IEC TR 61967-4-1:2005

(Main)Integrated circuits - Measurement of electromagnetic emissions, 150 kHz to 1 GHz - Part 4-1: Measurement of conducted emissions - 1 Ω/150 Ω direct coupling method - Application guidance to IEC 61967-4

Integrated circuits - Measurement of electromagnetic emissions, 150 kHz to 1 GHz - Part 4-1: Measurement of conducted emissions - 1 Ω/150 Ω direct coupling method - Application guidance to IEC 61967-4

Serves as an application guidance and relates to IEC 61967-4. The division of IC types into -> IC function modules and the software modules for -> cores with CPU can be used for Parts 3, 5 and 6 of IEC 61967. Gives advice for performing test methods described in IEC 61967-4 by classifying types of integrated circuits (ICs) and providing hints for test applications related to the IC type classification. To obtain comparable results of IC emission measurements using IEC 61967-4, definitions are given which are in addition to the general conditions specified in IEC 61967-1 and IEC 61967-4. These definitions concern IC related operating modes, pins and ports to be tested, test set-ups according IEC 61967-4, including description of load circuits and RF path, and IC related emission limits (or limit classes). Parts of the guidance provided by this technical report may be applicable to other parts of IEC 61967.

General Information

- Status

- Published

- Publication Date

- 06-Feb-2005

- Technical Committee

- SC 47A - Integrated circuits

- Drafting Committee

- WG 9 - TC 47/SC 47A/WG 9

- Current Stage

- PPUB - Publication issued

- Start Date

- 07-Feb-2005

- Completion Date

- 15-Feb-2005

Overview

IEC TR 61967-4-1:2005 is a Technical Report that provides application guidance to IEC 61967-4 for measuring electromagnetic emissions from integrated circuits (ICs) in the frequency band 150 kHz to 1 GHz. Focused on the 1 Ω / 150 Ω direct coupling method for conducted emissions, the report explains how to obtain comparable, repeatable IC emission measurements by defining IC-specific operating modes, ports and pins to test, test set-ups (including load circuits and RF path), and IC-related emission limits (limit classes). The guidance is intended to complement the general conditions in IEC 61967-1 and to be useful across other IEC 61967 parts (e.g., Parts 3, 5 and 6).

Key Topics

- IC function module classification: a method to split complex ICs into function modules (drivers, cores, oscillators, supplies) to standardize testing and reporting.

- Test workflow and philosophy: flowcharts and stepwise procedures for conducting IC EMC emission tests.

- Port and supply selection: guidance on which pins, ports and supplies to exercise and measure for representative conducted emissions.

- Test networks and load circuits: recommended 1 Ω and 150 Ω network implementations, RF path descriptions and modifications to IEC 61967-4 network where necessary.

- Parameter initialization and software modules: procedures for initializing ICs, including software test modules for cores with CPUs, and definitions of driver toggling and test vectors.

- Test procedures and measurement parameters: defined steps for driver switching noise, crosstalk, supply noise and oscillator-related emissions.

- Test board layout recommendations: PCB layout tips for implementing 150 Ω and 1 Ω networks to minimize measurement variability.

- Annexes for practical use: network modification details, trace impedance calculation and examples for splitting ICs.

Applications / Who Uses It

IEC TR 61967-4-1 is intended for:

- IC designers and semiconductor manufacturers - to assess and reduce conducted emissions during IC development.

- EMC engineers and test laboratories - to set up repeatable 1 Ω/150 Ω direct coupling measurements and interpret results against IC-specific limits.

- Compliance and system integrators - to understand IC-level emissions that may impact board- and system-level EMC.

- Firmware engineers - to implement test software modules that exercise cores and peripherals during EMC tests.

Practical benefits include improved comparability of IC emission data, targeted mitigation strategies at the IC level, and clear guidance for measurement setup and reporting.

Related Standards

- IEC 61967-4 (measurement of conducted emissions - 1 Ω/150 Ω direct coupling method)

- IEC 61967-1 (general conditions and definitions)

- IEC 61967 Parts 2, 3, 5, 6 (radiated/conducted methods)

- IEC 60050 (IEV terms)

Keywords: IEC TR 61967-4-1, integrated circuits, electromagnetic emissions, conducted emissions, 1 Ω/150 Ω, IC EMC testing, measurement guidance, 150 kHz–1 GHz.

IEC TR 61967-4-1:2005 - Integrated circuits - Measurement of electromagnetic emissions, 150 kHz to 1 GHz - Part 4-1: Measurement of conducted emissions - 1 Ω/150 Ω direct coupling method - Application guidance to IEC 61967-4

Frequently Asked Questions

IEC TR 61967-4-1:2005 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Integrated circuits - Measurement of electromagnetic emissions, 150 kHz to 1 GHz - Part 4-1: Measurement of conducted emissions - 1 Ω/150 Ω direct coupling method - Application guidance to IEC 61967-4". This standard covers: Serves as an application guidance and relates to IEC 61967-4. The division of IC types into -> IC function modules and the software modules for -> cores with CPU can be used for Parts 3, 5 and 6 of IEC 61967. Gives advice for performing test methods described in IEC 61967-4 by classifying types of integrated circuits (ICs) and providing hints for test applications related to the IC type classification. To obtain comparable results of IC emission measurements using IEC 61967-4, definitions are given which are in addition to the general conditions specified in IEC 61967-1 and IEC 61967-4. These definitions concern IC related operating modes, pins and ports to be tested, test set-ups according IEC 61967-4, including description of load circuits and RF path, and IC related emission limits (or limit classes). Parts of the guidance provided by this technical report may be applicable to other parts of IEC 61967.

Serves as an application guidance and relates to IEC 61967-4. The division of IC types into -> IC function modules and the software modules for -> cores with CPU can be used for Parts 3, 5 and 6 of IEC 61967. Gives advice for performing test methods described in IEC 61967-4 by classifying types of integrated circuits (ICs) and providing hints for test applications related to the IC type classification. To obtain comparable results of IC emission measurements using IEC 61967-4, definitions are given which are in addition to the general conditions specified in IEC 61967-1 and IEC 61967-4. These definitions concern IC related operating modes, pins and ports to be tested, test set-ups according IEC 61967-4, including description of load circuits and RF path, and IC related emission limits (or limit classes). Parts of the guidance provided by this technical report may be applicable to other parts of IEC 61967.

IEC TR 61967-4-1:2005 is classified under the following ICS (International Classification for Standards) categories: 31.200 - Integrated circuits. Microelectronics. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 61967-4-1:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

TECHNICAL IEC

REPORT TR 61967-4-1

First edition

2005-02

Integrated circuits –

Measurement of electromagnetic

emissions, 150 kHz to 1 GHz –

Part 4-1:

Measurement of conducted emissions –

1 Ω/150 Ω direct coupling method –

Application guidance to IEC 61967-4

Reference number

IEC/TR 61967-4-1:2005(E)

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/searchpub) enables you to

search by a variety of criteria including text searches, technical committees

and date of publication. On-line information is also available on recently issued

publications, withdrawn and replaced publications, as well as corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/online_news/ justpub)

is also available by email. Please contact the Customer Service Centre (see

below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

TECHNICAL IEC

REPORT TR 61967-4-1

First edition

2005-02

Integrated circuits –

Measurement of electromagnetic

emissions, 150 kHz to 1 GHz –

Part 4-1:

Measurement of conducted emissions –

1 Ω/150 Ω direct coupling method –

Application guidance to IEC 61967-4

IEC 2005 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale

X

International Electrotechnical Commission

Международная Электротехническая Комиссия

For price, see current catalogue

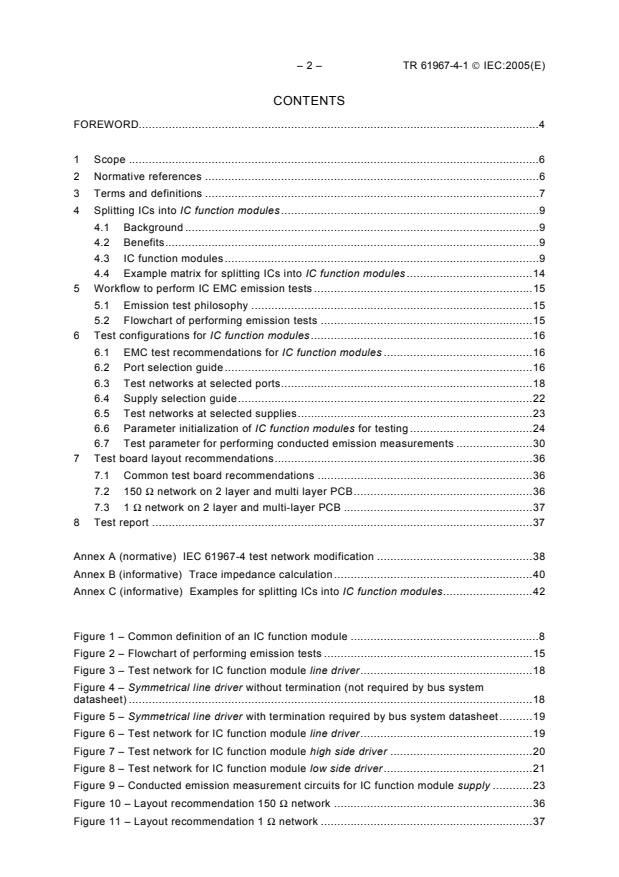

– 2 – TR 61967-4-1 IEC:2005(E)

CONTENTS

FOREWORD.4

1 Scope .6

2 Normative references .6

3 Terms and definitions .7

4 Splitting ICs into IC function modules.9

4.1 Background .9

4.2 Benefits.9

4.3 IC function modules.9

4.4 Example matrix for splitting ICs into IC function modules .14

5 Workflow to perform IC EMC emission tests .15

5.1 Emission test philosophy .15

5.2 Flowchart of performing emission tests .15

6 Test configurations for IC function modules.16

6.1 EMC test recommendations for IC function modules .16

6.2 Port selection guide .16

6.3 Test networks at selected ports.18

6.4 Supply selection guide.22

6.5 Test networks at selected supplies.23

6.6 Parameter initialization of IC function modules for testing .24

6.7 Test parameter for performing conducted emission measurements .30

7 Test board layout recommendations.36

7.1 Common test board recommendations .36

7.2 150 Ω network on 2 layer and multi layer PCB.36

7.3 1 Ω network on 2 layer and multi-layer PCB .37

8 Test report .37

Annex A (normative) IEC 61967-4 test network modification .38

Annex B (informative) Trace impedance calculation .40

Annex C (informative) Examples for splitting ICs into IC function modules.42

Figure 1 – Common definition of an IC function module .8

Figure 2 – Flowchart of performing emission tests .15

Figure 3 – Test network for IC function module line driver.18

Figure 4 – Symmetrical line driver without termination (not required by bus system

datasheet) .18

Figure 5 – Symmetrical line driver with termination required by bus system datasheet.19

Figure 6 – Test network for IC function module line driver.19

Figure 7 – Test network for IC function module high side driver .20

Figure 8 – Test network for IC function module low side driver.21

Figure 9 – Conducted emission measurement circuits for IC function module supply .23

Figure 10 – Layout recommendation 150 Ω network .36

Figure 11 – Layout recommendation 1 Ω network .37

TR 61967-4-1 IEC:2005(E) – 3 –

Figure A.1 – 150 Ω network, attenuation chart of some example capacitor values .38

Figure B.1 – Micro stripline .40

Figure B.2 – Symmetric stripline.41

Figure B.3 – Offset stripline .41

TTable 1 – Example matrix for splitting ICs into IC function modules T .14

TTable 2 – EMC test recommendations for IC function modules T.16

TTable 3 – Test port selection table T .17

TTable 4 – Creating priority for a subset of supply modules T.23

TTable 5 – Driver toggling definition T.24

TTable 6 – Test initialization software module for cores containing a CPU T .27

TTable 7 –Test loop software module for cores containing a CPU T.29

TTable 8 – Test procedure driver switching noise, with CPU T.30

TTable 9 – Test procedure driver switching noise, without CPU T.30

TTable 10 – Test procedure port internal crosstalk, with CPU T.31

TTable 11 – Test procedure regional signal driver supply noise, with CPU T.31

TTable 12 – Test procedure regional signal driver supply noise, without CPU T .31

TTable 13 – Test procedure symmetrical line drivers, with CPU T.32

TTable 14 – Test procedure symmetrical line drivers, without CPU T .32

TTable 15 –Test procedure high side drivers (without CPU) T.32

TTable 16 – Test procedure low side drivers (without CPU) T.33

TTable 17 – Test procedure core supply, without CPU T .33

TTable 18 – Test procedure core to drivers and inputs crosstalk, without CPU T.34

TTable 19 – Test procedure core supply, core with CPU T.34

TTable 20 – Test procedure core to drivers and inputs crosstalk, core with CPU, single

driver or input port T.35

TTable 21 – Test procedure core to drivers and inputs crosstalk, with CPU, multiple

driver or input port T.35

TTable 22 – Test procedure oscillator supply noise, with CPU T .36

TTable 23 – Test procedure oscillator supply noise, without CPU T .36

TTable A.1 – Limit frequencies of modified DC block capacitor values in 150 Ω network T .39

– 4 – TR 61967-4-1 IEC:2005(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

INTEGRATED CIRCUITS –

MEASUREMENT OF ELECTROMAGNETIC EMISSIONS,

150 kHz TO 1 GHz –

Part 4-1: Measurement of conducted emissions –

1 Ω/150 Ω direct coupling method –

Application guidance to IEC 61967-4

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC 61967-4-1, which is a technical report, has been prepared by subcommittee 47A: Integrated

circuits, of IEC technical committee 47: Semiconductor devices.

TR 61967-4-1 IEC:2005(E) – 5 –

The text of this technical report is based on the following documents:

Enquiry draft Report on voting

47A/694/DTR 47A/702A/RVC

Full information on the voting for the approval of this technical report can be found in the

report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

IEC 61967 consists of the following parts, under the general title Integrated circuits –

Measurement of electromagnetic emissions, 150 kHz to 1 GHz

Part 1 General conditions and definitions

Part 2 Measurement of radiated emissions – TEM-cell method

Part 3 Measurement of radiated emissions – Surface scan method

Part 4 Measurement of conducted emissions – 1 Ω / 150 Ω Direct coupling method

Part 5 Measurement of conducted emissions – Workbench Faraday cage method

Part 6 Measurement of conducted emissions – Magnetic probe method

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date T indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

A bilingual version of this Technical Report may be issued at a later date.

– 6 – TR 61967-4-1 IEC:2005(E)

INTEGRATED CIRCUITS –

MEASUREMENT OF ELECTROMAGNETIC EMISSIONS,

150 kHz TO 1 GHz –

Part 4-1: Measurement of conducted emissions –

1 Ω/150 Ω direct coupling method –

Application guidance to IEC 61967-4

1 Scope

This technical report serves as an application guidance and relates to IEC 61967-4.The

division of IC types into →IC function modules and the software modules for →cores with

CPU can be used for Parts 3, 5 and 6 of IEC 61967 as well. This report gives advice for

performing test methods described in IEC 61967-4 by classifying types of integrated circuits

(ICs) and providing hints for test applications related to the IC type classification.

To obtain comparable results of IC emission measurements using IEC 61967-4, definitions

are given which are in addition to the general conditions specified in IEC 61967-1 and

IEC 61967-4. These definitions concern IC related operating modes, pins and →ports to be

tested, test set-ups according IEC 61967-4, including description of load circuits and RF path,

and IC related emission limits (or limit classes). Parts of the guidance provided by this

technical report may be applicable to other parts of IEC 61967.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60050(101), International Electrotechnical Vocabulary (IEV) – Part 101: Mathematics

IEC 60050(161:1990), International Electrotechnical Vocabulary (IEV) – Part 161: Electro-

magnetic compatibility

Amendment 2 (1998)

IEC 61967-1, Integrated circuits – Measurement of electromagnetic emissions 150 kHz to

1 GHz – Part 1: General conditions and definitions

IEC 61967-2, Integrated circuits − Measurement of electromagnetic emissions 150 kHz to

1 GHz – Part 2: Measurement of radiated emissions, TEM-cell method T T

IEC 61967-3, Integrated circuits − Measurement of electromagnetic emissions 150 kHz to

1 GHz – Part 3: Measurement of radiated emissions, surface scan method T T

IEC 61967-4, Integrated circuits − Measurement of electromagnetic emissions 150 kHz to

1 GHz – Part 4: Measurement of conducted emissions – 1 Ω/150 Ω direct coupling method

———————

T T In preparation.

T T To be published.

TR 61967-4-1 IEC:2005(E) – 7 –

IEC 61967-5, Integrated circuits - Measurement of electromagnetic emissions, 150 kHz to

1 GHz - Part 5: Measurement of conducted emissions, Workbench Faraday Cage method

IEC 61967-6, Integrated circuits – Measurement of electromagnetic emissions, 150 kHz to

1 GHz – Part 6: Measurement of conducted emissions – Magnetic probe method

ISO 9141, Road vehicle – Diagnostic systems – Requirements for interchange of digital

information

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

analog

pertaining to the representation of information by means of a physical quantity which may at

any instant within a continuous time interval assume any value within a continuous interval of

values

NOTE The quantity considered may, for example, follow continuously the values of another physical quantity

representing information.

[IEV 101-12-05]

3.2

core

→IC function module without any connection outside the IC via pins

NOTE The supply is connected via the IC function module supply to pins, signals to pins are connected via the IC

function module driver.

3.3

common mode (CM) current

in a cable having more than one conductor, including shields and screens, if any, the

magnitude of the sum of the phasors representing the currents in each conductor

[IEV 161-04-39]

3.4

digital

pertaining to the representation of information by distinct states or discrete values

[IEV 101-12-07]

3.5

differential mode (DM) current

in a two-conductor cable, or for two particular conductors in a multi-conductor cable, half the

magnitude of the difference of the phasors representing the currents in each conductor

[IEV 161-04-38]

3.6

EMC pin type

3.6.1

global pin

signal carrier which comes from or leaves the application via a cable harness

NOTE The cable harness is an antenna for RF energy.

In general, there are series impedances (discrete components, PCB traces) and capacitances to an application's

ground system in between the cable harness and the IC pin to reduce the IC pin's RF emission.

– 8 – TR 61967-4-1 IEC:2005(E)

3.6.2

local pin

signal carrier which does not leave the application via a cable harness

NOTE 1 It remains on the application PCB as a signal between two components with or without additional EMC

components.

NOTE 2 In general, the PCB traces of these signals are as short as possible. Such a trace and the loop of the

signal current is a smaller antenna for RF energy in comparison to the cable harness, so the ability of the antenna

to radiate RF energy is smaller.

3.7

fixed function unit

FFU

functional core sub-unit of the →IC function module 'Core', designed to perform one fixed

function without instruction decode and execute capability

3.8

integrated circuit

IC

set of implemented →IC function modules in one die or package

3.9

IC type

IC with a characteristic set of functions built in

NOTE These functions are realized with →IC function modules.

3.10

IC function module

functional part of an IC with at least one function and its supply connection, if needed

3.10.1

passive IC function module

no supply system for function

3.10.2

active IC function module

dedicated supply connection needed for function

NOTE The supply connection is handled as a separate input/output pair as it has a dedicated EMC behavior.

supply connection

IC Function

inputs outputs

Module

supply reference

connection

Figure 1 – Common definition of an IC function module

3.11

printed circuit board

PCB

piece of isolating material with fixed metal traces to connect electronic components

TR 61967-4-1 IEC:2005(E) – 9 –

3.12

port

functional set of minimum one Driver and/or minimum one Input

NOTE It is physically related to one →fixed function unit (FFU, see IC function module core). It is very useful to

define this functional set of input and/or output IC function modules to get a common description of an interface

between an IC and its circuit environment.

3.13

active port

port switched to a defined configuration or connected to a →fixed function unit and controlled

during EMC measurements

3.14

inactive port

port switched to a defined configuration or connected to a →fixed function unit and remains

in a defined static mode

3.15

test port

port selected for IC EMC tests

3.16

supply pin pairs

all supply voltage pins of the same supply voltage system with their related ground pin(s) of

an IC supply module

4 Splitting ICs into IC function modules

4.1 Background

The functionality of an IC pin can be characterized as an IC function module. The defined set

of IC function modules is sufficient to be combined to every kind of IC on the market. The

advantage of this set of IC function modules is that it provides a description of EMC test set-

ups and emission limit levels for each single IC function module with its characteristic EMC

behaviour.

4.2 Benefits

– The number of test circuits is equivalent to the number of IC function modules

independent from all IC types currently existing and future IC types (for examples for

dividing actual IC types into IC function modules, see Annex C).

– The test circuit for each IC function module can be described precisely.

– Emission limits can be defined for each IC function module T T.

4.3 IC function modules

4.3.1 Port

The port is an interface between an IC and its circuit environment.

———————

T T Limit definitions are not the target of IEC standardization. Limits have to be defined by the specific user groups,

depending on application of EMC requirements in the business field concerned.

– 10 – TR 61967-4-1 IEC:2005(E)

IC function modules comprising a set of at least one IC function module 'Driver' and/or one IC

function module 'Input' are called 'port modules'. If there is no driver implemented in the port

or only 'local pin' defined drivers are implemented, the port is referred to as a 'local pin' type

port. If 'global pin' defined drivers are implemented, the port is referred to as a 'global pin' port.

PLL factor

Supply module Supply module

Core Oscillator

Oscillator

Supply Supply

(PLL)

Digital Logic

Digital Logic

or analog

or analog

Fixed-function Unit

Fixed-function Unit

Core

Digital Logic Digital Logic

or analog or analog

Fixed-function Unit Fixed-function Unit

Port

Supply module

Driver or Driver or Driver or Driver or

Port

Input Input Input Input

Supply

The Port can be a combination of eight kinds of port modules:

4.3.1.1 Line driver EMC pin type: 'global'

Drives signals into cables (signals leaving application to cable harness).

Examples: ISO 9141 outputs, LIN outputs.

4.3.1.2 Line receiver EMC pin type: 'global'

Receives signals from cables (signals get into application from cable harness).

Examples: ISO 9141 inputs, LIN inputs.

4.3.1.3 Symmetrical line driver EMC pin type: 'global'

Drives differential signals into cables with two phase-correlated outputs (signals leaving

application to cable harness).

Examples: CAN outputs, LVDS outputs.

4.3.1.4 Symmetrical line receiver EMC pin type: 'global'

Receives differential signals from cables with two phase-correlated inputs cables (signals get

into application from cable harness).

Examples: CAN inputs, LVDS inputs.

4.3.1.5 Regional signal driver EMC pin type: 'local'

Drives signals into all other kind of lines than cables not leaving the application (application

local signals).

TR 61967-4-1 IEC:2005(E) – 11 –

Examples: Digital signals: →Ports with inputs and outputs in 'Output mode', serial

data outputs, clock outputs, status signal outputs.

Analog signals: operational amplifier outputs.

4.3.1.6 Regional Input EMC pin type: 'local'

Receives signals with any or discrete voltage level from all kinds of lines other than cables

leaving the applications (local signals on application PCB).

Examples: Digital signals: →Ports with input and output modules in 'Input mode',

serial data inputs, clock inputs, status signal inputs (not

related to other IC function modules), interrupt inputs.

Analog signals: Input stages of operational amplifiers, input stages of

ADCs.

4.3.1.7 High side driver EMC pin type: 'global' or 'local'

Drives power into loads. The current flows out of the driver. If driver and load are on same

application PCB, the EMC pin type of the driver is 'local', if it is separated by a cable harness,

the EMC pin type of the driver is 'global'.

Examples: High side switch, switched power supply current output (step down converter).

4.3.1.8 Low side driver EMC pin type: 'global' or 'local'

Drives power into loads. The current flows into the driver. If driver and load is on same

application PCB, the EMC pin type of the driver is 'local', if it is separated by a cable harness,

the EMC pin type of the driver is 'global'.

Examples: Low side switch, switched power supply current input (step up converter).

4.3.2 Supply

Distributes supply current to at least one IC function module.

An IC function module with at least one current input pin of same supply system and minimum

one current output pin. It may contain active elements like voltage stabilization and/or passive

elements such as internal charge buffering, current limiting series elements and other kinds of

EMC filtering.

PLL factor

Supply module Supply module

Core Oscillator

Oscillator

Supply

Supply

(PLL)

Digital Logic

Digital Logic

or analog

or analog

Fixed-function Unit

Fixed-function Unit

Digital Logic Digital Logic

or analog or analog

Fixed-function Unit Fixed-function Unit

Supply module

Port

Driver or Driver or Driver or Driver or

Supply Input Input Input Input

– 12 – TR 61967-4-1 IEC:2005(E)

4.3.3 Core

A core is an IC function module without any connection outside of the IC via pins.

NOTE The supply is connected via the IC function module supply to pins. It contains a set of minimum one IC

function sub-module as described below.

PLL factor

Supply module

Supply module

Core

Oscillator

Oscillator

Supply

Supply

(PLL)

Digital Logic

Digital Logic

or analog

or analog

Fixed-function Unit

Fixed-function Unit

Core

Digital Logic Digital Logic

or analog or analog

Fixed-function Unit Fixed-function Unit

Supply module

Driver or Driver or Driver or Driver or

Port

Input Input Input Input

Supply

The core can be divided into two kinds of sub-modules:

4.3.3.1 Central processing unit (CPU)

A CPU decodes and executes instructions, can make decisions and jump to a new set of

instructions based on those decisions.

Sub-units within the CPU decode and execute instructions (Sub-Unit CU (Control Unit)) and

perform arithmetic and logical operations (Sub-Unit ALU (Arithmetic/Logic Unit)), making use

of small number-holding areas called registers.

4.3.3.2 Fixed function unit (FFU)

Functional core sub-unit -> IC function module ‘Core’, designed to perform one analog, digital,

or mixed-signal fixed function without instruction decode and execute capability

4.3.3.2.1 Digital logic fixed function unit

Functional core sub-unit, designed to perform one fixed core Udigital logic U function without

instruction decode and execute capability.

Examples: UClock distribution U, UMemory logic and arrays U, Registers, Timer, Watchdog Timer,

State Machines, Programmable Logic Arrays (PLA).

4.3.3.2.2 Analog fixed function unit

Functional core analog sub-unit, clocked or unclocked, designed to perform one fixed core

analog function without instruction decode and execute capability.

Examples: Analog-to-digital-converter (ADC), Digital-to-analog-converter (DAC), Sample-

and-hold-circuits, Switched capacitor filter, Charge Coupled Devices (CCDs).

TR 61967-4-1 IEC:2005(E) – 13 –

Dedicated analog fixed function unit: sensor element

A sensor element is a converter of an environmental value into an electrical value and

therefore a FFU.

Examples: Hall sensor element for magnetic field sensing, E-field sensing, acceleration

sensing. It can be combined with a precision amplifier (FFU), a supply module

and a line driver to realize an IC type "sensor".

4.3.4 Oscillator

Generates a periodic signal.

NOTE This IC function module is a combination of a fixed function module of the core with regional drivers and

regional inputs, but because of its EMC behaviour, it is dedicated to be defined as a separate IC function module.

A fixed-frequency oscillator may be part of a phase locked loop (PLL) circuit with voltage

controlled oscillator (VCO), low pass filter, frequency divider and phase detection. All pins

related to these circuits (for example divider, digital logic input pins) are part of this IC

function module.

PLL factor

Supply module

Supply module

Core

Oscillator

Oscillator

Supply

Supply

(PLL)

Digital Logic

Digital Logic

or analog

or analog

Fixed-function Unit

Fixed-function Unit

Core

Digital Logic Digital Logic

or analog or analog

Fixed-function Unit Fixed-function Unit

Supply module

Driver or Driver or Driver or Driver or

Port

Input Input Input Input

Supply

– 14 – TR 61967-4-1 IEC:2005(E)

4.4 Example matrix for splitting ICs into IC function modules

Table 1 – Example matrix for splitting ICs into IC function modules

Functional module Connection external circuit via pin No pin local external

circuits

Driver (outputs) Inputs Supplies Core Core/inputs

supply connec

IC Function

inputs output

Module

supply referen

connection

IC type examples

Microcontrollers

• • • • • • •

RAM, ROM, bus

• • • •

drivers

Logic gate ICs

• • • •

Operational

(•) (•) • • • •

amplifier

VCOs • • • • •

Sensor circuit • (•) (•) • •

High side switch

(•) • • • • (•) (•)

Low side switch

(•) • • • • (•)

Bridge

(•) • • • • • (•)

Symmetrical

communication

• • • • • • (•) (•)

(e.g. CAN,

LVDS)

Asymmetrical

communication

• • • • • • (•) (•)

(e.g. LIN, single

wire CAN)

Voltage regulator,

(•) • • (•) • (•) (•)

linear

Voltage regulator,

(•) (•) (•) (•) (•) (•)

• • •

switch mode

ASICs Any combination

• = standard configuration

(•) = possible alternative configuration

NOTE For visual examples, see Annex C.

Interface driver Power driver Analog ICs Digital ICs

Line driver

Symmetrical line driver

Regional signal driver

High side driver

Low side driver

Line receiver

Symmetrical line receiver

Regional input

All IC function module supplies

Digital fixed function unit

Analog fixed function unit

Central processing unit (CPU)

Oscillator

TR 61967-4-1 IEC:2005(E) – 15 –

5 Workflow to perform IC EMC emission tests

5.1 Emission test philosophy

The recommended order to test a DUT is to perform measurements from 'outside' to 'inside'.

Highest priority have signals and supplies defined as EMC pin type 'global', see Definition

3.6.1.

5.2 Flowchart of performing emission tests

Split DUT's internal functions (circuit blocks) into IC function modules

Identify the IC function modules of the DUT, see 4.3

Common test circuit

Create a test circuit with recommended components according datasheet

Ports (combinations of drivers and inputs)

1. Select Ports for emission tests, for selection guide see 6.1

2. Add test circuits (networks and connectors) according to 6.3.1 to 6.3.5 of corresponding drivers

and inputs to all selected Ports.

NOTE Crosstalk core-to-ports is measured with these test circuits, too.

Core (combinations of sub-modules without connection to outside of the IC)

Core with CPU: select active fixed function units by corresponding software as a combination of two

parts, the initialization part and the loop software part (see 6.6 ).

Core without CPU: select 'worst case' action of the core, if possible.

Supplies

1. Select Supplies (minimum the supplies of the ports selected above) for emission tests, for

selection guide see 6.4.

2. Add test circuits (networks and connectors) according to 6.5 to all selected Supplies.

Test board creation

Create test board layout with test circuit diagram designed above. For layout recommendations, see

Clause 7.

Performing measurements

Perform tests determined with the selections above.

Test report

Combine data to a test report: motivation of test pin selections, test circuit diagram, test board

description, software descriptions (if Core contains a CPU, see 6.7.7), supplies, environmental

parameters and result data. See Clause 8.

Figure 2 – Flowchart of performing emission tests

– 16 – TR 61967-4-1 IEC:2005(E)

6 Test configurations for IC function modules

6.1 EMC test recommendations for IC function modules

The following IC function modules should be tested for conducted emission:

Table 2 – EMC test recommendations for IC function modules

Kind of coupling

EMC pin type

Test to be

IC function module and emission

considered

output

Local Global

Port IC function modules

Line driver • Yes Directly to driver pin

Line receiver No -

•

Symmetrical line driver Yes Directly to driver pins

•

Symmetrical line receiver • No -

Regional signal driver • Yes Directly to driver pin

Regional input No -

•

1 1

High side driver • P P • P P Yes Directly to driver pin

1 1

Low side driver • P P • P P Yes Directly to driver pin

Indirectly by

Oscillator • Yes

crosstalk to pin

Core sub modules

Crosstalk to driver

CPU • Yes

pin

Crosstalk to driver

Digital Logic FFU • Yes

pin

Analog FFU No -

•

Analog FFU sensor element • No -

IC function modules supply

All available IC function module supplies • • Yes Directly to supply pin

P P EMC pin type depending on whether is a cable harness in between pin and load or not.

6.2 Port selection guide

6.2.1 Test pin selection

At least one port should be prepared for measurement.

6.2.2 If more than one port is implemented into the IC:

The selection of a 'representative port' should be carried out according to the following

priorities:

TR 61967-4-1 IEC:2005(E) – 17 –

Table 3 – Test port selection table

EMC risk Item Port selection Testing kind of coupling

Minimum one driver of a port is EMC

Direct coupling:

pin type 'global':

Driver switching noise

High All type 'global' driver pins

- line driver

Indirect coupling:

Crosstalk driver to driver P P

- symmetrical line driver

Fastest port, base for

selection: switch to 'multi-

High Port slew rate and driver strength function' and fastest switching Driver switching noise

edges and/or select port with

the highest driver capability

Dedicated digital signals: Examples

System clock outputs CLOCK_OUTx

SPI_CLOCK

High Serial communication outputs Driver switching noise

SPI_MOSI

CLOCK

Parallel communication outputs

DATAx

Use an already selected test

Medium Oscillator, digital FFU, CPU Crosstalk oscillator-to-port

port

P P More than one test network needed, for example see Figure 6, 'multiple driver port'.

For example:

In case of more than one multiple driver/input ports (e.g.: microcontroller):

Select the port, consisting of identical 4 or 8 or 16, … I/O-drivers according following criteria:

a) The port with the shortest rising and falling time capability for emission measurements.

NOTE EMC functionality, e.g. voltage edge control, should be disabled for port selection.

b) Additionally this port should be the closest to the core of the microcontroller or where the

highest crosstalk via supply and other noisy structures, for example clock distribution, is

expected.

– 18 – TR 61967-4-1 IEC:2005(E)

6.3 Test networks at selected ports

6.3.1 Line driver

(Z = 50 Ω)

trace

(Z = 50 Ω)

trace R

An

C

Bn

IC

IC

Ω

120 C

B2

R

A2

R C

1 1

C

R B1

R

A1

Ω)

(Z = 150

trace

R

(Z = 150 Ω)

trace

Circuit A: Single line driver port Circuit B: Multiple line driver port*

* Use circuit B, if more than one driver I to be tested simultaneously (means: all drivers are active) of a multiple line

driver port, only suitable for sum emission measurement of all drivers.

C B B 6,8 nF or maximum load capacitance according to IC data sheet (see Annex A)

R B B=

A1

R = 120Ω ⋅ n n = number of line drivers

A ±5%

R B B=.

A2

Select a resistor according resistor standard set within the tolerance of 5 %

=R B B

An

C

C B B=

B1 1

C = n = number of line drivers

B ±5%

C B B=.

B2

n

= C B B

Bn

Select a capacitor according to capacitor standard set within the tolerance of 5 %

Figure 3 – Test network for IC function module line driver

6.3.2 Symmetrical line driver

6.3.2.1 Bus system with separate termination*

(Z = 50 Ω)

trace

IC

R

A

C

B

R

A

C

B

R

(Z = 150 Ω)

trace-to-ground

(Z according bus

trace-to-trace

system datasheet )

CB 6,8 nF or maximum load capacitance according to IC data sheet (see Annex A)

1B

Common bus systems 240 Ω

RB Deviant definition: CAN 120 Ω

AB

-3T

NOTE The resistance matching tolerance shall be better than 10T

Common bus systems 6,8 nF

Deviant definition: CAN 4,7 nF

CB

BB

NOTE The impedance of both capacitors CB shall be small compared to RA, the matching tolerance may

be not so tight as with the resistors. By default for CB a capacitance matching tolerance of better than 10-2

is sufficient.

*

P PTermination not part of the test network, but may be needed for the symmetrical line driver.

Figure 4 – Symmetrical line driver without termination

(not required by bus system datasheet)

Core

Line Driver

Core

Symmetrical

51 Ω

Line Driver

Core

Ω

Line Driver

Ω

TR 61967-4-1 IEC:2005(E) – 19 –

6.3.2.2 Bus system with termination used for test network

(Z = 50 Ω)

trace

R

IC

A2

R

A1

R C

B 1

R

(Z = 150 Ω)

trace-to-ground

(Z according bus

trace-to-trace

system datasheet )

C B B 6,8 nF or maximum load capacitance according IC data sheet (see Annex A)

Examples:

Bus system R B B

Ax

Termination according bus system datasheet to the symmetrical

R B B=

A1

star point (this point has no resulting current to reference ground, High speed CAN 30 Ω

R B B

A2

if there is no common mode current on lines)

LVDS

50 Ω

Airbag squib e.g. 1 Ω

Examples:

R

Bus system R B B

A

B

R = 125 Ω −

B ±5%

High Speed CAN

R B B 110 Ω

B

Select a resistor according resistor standard set within the

LVDS 100 Ω

tolerance of 5 %

Airbag squib 130 Ω

Figure 5 – Symmetrical line driver with termination required by bus system datasheet

6.3.3 Regional signal driver

**

R

Pullup

(Z = 150 Ω) (Z = 50 Ω)

trace trace

V

cc

R C

1 1

*

Ω

R 120

Pullup IC

V

cc

(Z = 50 Ω)

trace

V

cc

IC

R

120 Ω 2

V

cc

R 6.8nF

Ω 3

R

* 4

Network B

C

R C

LOAD

1 1

R

(Z = 150 Ω)

trace

Network A

Network A Network B

static output tests toggle output tests

Single driver port Multiple driver port, minimum test configuration

C B B, C B B 6,8 nF or maximum load capacitance according IC data sheet (see Annex A)

1 Load

Digital signal: according IC data sheet, if it is needed for external pull up (default 3 300 Ω)

at IC function module input

R B B

Pullup

Analog signal: signal connection to functional required circuit

Figure 6 – Test network for IC function module line driver

Core

Region Driver

al

or Input

Core

Symmetrical

Line Driver

Ω

Core

Regional Drivers

or Inputs

Ω

51 Ω

51 Ω

– 20 – TR 61967-4-1 IEC:2005(E)

6.3.4 High side driver

(Z = 50 Ω)

trace

supply

120 Ω

Ω) R 6.8 nF

(Z = 150

trace

IC output C R

1 2

L L

reference D C

1 2

R

49 Ω

Load

1 2

Alternative measurements depending on

configuration and load, see definition below

1 Ω Probe

Setup component variation

Placement depending on circuit type

Item Value

Linear voltage Switched mode power

High side driver circuit

regulator circuit supply circuit

L B B 5 µH • • •

L B B acc. IC data sheet Shorted Shorted •

D B B acc. IC data sheet

•

C B B acc. IC data sheet • •

• • •

ΔT

R B B According I B B

Load mes

I =

mes

I B B= 80% of I B B I B B= 80% of I B B

R ⋅ R

mes nom mes nom

th ON150

(ΔT = 65 K, I B B ≤ 10 A)

mes

R B B ≤ 30 Ω 1 1 1

Load

Test

DC load current: 1

network

1 1

R B B > 30 Ω

Load

PWM load current: 2

Figure 7 – Test network for IC function module high side driver

Core

High Side

Driver

1 Ω

51 Ω

TR 61967-4-1 IEC:2005(E) – 21 –

6.3.5 Low side driver

V

DD

R

Load,1

1 2 Alternative measurements

depending on configuration and

L

load, see definition below

supply

L

2 (Z = 50 Ω)

C trace

D (Z = 150 Ω)

trace

IC output

120 Ω

6.8 nF

R

C

R

reference 2

C R

2 Load,2

49 Ω

1 Ω Probe

Setup component variation

Placement depending on circuit type

Item Value

Low side driver Boost converter

C B B acc. IC data sheet

•

C B B acc. IC data sheet

•

L B B 5 µH • Optional

L B B acc. IC data sheet Shorted •

D B B acc. IC data sheet Shorted

•

• Shorted

ΔT

R B B According I B B

Load,1 mes I =

mes

R ⋅ R

th ON150

(ΔT = 65 K, I

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...