IEC 63251:2023

(Main)Test method for mechanical properties of flexible opto-electric circuit boards under thermal stress

Test method for mechanical properties of flexible opto-electric circuit boards under thermal stress

IEC 63251:2023 defines the thermal endurance test methods for reliability assessment of flexible opto-electric circuit boards. The purpose of this document is to accommodate the uniform thermal characteristics required by the flexible opto-electric circuit in high temperature environments such as automobiles. In particular, this document specifies a test method to inspect the occurrence of colour exchange, deformation and delamination of flexible opto-electric circuit boards under thermal stress.

Méthode d’essai des propriétés mécaniques des circuits optoélectriques souples sous contrainte thermique

L'IEC 63251:2023 définit les méthodes d’essai d’endurance thermique relatives à l’évaluation de la fiabilité des circuits optoélectriques souples. Le présent document a pour objet de tenir compte des caractéristiques thermiques uniformes exigées par le circuit optoélectrique souple dans les environnements à haute température comme les automobiles. Le présent document spécifie notamment une méthode d’essai pour déceler l’apparition d’un changement de couleur, d’une déformation et d’une déstratification des circuits optoélectriques souples sous contrainte thermique.

General Information

- Status

- Published

- Publication Date

- 31-Oct-2023

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 10 - TC 91/WG 10

- Current Stage

- PPUB - Publication issued

- Start Date

- 01-Nov-2023

- Completion Date

- 01-Dec-2023

Overview

IEC 63251:2023 is an international standard published by the International Electrotechnical Commission (IEC) that specifies test methods for the mechanical properties of flexible opto-electric circuit boards under thermal stress. This standard provides a structured approach to evaluating the thermal endurance and reliability of flexible opto-electric circuit boards, particularly under high temperature conditions such as those in automotive environments. Key tests include the inspection for colour exchange, deformation, and delamination, which are common failure modes when flexible opto-electric circuits are exposed to thermal stress.

The standard supports manufacturers and testing laboratories in conducting uniform, repeatable thermal stress tests, ensuring consistent product quality and reliability across global markets. IEC 63251:2023 addresses the growing use of flexible opto-electric circuit boards (FOECBs), which are critical components in modern electronics requiring both flexibility and thermal stability.

Key Topics

Thermal Endurance Test Methods

Provides detailed procedures for conducting tests like dry heat exposure, temperature cycling, and humidity stress to evaluate the thermal performance of FOECBs.Mechanical Property Assessment

Focuses on key mechanical changes such as deformation, delamination, and colour changes under thermal loads to determine material and assembly reliability.Test Sample Preparation and Conditioning

Guidelines on the preparation of test samples, including manufacturing processes and preconditioning steps, to ensure representative and comparable test results.Measurement and Reporting

Defines the final measurement techniques and the required test report structure, ensuring transparency and traceability of results.Scope for Automotive and High-Temperature Applications

Targets reliability of FOECBs in challenging environments like automobile electronics, where thermal cycles and extreme temperatures are common.

Applications

Automotive Electronics

Ensures FOECBs used in vehicles maintain integrity and performance during thermal cycling, protecting critical functions such as sensor systems, lighting, and communication modules.Flexible Display and Optics Devices

Assesses the impact of thermal stress on the flexible circuitry integral to displays, optical interconnections, and wearable devices.Consumer Electronics

Validates the durability of flexible opto-electric circuits in mobile devices and home automation products exposed to daily temperature variations.Industrial Equipment

Applies to flexible opto-electric circuits employed in harsh industrial interfaces where temperature-induced mechanical stress may occur.Quality Assurance and Product Development

Helps manufacturers improve design and material choices by understanding thermal endurance limits and failure mechanisms.

Related Standards

IEC 60068 Series (Environmental Testing)

- IEC 60068-2-2: Dry heat testing

- IEC 60068-2-14: Temperature change testing

- IEC 60068-2-78: Damp heat steady-state testing

These referenced standards complement IEC 63251 by providing standardized environmental test conditions.

ISO/IEC Directives

Guidelines on document development and terminology consistency ensuring the precision and usability of IEC 63251.Other IEC Technical Standards on Electronics Assembly Technology

IEC technical committee 91 oversees related standards focused on electronic assembly processes and reliability testing.

Keywords: IEC 63251, flexible opto-electric circuit boards, thermal stress testing, mechanical properties, thermal endurance, deformation, delamination, colour change, flexible electronics reliability, automotive electronics testing, environmental testing standards, IEC, FOECB testing, flexible circuit boards under thermal stress.

Frequently Asked Questions

IEC 63251:2023 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Test method for mechanical properties of flexible opto-electric circuit boards under thermal stress". This standard covers: IEC 63251:2023 defines the thermal endurance test methods for reliability assessment of flexible opto-electric circuit boards. The purpose of this document is to accommodate the uniform thermal characteristics required by the flexible opto-electric circuit in high temperature environments such as automobiles. In particular, this document specifies a test method to inspect the occurrence of colour exchange, deformation and delamination of flexible opto-electric circuit boards under thermal stress.

IEC 63251:2023 defines the thermal endurance test methods for reliability assessment of flexible opto-electric circuit boards. The purpose of this document is to accommodate the uniform thermal characteristics required by the flexible opto-electric circuit in high temperature environments such as automobiles. In particular, this document specifies a test method to inspect the occurrence of colour exchange, deformation and delamination of flexible opto-electric circuit boards under thermal stress.

IEC 63251:2023 is classified under the following ICS (International Classification for Standards) categories: 31.180 - Printed circuits and boards. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 63251:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 63251 ®

Edition 1.0 2023-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Test method for mechanical properties of flexible opto-electric circuit boards

under thermal stress

Méthode d’essai des propriétés mécaniques des circuits optoélectriques

souples sous contrainte thermique

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur les adapté à vos besoins.

projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au monde,

Restez informé sur les nouvelles publications IEC. Just

avec plus de 22 300 articles terminologiques en anglais et en

Published détaille les nouvelles publications parues.

français, ainsi que les termes équivalents dans 19 langues

Disponible en ligne et une fois par mois par email.

additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 63251 ®

Edition 1.0 2023-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Test method for mechanical properties of flexible opto-electric circuit boards

under thermal stress

Méthode d’essai des propriétés mécaniques des circuits optoélectriques

souples sous contrainte thermique

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.180 ISBN 978-2-8322-7750-8

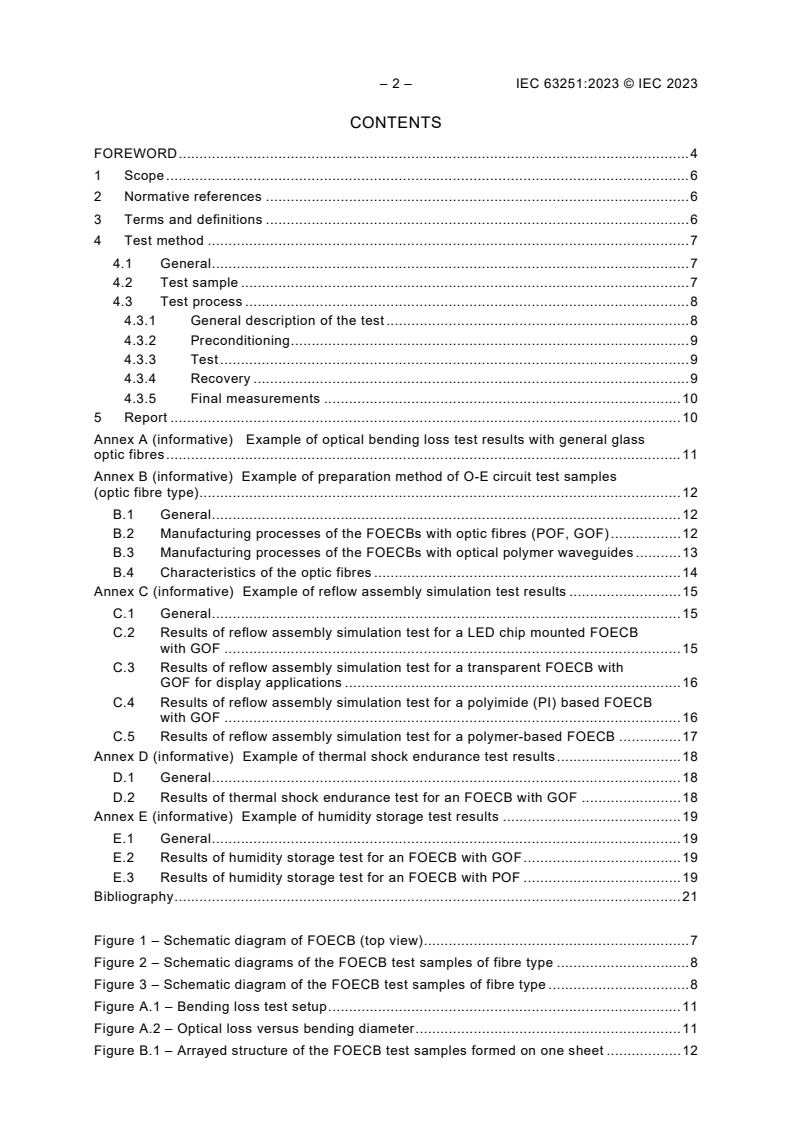

– 2 – IEC 63251:2023 © IEC 2023

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Test method . 7

4.1 General . 7

4.2 Test sample . 7

4.3 Test process . 8

4.3.1 General description of the test . 8

4.3.2 Preconditioning . 9

4.3.3 Test . 9

4.3.4 Recovery . 9

4.3.5 Final measurements . 10

5 Report . 10

Annex A (informative) Example of optical bending loss test results with general glass

optic fibres . 11

Annex B (informative) Example of preparation method of O-E circuit test samples

(optic fibre type) . 12

B.1 General . 12

B.2 Manufacturing processes of the FOECBs with optic fibres (POF, GOF) . 12

B.3 Manufacturing processes of the FOECBs with optical polymer waveguides . 13

B.4 Characteristics of the optic fibres . 14

Annex C (informative) Example of reflow assembly simulation test results . 15

C.1 General . 15

C.2 Results of reflow assembly simulation test for a LED chip mounted FOECB

with GOF . 15

C.3 Results of reflow assembly simulation test for a transparent FOECB with

GOF for display applications . 16

C.4 Results of reflow assembly simulation test for a polyimide (PI) based FOECB

with GOF . 16

C.5 Results of reflow assembly simulation test for a polymer-based FOECB . 17

Annex D (informative) Example of thermal shock endurance test results . 18

D.1 General . 18

D.2 Results of thermal shock endurance test for an FOECB with GOF . 18

Annex E (informative) Example of humidity storage test results . 19

E.1 General . 19

E.2 Results of humidity storage test for an FOECB with GOF . 19

E.3 Results of humidity storage test for an FOECB with POF . 19

Bibliography . 21

Figure 1 – Schematic diagram of FOECB (top view) . 7

Figure 2 – Schematic diagrams of the FOECB test samples of fibre type . 8

Figure 3 – Schematic diagram of the FOECB test samples of fibre type . 8

Figure A.1 – Bending loss test setup . 11

Figure A.2 – Optical loss versus bending diameter . 11

Figure B.1 – Arrayed structure of the FOECB test samples formed on one sheet . 12

Figure B.2 – Fabrication of the optic circuits with optic fibres . 13

Figure B.3 – Fabrication of the optic circuits with optic polymer waveguide via the

photo-etching method . 13

Figure C.1 – LED chip mounted FOECB. 15

Figure C.2 – Appearance of a LED chip mounted FOECB after the reflow assembly

simulation test . 15

Figure C.3 – Appearance of a transparent FOECB with GOFs after the reflow assembly

simulation test . 16

Figure C.4 – Appearance of a PI based FOECB with GOF after the reflow assembly

simulation test . 16

Figure C.5 – Appearance of a polymer-based FOECB after the reflow assembly

simulation test . 17

Figure D.1 – Appearance of an FOECB with GOF after the thermal shock test . 18

Figure E.1 – Appearance of an FOECB with GOF after the humidity storage test . 19

Figure E.2 – Appearance of an FOECB with POF after the humidity storage test . 20

Table 1 – Thermal endurance test class for FOECB . 9

– 4 – IEC 63251:2023 © IEC 2023

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

TEST METHOD FOR MECHANICAL PROPERTIES OF FLEXIBLE

OPTO-ELECTRIC CIRCUIT BOARDS UNDER THERMAL STRESS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

IEC 63251 has been prepared by IEC technical committee 91: Electronics assembly technology.

It is an International Standard.

The text of this International Standard is based on the following documents:

Draft Report on voting

91/1898/FDIS 91/1914/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn, or

• revised.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

– 6 – IEC 63251:2023 © IEC 2023

TEST METHOD FOR MECHANICAL PROPERTIES OF FLEXIBLE

OPTO-ELECTRIC CIRCUIT BOARDS UNDER THERMAL STRESS

1 Scope

This International Standard defines the thermal endurance test methods for reliability

assessment of flexible opto-electric circuit boards. The purpose of this document is to

accommodate the uniform thermal characteristics required by the flexible opto-electric circuit in

high temperature environments such as automobiles. In particular, this document specifies a

test method to inspect the occurrence of colour exchange, deformation and delamination of

flexible opto-electric circuit boards under thermal stress.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60068-2-2, Environmental testing – Part 2-2: Tests – Test B: Dry heat

IEC 60068-2-14, Environmental testing – Part 2-14: Tests – Test N: Change of temperature

IEC 60068-2-78, Environmental testing – Part 2-78: Tests – Test Cab: Damp heat, steady state

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1

optic circuit

circuit that is composed of optical waveguides and can transmit optical signals

3.2

glass optic fibre

GOF

optic fibre made of glass material

3.3

polymer optic fibre

POF

optic fibre made of polymer material

3.4

opto-electric circuit

O-E circuit

circuit that contains both optic circuit and electric circuit

3.5

flexible opto-electric circuit board

FOECB

flexible circuit board that contains both optic and electric circuits integrated into a flexible sheet

NOTE Figure 1 shows an example of the top view of a flexible opto-electric circuit board.

Figure 1 – Schematic diagram of FOECB (top view)

4 Test method

4.1 General

The FOECBs shall include optical and electrical circuits on a same board. Since the materials

used for the O-E circuits have different thermal properties from those used for the conventional

electric circuits, the requirements for the thermal performance tests will be different between

the two types of circuits. Thus, the thermal properties of the materials, such as glass optic fibre

(hereafter referred as GOF), polymer optic fibre (hereafter referred as POF), polymer film, etc.,

shall be identified in advance for applications to optic circuits in the given applications.

4.2 Test sample

The test samples of the FOECBs consist of electric and optic film circuits. The optic circuit shall

be positioned at the central part of the entire FOECB. An electric circuit shall be positiond at

the periphery part of the optic circuit in a symmetrical structure. The symmetrical structure shall

have superior characteristics in terms of size stability from the point of view of design and

reliability of the FOECBs.

The test samples shall be divided into two groups: a parallel array structure for multichannel

photonic circuit test (Figure 2a)) and a round loop structure for long-distance photonic circuit

test (Figure 2b)). If the test sample contains a fibre optic circuit, it shall have a protruded

structure with a length of l at one side, and this structure shall allow an easy connection to

another fibre with fusion splicing (or with another optical connection means). The protruded

length l shall have a sufficiently long length over 10 cm for easy connections with other fibres

(for an example, via the fibre fusion splicing). In the case of the round loop structure, the closed

side of the test sample shall have a structure of continuous fibre bending with a bending

diameter larger than 6 mm (Figure 2b)). The bending diameter l of larger than 6 mm for optic

fibre should be maintained to minimize the optical bending loss.

An example of the test results from measurement of the optical bending loss of an FOECB with

the general optic glass fibre as a function of the bending radius is shown in Annex A.

The size of the test samples can be determined from the user’s requirements.

– 8 – IEC 63251:2023 © IEC 2023

a) Parallel array structure (type 1) b) Round loop structure (type 2)

Key

1 Optic circuit

2 Electric circuit

Figure 2 – Schematic diagrams of the FOECB test samples of fibre type

For each test group a minimum of three samples having the same physical conditions shall be

prepared in the same fabrication processes.

Details of the preparation for the FOECB test samples (optic fibre type) are shown in Annex B.

4.3 Test process

4.3.1 General description of the test

In order for the FOECBs to be used in harsh environments, the thermal properties of the FOECB

test sample shall be specified with four severe test conditions of reflow assembly simulation,

thermal shock endurance, high temperature endurance and humidity storage.

It is recommended to use different test samples to perform each test.

A flow chart for each test should be as follows. The test process should be started with the

loading of the test sample into the test chamber, and proceed in the order of preconditioning,

test, recovery, final measurement, etc (see Figure 3).

Figure 3 – Schematic diagram of the FOECB test samples of fibre type

The thermal endurance test conditions of the test sample shall be classified as two grades

(class 1, class 2) according to the application area (see Table 1).

Table 1 – Thermal endurance test class for FOECB

Classify Temperature cycling High temperature exposure Humidity Storage

Class 1 (harsh area) 5 cycles (−55 °C to +125 °C) Duration 1 000 h at 150 °C Duration 56 days at 85 °C,

85 % RH

Class 2 (room area) 5 cycles (−40 °C to +82 °C) Duration 1 000 h at 82 °C Duration 12 h at 85 °C, 85 %

RH

4.3.2 Preconditioning

The test sample shall be at the ambient temperature of the laboratory, +25 °C ± 5 K. If required

by the relevant specification, the test sample shall be brought into the operating conditions.

4.3.3 Test

4.3.3.1 Reflow assembly simulation test

The reflow assembly simulation test conditions (260 °C, 20 s to 30 s, 2 cycles to 3 cycles) for

the FOECB test samples follow the detailed guidelines given in IPC-TM-650 2.6.27.

4.3.3.2 Thermal shock endurance test

The thermal shock endurance test conditions for the FOECB test samples shall follow the

detailed guidelines (test Na) given in IEC 60068-2-14.

The preferred number of test cycles shall be five with 30 min at extreme temperature of the

technical data sheet, unless otherwise specified in the relevant specification.

4.3.3.3 High temperature endurance test

The high temperature endurance test conditions for the FOECB test samples shall follow the

detailed guidelines given in IEC 60068-2-2.

The preferred number of test cycles shall be 1 000 h at extreme temperature of the technical

data sheet, unless otherwise specified in the relevant specification.

4.3.3.4 Humidity storage test

The humidity storage test conditions for the FOECB test samples shall follow the detailed

guidelines given in IEC 60068-2-78.

The preferred test durations are 12 h, 16 h, 24 h, 2 d, 4 d, 10 d, 21 d or 56 d at humidity storage

condition (85 °C, 85 %RH).

4.3.4 Recovery

At the end of the test cycle, the test samples shall remain in the standard atmospheric conditions

for testing for a period adequate for the attainment of temperature stability.

The duration of recovery shall be 24 h ± 2 h at room temperature conditions.

– 10 – IEC 63251:2023 © IEC 2023

4.3.5 Final measurements

When the thermal test for the test samples is completed, the following additional tests should

be carried out to check any changes in their characteristics:

– identification of changes in the mechanical properties;

– after the thermal endurance test for the test samples, any appearance change, such as

colour change, deformation, and delamination, of the test samples can be checked visually

first;

– the delamination can be checked by polishing the cross section of the test samples and by

performing microscopic examination on the polished sections;

– finally, the flexibility of the test samples should be checked according to the methods

described in the bending test (IEC 62496-3-1), the MIT test (ISO-5626), and the folding

flexible cable (IPC-TM-650 2.4.31).

Annex C shows an example of the simulation test results for the reflow assembly of an FOECB

test sample.

Annex D shows an example of the high temperature endurance test results for an FOECB test

sample.

Annex E shows an example of the humidity storage test results for an FOECB test sample.

5 Report

a) test sample . (size and number)

b) customer . (name and address)

c) test laboratory . (name and address and details of accreditation – if any)

d) test dates . (dates when test was run)

e) type of test . (reflow assembly simulation, themal shock endurance,

................................................................. high temperature endurance, humidity storage)

f) test standard, edition . (IEC 63251, edition used)

g) any variations/deviation from the sample . (change or not)

h) test sample description . (drawing, photo, quantity build status, etc.)

i) any variation from the defined test method . (change or not)

j) performance of test sample . (results of functional tests,

...................................................... optic & electric properties, mechanical properties etc.)

k) summary of test . (test summary)

Annex A

(informative)

Example of optical bending loss test results

with general glass optic fibres

The results of the optical bending loss measurement of an FOECB test sample with embedded

standard multi-mode fibres (as referred to in the IEC 60793-2 series) are described below (see

Figure A.1):

– optical loss increases with reduced bending diameter;

– bending diameter l shall have a folding range above 5 mm for the optical loss free (see

Figure A.2).

a) Schematic diagram for bending test b) Photograph of the experimental demonstration

Key

1 O-E circuit board

2 Optic fibre (MM)

Figure A.1 – Bending loss test setup

Figure A.2 – Optical loss versus bending diameter

– 12 – IEC 63251:2023 © IEC 2023

Annex B

(informative)

Example of preparation method of O-E circuit test samples

(optic fibre type)

B.1 General

The FOECB test samples are prepared in a sheet shape first. Then, several test samples are

formed on the sheet in an arrayed structure, each having the same size (see Figure B.1). Once

the test sample arrays are produced on one sheet during one batch process, all the test samples

are expected to have uniform mechanical structures and material characteristics. Therefore,

the samples can show the uniform measurement properties for the thermal endurance test.

a) Arrayed test sample b) Photograph picture of test sample

Figure B.1 – Arrayed structure of the FOECB test samples formed on one sheet

In general, the FOECB test samples can be fabricated with two types of optical waveguides,

optic fibre and optical polymer waveguide.

B.2 Manufacturing processes of the FOECBs with optic fibres (POF, GOF)

The FOECBs of the optic fibre-type are fabricated with a lamination process in which an optic

fibre is inserted into a polyimide (PI) film of an existing electric circuit structure (see

Figure B.2a)).

a) Lamination lay-up for optic fibre b) Photograph of micro-cross section of test sample

Figure B.2 – Fabrication of the optic circuits with optic fibres

Since the optic fibre is long, voids can occur between the adhesive and the film during the

manufacturing process of the optic circuits (see Figure B.2b)). It is necessary to have a

sufficient thickness of the adhesive to avoid occurrence of the voids. Otherwise, the voids can

have a large influence on the deterioration of thermal properties of the optic circuits.

B.3 Manufacturing processes of the FOECBs with optical polymer waveguides

Generally the FOECBs with the optical polymer waveguides can be fabricated with a photo

etching process, and have a structure whose optical core materials is surrounded by cladding

materials (see Figure B.3).

Figure B.3 – Fabrication of the optic circuits with optic polymer

waveguide via the photo-etching method

The polymer optical waveguides have the advantages of high flexibility and of PCB process

compatibility. However, they have the disadvantages of high material cost, low thermal

endurance, relatively short length, and high optical loss.

– 14 – IEC 63251:2023 © IEC 2023

B.4 Characteristics of the optic fibres

Generally, the properties of the POF are a large core size (over 250 µm) and low thermal

endurance below 85 °C. The properties of the GOF are a small core size (under 50 µm) and

high thermal endurance above 1 000 °C.

Annex C

(informative)

Example of reflow assembly simulation test results

C.1 General

The reflow assembly simulation process is a preconditioning test to be performed before

carrying out the high thermal shock process. The FOECBs are subjected to high thermal shock

during the soldering process (see Figure C.1).

Figure C.1 – LED chip mounted FOECB

C.2 Results of reflow assembly simulation test for a LED chip mounted FOECB

with GOF

An example of an FOECB having a LED chip mounted with GOF is shown in Figure C.1 and is

tested for the reflow assembly simulation process. Its results are shown in Figure C.2:

– reflow test condition: 260 °C, 20 s, 3 cycles;

– test result: no optical loss variance, but slight deformation.

Figure C.2 – Appearance of a LED chip mounted FOECB after

the reflow assembly simulation test

– 16 – IEC 63251:2023 © IEC 2023

C.3 Results of reflow assembly simulation test for a transparent FOECB with

GOF for display applications

A transparent FOECB with GOFs is tested for the reflow assembly simulation process, and its

results are shown in Figure C.3:

– reflow test condition: 260 °C, 20 s, 3-cycle reflow;

– test result: no variance in optical and electrical losses, but a small colour change.

Figure C.3 – Appearance of a transparent FOECB with GOFs after

the reflow assembly simulation test

C.4 Results of reflow assembly simulation test for a polyimide (PI) based

FOECB with GOF

A polyimide based FOECB with GOF is tested for the reflow assembly simulation process, and

its results are shown in Figure C.4:

– reflow test condition: 260 °C, 20 s, 3 cycles;

– test result: no variance appears in optical and electrical losses after the reflow test except

the pad portions of the Cu circuit are corroded.

Figure C.4 – Appearance of a PI based FOECB with GOF after

the reflow assembly simulation test

C.5 Results of reflow assembly simulation test for a polymer-based FOECB

A polymer-based FOECB is tested for the reflow assembly simulation process, and its results

are shown in Figure C.5:

– reflow test condition: 260 °C, 20 s, 3 cycles;

– test result: the test specimen is severely deformed.

Figure C.5 – Appearance of a polymer-based FOECB after

the reflow assembly simulation test

– 18 – IEC 63251:2023 © IEC 2023

Annex D

(informative)

Example of thermal shock endurance test results

D.1 General

In many cases, the assembled FOECB is subject to operation under optically and electrically

supplied powers and to thermal shocks during the operation cycles. The rapid temperature

change associated with the thermal shock can cause a detrimental effect to the contact portions

of the FOECB due to the fact that the optical and electric circuits absorb and give off heat at

different rates.

Since the optical and electrical circuits in the FOECB are made of different materials,

probabilities for delamination, deformation, and optical and electrical property changes are high

for a sudden thermal shock due to the mismatch of their coefficients of thermal expansion.

D.2 Results of thermal shock endurance test for an FOECB with GOF

An FOECB with GOF is tested for the thermal shock processes, and its result is shown in

Figure D.1:

– thermal shock test condition: -55 °C ~ 140 °C, 30 min/cycle, 1 000 cycles;

– test result: no variation in the optical loss through the optic circuits is observed except minor

physical deformation and delamination.

Figure D.1 – Appearance of an FOECB with GOF after the thermal shock test

Annex E

(informative)

Example of humidity storage test results

E.1 General

FOECBs with GOFs are likely to be exposed to high temperature and high humidity

environments for a long period of time during transportation and storage.

E.2 Results of humidity storage test for an FOECB with GOF

An FOECB with GOF is tested for the humidity storage test, and its result is shown in Figure E.1:

– humidity storage test condition: begin with the original normal test conditions of 85 °C / 85 %

RH, 1 000 h, and then follow the main test under a highly accelerated temperature and

humidity stress test (HAST) condition (130 °C / 85 % RH, 24 h);

– test result: no variance in optical loss of the optic circuit of the FOECB is observed except

slight deformation. Exposure to high temperature and high humidity conditions for a long

period of time causes corrosion on the electric circuit pad area.

Figure E.1 – Appearance of an FOECB with GOF after the humidity storage test

E.3 Results of humidity storage test for an FOECB with POF

An FOECB with POF is tested for the humidity storage test, and its result is shown in Figure E.2:

– humidity storage test condition: begin with the original normal test conditions of 85 °C / 85 %

RH, 1 000 h, and then follow the main test under a HAST condition (130 °C / 85 % RH 24 h);

– test result: the POF circuit portions are melted after the HAST process.

– 20 – IEC 63251:2023 © IEC 2023

Figure E.2 – Appearance of an FOECB with POF after the humidity storage test

Bibliography

IEC 60793-2 (all parts), Optical fibres – Part 2-X: Product specifications

IEC 62496-3-1, Optical circuit boards – Part 3-1: Performance standards – Flexible optical

circuit boards using unconnectorized optical glass fibres

ISO 5626, Paper – Determination of folding endurance

IPC-6012DA 2016-April, Automotive Applications Addendum to IPC-6012D Qualification and

Performance Specification for Rigid Printed Boards

IPC-TM-650 2.6.27, Thermal Stress, Convection Reflow Assembly Simulation Optic fibre

IPC-TM-650 2.4.31A, Folding, Flexible Flat Cable

___________

– 22 – IEC 63251:2023 © IEC 2023

SOMMAIRE

AVANT-PROPOS . 24

1 Domaine d’application . 26

2 Références normatives . 26

3 Termes et définitions . 26

4 Méthode d’essai . 27

4.1 Généralités . 27

4.2 Échantillon d’essai . 27

4.3 Processus d’essai . 28

4.3.1 Description générale de l’essai . 28

4.3.2 Préconditionnement . 29

4.3.3 Essai . 29

4.3.4 Récupération . 30

4.3.5 Mesures finales . 30

5 Rapport . 31

Annexe A (informative) Exemple des résultats d’essai de perte optique de courbure

sur fibres optiques de verre courantes . 32

Annexe B (informative) Exemple de méthode de préparation d’échantillons d’essai du

circuit optoélectrique (type de fibre optique) . 33

B.1 Généralités . 33

B.2 Procédés de fabrication des FOECB avec fibres optiques (POF, GOF) . 33

B.3 Procédés de fabrication des FOECB avec guides d’ondes optiques

polymères . 34

B.4 Caractéristiques des fibres optiques . 35

Annexe C (informative) Exemple de résultats d’essai de simulation d’assemblage par

refusion . 36

C.1 Généralités . 36

C.2 Résultats de l’essai de simulation d’assemblage par refusion pour un

FOECB à puce LED avec des GOF . 36

C.3 Résultats de l’essai de simulation d’assemblage par refusion pour un

FOECB transparent avec des GOF pour applications d’affichage . 37

C.4 Résultats de l’essai de simulation d’assemblage par refusion pour un

FOECB à base de polyimide (PI) avec des GOF . 37

C.5 Résultats de l’essai de simulation d’assemblage par refusion pour un

FOECB à base de polymère . 38

Annexe D (informative) Exemple de résultats d’essai d’endurance au choc thermique . 39

D.1 Généralités . 39

D.2 Résultats de l’essai d’endurance au choc thermique pour un FOECB avec

des GOF . 39

Annexe E (informative) Exemple de résultats d’essai de stockage humide . 40

E.1 Généralités . 40

E.2 Résultats de l’essai de stockage humide pour un FOECB avec des GOF . 40

E.3 Résultats de l’essai de stockage humide pour un FOECB avec des POF . 40

Bibliographie . 42

Figure 1 – Représentation schématique du FOECB (vue du dessus) . 27

Figure 2 – Schémas des échantillons d’essai de FOECB du type de fibre . 28

Figure 3 – Schéma des échantillons d’essai FOECB du type de fibre . 29

Figure A.1 – Montage d’essai pour perte de courbure . 32

Figure A.2 – Perte optique en fonction du diamètre de courbure . 32

Figure B.1 – Structure groupée des échantillons d’essai de FOECB formée sur une

seule feuille . 33

Figure B.2 – Fabricati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...