IEC 61189-2-501:2022

(Main)Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 2-501: Test methods for materials for interconnection structures - Measurement of resilience strength and resilience strength retention factor of flexible dielectric materials

Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 2-501: Test methods for materials for interconnection structures - Measurement of resilience strength and resilience strength retention factor of flexible dielectric materials

IEC 61189-2-501:2022 establishes a method suitable for testing the softness of FCCL (Flexible Copper Clad Laminate) products and related materials. This method determines the resilience under specified conditions. The test is performed on the sample as manufactured and without conditioning. The test does not apply to the resilience force lower than 10 mN.

Méthodes d’essai pour les matériaux électriques, les cartes imprimées et autres structures d’interconnexion et ensembles - Partie 2-501: Méthodes d’essai des matériaux pour structures d’interconnexion - Mesure de la puissance élastique et du facteur de rétention de la puissance élastique des matériaux diélectriques flexibles

L’IEC 61189-2-501:2022 établit une méthode mettant à l’essai la souplesse d’un stratifié flexible recouvert de cuivre (FCCL, Flexible Copper Clad Laminate) et des matériaux apparentés. Cette méthode détermine l’élasticité dans des conditions spécifiées. L’essai est effectué sur un échantillon tel que fabriqué et sans conditionnement. L’essai ne s’applique pas à une force élastique inférieure à 10 mN.

General Information

- Status

- Published

- Publication Date

- 02-Feb-2022

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 10 - TC 91/WG 10

- Current Stage

- PPUB - Publication issued

- Start Date

- 28-Jan-2022

- Completion Date

- 03-Feb-2022

Overview

IEC 61189-2-501:2022 is an international standard published by the International Electrotechnical Commission (IEC) that defines test methods for evaluating the mechanical resilience of flexible dielectric materials used in electrical interconnection structures. This part 2-501 standard specifically focuses on measuring the resilience strength and the resilience strength retention factor of flexible copper clad laminates (FCCLs) and similar flexible dielectric materials commonly utilized in printed boards and electronic assemblies.

Designed to assess the softness and mechanical response of FCCL products as manufactured, IEC 61189-2-501 provides a precise, reproducible method to quantify how these materials withstand compression and retain their elasticity without conditioning or aging processes. It excludes tests on samples with resilience force below 10 mN, ensuring the method targets materials relevant for industrial applications.

Key Topics

- Softness Measurement: Defines softness as the resistance to pressure, which enables easy molding essential for flexible dielectric materials.

- Resilience Force & Strength: The standard measures the force generated by a material when compressed (resilience force) and the force normalized by specimen width (resilience strength, mN/mm).

- Retention Factor: Evaluates how well the material maintains its resilience after holding compression, expressed by the resilience strength retention factor (ratio of post-compression to maximum resilience force).

- Test Specimens and Apparatus: Specifies requirements for precision measurement tools including micrometers, calipers, rulers, and specially designed compressive jigs for consistent testing.

- Test Procedure: Covers sample preparation without conditioning, compression testing at a controlled 50 mm/min rate, and detailed force measurement until a pre-set final distance between clamps is reached.

- Directions and Dimensions: Considers the machine direction (MD) and transverse direction (TD) of flexible materials, ensuring tests reflect manufacturing orientations and real-world conditions.

Applications

The IEC 61189-2-501 standard is invaluable for:

- Quality Assurance in Electronics Manufacturing: Ensures FCCL materials used in printed circuit boards (PCBs) meet mechanical resilience criteria to avoid failures in flexible interconnections.

- Material Selection and Development: Provides reliable data for manufacturers developing flexible dielectric materials with optimized softness and resilience tailored to various electronic applications.

- Research and Development: Supports engineering teams in quantifying mechanical properties critical for flexible interconnection designs in advanced electronics including wearable devices, foldable displays, and flexible sensors.

- Supplier Certification: Aids in establishing consistent criteria for suppliers of FCCLs and dielectric films, ensuring materials conform to internationally recognized resilience performance.

- Compliance and Interoperability: Helps manufacturers align with global standards facilitating smoother international trade and technology integration.

Related Standards

IEC 61189-2-501:2022 is part of the broader IEC 61189 series that governs test methods for electrical materials, printed boards, and interconnection assemblies. Related documents in this series cover additional mechanical, physical, and electrical tests such as:

- IEC 61189-2-x: Various parts focusing on different test methods for materials used in electronic interconnections.

- IEC 61249: Standards for base materials like copper-clad laminates for printed boards.

- IPC Standards (e.g., IPC-TM-650): Widely referenced US standards for flexible circuit material testing that complement IEC methodologies.

- ISO/IEC Directives: Provide guidance on the development and implementation of IEC standards ensuring conformity and harmonization.

Adoption of IEC 61189-2-501:2022 promotes standardized evaluation of flexible dielectric materials contributing to higher reliability and performance in modern flexible electronics. Its focus on resilience strength measurement underlines the critical role of mechanical properties in the durability and effectiveness of flexible interconnection structures used worldwide.

IEC 61189-2-501:2022 - Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 2-501: Test methods for materials for interconnection structures - Measurement of resilience strength and resilience strength retention factor of flexible dielectric materials

Frequently Asked Questions

IEC 61189-2-501:2022 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 2-501: Test methods for materials for interconnection structures - Measurement of resilience strength and resilience strength retention factor of flexible dielectric materials". This standard covers: IEC 61189-2-501:2022 establishes a method suitable for testing the softness of FCCL (Flexible Copper Clad Laminate) products and related materials. This method determines the resilience under specified conditions. The test is performed on the sample as manufactured and without conditioning. The test does not apply to the resilience force lower than 10 mN.

IEC 61189-2-501:2022 establishes a method suitable for testing the softness of FCCL (Flexible Copper Clad Laminate) products and related materials. This method determines the resilience under specified conditions. The test is performed on the sample as manufactured and without conditioning. The test does not apply to the resilience force lower than 10 mN.

IEC 61189-2-501:2022 is classified under the following ICS (International Classification for Standards) categories: 31.180 - Printed circuits and boards. The ICS classification helps identify the subject area and facilitates finding related standards.

You can purchase IEC 61189-2-501:2022 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of IEC standards.

Standards Content (Sample)

IEC 61189-2-501 ®

Edition 1.0 2022-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Test methods for electrical materials, printed boards and other interconnection

structures and assemblies –

Part 2-501: Test methods for materials for interconnection structures –

Measurement of resilience strength and resilience strength retention factor of

flexible dielectric materials

Méthodes d'essai pour les matériaux électriques, les cartes imprimées et autres

structures d'interconnexion et ensembles –

Partie 2-501: Méthodes d’essai des matériaux pour structures d’interconnexion –

Mesure de la puissance élastique et du facteur de rétention de la puissance

élastique des matériaux diélectriques flexibles

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 19 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur adapté à vos besoins.

les projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au

Restez informé sur les nouvelles publications IEC. Just

monde, avec plus de 22 300 articles terminologiques en

Published détaille les nouvelles publications parues.

anglais et en français, ainsi que les termes équivalents dans

Disponible en ligne et une fois par mois par email.

19 langues additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 61189-2-501 ®

Edition 1.0 2022-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Test methods for electrical materials, printed boards and other interconnection

structures and assemblies –

Part 2-501: Test methods for materials for interconnection structures –

Measurement of resilience strength and resilience strength retention factor of

flexible dielectric materials

Méthodes d'essai pour les matériaux électriques, les cartes imprimées et autres

structures d'interconnexion et ensembles –

Partie 2-501: Méthodes d’essai des matériaux pour structures d’interconnexion –

Mesure de la puissance élastique et du facteur de rétention de la puissance

élastique des matériaux diélectriques flexibles

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.180 ISBN 978-2-8322-1071-7

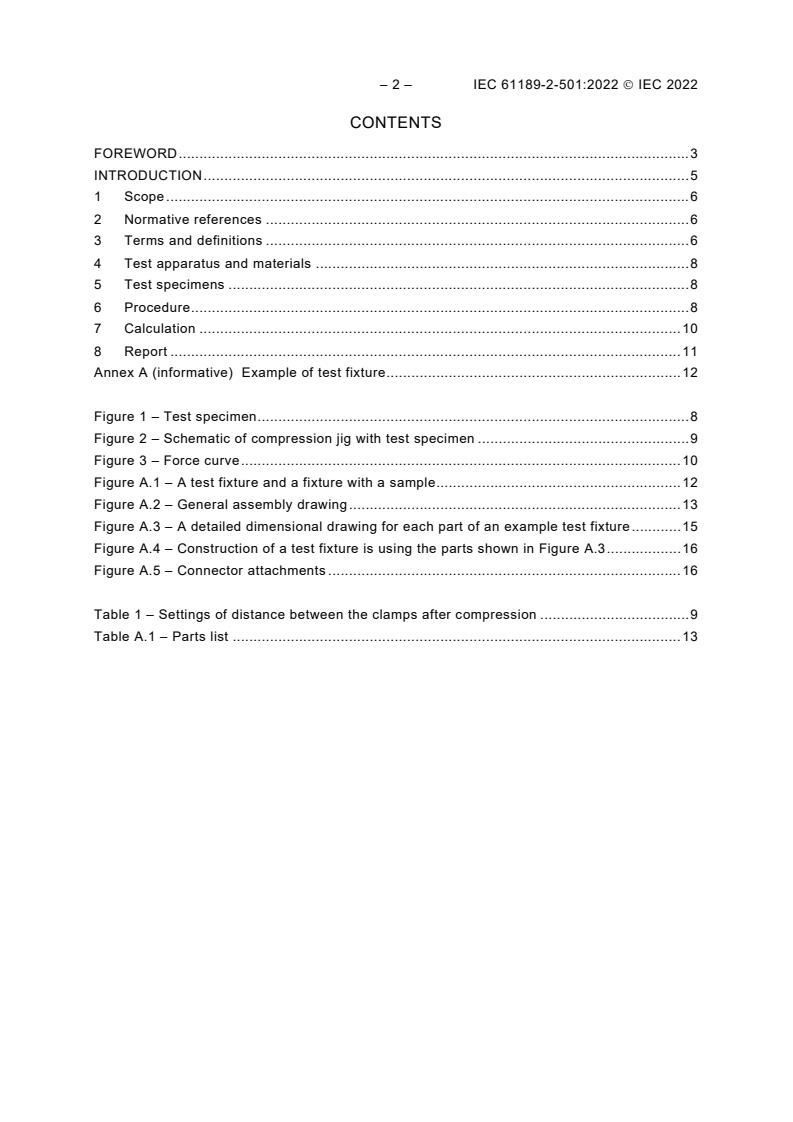

– 2 – IEC 61189-2-501:2022 IEC 2022

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Test apparatus and materials . 8

5 Test specimens . 8

6 Procedure . 8

7 Calculation . 10

8 Report . 11

Annex A (informative) Example of test fixture . 12

Figure 1 – Test specimen . 8

Figure 2 – Schematic of compression jig with test specimen . 9

Figure 3 – Force curve . 10

Figure A.1 – A test fixture and a fixture with a sample . 12

Figure A.2 – General assembly drawing . 13

Figure A.3 – A detailed dimensional drawing for each part of an example test fixture . 15

Figure A.4 – Construction of a test fixture is using the parts shown in Figure A.3 . 16

Figure A.5 – Connector attachments . 16

Table 1 – Settings of distance between the clamps after compression . 9

Table A.1 – Parts list . 13

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

TEST METHODS FOR ELECTRICAL MATERIALS, PRINTED BOARDS

AND OTHER INTERCONNECTION STRUCTURES AND ASSEMBLIES –

Part 2-501: Test methods for materials for interconnection structures –

Measurement of resilience strength and resilience strength retention

factor of flexible dielectric materials

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 61189-2-501 has been prepared by IEC technical committee TC 91: Electronics assembly

technology. It is an International Standard.

The text of this International Standard is based on the following documents:

Draft Report on voting

91/1765/FDIS 91/1774/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

– 4 – IEC 61189-2-501:2022 IEC 2022

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts in the IEC 61189 series, published under the general title Test methods for

electrical materials, printed boards and other interconnection structures and assemblies, can

be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

INTRODUCTION

The International Electrotechnical Commission (IEC) draws attention to the fact that it is claimed

that compliance with this document may involve the use of a patent. IEC takes no position

concerning the evidence, validity, and scope of this patent right.

The holder of this patent right has assured IEC that s/he is willing to negotiate licences under

reasonable and non-discriminatory terms and conditions with applicants throughout the world.

In this respect, the statement of the holder of this patent right is registered with IEC. Information

may be obtained from the patent database available at http://patents.iec.ch.

Attention is drawn to the possibility that some of the elements of this document may be the

subject of patent rights other than those in the patent database. IEC shall not be held

responsible for identifying any or all such patent rights.

– 6 – IEC 61189-2-501:2022 IEC 2022

TEST METHODS FOR ELECTRICAL MATERIALS, PRINTED BOARDS

AND OTHER INTERCONNECTION STRUCTURES AND ASSEMBLIES –

Part 2-501: Test methods for materials for interconnection structures –

Measurement of resilience strength and resilience strength retention

factor of flexible dielectric materials

1 Scope

This part of IEC 61189 establishes a method suitable for testing the softness of FCCL (Flexible

Copper Clad Laminate) products and related materials. This method determines the resilience

under specified conditions. The test is performed on the sample as manufactured and without

conditioning. The test does not apply to the resilience force lower than 10 mN.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

softness

property of little resistance to pressure

Note 1 to entry: This property enables easy molding.

3.2

resilience force

force produced by the deformation of an object under a force, which is opposite to the direction

of the applied force

3.3

maximum resilience force

L

max

resilience force when compressed to the final distance, expressed in millinewtons (mN)

3.4

resilience strength

F

max

resilience force per unit width, expressed in millinewtons per millimetres (mN/mm)

3.5

resilience force at the end of holding pressure

L

end

resilience force after compression to the final distance and held for a specified time, expressed

in millinewtons (mN)

3.6

resilience strength at the end of holding pressure

F

end

resilience force per unit width at the end of holding pressure, expressed in millinewtons per

millimetres (mN/mm)

3.7

resilience strength retention factor

K

Rf

ratio of the resilience strength at the end of holding pressure to the maximum resilience strength

at the final distance, reflecting the ability of the material to continue to retain the resilience after

the compression is completed

3.8

MD

machine direction

direction of flexible dielectric materials passing through an assembly line viewed from the

operator side

3.9

TD

transverse direction

direction perpendicular to the machine direction

3.10

initial distance

distance between the clamps before compression, expressed in millimetres (mm)

3.11

clamp distance

distance between the clamps, expressed in millimetres (mm)

3.12

test equipment

calibrated test equipment equipped with a load cell, capable of measuring to the nearest

0,001 N, and capable of a feed rate of (50 ± 1) mm per minutes

Note 1 to entry: The clamp jaws must cover the width of specimens.

3.13

test fixture

apparatus for compressing the test specimens

SEE: Figure 2

Note 1 to entry: See Annex A for additional information.

– 8 – IEC 61189-2-501:2022 IEC 2022

4 Test apparatus and materials

The test apparatus and materials are the following:

– micrometer: apparatus with 0,001 mm resolution for measuring the thickness of the test

specimens;

– calliper: apparatus with 0,01 mm resolution for measuring the width of the test specimens;

– ruler: apparatus with 0,1 mm resolution for measuring the length of the test specimens;

– sample cutter: apparatus for cutting the test specimens;

– marking pen: apparatus for drawing a straight line on test specimens as shown in Figure 1

with a clearly readable colour, in contrast to the colour of the test specimen.

The marking should be durable through the whole test procedure.

5 Test specimens

Test specimens should be cut of unclad material. The size of each specimen should be

(120 ± 2,0) mm × (15 ± 0,1) mm, described in Figure 1. Each specimen should be marked as

described in Figure 1. The test specimen should be free of incisions, twists, wrinkles and burrs.

Dimensions in millimetres

Figure 1 – Test specimen

6 Procedure

The procedure is as follows:

a) determine the thickness (h) and width (W ) of each prepared specimen;

S

b) initial distance is set to (30 ± 0,05) mm;

c) set the distance of the clamps after compression according to Table 1; the distance between

the clamps after compression is set according to the sample thickness, accurate to

± 0,05 mm, as shown in Table 1;

Dimensions in millimetres

Figure 2 – Schematic of compression jig with test specimen

Table 1 – Settings of distance between the clamps after compression

Specimen thickness, h Clamps distance after compression

h < 0,1 mm (1 ± 0,05) mm

0,1 mm ≤ h < 0,2 mm (2 ± 0,05) mm

0,2 mm ≤ h < 0,3 mm (3 ± 0,05) mm

0,3 mm ≤ h < 0,4 mm (4 ± 0,05) mm

Or user-defined

d) compression rate is set to (50 ± 1) mm/min;

e) pressure holding time after compression is set to (30 ± 0,5) s;

f) clamp the test specimen vertically in the upper and lower compression jigs to ensure that

the marked lines at both end are parallel with the edge of the jigs;

g) test Single-side adhesive specimens in a manner of adhesive-side inward bending, and

double-side asymmetric adhesive specimens in a manner of thicker adhesive-side inward

bending;

h) set the force of test equipment to zero and start the compression process according to the

above settings, and record the test process. The force curve is as shown in Figure 3;

– 10 – IEC 61189-2-501:2022 IEC 2022

Figure 3 – Force curve

i) record the maximum load value L and Load at the end of holding pressure value L of

max end

each specimen.

7 Calculation

a) Calculate the maximum resilience strength per Formula (1):

L

max

F =

max (1)

W

S

where

F is the maximum resilience strength, expressed in millinewtons per millimetres

max

(mN/mm);

L is the maximum load, expressed in millinewtons (mN);

max

W is the measured width of the specimen, expressed in millimetres (mm).

S

b) Calculate the resilience strength at the end of holding pressure as per the Formula (2):

L

end

F = (2)

end

W

S

where

F is the resilience strength at the end of holding pressure, expressed in millinewtons

end

per millimetres (mN/mm);

L is the resilience force at the end of holding pressure, expressed in millinewtons

end

(mN);

W is the measured width of the specimen, expressed in millimetres (mm).

S

c) Calculate the resilience strength retention factor as per the Formula (3):

F

end

K =

Rf (3)

F

max

where

K is the resilience strength retention factor;

Rf

F is the maximum resilience strength;

max

F is the resilience strength at the end of holding pressure

end

8 Report

Report the following:

a) test environment (temp

...

記事のタイトル:IEC 61189-2-501:2022 - 電気材料、プリント基板、他の接続構造および組立体の試験方法 - 第2-501部:接続構造用材料の試験方法 - 柔軟な絶縁材料の残留力と残留力保持係数の測定 記事の内容:IEC 61189-2-501:2022は、柔軟性銅被覆ラミネート(FCCL)製品および関連する材料の柔軟性を試験するための適切な方法を確立しています。この方法は、指定された条件下での残留力を決定します。このテストは、サンプルが製造されたままで、調整なしで行われます。ただし、残留力が10 mN未満の場合は、このテストは適用されません。

글 제목: IEC 61189-2-501:2022 - 전기 소재, 인쇄 기판 및 기타 상호 연결 구조물 및 조립품에 대한 시험 방법 - 제 2-501 부: 상호 연결 구조물용 소재의 시험 방법 - 유연한 절연 소재의 복원력 강도 및 복원력 유지율의 측정 글 내용: IEC 61189-2-501:2022은 FCCL (유연한 동박 구리 도금 기판) 제품 및 관련 소재의 연성을 테스트하는 데 적합한 방법을 제시합니다. 이 방법은 지정된 조건에서의 복원력을 결정합니다. 이 테스트는 제조 과정에서의 샘플에 대해 수행되며, 조건부 없이 진행됩니다. 그러나 복원력 힘이 10 mN보다 낮은 경우에는 이 테스트를 적용할 수 없습니다.

The article discusses a new test method, IEC 61189-2-501:2022, that measures the softness or resilience of Flexible Copper Clad Laminate (FCCL) products and related materials. The test is conducted on the sample as it is manufactured and without any conditioning. However, the test is not suitable for measuring resilience forces lower than 10 mN.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...