stress tests (HAST), and dew cyclic tests are described to simulate and detect ECM under different environmental stresses.

Electrical Testing: The document includes protocols for measuring insulation resistance and dielectric characteristics of PWBs, which are critical for evaluating ECM impact.

Failure Analysis and Data Interpretation: Guidance on failure criteria, data analysis techniques, and case studies provide practical tools for assessing ECM effects and determining failure causes.

Life Evaluation and Environmental Factors: Annexes discuss the impact of voltage, temperature, and humidity on service life and introduce acceleration factors to estimate long-term reliability from accelerated tests.

Applications

IEC TR 62866:2014 offers practical value for:

Electronics Manufacturers: To develop reliable printed wiring boards and assemblies by understanding ECM mechanisms and ensuring compliance with standardized testing methods.

Quality Assurance and Reliability Engineers: For implementing robust environmental and electrical testing regimes to detect ECM-induced degradation before market release.

Failure Analysis Labs: To utilize recommended analytical methods, including optical observation and cross-sectional analysis, for identifying ECM-related defects.

Product Designers: By selecting appropriate materials and designing test specimens consistent with IEC guidelines, designers can mitigate ECM risks in high-moisture or high-voltage applications.

Maintenance and Field Service: Understanding ECM facilitates monitoring and preventive maintenance strategies in the field, minimizing downtime due to insulation failures.

Related Standards

IEC 60068 Series: Environmental testing standards that complement the temperature and humidity test profiles specified for ECM evaluation.

IPC Standards (e.g., IPC-2221): For design requirements related to printed circuit boards and assemblies, which include factors influencing ECM susceptibility.

JEDEC and JPCA Guidelines: Provide additional methodologies for specimen preparation and accelerated testing methods aligned with ECM assessments.

ISO 9001: Quality management principles supporting systematic testing and failure analysis to uphold manufacturing standards involving ECM resistance.

By following IEC TR 62866:2014, professionals can effectively address the challenges posed by electrochemical migration in printed wiring boards, ensuring enhanced durability and performance of electronic assemblies under various environmental conditions.

Frequently Asked Questions

IEC TR 62866:2014 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Electrochemical migration in printed wiring boards and assemblies - Mechanisms and testing". This standard covers: IEC TR 62866:2014 describes the history of the degradation of printed wiring boards caused by electrochemical migration, the measurement method, observation of the failure and remarks to testing in detail.

IEC TR 62866:2014 describes the history of the degradation of printed wiring boards caused by electrochemical migration, the measurement method, observation of the failure and remarks to testing in detail.

IEC TR 62866:2014 is classified under the following ICS (International Classification for Standards) categories: 31.180 - Printed circuits and boards. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 62866:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TR 62866 ®

Edition 1.0 2014-05

TECHNICAL

REPORT

RAPPORT

TECHNIQUE

colour

inside

Electrochemical migration in printed wiring boards

and assemblies – Mechanisms and testing

Migration électrochimique dans les cartes a circuits imprimés et assemblages –

Mécanismes et essais

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

14 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 55 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC TR 62866 ®

Edition 1.0 2014-05

TECHNICAL

REPORT

RAPPORT

TECHNIQUE

colour

inside

Electrochemical migration in printed wiring boards

and assemblies – Mechanisms and testing

Migration électrochimique dans les cartes a circuits imprimés et assemblages –

Mécanismes et essais

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX XD

ICS 31.180 ISBN 978-2-8322-1559-3

– 2 – IEC TR 62866:2014 © IEC 2014

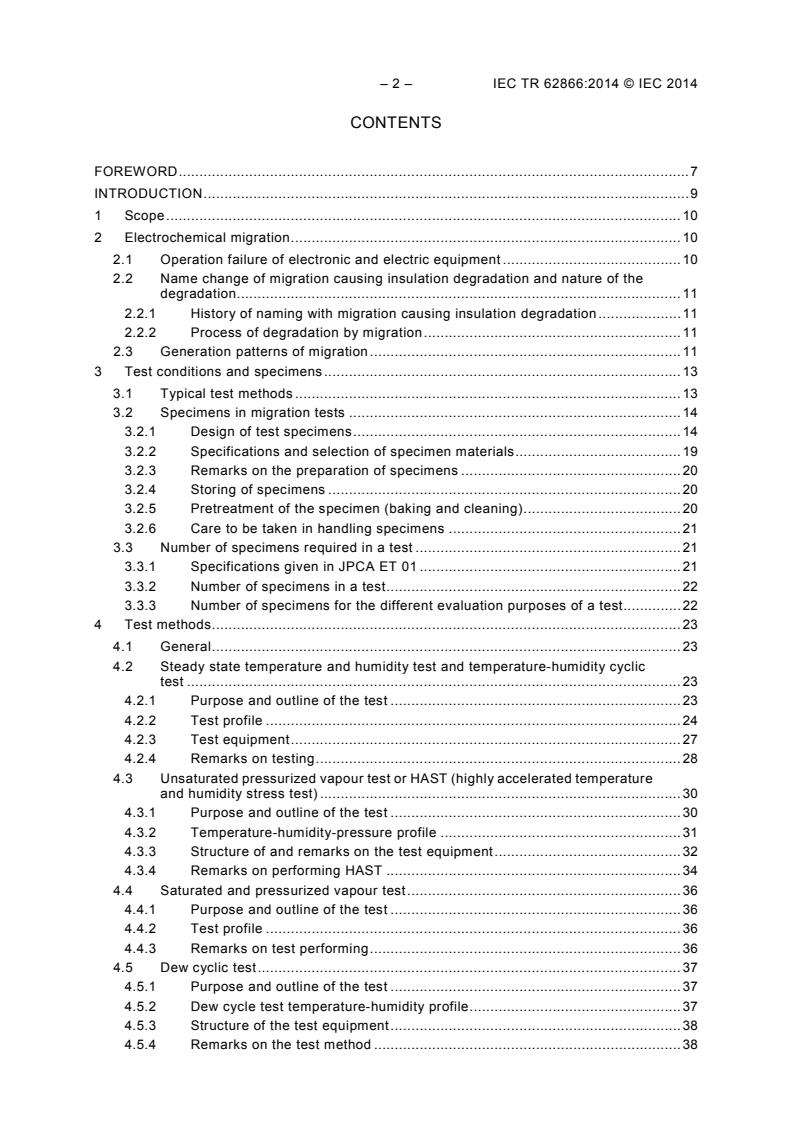

CONTENTS

FOREWORD . 7

INTRODUCTION . 9

1 Scope . 10

2 Electrochemical migration . 10

2.1 Operation failure of electronic and electric equipment . 10

2.2 Name change of migration causing insulation degradation and nature of the

degradation. 11

2.2.1 History of naming with migration causing insulation degradation . 11

2.2.2 Process of degradation by migration . 11

2.3 Generation patterns of migration . 11

3 Test conditions and specimens . 13

3.1 Typical test methods . 13

3.2 Specimens in migration tests . 14

3.2.1 Design of test specimens . 14

3.2.2 Specifications and selection of specimen materials . 19

3.2.3 Remarks on the preparation of specimens . 20

3.2.4 Storing of specimens . 20

3.2.5 Pretreatment of the specimen (baking and cleaning) . 20

3.2.6 Care to be taken in handling specimens . 21

3.3 Number of specimens required in a test . 21

3.3.1 Specifications given in JPCA ET 01 . 21

3.3.2 Number of specimens in a test . 22

3.3.3 Number of specimens for the different evaluation purposes of a test. 22

4 Test methods . 23

4.1 General . 23

4.2 Steady state temperature and humidity test and temperature-humidity cyclic

test . 23

4.2.1 Purpose and outline of the test . 23

4.2.2 Test profile . 24

4.2.3 Test equipment . 27

4.2.4 Remarks on testing . 28

4.3 Unsaturated pressurized vapour test or HAST (highly accelerated temperature

and humidity stress test) . 30

4.3.1 Purpose and outline of the test . 30

4.3.2 Temperature-humidity-pressure profile . 31

4.3.3 Structure of and remarks on the test equipment . 32

4.3.4 Remarks on performing HAST . 34

4.4 Saturated and pressurized vapour test . 36

4.4.1 Purpose and outline of the test . 36

4.4.2 Test profile . 36

4.4.3 Remarks on test performing . 36

4.5 Dew cyclic test . 37

4.5.1 Purpose and outline of the test . 37

4.5.2 Dew cycle test temperature-humidity profile . 37

4.5.3 Structure of the test equipment . 38

4.5.4 Remarks on the test method . 38

4.5.5 An example of migration in the solder flux from the dew cycle test . 41

4.6 Simplified ion migration tests . 43

4.6.1 General . 43

4.6.2 De-ionized water drop method . 43

4.6.3 Diluted solution method . 45

4.7 Items to be noted in migration tests . 46

5 Electrical tests . 49

5.1 Insulation resistance measurement . 49

5.1.1 Standards of insulation resistance measurement . 49

5.1.2 Measurement method of insulation resistance . 49

5.1.3 Special remarks on insulation resistance measurement . 52

5.2 Measurement of dielectric characteristics . 55

5.2.1 General . 55

5.2.2 Dielectric characteristics of board surface . 55

5.2.3 Migration and dielectric characteristics of the printed wiring board surface

5.2.4 Evaluation of migration by AC impedance measurement . 59

6 Evaluation of failures and analysis . 60

6.1 Criteria for failures . 60

6.2 Data analysis . 61

6.2.1 Analysis of experimental data . 61

6.2.2 Relationship of the parameters in the experimental data and an example

of the analysis . 63

6.2.3 Electric field strength distribution . 64

6.3 Analysis of specimen with a failure, methods of analysis and case study . 65

6.3.1 General . 65

6.3.2 Cross section. 66

6.3.3 Optical observation . 70

6.3.4 Analysis methods . 72

6.3.5 Defect observation and analysis . 72

6.4 Special remarks on the migration phenomenon after the test . 77

Annex A (informative) Life evaluation . 80

A.1 Voltage dependence of life . 80

A.2 Temperature dependence of life . 80

A.3 Humidity dependence of life . 80

A.3.1 General . 80

A.3.2 Relation between temperature (°C), relative humidity ( %RH) and vapour

pressure (hPa) . 81

A.4 Acceleration test of life and acceleration factor . 81

A.5 Remarks . 82

Annex B (informative) Measurement of temperature-humidity . 83

B.1 Measurement of temperature and humidity . 83

B.1.1 General . 83

B.1.2 Commonly used temperature-humidity measurement systems and their

merits . 83

B.1.3 Requirements for the humidity measurements in a steady-state

temperature-humidity test chamber . 83

B.2 Typical methods of temperature and humidity measurement . 83

B.2.1 General . 83

– 4 – IEC TR 62866:2014 © IEC 2014

B.2.2 Checking procedure for temperature measurement . 84

B.2.3 Checking procedure for humidity measurement . 85

B.2.4 Derivation of temperature in a chamber . 86

B.2.5 Definition of relative humidity in HAST . 87

Bibliography . 89

Figure 1 – Main causes of insulation degradation in electronic equipment . 10

Figure 2 – Generation patterns of migration . 12

Figure 3 – Basic comb pattern . 14

Figure 4 – Comb type fine pattern . 15

Figure 5 – ECM group comb type pattern (mm) . 16

Figure 6 – Comb pattern for insulation resistance of flexible printed wiring board. 16

Figure 7 – Insulation evaluation pattern for through-holes and via holes . 17

Figure 8 – Details of the insulation evaluation pattern of Figure 7 (cross section of 4

and 5) . 18

Figure 9 – Test pattern of the migration study group . 18

Figure 10 – Recommended profiles of increasing temperature and humidity . 24

Figure 11 – Humidity cyclic profile (12 h + 12 h) . 25

Figure 12 – Profiles of combined temperature-humidity cyclic test . 26

Figure 13 – Structure of steady state temperature-humidity test equipment . 27

Figure 14 – Specimen arrangement and air flow in test chamber . 29

Figure 15 – Effective space in a test chamber . 30

Figure 16 – HAST profile . 31

Figure 17 – Two types of HAST equipment and their structures . 32

Figure 18 – Difference in failure time among different test laboratories . 33

Figure 19 – Colour difference of specimen surface among different laboratories

°C/85 %RH/DC 50 V) . 34

(130

Figure 20 – Resistance and pull-strength of cables used in HAST (130 °C 85 %RH) . 35

Figure 21 –Difference between unsaturated and saturation control of PCT equipment

(relative humidity and average failure time) . 37

Figure 22 – Temperature-humidity profile of dew cycle test . 38

Figure 23 – Structure of dew test equipment . 39

Figure 24 – Dew-forming temperature and dew size . 40

Figure 25 – Board surface at the best dew formation condition . 41

Figure 26 – Surface state before test . 42

Figure 27 – Surface state after 27 h . 42

Figure 28 – SEM image of specimen surface after the test . 42

Figure 29 – Element analysis of the surface after the test . 43

Figure 30 – Circuit diagram of water drop test . 44

Figure 31 – Migration generated in the water drop test . 44

Figure 32 – Electroerosion test method using the diluted solution . 45

Figure 33 – Current and concentration of electrolytic solution . 46

Figure 34 – Precipitation on a specimen and its element analysis . 46

Figure 35 – An example of insulation resistance measurement outside of the chamber . 50

Figure 36 – Circuit diagram of insulation resistance measurement . 51

Figure 37 – Examples of leakage current characteristics . 52

Figure 38 – Relationship insulation resistance with charging time of capacitor mounted

boards . 53

Figure 39 – Comparison of insulation resistance measurement inside and outside a test

chamber . 53

Figure 40 – Relative humidity and insulation resistance . 54

Figure 41 – Effect of interruption of measurement on insulation resistance (variation of

insulation resistance with the time left in atmospheric environment) . 55

Figure 42 – Frequency response of dielectric characteristics of printed wiring board . 57

Figure 43 – Temperature response of dielectric characteristics of printed wiring board . 57

Figure 44 – Changes of static capacitance and tan δ of a specimen through a

deterioration test . 58

Figure 45 – Test procedure of a dielectric characteristics test . 59

Figure 46 – Comparison of dielectric characteristics of two types of flux . 59

Figure 47 – Measurement principle of EIS (Electrical Insulation System) . 60

Figure 48 – Gold (Au) plating, non-cleaning . 60

Figure 49 – Bath tub curve . 61

Figure 50 – Relation between the variation of insulation resistance and the weight

changes by water absorption . 64

Figure 51 – Distribution of electric field between line and plane . 65

Figure 52 – Distribution of the electric field between lines . 65

Figure 53 – Different observations of the same dendrite according to different cross

section cutting planes . 66

Figure 54 – An example of angle lapping . 68

Figure 55 – Structure analysis of an angle lapped solder resist in the depth direction . 69

Figure 56 – Observed images of dendrite with different illumination methods (without

solder resist) . 73

Figure 57 – EPMA analysis of migration (dendrite) on a comb type electrode . 73

Figure 58 – EPMA analysis of migration (dendrite) in the solder resist . 74

Figure 59 – 3D shape measuring system . 75

Figure 60 – Electrodes which migration was generated . 75

Figure 61 – 3D observation of electrodes before and after the test . 76

Figure 62 – 3D observation of dendrite . 77

Figure A.1 – Temperature and saturated vapour pressure . 81

Figure B.1 – Specification of sensors used in the test and their shapes . 85

Figure B.2 – Calculation method of the average temperature (humidity), the average

maximum temperature (humidity) and the average minimum temperature (humidity) . 86

Figure B.3 – Relative humidity in a pressurized chamber . 88

Table 1 – Standards for migration tests . 13

Table 2 – Standard comb type pattern (based on IPC-SM-840) . 15

Table 3 – Comb fine pattern (based on JPCA BU 01) . 15

Table 4 – Dimension of insulation evaluation pattern for through-holes . 18

Table 5 – Surface pretreatment to printed wiring board . 21

– 6 – IEC TR 62866:2014 © IEC 2014

Table 6 – Number of specimens (JPCA ET 01) . 22

Table 7 – Approximate number of specimens required depending on the purpose of the

test 22

–6

Table 8 – Ionic impurity concentration of wick (10 ) . 29

Table 9 – Insulation covering materials for cables for voltage application . 34

Table 10 – Dew cycle test condition . 38

Table 11 – Dew formation condition and dew size . 41

Table 12 – Dew cycle test condition . 41

Table 13 – Water quality for test . 47

–6

Table 14 – Water quality change in steady-state temperature-humidity test (10 ) . 47

–6

Table 15 – Ionic impurities in voltage applying cables (10 ) . 48

Table 16 – Standards of insulation resistance measurement . 49

Table 17 – Criteria of migration failure by insulation resistance . 61

Table 18 – Various methods for optical observation of failures . 70

Table 19 – Various methods for defect analysis . 72

Table 20 – Board specification and test conditions . 77

Table 21 – Effect of the overlap of electrodes . 78

Table 22 – Effect of the area of the conductor . 78

Table 23 – Effect of the shape of the tip of the electrodes . 79

Table A.1 – Vapour pressure at test temperature and relative humidity . 81

Table B.1 – Merits of and remarks on various humidity measuring methods (applicable to

steady state temperature-humidity tests) . 84

Table B.2 – Derivation of relative humidity from dry-and-wet bulb humidity meter . 87

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTROCHEMICAL MIGRATION IN PRINTED WIRING BOARDS

AND ASSEMBLIES – MECHANISMS AND TESTING

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and in

addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and expenses

arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected data

of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC/TR 62866, which is a technical report, has been prepared by IEC technical committee 91:

Electronics assembly technology.

The text of this technical report is based on the following documents:

Enquiry draft Report on voting

91/1102/DTR 91/1128/RVC

Full information on the voting for the approval of this technical report can be found in the report

on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 8 – IEC TR 62866:2014 © IEC 2014

The committee has decided that the contents of this publication will remain unchanged until the

stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data related to

the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

INTRODUCTION

Electronic products including components nowadays are designed to satisfy the demands for

miniaturization, high functionality and environmentally friendly products. Various types of

degradation occur in the electronic products used in the field. Appropriate measures are

required to mitigate such degradation from the standpoint of reliability assurance. A study has

been carried out to develop the understanding of the phenomenon and has proposed test

methods for electrochemical migration with the purpose of suppressing the migration in products

used in the field.

This Technical Report is related to electrochemical migration including conductive anodic

filament (CAF). Specifically, it explains:

• the preliminary test: the steady state temperature humidity test, the temperature humidity

cycle test, the unsaturated pressurized vapor test, the saturated pressurized vapor

pressure test, the dew condensation cycle test and the water drop test;

• the insulation resistance measurement method: manual measurement, automatic

measurement, a dielectric characteristics method, and an AC impedance method. Moreover,

the difference between the measurement while the specimen is kept in the testing

environment and not taken out of the chamber for measurement, and the measurement of

the resistance of a specimen while it is taken out of the test chamber, and the merit of an

automatic measurement are also described;

• the equipment used for analysis, the observation method of a failure part, and examples

which are used for analysis.

This Technical Report generates a number of benefits for the user:

Usefulness the user can examine the electrochemical migration test in a short

time, and can use it as an indicator of exact analysis.

Test method selection since for the user the test method which responds to the operating

condition of the equipment or the purpose is clearly demonstrated,

comparison of test condition becomes easy. Compared to the

measurement resistance of a specimen while it is taken out of the

test chamber after the test chamber is return to the standard

atmosphere condition, the measurement in the test chamber by

automatic measurement does not experience the environmental

change of a specimen at the time of measurement, and since

continuous measurement can be carried out, the resistance change

and failure time can be grasped correctly.

Avoidance of trouble by observing the notice on the test, the user can avoid a trouble and

carry out test and analysis efficiently.

– 10 – IEC TR 62866:2014 © IEC 2014

ELECTROCHEMICAL MIGRATION IN PRINTED WIRING BOARDS

AND ASSEMBLIES – MECHANISMS AND TESTING

1 Scope

This Technical Report describes the history of the degradation of printed wiring boards caused

by electrochemical migration, the measurement method, observation of the failure and remarks

to testing in detail.

2 Electrochemical migration

NOTE Electrochemical migration is sometimes called ion migration. In this technical report electrochemical

migration/ion migration will be referred to as migration.

2.1 Operation failure of electronic and electric equipment

It is known that failures caused by various degradation phenomena occur in electric and

electronic products while they are used in the field. Causes of such failures are classified in

Figure 1. The causes may be classified into: electric, thermal, mechanical and electrochemical

origins. They are entwined with each other. The environment in which equipment is used also

affects the generation of failures.

Growth of an electrically conducting filament caused by migration will short-circuit two

conductors when a bias voltage is applied between them and will lead to a malfunctioning in the

equipment.

Electric

Partial discharge

Electrical treeing

Water treeing

Electrochemical migration

Tracking

Arc

Chemical and thermal

Environmental Electrochemical

Whisker

Corrosion

Crack

Chemical treeing

Interfacial

-separation

Mechanical

IEC 1272/14

Figure 1 – Main causes of insulation degradation in electronic equipment

2.2 Name change of migration causing insulation degradation and nature of the

degradation

2.2.1 History of naming with migration causing insulation degradation

Migration causing insulation failure had been called “ion migration” in Japan. A change of the

definition of the phenomenon resulted in a change of name to “electrochemical migration”, but

the name of “ion migration” is sometimes still used. The following description is the history of the

change of name.

The first report on insulation failure was made in 1955, where the failure caused by the migration

of silver atoms was reported and the phenomenon was called “silver migration”. It was also

found that other metal atoms, including Pb and Cu, caused similar insulation failures, and so the

phenomenon was called “metal migration”. The term “electromigration” was used as a general

term for the phenomenon, and has been used for a long time in the IPC test method,

IPC-TM-650:1987, 2.6.14A.

It was found since the latter half of the 1960s that interconnection failures in semiconductor

devices were serious problems as the current flowing through a conductor significantly

increased. This phenomenon was also called “electromigration”. The opening of a conductor

was caused by the movement of metal atoms due to an increased current density, which

produced dense and sparse layers within the conductor and resulted in a break of the conductor.

IPC changed the name of the phenomenon to “electrochemical migration” in its technical report

IPC-TR-467A, and developed a new test method, IPC-TM-650:2000, 2.6.14C, which

ISO adopted as ISO 9455-17. IEC 60194 which provides the terms and definitions for printed

board design, manufacture and assembly, still uses the term “electromigration”. However, the

name should be changed in the near future.

NOTE IPC-9201A uses and defines both electromigration (EMg) and electrochemical migration (ECMg).

References: 1) KOHMAN G. T., et al. Silver migration in electrical insulation, BSTJ 34 299, 1955

2) POURBAIX, M., Atlas d’Equilibres Electrochimiques, Gauthier-Villars et Cie ed., 1963

2.2.2 Process of degradation by migration

Good insulation between electrodes may be maintained in the application of DC voltage

between electrodes on a printed wiring board of electronic equipment, as long as the electrodes

are isolated by an insulating material of a high resistivity. If the insulating material absorbs

moisture and the insulation resistance decreases, residual ionic contaminants in the insulating

material or ions in the absorbed moisture will become active and metal atoms in the material will

be ionized. Metal ions dissolve from the metal electrodes, either from an anode or a cathode,

into the moistened electrolyte. Ions are transferred through the electrolyte by the electric field

force. Metal ions (migration) move to an electrode and then educe in the form of dendrite. The

dendrite bridges the neighbouring conductor electrode. The generation of (electrochemical)

migration is described in 2.3.

2.3 Generation patterns of migration

Migration begins in the anode by dissolving as metal ions by an electrochemical reaction. There

are two cases of this phenomenon as shown in Figure 2. In the first case, the reduction of ions

into metal atoms or chemical compound molecules occurs somewhere in between the electrodes.

In the second case, the reduction of metal ions occurs when the ions reach the cathode.

The first case is observed when the insulating material still maintains a high resistance to the

order of 10 Ω or higher. The second case is often observed in HAST (highly accelerated

temperature and humidity stress test), where the insulation resistance is reduced by the

presence of dew, solder resist or cover layer on the insulation surface.

The difference in these two cases of migration seems due to the difference in the degree of

easiness of movement of the metal ions. The second type of migration becomes dominant when

– 12 – IEC TR 62866:2014 © IEC 2014

the apparent resistance decrease exists and the metal ions can move more easily than in the

first case, while the first case is dominant when metal ions resolve from the anode but cannot

move easily in the insulation. The change of one mechanism to the other in the migration is not

an independent phenomenon but is simply due to the difference in insulation resistivity of the

electrolyte material between electrodes.

Reduction of metal ions left from the anode into

metal atoms or reduction of ions to form chemical

compounds in insulation

Reduction of metal ions reaching to the cathode and

receiving electrons to become metal ions

Anode

Cathode

IEC 1273/14

Figure 2 – Generation patterns of migration

3 Test conditions and specimens

3.1 Typical test methods

the main test method for migration is shown in Table 1.

Table 1 – Standards for migration tests

Items Humidifying conditions Duration and bias Document no.

Steady state IEC 60068-2-78

40 °C ± 2 °C +24

168 h

Temperature/ 0

93 % ± 3 %RH

humidity test

500 h ± 48 h

1 000 h ± 96 h

60 °C ± 2 °C IEC 60068-2-78

+24

168 h, 500 h ± 48 h

+2

93 %RH

1 000 h ± 96 h

−3

IEC 60068-2-67

85 °C ± 2 °C

+24

168 h, 500 h ± 48 h

85 % ± 3 %RH

1 000 h ± 96 h

Temperature/ Relative humidity: 90 % to As agreed between user and IEC 60068-2-38

humidity cycle test 98 % supplier

80 % in rising and falling Abou

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...