IEC 62951-3:2018

(Main)Semiconductor devices - Flexible and stretchable semiconductor devices - Part 3: Evaluation of thin film transistor characteristics on flexible substrates under bulging

Semiconductor devices - Flexible and stretchable semiconductor devices - Part 3: Evaluation of thin film transistor characteristics on flexible substrates under bulging

IEC 62951-3:2018(E) specifies the method for evaluating thin film transistor characteristics on flexible substrates under bulging. The thin film transistor is fabricated on flexible substrates, including polyethylene terephthalate (PET), polyimide (PI), elastomer and others. The stress is applied by applying a uniformly-distributed pressure to the flexible substrate using the equipment.

General Information

- Status

- Published

- Publication Date

- 06-Nov-2018

- Technical Committee

- TC 47 - Semiconductor devices

- Drafting Committee

- WG 6 - TC 47/WG 6

- Current Stage

- PPUB - Publication issued

- Start Date

- 07-Nov-2018

- Completion Date

- 12-Oct-2018

Overview

IEC 62951-3:2018 specifies a standardized method for evaluating thin film transistor (TFT) characteristics on flexible substrates under bulging. The standard covers test-piece preparation, measurement of dimensions, storage prior to testing, test apparatus and procedure, data analysis and reporting. It applies to TFTs fabricated on flexible substrates such as PET, polyimide (PI), elastomers and other flexible materials where a uniformly distributed pressure (bulging) is used to apply stress.

Key technical topics and requirements

- Scope and purpose: Measure electromechanical behavior of TFTs when a flexible substrate is deformed by uniform pressure (bulge test), enabling comparison and repeatable characterization.

- Test-piece preparation: TFTs must be fabricated to avoid cracks, flaws or delamination; devices should be placed in the central region of the test piece where strain is uniform.

- Dimensional measurement: Accurate measurement of substrate and thin-film thicknesses and dimensions is required because these values feed into mechanical and electrical analysis. The standard recommends that thin-film thickness be smaller than substrate thickness and that substrate material be in‑plane isotropic to achieve equibiaxial stress.

- Storage and handling: Control storage environment to prevent oxidation or surface deterioration prior to testing; damaged specimens (not present immediately after fabrication) should not be tested.

- Test apparatus: Uses a pressure chamber with a defined open window to apply uniformly distributed pressure. Multiple equipment types are referenced (e.g., absorption-type, bulging-type with heating). Lead wires must be attached to source, drain and gate pads for electrical measurement.

- Test procedure and data analysis: Perform bulge testing at specified temperatures, collect mechanical (pressure–deflection/strain) and electrical (DC characteristics) data, and extract TFT parameters (for example, mobility and subthreshold slope) as part of evaluation.

- Reporting: Test report shall include specimen dimensions, test conditions, apparatus description, measurement data and analysis results.

Practical applications and users

IEC 62951-3 is useful for:

- Semiconductor manufacturers developing flexible and stretchable electronics (flexible displays, wearable sensors).

- R&D labs and universities researching electromechanical performance of flexible TFTs.

- Qualification and test laboratories performing comparative or compliance testing of flexible devices and materials.

- Materials and process engineers assessing substrate choices (PET, PI, elastomers) and fabrication effects on device reliability.

By standardizing bulge-based electromechanical test methods, this IEC part helps ensure repeatability and comparability of TFT performance under biaxial strain conditions.

Related standards

- IEC 62047-17 - Bulge test method for measuring mechanical properties of thin films (referenced normative).

- IEC 60747-8 - Field-effect transistors (referenced for transistor terminology and electrical test methods).

Keywords: IEC 62951-3, thin film transistor, TFT, flexible substrates, bulging test, bulge test, PET, polyimide, elastomer, electromechanical properties, pressure chamber, test procedure.

Get Certified

Connect with accredited certification bodies for this standard

BSMI (Bureau of Standards, Metrology and Inspection)

Taiwan's standards and inspection authority.

Sponsored listings

Frequently Asked Questions

IEC 62951-3:2018 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Semiconductor devices - Flexible and stretchable semiconductor devices - Part 3: Evaluation of thin film transistor characteristics on flexible substrates under bulging". This standard covers: IEC 62951-3:2018(E) specifies the method for evaluating thin film transistor characteristics on flexible substrates under bulging. The thin film transistor is fabricated on flexible substrates, including polyethylene terephthalate (PET), polyimide (PI), elastomer and others. The stress is applied by applying a uniformly-distributed pressure to the flexible substrate using the equipment.

IEC 62951-3:2018(E) specifies the method for evaluating thin film transistor characteristics on flexible substrates under bulging. The thin film transistor is fabricated on flexible substrates, including polyethylene terephthalate (PET), polyimide (PI), elastomer and others. The stress is applied by applying a uniformly-distributed pressure to the flexible substrate using the equipment.

IEC 62951-3:2018 is classified under the following ICS (International Classification for Standards) categories: 17.220.20 - Measurement of electrical and magnetic quantities; 31.080.99 - Other semiconductor devices. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62951-3:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62951-3 ®

Edition 1.0 2018-11

INTERNATIONAL

STANDARD

colour

inside

Semiconductor devices – Flexible and strechable semiconductor devices –

Part 3: Evaluation of thin film transistor characteristics on flexible substrates

under bulging

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 62951-3 ®

Edition 1.0 2018-11

INTERNATIONAL

STANDARD

colour

inside

Semiconductor devices – Flexible and strechable semiconductor devices –

Part 3: Evaluation of thin film transistor characteristics on flexible substrates

under bulging

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 31.080.99 ISBN 978-2-8322-6161-3

– 2 – IEC 62951-3:2018 © IEC 2018

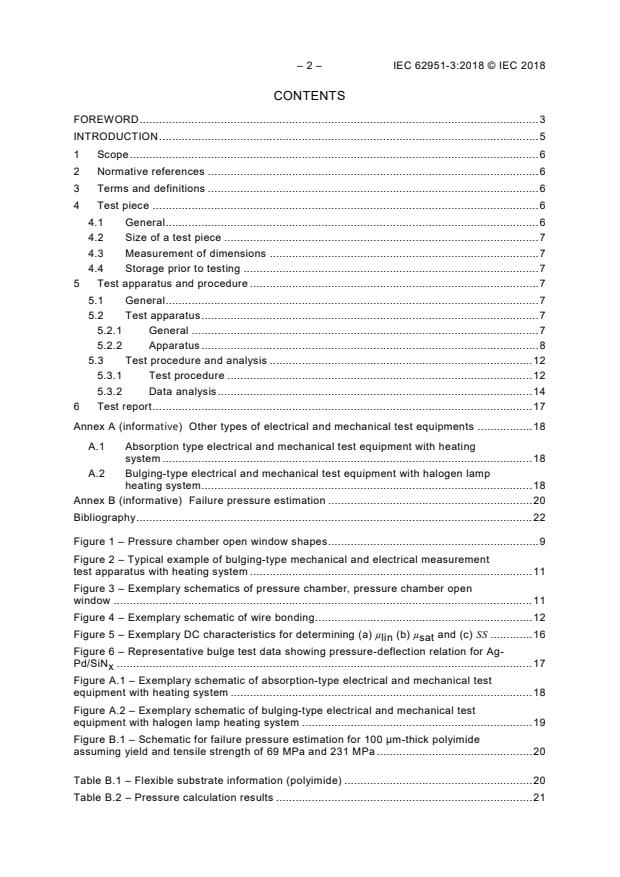

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Test piece . 6

4.1 General . 6

4.2 Size of a test piece . 7

4.3 Measurement of dimensions . 7

4.4 Storage prior to testing . 7

5 Test apparatus and procedure . 7

5.1 General . 7

5.2 Test apparatus . 7

5.2.1 General . 7

5.2.2 Apparatus . 8

5.3 Test procedure and analysis . 12

5.3.1 Test procedure . 12

5.3.2 Data analysis . 14

6 Test report . 17

Annex A (informative) Other types of electrical and mechanical test equipments . 18

A.1 Absorption type electrical and mechanical test equipment with heating

system . 18

A.2 Bulging-type electrical and mechanical test equipment with halogen lamp

heating system . 18

Annex B (informative) Failure pressure estimation . 20

Bibliography . 22

Figure 1 – Pressure chamber open window shapes . 9

Figure 2 – Typical example of bulging-type mechanical and electrical measurement

test apparatus with heating system . 11

Figure 3 – Exemplary schematics of pressure chamber, pressure chamber open

window . 11

Figure 4 – Exemplary schematic of wire bonding. 12

Figure 5 – Exemplary DC characteristics for determining (a) μ (b) μ and (c) SS . 16

lin sat

Figure 6 – Representative bulge test data showing pressure-deflection relation for Ag-

Pd/SiN . 17

x

Figure A.1 – Exemplary schematic of absorption-type electrical and mechanical test

equipment with heating system . 18

Figure A.2 – Exemplary schematic of bulging-type electrical and mechanical test

equipment with halogen lamp heating system . 19

Figure B.1 – Schematic for failure pressure estimation for 100 μm-thick polyimide

assuming yield and tensile strength of 69 MPa and 231 MPa . 20

Table B.1 – Flexible substrate information (polyimide) . 20

Table B.2 – Pressure calculation results . 21

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SEMICONDUCTOR DEVICES –

FLEXIBLE AND STRECHABLE SEMICONDUCTOR DEVICES –

Part 3: Evaluation of thin film transistor characteristics

on flexible substrates under bulging

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

International Standard IEC 62951-3 has been prepared by IEC technical committee 47:

Semiconductor devices.

The text of this International Standard is based on the following documents:

FDIS Report on voting

47/2492/FDIS 47/2511/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62951 series, published under the general title Semiconductor

devices – Flexible and stretchable semiconductor devices, can be found on the IEC website.

– 4 – IEC 62951-3:2018 © IEC 2018

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

The International Electrotechnical Commission (IEC) draws attention to the fact that it is

claimed that compliance with this document may involve the use of a patent concerning the

method and apparatus for testing flexible elements.

IEC takes no position concerning the evidence, validity and scope of this patent right.

The holder of this patent right has assured the IEC that he/she is willing to negotiate licences

under reasonable and non-discriminatory terms and conditions with applicants throughout the

world. In this respect, the statement of the holder of this patent right is registered with IEC.

Information may be obtained from:

Industry Academy Cooperation Foundation of Sejong University,

Korea Institute of Machinery and Materials,

Electronics and Telecommunications Research Institute

1002 GwangGaeTo B/D

209, Neungdong-ro, Gwangjin-gu, Seoul, 05006,

KOREA

Attention is drawn to the possibility that some of the elements of this document may be the

subject of patent rights other than those identified above. IEC shall not be held responsible for

identifying any or all such patent rights.

ISO (www.iso.org/patents) and IEC (http://patents.iec.ch) maintain on-line data bases of

patents relevant to their standards. Users are encouraged to consult the data bases for the

most up to date information concerning patents.

– 6 – IEC 62951-3:2018 © IEC 2018

SEMICONDUCTOR DEVICES –

FLEXIBLE AND STRECHABLE SEMICONDUCTOR DEVICES –

Part 3: Evaluation of thin film transistor characteristics

on flexible substrates under bulging

1 Scope

This part of IEC 62951 specifies the method for evaluating thin film transistor characteristics

on flexible substrates under bulging. The thin film transistor is fabricated on flexible

substrates, including polyethylene terephthalate (PET), polyimide (PI), elastomer and others.

The stress is applied by applying a uniformly-distributed pressure to the flexible substrate

using the equipment.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 62047-17, Semiconductor devices – Micro-electromechanical devices – Part 17: Bulge

test method for measuring mechanical properties of thin films

IEC 60747-8, Semiconductor devices – Discrete devices – Part 8: Field-effect transistors

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 62047-17, in

IEC 60747-8 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

flexible substrate

substrate with flexibility onto which a thin film transistor is fabricated

4 Test piece

4.1 General

The test piece shall be prepared using the thin film transistor fabrication process on flexible

substrates. The mechanical and electrical properties of thin film transistors may depend on

the fabrication processes. Thin film transistors shall be prepared to prevent formation of

cracks or flaws and delamination from the substrate.

4.2 Size of a test piece

As long as the size of a test piece is larger than that of the chamber open area, any test piece

will suffice. Since the change in electrical characteristics is related to strain or stress, it is

recommended that the thin film transistors be fabricated in a central region, where the strain

is uniform. To measure the electrical characteristics, attach lead wires to the source, drain

and gate pads of thin film transistors of the test piece.

4.3 Measurement of dimensions

The thickness and dimension of the thin film transistors and flexible substrate shall be

accurately measured respectively, because they are used to determine the mechanical and

electrical properties of thin film transistors. It is recommended that the thickness of thin film

transistors be smaller than that of the substrate in order to keep the deformation of the thin

film transistors uniform. The substrate material should be in-plane isotropic in order to keep

the stress and strain applied on the thin film transistor equibiaxial. There can be some

combinations of thin film transistor and substrate where it is difficult to fulfil the tolerance of

thickness measurement. In this case the average and the standard deviation of the thickness

measurement should be reported.

4.4 Storage prior to testing

In the case of thin film transistors, the storage environment may affect the electromechanical

properties of the thin film transistors. For example, oxidation on the test piece surface will

deteriorate the electrical and mechanical properties of the test piece. If there is an interval

between final preparation and testing, particular care should be taken in storing the test

pieces, and the specimens should be examined by appropriate means to ensure that the

surface has not deteriorated during the storage period. If any deterioration is observed that

was not present after the specimens were prepared, testing shall not be performed. However,

if the damage was introduced during the preparation processes, the test shall be performed.

5 Test apparatus and procedure

5.1 General

The test is performed by bulging a test piece at a specified temperature. To measure the

change in electrical characteristics along with the change in mechanical strain, carefully

select the measuring section. The section for measuring mechanical strain shall be coincident

with or scalable to that for measuring electrical characteristics. There are several types of

bulging equipment by which to measure the electromechanical property of thin film transistors.

It is not necessary that a certain type of bulging test method be preferred. As examples,

absorption-type electrical and mechanical test equipment with a heating system and

bulging-type electrical and mechanical test equipment with a halogen lamp heating system

are described in Annex A.

5.2 Test apparatus

5.2.1 General

By applying pressure to the specimen, the deformation response, i.e. the change in bulge

height as well as the electrical response of the thin film transistor on flexible substrate, shall

be measured. In general, test apparatus can be composed of pressuring device, pressure

chamber, pressure chamber open window, heating device (optional), bulging height

measurement unit and electrical measurement units as shown in Figure 2. Exemplary

schematics of pressure chamber, pressure chamber open window and wire bonding are given

in Figure 3 and Figure 4.

– 8 – IEC 62951-3:2018 © IEC 2018

5.2.2 Apparatus

5.2.2.1 Pressuring device

The pressuring device should be equipped to apply a specified continuous pressure with a

controlled rate or a certain level of pressure to the pressure chamber open window to be

stressed. Pressure media can be oil, gas and distilled water. In general, the device can be

composed of a pressure sensor and pressure controller. The controller should show an

accuracy of 1 % in the full test scale.

NOTE At the pressures encountered in the tests, gas is over a million times more compressible than typical

liquids such as oil and distilled water.

5.2.2.2 Pressure chamber

The pressure chamber should be as compact as possible, to reduce the compliance of the

test system. The volume, which has to be pressurized and which potentially contributes to the

compliance, would be minimized.

In case liquid is used to pressurize the test system, the system shall contain as little air as

possible because even a small air bubble trapped inside the test system can dominate the

system’s compliance. It is recommended that the system including the chamber be designed

so that there are no places where air bubbles can hide and that the liquid can be refilled

easily. It is necessary that special care be taken not to introduce air bubbles when the test

piece is mounted and removed.

The material of the chamber should be chosen considering the pressure media for the test,

testing pressure range, measurement temperature range and interference with the electrical

measurements.

In case liquid is used to pressurize the test system, it is recommended that the testing

apparatus be made out of transparent plexiglass (polymethyl methacrylate) in order to see air

bubbles and then to minimize them trapped within the chamber.

The pressure chamber is connected to the pressuring device and thus allows a test piece to

be deformed with fine control. The test piece is mounted on the pressure chamber by

mechanical clamping or the epoxy gluing method, etc.

NOTE In the case of a capacitance measurement type, the pressure chamber has an electrode and a mechanical

spacer. The electrode, which measures the height change of a test specimen due to deformation, is made of Cu-

coated polychlorinated biphenyl (PCB). A mechanical spacer that is located between the specimen and the

electrode controls a sensitivity of capacitance change by adjusting the thickness of the spacer.

The pressure inside the chamber shall be monitored and measured through a suitable

pressure sensor, which can be installed directly in the chamber or connected though the tube

transporting the pressure without loss of the pressure to be measured.

It is recommended that exposition of the area of the pressure sensor to the pressure media be

minimized and that the area have no indentation or internal cavities tr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...