IEC 61189-5-301:2021

(Main)Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 5-301: General test methods for materials and assemblies - Soldering paste using fine solder particles

Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 5-301: General test methods for materials and assemblies - Soldering paste using fine solder particles

IEC 61189-5-301:2021 specifies methods for testing the characteristics of soldering paste using fine solder particles (hereinafter referred to as solder paste).

This document is applicable to the solder paste using fine solder particle such as type 6, type 7 specified in IEC 61190-1-2 or finer particle sizes.

This type of solder paste is used for connecting wiring and components in high-density printed circuit boards which are used in electronic or communication equipment and such, equipping fine wiring (e.g., minimum conductor widths and minimum conductor gaps of 60 µm or less).

Test methods for the characteristics of solder paste in this document are considering the effect of surface activation force due to the fine sized solder particles which could affect the test result by existing test methods.

Méthodes d’essai pour les matériaux électriques, les cartes imprimées et autres structures d’interconnexion et ensembles - Partie 5-301: Méthodes d’essai générales pour les matériaux et les assemblages - Pâte à braser à fines particules de brasage

L'IEC 61189-5-301:2021 spécifie les méthodes pour soumettre à essai les caractéristiques de la pâte à braser à fines particules de brasage (ci-après désignée pâte à braser).

Le présent document s’applique à la pâte à braser à fines particules de brasage, telle que le type 6 et le type 7 spécifiés dans l’IEC 61190-1-2, ou à une pâte à braser à particules plus fines.

Ce type de pâte à braser est utilisé pour connecter des câblages et composants sur des cartes imprimées à haute densité employées dans les équipements électroniques ou de communication ou tout appareillage similaire équipé de câblage fin (par exemple des largeurs minimales de conducteurs et des espaces minimaux entre conducteurs de 60 µm ou moins).

Les méthodes d’essai pour les caractéristiques de la pâte à braser présentées dans le présent document tiennent compte de la force d’activation de la surface due à la finesse des particules de brasage qui peut affecter les résultats d’essais effectués selon les méthodes existantes.

General Information

- Status

- Published

- Publication Date

- 16-Mar-2021

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 3 - TC 91/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 17-Mar-2021

- Completion Date

- 13-Apr-2021

Overview

IEC 61189-5-301:2021 is an international standard developed by the International Electrotechnical Commission (IEC) that specifies general test methods for soldering paste using fine solder particles. This standard focuses on the characterization and quality assessment of solder paste types 6, 7, and finer, as defined in IEC 61190-1-2, primarily used for high-density printed circuit boards (PCBs). Such PCBs are common in electronic and communication equipment requiring fine wiring connections with minimum conductor widths and gaps of 60 µm or less.

The document addresses unique challenges related to solder paste with fine particles-particularly the effects of surface activation forces impacting test outcomes in traditional procedures. It provides standardized methodologies to ensure reliable evaluation, enhancing solder paste quality control and promoting consistent assembly performance.

Key Topics

Particle Size Distribution Measurement

The standard defines multiple techniques for measuring solder powder particle size, including scanning electron microscopy, laser diffraction, and digital microscopy. These procedures ensure precise evaluation of the fine solder particles’ distribution, critical for predicting solder paste behavior during assembly.Viscosity Testing

Viscosity is measured using two main spiral pump methods: the Trace spiral pump method and the Spiral pump method compliant with IEC 61189-5-3. Accurate viscosity measurements are crucial for assessing solder paste printability and rheological performance on fine-pitch substrates.Printability Test

The standard includes printability tests using metal masks designed for fine solder particles. These tests evaluate the solder paste’s ability to deposit accurately and uniformly on PCBs, reflecting the paste's suitability for high-density assembly processes.Slump Test

Slump testing assesses the solder paste's stability and tendency to spread or slump after printing and before reflow, ensuring dimensional integrity within fine conductor gaps.Reflow Test

Reflow tests simulate soldering temperature profiles to evaluate melting behavior and solder joint formation consistency in fine-pitch PCB assemblies.High Temperature Observation Test

This test observes the solder paste characteristics, such as melting and wetting at elevated temperatures, providing insights into paste performance under thermal stress.Test Reporting and Evaluation

Annexes provide sample test reports and evaluation criteria to guide users in documenting and interpreting test results consistently.

Applications

IEC 61189-5-301:2021 is essential for manufacturers, quality engineers, and researchers involved with:

- Printed Circuit Board (PCB) assembly requiring fine solder paste for high-density interconnects

- Electronic and communication equipment production where miniaturization demands precise solder paste handling

- Solder paste development and quality control to ensure consistent electrical and mechanical connections

- Process optimization and failure analysis related to solder paste performance in advanced electronic assemblies

By applying these test methods, organizations can reduce manufacturing defects, improve yield rates, and maintain compliance with international standards for advanced electronics production.

Related Standards

IEC 61190-1-2

Defines solder paste types by particle size and composition, forming the basis for material classification.IEC 61189-5-3

Specifies solder paste viscosity assessment methods that are referenced within the spiral pump viscosity tests.IPC Standards for Solder Paste

Complementary industry standards focusing on solder paste properties and application techniques for electronic assembly.ISO Standards for PCB Assembly

Related environmental and performance standards that intersect with soldering process control.

Keywords: IEC 61189-5-301, soldering paste, fine solder particles, solder paste test methods, PCB assembly, solder paste viscosity, printability test, solder paste slump, reflow test, high-density printed circuit boards, electronic manufacturing standards, IEC standards for solder paste

IEC 61189-5-301:2021 - Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 5-301: General test methods for materials and assemblies - Soldering paste using fine solder particles

Frequently Asked Questions

IEC 61189-5-301:2021 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 5-301: General test methods for materials and assemblies - Soldering paste using fine solder particles". This standard covers: IEC 61189-5-301:2021 specifies methods for testing the characteristics of soldering paste using fine solder particles (hereinafter referred to as solder paste). This document is applicable to the solder paste using fine solder particle such as type 6, type 7 specified in IEC 61190-1-2 or finer particle sizes. This type of solder paste is used for connecting wiring and components in high-density printed circuit boards which are used in electronic or communication equipment and such, equipping fine wiring (e.g., minimum conductor widths and minimum conductor gaps of 60 µm or less). Test methods for the characteristics of solder paste in this document are considering the effect of surface activation force due to the fine sized solder particles which could affect the test result by existing test methods.

IEC 61189-5-301:2021 specifies methods for testing the characteristics of soldering paste using fine solder particles (hereinafter referred to as solder paste). This document is applicable to the solder paste using fine solder particle such as type 6, type 7 specified in IEC 61190-1-2 or finer particle sizes. This type of solder paste is used for connecting wiring and components in high-density printed circuit boards which are used in electronic or communication equipment and such, equipping fine wiring (e.g., minimum conductor widths and minimum conductor gaps of 60 µm or less). Test methods for the characteristics of solder paste in this document are considering the effect of surface activation force due to the fine sized solder particles which could affect the test result by existing test methods.

IEC 61189-5-301:2021 is classified under the following ICS (International Classification for Standards) categories: 31.180 - Printed circuits and boards. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61189-5-301:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61189-5-301 ®

Edition 1.0 2021-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Test methods for electrical materials, printed boards and other interconnection

structures and assemblies –

Part 5-301: General test methods for materials and assemblies – Soldering paste

using fine solder particles

Méthodes d’essai pour les matériaux électriques, les cartes imprimées et autres

structures d’interconnexion et ensembles –

Partie 5-301: Méthodes d’essai générales pour les matériaux et les

assemblages – Pâte à braser à fines particules de brasage

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC online collection - oc.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur adapté à vos besoins.

les projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au

Restez informé sur les nouvelles publications IEC. Just

monde, avec plus de 22 000 articles terminologiques en

Published détaille les nouvelles publications parues.

anglais et en français, ainsi que les termes équivalents dans

Disponible en ligne et une fois par mois par email.

16 langues additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 61189-5-301 ®

Edition 1.0 2021-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Test methods for electrical materials, printed boards and other interconnection

structures and assemblies –

Part 5-301: General test methods for materials and assemblies – Soldering

paste using fine solder particles

Méthodes d’essai pour les matériaux électriques, les cartes imprimées et autres

structures d’interconnexion et ensembles –

Partie 5-301: Méthodes d’essai générales pour les matériaux et les

assemblages – Pâte à braser à fines particules de brasage

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.180 ISBN 978-2-8322-9534-2

– 2 – IEC 61189-5-301:2021 © IEC 2021

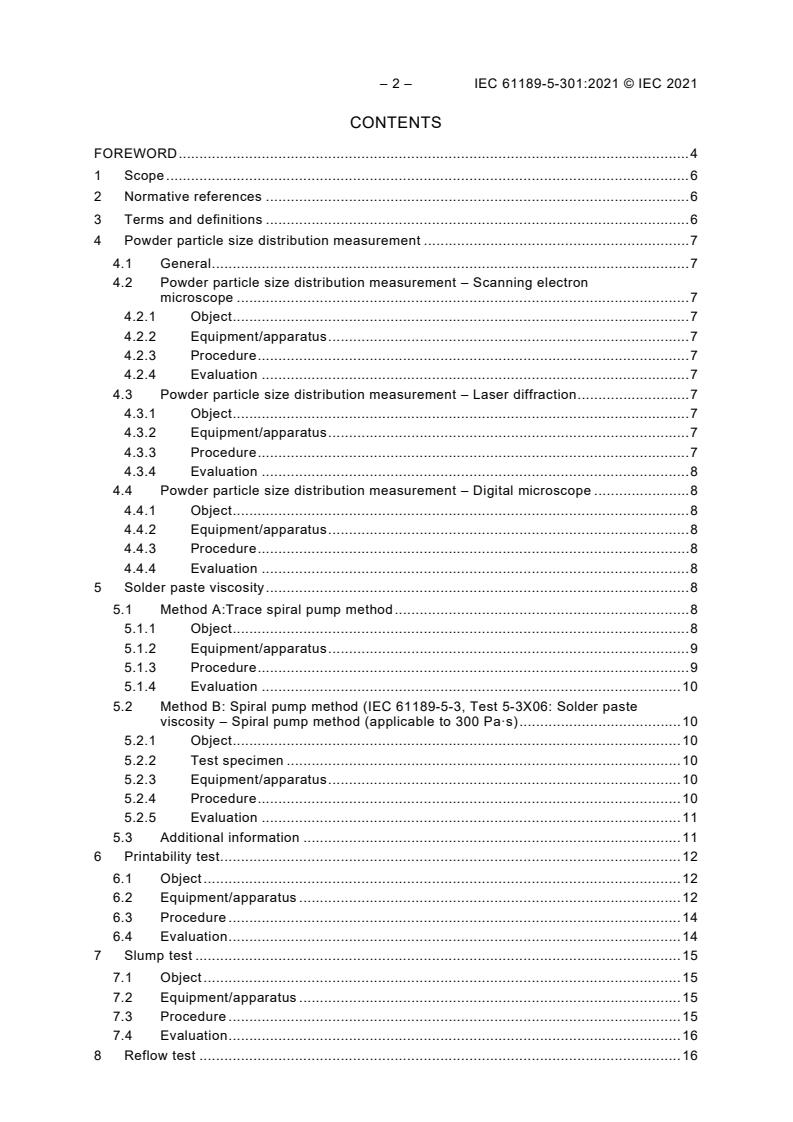

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Powder particle size distribution measurement . 7

4.1 General . 7

4.2 Powder particle size distribution measurement – Scanning electron

microscope . 7

4.2.1 Object . 7

4.2.2 Equipment/apparatus . 7

4.2.3 Procedure . 7

4.2.4 Evaluation . 7

4.3 Powder particle size distribution measurement – Laser diffraction . 7

4.3.1 Object . 7

4.3.2 Equipment/apparatus . 7

4.3.3 Procedure . 7

4.3.4 Evaluation . 8

4.4 Powder particle size distribution measurement – Digital microscope . 8

4.4.1 Object . 8

4.4.2 Equipment/apparatus . 8

4.4.3 Procedure . 8

4.4.4 Evaluation . 8

5 Solder paste viscosity . 8

5.1 Method A:Trace spiral pump method . 8

5.1.1 Object . 8

5.1.2 Equipment/apparatus . 9

5.1.3 Procedure . 9

5.1.4 Evaluation . 10

5.2 Method B: Spiral pump method (IEC 61189-5-3, Test 5-3X06: Solder paste

viscosity – Spiral pump method (applicable to 300 Pa·s) . 10

5.2.1 Object . 10

5.2.2 Test specimen . 10

5.2.3 Equipment/apparatus . 10

5.2.4 Procedure . 10

5.2.5 Evaluation . 11

5.3 Additional information . 11

6 Printability test. 12

6.1 Object . 12

6.2 Equipment/apparatus . 12

6.3 Procedure . 14

6.4 Evaluation . 14

7 Slump test . 15

7.1 Object . 15

7.2 Equipment/apparatus . 15

7.3 Procedure . 15

7.4 Evaluation . 16

8 Reflow test . 16

8.1 Object . 16

8.2 Equipment/apparatus . 16

8.3 Procedure . 16

8.4 Evaluation . 17

9 High temperature observation test . 18

9.1 Object . 18

9.2 Equipment/apparatus . 18

9.3 Procedure . 20

9.4 Evaluation . 21

Annex A (informative) Example of the test report on powder particle size distribution

measurement . 22

Annex B (informative) Example of the test report on viscosity characteristics . 23

Annex C (informative) Example of the test report on printability test . 24

C.1 Test report form . 24

C.2 Test report entry example . 25

Annex D (informative) Example of the test report on slump test . 26

Annex E (informative) Example of the test report on reflow test . 27

E.1 Test report form . 27

E.2 Test report entry example . 28

Annex F (informative) Example of the test report on high temperature observation test . 29

F.1 Test report form . 29

F.2 Melting property report form . 30

F.3 Entry example for melting property. 30

Annex G (informative) Example pictures of the printing and reflow test . 31

G.1 Printing test . 31

G.2 Reflow test . 32

Figure 1 – Metal mask for printability test . 13

Figure 2 – Test board with slits for splitting . 14

Figure 3 – Temperature profile for slump test . 16

Figure 4 – Temperature profile for reflow test. 17

Figure 5 – Metal mask for high temperature observation test . 19

Figure 6 – Example structure of high temperature observation apparatus . 20

Table 1 – QC procedure for Trace spiral-type viscometer . 9

Table 2 – QC procedure for spiral-type viscometer according to Test 5-3X06

in IEC 61189-5-3 . 11

Table 3 – Evaluation index for printability test . 15

Table 4 – Evaluation index for reflow test . 18

– 4 – IEC 61189-5-301:2021 © IEC 2021

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

TEST METHODS FOR ELECTRICAL MATERIALS, PRINTED BOARDS AND

OTHER INTERCONNECTION STRUCTURES AND ASSEMBLIES –

Part 5-301: General test methods for materials and assemblies –

Soldering paste using fine solder particles

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 61189-5-301 has been prepared by IEC technical committee TC 91: Electronics assembly

technology. It is an International Standard.

The text of this International Standard is based on the following documents:

Draft Report on voting

91/1655/CDV 91/1698/RVC

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts in the IEC 61189 series, published under the general title Test methods for

electrical materials, printed boards and other interconnection structures and assemblies, can

be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

– 6 – IEC 61189-5-301:2021 © IEC 2021

TEST METHODS FOR ELECTRICAL MATERIALS, PRINTED BOARDS AND

OTHER INTERCONNECTION STRUCTURES AND ASSEMBLIES –

Part 5-301: General test methods for materials and assemblies –

Soldering paste using fine solder particles

1 Scope

This part of IEC 61189 specifies methods for testing the characteristics of soldering paste using

fine solder particles (hereinafter referred to as solder paste).

This document is applicable to the solder paste using fine solder particle such as type 6, type 7

specified in IEC 61190-1-2 or finer particle sizes.

This type of solder paste is used for connecting wiring and components in high-density printed

circuit boards which are used in electronic or communication equipment and such, equipping

fine wiring (e.g., minimum conductor widths and minimum conductor gaps of 60 µm or less).

Test methods for the characteristics of solder paste in this document are considering the effect

of surface activation force due to the fine sized solder particles which could affect the test result

by existing test methods.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 61189-5-3:2015, Test methods for electrical materials, printed boards and other

interconnection structures and assemblies – Part 5-3: General test methods for materials and

assemblies: Soldering paste for printed board assemblies

IEC 61190-1-2:2014, Attachment materials for electronic assembly – Part 1-2: Requirements

for soldering pastes for high-quality interconnects in electronics assembly

ISO 857-2, Welding and allied processes – Vocabulary – Part 2: Soldering and brazing

processes and related terms

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 857-2 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

digital microscope

microscope displaying an enlarged image on a screen of a personal computer or a monitor

4 Powder particle size distribution measurement

4.1 General

This measurement is for determining whether or not the solder particle used in the solder paste

complies with the relevant powder particle size type. Solder particle specimen shall be obtained

from the supplier or extracted from the solder paste according to 4.14.4 and 4.14.5 of

IEC 61189-5-3:2015.

4.2 Powder particle size distribution measurement – Scanning electron microscope

4.2.1 Object

The powder particle size distribution of the solder particle is measured using scanning electron

microscope (hereinafter, referred to as SEM).

4.2.2 Equipment/apparatus

SEM (Scanning Electron Microscope): 1 000 times or more magnification with image storage

device.

4.2.3 Procedure

At least 100 solder particles shall be observed using SEM. Observation may be done either

directly or using the acquired SEM image. The solder particle size shall be determined by

assumption that the solder particles are spherical. The solder particle shall be sorted out

according to the assigned classification type specified in Table 2 of IEC 61190-1-2:2014. The

number of sorted solder particle shall be counted and converted into masses.

4.2.4 Evaluation

Express the masses of the particle above, within, and below the nominal size range as

percentages of the mass of the original specimen. Enter the data in the test report. Annex A

shows an example of the test report.

4.3 Powder particle size distribution measurement – Laser diffraction

4.3.1 Object

The powder particle size distribution of the solder powder is measured using laser diffraction

type particle size distribution measuring apparatus.

4.3.2 Equipment/apparatus

a) laser diffraction type particle size distribution measuring apparatus;

b) balance: 0,01 g sensitivity;

c) spatula.

4.3.3 Procedure

Measurement shall be done in accordance with the instructions of the measuring apparatus.

Measure the blank sample to ensure the measuring apparatus is clean enough for measuring.

0,5 g to 10 g of solder powder shall be measured for the particle size distribution.

– 8 – IEC 61189-5-301:2021 © IEC 2021

4.3.4 Evaluation

Express the masses of the particle above, within, and below the nominal size range as

percentages of the mass of the original specimen. Enter the data in the test report. Annex A

shows an example of the test report.

4.4 Powder particle size distribution measurement – Digital microscope

4.4.1 Object

The powder particle size distribution of the solder powder is measured using a digital

microscope capable of three-dimensional (3D) observation by 3D construction of an acquired

image.

4.4.2 Equipment/apparatus

a) Glass slide

b) 3D digital microscope:

1) 1 000 times or more magnification;

2) equipping telecentric optical system and transmissive illumination which enable high-

precision measurement;

3) equipping an image storage device which is capable of 3D construction from the stored

images.

4.4.3 Procedure

Measurement shall be done in accordance with the instructions of the measuring apparatus. At

least 100 solder particles shall be placed on a glass slide, then observed using a digital

microscope. 3D image shall be stored.

The powder particle size shall be determined by assumption that the solder powders are

spherical. The powders shall be sorted out according to the assigned classification type

specified in Table 2 of IEC 61190-1-2:2014. The number of sorted particles shall be counted

and converted into masses.

4.4.4 Evaluation

Express the masses of the powder above, within, and below the nominal size range as

percentages of the mass of the original specimen. Enter the data in the test report. Annex A

shows an example of the test report form.

5 Solder paste viscosity

5.1 Method A:Trace spiral pump method

5.1.1 Object

This test specifies a standard procedure for determining viscosity-shear rate characteristics and

thixotropy (thixotropic index), which is also close relating to the printability of the solder paste.

Trace spiral viscometer is a coaxial-cylinder rotational type viscometer with a small sample

receptance, for example 0,2 cm capacity. Outer barrel of the viscometer is rotated to draw up

the solder paste specimen from the receptacle. After all of the solder paste is drawn up, the

outer cylinder is rotated in the opposite direction to return the solder paste into the receptacle.

This action is repeated, with the solder paste ascending and descending from the receptacle.

This subjects the solder paste to shear stresses, which is detected as a torque on the inner

barrel during the ascending period, and the viscosity characteristic being obtained from the

rotational speed of the cylinder. In addition, the thixotropic index is calculated from the viscosity

−1

characteristics. Shear rate is defined as D = v/y(s ) using rotational speed of the outer cylinder

(v) and the gap between inner barrel and outer cylinder (y).

The test may be performed in accordance with Test 5-3X06 in IEC 61189-5-3:2014 as test

method B.

5.1.2 Equipment/apparatus

a) spatula;

b) viscometer: trace spiral-type viscometer;

c) constant temperature chamber: either with the viscometer body built-in or external;

d) metal receptacle: 0,2 cm capacity for trace spiral-type viscometer;

e) recorder: personal computer, etc.;

f) solvent: propan-2-ol (reagent grade), ethyl alcohol (reagent grade), etc.

5.1.3 Procedure

See Table 1 for the test procedure.

a) If necessary, leave the solder paste at room temperature.

b) Stir with a spatula to homogenize the solder paste.

c) Put the solder paste into a metal receptacle.

d) Set the metal receptacle containing the solder paste into the micro spiral viscometer.

e) Rotate the outer cylinder to fill the solder paste between the inner barrel and the outer

cylinder; set the temperature of the constant temperature chamber to 25 °C±0.5 °C while the

outer cylinder is stationary and wait for approximately 10 minutes until the temperature of

the constant temperature chamber is stabilized.

f) After the temperature of the constant temperature chamber is stabilized, measure viscosity

at the rotational speed of 10 r /min ± 0,5 r /min for approximately 2 minutes.

g) Take out the metal receptacle, the inner barrel and the outer cylinder; clean them with

suitable reagent grade solvent such as propan-2-ol or ethyl alcohol; put a new solder paste

into the metal receptacle; set them again into a trace spiral viscometer.

h) Rotating the outer cylinder again; once the solder paste has filled the area between the

inner cylinder and the outer cylinder, set the temperature of the constant temperature

chamber to 25 °C ± 0,5 °C while the outer cylinder is stationary; wait for approximately

10 min until the temperature of the constant temperature chamber stabilizes.

i) Measure viscosity at the rotational speed of 5 r/min ± 0,25 r/min for approximately 4 min,

followed by 20 r/min ± 1,0 r/min for approximately 1 min; viscosity values at

5 r/min ± 0,25 r/min and 20 r /min ± 1,0 r/min shall be read.

Table 1 – QC procedure for Trace spiral-type viscometer

Speed Time

(r/min) (min)

10 2

Remove soldering paste and clean the inner barrel and

the outer cylinder. Then, fill fresh soldering paste into

a metal receptacle

5 4

20 1

– 10 – IEC 61189-5-301:2021 © IEC 2021

The thixotropy index (TI) is obtained from the following formula.

log(/ηη )

TI=

log(DD/ )

2 1

where

η is the viscosity (Pa·s) at shear rate D ;

1 1

η is the viscosity (Pa·s) at shear rate D ;

2 2

−1 −1

D is the shear rate 1 (s ), D = 3 (s ) at 5 r/min;

1 1

−1 −1

D is the shear rate 2 (s ), D = 12 (s ) at 20 r/min.

2 2

5.1.4 Evaluation

Annex B shows an example of the test report form. Enter the viscosity measured in 5.1.2 f) and

thixotropy index obtained in 5.1.3 i).

5.2 Method B: Spiral pump method (IEC 61189-5-3, Test 5-3X06: Solder paste

viscosity – Spiral pump method (applicable to 300 Pa·s)

5.2.1 Object

This test specifies a standard procedure for determining the viscosity of solder paste applicable

to 300 Pa·s.

5.2.2 Test specimen

The paste to be tested shall be stabilized at (25 ± 1) °C for a minimum of 24 h prior to testing.

The paste volume shall be sufficient to fill the viscometer receptacle to about 60 % of its depth.

5.2.3 Equipment/apparatus

The equipment used shall be a spiral pump viscometer. Set the instrument rotational speed for

10 r/min. Other equipment may be used provided the results can be empirically correlated as

mutually agreed upon. Additional shear rates may be specified by the user or the supplier.

5.2.4 Procedure

5.2.4.1 Preparation

a) Open the container(s), remove any internal cover, scrape off paste adhering to the lids or

internal cover(s) and the container wall(s) and add this to the paste in the container(s).

b) Using a spatula, stir the paste gently for 1 to 2 min to homogenize it, taking care to avoid

the introduction of air.

c) Transfer sufficient paste to the viscometer receptacle to fill this to about 60 % of its depth.

Place the receptacle in the temperature-controlled unit on the viscometer and allow it to

stabilize at (25 ± 0,25) °C for 15 min.

5.2.4.2 Test

See Table 2 for the test procedure.

a) Immerse the instrument sensor into the sample in accordance with the equipment

manufacturer's instructions. The solder paste shall not cover the pump outlet.

b) Turn on the chart recorder and set the instrument to run at one specific shear rate. Take a

reading when the output has been stable for at least 1 min.

Table 2 – QC procedure for spiral-type viscometer according to Test 5-3X06

in IEC 61189-5-3

Speed Time

(r/min) (min)

10 3

3 6

4 3

5 3

10 3

20 1

30 1

10 1

The thixotropy index (TI) is obtained from the following formula:

log(/ηη )

TI=

log(DD/ )

2 1

where

η is the viscosity (Pa·s) at shear rate D ;

1 1

η is the viscosity (Pa·s) at shear rate D ;

2 2

−1 −1

D is the shear rate 1 (s ), D =1.8 (s ) at 3 r/min;

1 1

−1 −1

D is the shear rate 2 (s ), D =18 (s ) at 30 r/min.

2 2

5.2.5 Evaluation

Record the data into the test report form.

5.3 Additional information

Test equipment sources: The equipment sources described below represent those currently

known to the industry. Users of this test method are urged to submit additional source names

as they become available, so that this list can be kept as up-to-date as possible.

Spiral pump viscometer equipment :

Brookfield Engineering Laboratories, Inc., 240 Cushing Street, Stoughton, MA 02072

(617) 344-4310;

Malcom Instruments Corp., 26226 Industrial Blvd., Hayward, CA 94545, (510) 293-0580,

(510) 293-0584.

___________

This information is given for the convenience of users of this document and does not constitute an endorsement

by IEC of the product named. Equivalent products may be used if they can be shown to lead to the same

results.

– 12 – IEC 61189-5-301:2021 © IEC 2021

6 Printability test

6.1 Object

This test specifies a standard procedure for determining printability of the solder paste.

The solder paste under evaluation is printed onto the copper-clad laminate board (hereinafter,

referred to as test board) using the printing pattern shown in Figure 1 for evaluating the

printability. The shape and dimensions of the printed solder paste are evaluated, at the

beginning of printing and at the time of continuous printing, and their stability. The planar shape

and thickness (distribution) of the printed solder pastes and their stability during continuous

printing are measured.

The printed solder paste on the board may be used for tests 7 through 9.

6.2 Equipment/apparatus

a) Metal mask:

1) (30 ± 5) μm thickness, made of additive nickel plate;

2) the hole opening pattern is as shown in Figure 1, straight holes without taper;

3) outer frame dimensions should be designed to meet the printing machine, for example,

650 mm × 550 mm for automatic printing machine.

b) Test board:

1) copper-clad laminate board, preferred dimensions are 92 mm (width) × 80 mm

(length) × 0,8 mm (thickness); copper foil thickness of approximately 12 µm; other

dimensions or copper foil thickness may be used in accordance with printing machine

requirement;

2) if necessary, alignment mark may be indicated;

3) if the printing for printability test and for the high-temperature observing test are

performed simultaneously then a test board having the arrangement shown in Figure 2

with split grooves for dividing substrates may be used.

c) Printing machine: capable of automatic printing with alignment mechanism;

d) Spatula;

e) 3D microscopes: 200 times or more magnification with image storage device;

f) Laser-type displacement gauges and non-contact shape-measuring devices: 0,1 µm or finer

resolution.

Key

G Pattern gap

Ø Opening hole diameter

a) Details of the metal mask opening (130 µm opening hole diameter – 60 µm gap)

Key

G Pattern gap in µm

Ø Opening hole diameter in µm

b) Metal mask opening array

Dimensions in millimetres

Key

A Example of 4 metal mask array (Figure 1 b)) arrangements, 90º rotation each other.

B Example of arranging 4 patterns for high temperature observation test (Refer to Figure 5).

c) Example of metal mask arrangement for printability test

Figure 1 – Metal mask for printability test

– 14 – IEC 61189-5-301:2021 © IEC 2021

Dimensions in millimetres

Key

C Slit for splitting

Figure 2 – Test board with slits for splitting

6.3 Procedure

a) If necessary, leave the solder paste at room temperature: (20 ± 5) °C.

b) Stir with a spatula to homogenize the solder paste.

c) The solder paste is put on a metal mask placed on a printing machine, and the solder paste

is printed on a test board using a squeegee. Printing temperature shall be controlled

between (20 ± 5) °C.

d) The planar shape (dimensions) of the printed solder paste shall be measured using captured

image by a 3D microscope. The thickness of the solder paste shall be measured using a

laser displacement meter or a non-contact shape measuring device.

6.4 Evaluation

The printed solder paste of the first and the tenth printing during continuous printing shall be

evaluated. Evaluation items are the presence or absence of bleeding, blurring and bridging

comparing the difference between the metal mask hole dimension and the shape of the printed

solder paste. Table 3 shows the evaluation index.

Annex C shows an example of the test report. Annex G (see Clause G.1) shows the example

pictures corresponding to Table 3.

Table 3 – Evaluation index for printability test

Evaluation index for

Description Image

printability

Printing defects such as bleeding,

blurring, bridging, and chipping are not

existing.

A Good

The printed solder paste does not greatly

differ from the shape and size of the

holes in the metal mask.

Solder paste spreads thinly around the

N Bleeding

bottom of adjacent printing units.

Printed solder paste forms icicle like

T Icicle

shape.

Missing or short Solder paste is partially missing or short

L

of solder amount of solder amount.

B Bridge Connecting adjacent printing units

Printed solder paste is thinner than the

K Grazing thickness of the metal mask (including

unprinted).

7 Slump test

7.1 Object

This test specifies a standard procedure for evaluating the degree of solder paste slump under

the preheating conditions in the reflow soldering.

7.2 Equipment/apparatus

a) metal mask: according to 6.2 a);

b) test board: according to 6.2 b);

c) printing machine: according to 6.2 c);

d) reflow furnace: capable to control the temperature profile specified in Figure 3; in the furnace,

nitrogen atmosphere controlling the oxygen concentration of 200 ppm or less;

e) magnifying equipment: microscope, etc.

7.3 Procedure

a) Printing shall be done according to 6.3 a) through c).

b) The printed test board shall be subjected to the temperature profile specified in Figure 3

using reflow furnace, under the atmospheric oxygen concentration of 200 ppm or less;

heating starts at room temperature; heating temperature shall be equal to or less than the

solidus temperature of the solder alloy used in the solder paste (ex. 130 °C to 180 °C for

Sn63Pb37 or Sn96,5Ag3Cu,5 solder alloy); ramp down rate for cooling is not specified.

c) After cooling, the solder paste on the test board shall be subjected to visual inspection using

magnifying equipment such as a microscope; for each printed solder paste diameter, identify

the minimum gap where no bridge occurs.

– 16 – IEC 61189-5-301:2021 © IEC 2021

Key

K Ramp up rate: 2 K/s to 3 K/s

a

T Heating temperature

a

t Heating duration: at least 120 s

a

Figure 3 – Temperature profile for slump test

7.4 Evaluation

Annex D shows an example of the test report.

8 Reflow test

8.1 Object

This test specifies a standard procedure for evaluating the reflow properties of the solder paste

under the reflow soldering conditions.

8.2 Equipment/apparatus

a) metal mask: according to 6.2 a);

b) test board: according to 6.2 b);

c) printing machine: according to 6.2 c);

d) reflow furnace: capable to control the temperature profile specified in Figure 4; in the furnace,

nitrogen atmosphere controlling the oxygen concentration of 200 ppm or less;

e) magnifying equipment: microscope, etc.

8.3 Procedure

a) Printing shall be done according to 6.3 a) through c).

b) Reflow shall be done within 8 h after printing.

c) The printed test board shall be subjected to the temperature profile specified in Figure 4

using reflow furnace, under the atmospheric oxygen concentration of 200 ppm or less;

heating starts at room temperature (15 °C to 35 °C); ramp down rate for cooling is not

specified.

Key

K Ramp up rate to pre-heating: 2 K/s to 3 K/s

a

T Pre-heating temperature range: 130 °C to 180 °C, not exceed the solidus temperature of the solder alloy.

p

t Pre-heating duration: 120 s to 200 s

p

K Ramp up rate to heating: 1 K/s to 2 K/s

a

T Heating temperature: (240 ± 3) °C for Sn96,5Ag3Cu,5 solder alloy, or (30 ± 3) °C above the liquidus temperature

b

of the solder alloy.

t Heating duration: 10 s or less

b

Figure 4 – Temperature profile for reflow test

d) After cooling, the solder paste on the test board shall be subjected to visual inspection using

magnifying equipment such as a microscope.

8.4 Evaluation

Table 4 shows the valuation index. Annex E shows an example of the test report.

Annex G (see Clause G.2) shows the example pictures corresponding to Table 4.

– 18 – IEC 61189-5-301:2021 © IEC 2021

Table 4 – Evaluation index for reflow test

Evaluation index

Description Reflow image

for reflow

No un-merged and de-wetting

are existing. The printed

1 No defect

solder paste wets over the

printed area.

Connecting adjacent reflowed

Bridge

2B units

Un-merged solder particles

Solder ball

2S around a big merged solder

No un-melted solder exists.

3 De-wetting But the de-wetting area

spreads.

Although un-melted solder

Partially particles exist, most of the

un-melted solder particles melted and

integrated.

Almost all the solder particles

5 Un-melted

are un-melted.

9 Hi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...