IEC 62895:2017

(Main)High voltage direct current (HVDC) power transmission - Cables with extruded insulation and their accessories for rated voltages up to 320 kV for land applications - Test methods and requirements

High voltage direct current (HVDC) power transmission - Cables with extruded insulation and their accessories for rated voltages up to 320 kV for land applications - Test methods and requirements

IEC 62895:2017 specifies test methods and requirements for transmission power cable systems, cables with extruded insulation and their accessories for fixed land installations, for rated voltages up to and including 320 kV.

Within the scope of this standard “extruded insulation” means insulation manufactured by extrusion of either thermoplastic (e.g. polyethylene) or crosslinked (e.g. crosslinked polyethylene, ethylene propylene rubber, etc.) material. The insulation material may be either unfilled or filled (e.g. with mineral or carbon).

The requirements apply to single-core cables in combination with their accessories, outdoor and terminations for gas insulated systems, joints, and asymmetric joints for usual conditions of installation and operation, but not to special cables and their accessories, such as submarine cables, for which modifications to the standard tests may be necessary or special test conditions may need to be devised.

Câbles haute tension en courant continu (CCHT) - Câbles d'énergie à isolation extrudée et leurs accessoires pour des tensions assignées jusqu'à 320 kV pour les applications terrestres - Méthodes et exigences d'essai

L'IEC 62895:2017 spécifie les méthodes et exigences d’essai applicables aux systèmes de câbles d’énergie, comprenant les câbles à isolation extrudée et leurs accessoires pour installations terrestres fixes, pour des tensions assignées jusqu’à 320 kV.

Dans le cadre du domaine d’application de la présente norme, le terme «extrudé» signifie une enveloppe réalisée par extrusion de matières thermoplastiques (par exemple, polyéthylène) ou de matières réticulées (par exemple, polyéthylène réticulé, caoutchouc éthylène-propylène, etc.). Le matériau peut être non chargé ou chargé (par exemple, de matière minérale ou de carbone).

Les exigences sont applicables aux câbles monoconducteurs combinés à leurs accessoires, extrémités extérieures et pour postes sous enveloppe métallique à isolation gazeuse, jonctions et jonctions asymétriques, pour des conditions habituelles d’installation et de fonctionnement, mais pas à des câbles spéciaux et à leurs accessoires comme les câbles sous-marins, pour lesquels il peut être nécessaire d’apporter des modifications aux essais normaux ou d’élaborer des conditions d’essai particulières.

General Information

- Status

- Published

- Publication Date

- 10-May-2017

- Technical Committee

- TC 20 - Electric cables

- Drafting Committee

- PT 62895 - TC 20/PT 62895

- Current Stage

- PPUB - Publication issued

- Start Date

- 11-May-2017

- Completion Date

- 12-May-2017

Overview

IEC 62895:2017 is an international standard developed by the International Electrotechnical Commission (IEC) that specifies comprehensive test methods and requirements for high voltage direct current (HVDC) power transmission cables with extruded insulation and their accessories. This standard targets cables used in fixed land installations with rated voltages up to and including 320 kV. The scope encompasses single-core cables and their components such as joints, outdoor terminations, and gas-insulated system accessories, focusing on standard installation and operating conditions.

Extruded insulation, as defined by the standard, includes materials manufactured by extrusion of thermoplastic or crosslinked materials (e.g., polyethylene, crosslinked polyethylene, ethylene propylene rubber). It applies to both unfilled and filled insulation variants, which may include mineral or carbon fillers.

Key Topics

Test Methods: IEC 62895:2017 provides detailed procedures for electrical, mechanical, and material-related tests to ensure the reliability and performance of HVDC cables and accessories. These include routine tests, sample tests, type tests, prequalification tests, and tests on complete cable systems.

Cable Characteristics: Specification of physical and electrical properties, such as insulation thickness, metal shielding, dielectric strength, and resistance to water penetration.

Voltage Designations: Defined rated voltages up to 320 kV, including impulse test voltages and polarity reversal tests, ensuring HVDC cables meet stringent operational voltage conditions.

Insulating Materials: Requirements for thermoplastic and crosslinked materials used in cable insulation, emphasizing material quality, thermal properties, and aging characteristics.

Accessories: Standards for joints, terminations, and outdoor components compatible with HVDC cables, covering electrical and mechanical integrity under operational stresses.

Water Penetration Protection: Guidelines to prevent longitudinal water ingress in cables, critical for maintaining insulation integrity and operational longevity in land applications.

Mechanical and Thermal Tests: Procedures to verify cable performance under stress, including bending tests, heating cycle voltage tests, and fire resistance assessments.

Applications

IEC 62895:2017 is essential for engineers, manufacturers, and utilities involved in the design, production, testing, and installation of HVDC power transmission systems. Its applications include:

HVDC Land Transmission Projects: Ensuring cables and accessories meet safety and performance requirements for high-voltage underground or overhead power lines.

Power Grid Infrastructure: Supporting the development and maintenance of reliable long-distance power transmission networks utilizing HVDC technology.

Cable Manufacturing: Providing manufacturers with uniform test methods and technical criteria to guarantee product quality and compliance with international standards.

System Specification & Procurement: Assisting utility companies in defining precise technical specifications for HVDC cable systems and ensuring vendor compliance during procurement.

Installation and Maintenance: Offering guidelines to verify cable system readiness and durability, contributing to reduced downtime and enhanced operational safety.

Related Standards

IEC 60840: Power cables with extruded insulation for rated voltages above 30 kV up to 150 kV-Relevant for AC cable systems in a similar voltage range.

IEC 62067: Power cables with extruded insulation for rated voltages above 150 kV up to 500 kV-Focuses on higher voltage cable systems.

IEC 62095: Cable systems for HVDC underground transmission-Covers other aspects of HVDC systems beyond cable testing.

IEC 61442: Power cable accessories for rated voltages from 3,6 kV up to 245 kV-Provides testing requirements for cable accessories.

ISO/IEC standards on electrical components and testing methods: Provide complementary guidelines on terminology and testing techniques applicable to electrical insulation and cable systems.

By adhering to IEC 62895:2017, stakeholders ensure that HVDC cable systems with extruded insulation meet the highest international requirements for safety, durability, and electrical performance, optimizing the reliability and efficiency of modern power transmission infrastructure.

Buy Documents

IEC 62895:2017 - High voltage direct current (HVDC) power transmission - Cables with extruded insulation and their accessories for rated voltages up to 320 kV for land applications - Test methods and requirements

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

TL 9000 QuEST Forum

Telecommunications quality management system.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC 62895:2017 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "High voltage direct current (HVDC) power transmission - Cables with extruded insulation and their accessories for rated voltages up to 320 kV for land applications - Test methods and requirements". This standard covers: IEC 62895:2017 specifies test methods and requirements for transmission power cable systems, cables with extruded insulation and their accessories for fixed land installations, for rated voltages up to and including 320 kV. Within the scope of this standard “extruded insulation” means insulation manufactured by extrusion of either thermoplastic (e.g. polyethylene) or crosslinked (e.g. crosslinked polyethylene, ethylene propylene rubber, etc.) material. The insulation material may be either unfilled or filled (e.g. with mineral or carbon). The requirements apply to single-core cables in combination with their accessories, outdoor and terminations for gas insulated systems, joints, and asymmetric joints for usual conditions of installation and operation, but not to special cables and their accessories, such as submarine cables, for which modifications to the standard tests may be necessary or special test conditions may need to be devised.

IEC 62895:2017 specifies test methods and requirements for transmission power cable systems, cables with extruded insulation and their accessories for fixed land installations, for rated voltages up to and including 320 kV. Within the scope of this standard “extruded insulation” means insulation manufactured by extrusion of either thermoplastic (e.g. polyethylene) or crosslinked (e.g. crosslinked polyethylene, ethylene propylene rubber, etc.) material. The insulation material may be either unfilled or filled (e.g. with mineral or carbon). The requirements apply to single-core cables in combination with their accessories, outdoor and terminations for gas insulated systems, joints, and asymmetric joints for usual conditions of installation and operation, but not to special cables and their accessories, such as submarine cables, for which modifications to the standard tests may be necessary or special test conditions may need to be devised.

IEC 62895:2017 is classified under the following ICS (International Classification for Standards) categories: 29.060.20 - Cables; 33.120.30 - RF connectors. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62895:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62895 ®

Edition 1.0 2017-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

High voltage direct current (HVDC) power transmission – Cables with extruded

insulation and their accessories for rated voltages up to 320 kV for land

applications – Test methods and requirements

Câbles haute tension en courant continu (CCHT) – Câbles d’énergie à isolation

extrudée et leurs accessoires pour des tensions assignées jusqu’à 320 kV pour

les applications terrestres – Méthodes et exigences d’essai

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

65 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 62895 ®

Edition 1.0 2017-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

High voltage direct current (HVDC) power transmission – Cables with extruded

insulation and their accessories for rated voltages up to 320 kV for land

applications – Test methods and requirements

Câbles haute tension en courant continu (CCHT) – Câbles d’énergie à isolation

extrudée et leurs accessoires pour des tensions assignées jusqu’à 320 kV pour

les applications terrestres – Méthodes et exigences d’essai

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.060.20 ISBN 978-2-8322-4292-6

– 2 – IEC 62895:2017 © IEC 2017

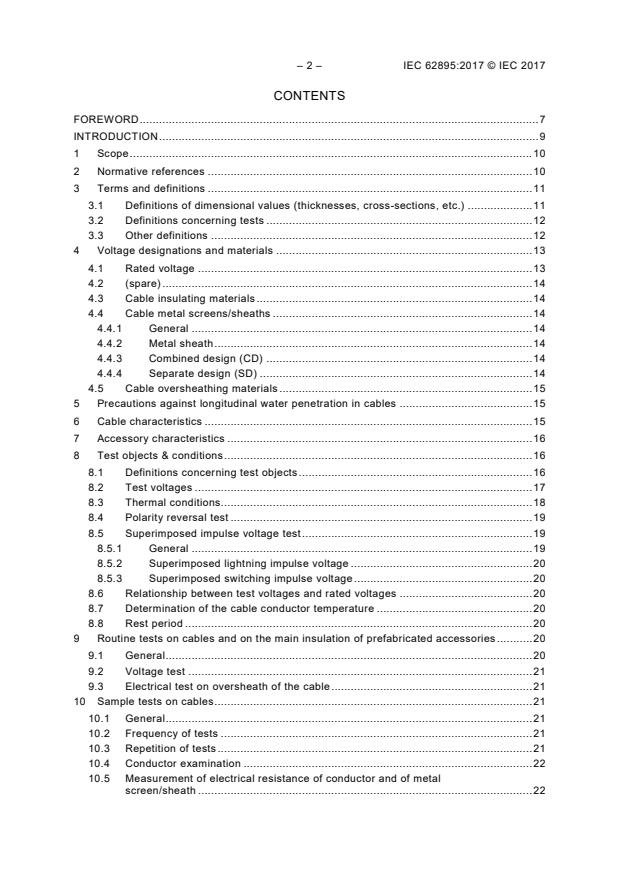

CONTENTS

FOREWORD . 7

INTRODUCTION . 9

1 Scope . 10

2 Normative references . 10

3 Terms and definitions . 11

3.1 Definitions of dimensional values (thicknesses, cross-sections, etc.) . 11

3.2 Definitions concerning tests . 12

3.3 Other definitions . 12

4 Voltage designations and materials . 13

4.1 Rated voltage . 13

4.2 (spare) . 14

4.3 Cable insulating materials . 14

4.4 Cable metal screens/sheaths . 14

4.4.1 General . 14

4.4.2 Metal sheath . 14

4.4.3 Combined design (CD) . 14

4.4.4 Separate design (SD) . 14

4.5 Cable oversheathing materials . 15

5 Precautions against longitudinal water penetration in cables . 15

6 Cable characteristics . 15

7 Accessory characteristics . 16

8 Test objects & conditions . 16

8.1 Definitions concerning test objects . 16

8.2 Test voltages . 17

8.3 Thermal conditions. 18

8.4 Polarity reversal test . 19

8.5 Superimposed impulse voltage test . 19

8.5.1 General . 19

8.5.2 Superimposed lightning impulse voltage . 20

8.5.3 Superimposed switching impulse voltage . 20

8.6 Relationship between test voltages and rated voltages . 20

8.7 Determination of the cable conductor temperature . 20

8.8 Rest period . 20

9 Routine tests on cables and on the main insulation of prefabricated accessories . 20

9.1 General . 20

9.2 Voltage test . 21

9.3 Electrical test on oversheath of the cable . 21

10 Sample tests on cables . 21

10.1 General . 21

10.2 Frequency of tests . 21

10.3 Repetition of tests . 21

10.4 Conductor examination . 22

10.5 Measurement of electrical resistance of conductor and of metal

screen/sheath . 22

10.6 Measurement of thickness of insulation and cable oversheath . 22

10.6.1 General . 22

10.6.2 Requirements for the insulation . 22

10.6.3 Requirements for the cable oversheath . 22

10.7 Measurement of thickness of metal sheath . 23

10.7.1 Lead or lead alloy sheath . 23

10.7.2 Plain or corrugated aluminium sheath . 23

10.8 Measurement of diameter . 24

10.9 Hot set test for XLPE and EPR insulations . 24

10.9.1 Procedure . 24

10.9.2 Requirements . 24

10.10 Measurement of capacitance . 24

10.11 Measurement of density of HDPE insulation . 24

10.11.1 Procedure . 24

10.11.2 Requirements . 24

10.12 Impulse voltage test . 24

10.13 Water penetration test . 25

10.14 Adhesion and peel strength of the laminated metal foil. 25

11 Sample tests on accessories . 25

11.1 Tests on components . 25

11.2 Tests on complete accessory . 25

12 Type tests on cable systems . 25

12.1 General . 25

12.2 Range of type approval . 25

12.3 Summary of type tests . 26

12.4 Electrical type tests on complete cable systems . 27

12.4.1 Test voltage values . 27

12.4.2 Tests and sequence of tests . 27

12.4.3 Bending test . 27

12.4.4 Heating cycle voltage test . 28

12.4.5 Superimposed impulse voltage test. 29

12.4.6 Examination . 30

12.4.7 Resistivity of semi-conducting screens . 30

12.5 Non-electrical type tests on cable components and on complete cable . 31

12.5.1 General . 31

12.5.2 Check of cable construction . 31

12.5.3 Tests for determining the mechanical properties of insulation before and

after ageing . 31

12.5.4 Tests for determining the mechanical properties of oversheaths before

and after ageing . 32

12.5.5 Ageing tests on pieces of complete cable to check compatibility of

materials . 32

12.5.6 Loss of mass test on PVC oversheaths of type ST . 32

12.5.7 Pressure test at high temperature on oversheaths . 33

12.5.8 Test on PVC oversheaths (ST and ST ) at low temperature . 33

1 2

12.5.9 Heat shock test for PVC oversheaths (ST and ST ) . 33

1 2

12.5.10 Ozone resistance test for EPR insulation . 33

12.5.11 Hot set test for EPR and XLPE insulations . 33

12.5.12 Measurement of density of HDPE insulation . 33

– 4 – IEC 62895:2017 © IEC 2017

12.5.13 Measurement of carbon black content of black PE oversheaths (ST

and ST ) . 33

12.5.14 Test under fire conditions . 34

12.5.15 Water penetration test . 34

13 Prequalification test of the cable system . 34

13.1 General and range of prequalification test approval . 34

13.2 Prequalification test on complete cable system . 35

13.2.1 Summary of prequalification tests . 35

13.2.2 Test voltage values . 35

13.2.3 Test arrangement . 35

13.2.4 Heating cycle voltage test . 36

13.2.5 Superimposed impulse voltage test. 36

13.2.6 Examination . 36

13.3 Tests for the extension of the PQ of a cable system . 37

14 Type test on cables . 37

15 Type test on accessories . 37

16 Electrical tests after installation . 37

16.1 General . 37

16.2 DC voltage test of the oversheath . 37

16.3 High voltage test of the insulation . 37

16.4 TDR measurement . 37

Annex A (informative) Determination of the cable conductor temperature . 45

A.1 Purpose . 45

A.2 Calibration of the temperature of the main test loop . 45

A.2.1 General . 45

A.2.2 Installation of cable and temperature sensors . 45

A.2.3 Calibration method . 47

A.3 Heating for the test . 47

Annex B (normative) Rounding of numbers . 49

Annex C (informative) List of type and prequalification tests of cable systems . 50

Annex D (normative) Method of measuring resistivity of semi-conducting screens . 51

Annex E (normative) Water penetration test . 53

E.1 Test piece . 53

E.2 Test . 53

E.3 Requirements . 53

Annex F (normative) Tests on components of cables with a longitudinally applied

metal tape or foil, bonded to the oversheath . 55

F.1 Visual inspection . 55

F.2 Adhesion strength of metal foil – Procedure . 55

F.3 Peel strength of overlapped metal foil – Procedure . 56

Annex G (informative) Development test on cable and cable system with longitudinal

applied metal foil, bonded to the oversheath . 57

G.1 General . 57

G.2 List of tests . 57

G.2.1 Tests on cable . 57

G.2.2 Tests on cable system – Short circuit test including accessories . 57

Annex H (normative) Tests of outer protection for joints . 58

H.1 General . 58

H.2 Range of approval. 58

H.3 Water immersion and heat cycling. 58

H.4 Voltage tests . 58

H.4.1 General . 58

H.4.2 Assemblies embodying accessories without sheath sectionalizing

insulation . 58

H.4.3 Assemblies embodying accessories with sheath sectionalizing

insulation . 59

H.5 Examination of test assembly . 59

Annex I (normative) Return cable . 60

Annex J (informative) TDR measurement . 61

Bibliography . 62

Figure 1 – Example of configuration of test objects within a test loop . 17

Figure 2 – Schematic representations of the switching impulse and lightning impulse

test voltages . 18

Figure A.1 – Schematic of sensor position in test set-up for the reference loop and the

main test loop . 46

Figure A.2 – Example of an arrangement of the temperature sensors on the conductor

of the reference loop . 47

Figure D.1 – Preparation of samples for measurement of resistivity of conductor and

insulation screens . 52

Figure E.1 – Schematic diagram of apparatus for water penetration test . 54

Figure F.1 – Test arrangement for adhesion strength of metal foil . 55

Figure F.2 – Example of overlapped metal foil . 56

Figure F.3 – Test arrangement for peel strength of overlapped metal foil . 56

Figure J.1 – Circuit diagram for TDR testing, traditional transmission line diagram, π-

model . 61

Table 1 – Insulation compounds for cables . 38

Table 2 – Oversheathing compounds for cables . 38

Table 3 – Test requirements for particular characteristics of insulating compounds for

cables . 38

Table 4 – Non-electrical type tests for insulating and oversheath compounds for cables . 39

Table 5 – Test requirements for adhesion or peel strength forces . 39

Table 6 – Sequence of heating cycle voltage test for LCC type test . 39

Table 7 – Sequence of heating cycle voltage test for VSC type test . 40

Table 8 – Sequence of switching and lightning impulse test for LCC type test . 40

Table 9 – Sequence of switching and lightning impulse test for VSC type test . 40

Table 10 – Test requirements for mechanical characteristics of insulating compounds

for cables (before and after ageing) . 41

Table 11 – Test requirements for mechanical characteristics of oversheathing

compounds for cables (before and after ageing) . 42

Table 12 – Test requirements for particular characteristics of PVC oversheathing for

cables . 43

– 6 – IEC 62895:2017 © IEC 2017

Table 13 – Sequence of heating cycle voltage test for LCC PQ test . 43

Table 14 – Sequence of heating cycle voltage test for VSC PQ test . 44

Table C.1 – Type tests on cable systems . 50

Table C.2 – PQ tests on cable systems . 50

Table H.1 – Impulse voltage tests . 59

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

HIGH VOLTAGE DIRECT CURRENT (HVDC) POWER TRANSMISSION –

CABLES WITH EXTRUDED INSULATION AND THEIR ACCESSORIES FOR

RATED VOLTAGES UP TO 320 kV FOR LAND APPLICATIONS –

TEST METHODS AND REQUIREMENTS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62895 has been prepared by IEC technical committee 20: Electric

cables.

The text of this standard is based on the following documents:

FDIS Report on voting

20/1708A/FDIS 20/1726/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 8 – IEC 62895:2017 © IEC 2017

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

As a result of major developments in cable systems with extruded insulation for high voltage

DC (HVDC) applications, CIGRE study committee B1 set up working group (WG) B1.32 in

2008 with the aim to prepare recommendations for testing DC extruded cable systems for

power transmission at a rated voltage of up to 500 kV.

The recommendations of WG B1.32 were published in TB 496 in April 2012. At the time of

preparing the CIGRE recommendation there was laboratory experience at voltages up to and

including 500 kV, but operating experience was limited to 200 kV. At the time of preparation of

this standard several projects up to 320 kV are in progress and many others are planned for

the near future.

A list of relevant references is given in the Bibliography.

– 10 – IEC 62895:2017 © IEC 2017

HIGH VOLTAGE DIRECT CURRENT (HVDC) POWER TRANSMISSION –

CABLES WITH EXTRUDED INSULATION AND THEIR ACCESSORIES FOR

RATED VOLTAGES UP TO 320 kV FOR LAND APPLICATIONS –

TEST METHODS AND REQUIREMENTS

1 Scope

This International Standard specifies test methods and requirements for HVDC transmission

power cable systems, employing cables with extruded insulation and their accessories, for

fixed land installations, for rated voltages up to and including 320 kV.

Within the scope of this standard “extruded insulation” means insulation manufactured by

extrusion of either thermoplastic (e.g. polyethylene) or crosslinked (e.g. crosslinked

polyethylene, ethylene propylene rubber, etc.) material. The insulation material may be either

unfilled or filled (e.g. with mineral or carbon).

The requirements apply to single-core cables in combination with their accessories, outdoor

and terminations for gas insulated systems, joints, and asymmetric joints for usual conditions

of installation and operation, but not to special cables and their accessories, such as

submarine cables, for which modifications to the standard tests may be necessary or special

test conditions may need to be devised.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60060-2, High-voltage test techniques – Part 2: Measuring systems

IEC 60228, Conductors of insulated cables

IEC 60229, Electric cables – Tests on extruded oversheaths with a special protective function

IEC 60230, Impulse tests on cables and their accessories

IEC 60287-1-1:2006, Electric cables – Calculation of the current rating – Part 1-1: Current

rating equations (100 % load factor) and calculation of losses – General

IEC 60287-1-1:2006/AMD1:2014

IEC 60332-1-2, Tests on electric and optical fibre cables under fire conditions – Part 1-2: Test

for vertical flame propagation for a single insulated wire or cable – Procedure for 1 kW pre-

mixed flame

IEC 60502-2:2014, Power cables with extruded insulation and their accessories for rated

voltages from 1 kV (U = 1,2 kV) up to 30 kV (U = 36 kV) – Part 2: Cables for rated voltages

m m

from 6 kV (U = 7,2 kV) up to 30 kV (U = 36 kV)

m m

IEC 60502-4, Power cables with extruded insulation and their accessories for rated voltages

from 1 kV (U = 1,2 kV) up to 30 kV (U = 36 kV) – Part 4: Test requirements on accessories

m m

for cables with rated voltages from 6 kV (U = 7,2 kV) up to 30 kV (U = 36 kV)

m m

IEC 60811-201, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 201: General tests – Measurement of insulation thickness

IEC 60811-202, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 202: General tests – Measurement of thickness of non-metallic sheath

IEC 60811-203, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 203: General tests – Measurement of overall dimensions

IEC 60811-401, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 401: Miscellaneous tests – Thermal ageing methods – Ageing in an air oven

IEC 60811-403, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 403: Miscellaneous tests – Ozone resistance test on cross-linked compounds

IEC 60811-409, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 409: Miscellaneous tests – Loss of mass test for thermoplastic insulations and sheaths

IEC 60811-412, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 412: Miscellaneous tests – Thermal ageing methods – Ageing in an air bomb

IEC 60811-501, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 501: Mechanical tests – Tests for determining the mechanical properties of insulating and

sheathing compounds

IEC 60811-505, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 505: Mechanical tests – Elongation at low temperature for insulations and sheaths

IEC 60811-506, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 506: Mechanical tests – Impact test at low temperature for insulations and sheaths

IEC 60811-507, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 507: Mechanical tests – Hot set test for cross-linked materials

IEC 60811-508, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 508: Mechanical tests – Pressure test at high temperature for insulation and sheaths

IEC 60811-509, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 509: Mechanical tests – Test for resistance of insulations and sheaths to cracking (heat

shock test)

IEC 60811-605, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 605: Physical tests – Measurement of carbon black and/or mineral filler in polyethylene

compounds

IEC 60811-606, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 606: Physical tests – Methods for determining the density

IEC 62067, Power cables with extruded insulation and their accessories for rated voltages

above 150 kV (U = 170 kV) up to 500 kV (U = 550 kV) – Test methods and requirements

m m

3 Terms and definitions

For the purposes of this document the following terms and definitions apply.

3.1 Definitions of dimensional values (thicknesses, cross-sections, etc.)

3.1.1

nominal value

value by which a quantity is designated and which is often used in tables

Note 1 to entry: In this standard, nominal values usually give rise to values to be checked by measurements

taking into account specified tolerances.

3.1.2

median value

value which is, when several test results have been obtained and ordered in an increasing (or

decreasing) succession, the middle value if the number of available values is odd, and the

mean of the two middle values if the number is even

– 12 – IEC 62895:2017 © IEC 2017

3.2 Definitions concerning tests

3.2.1

routine test

test carried out by the manufacturer on each manufactured component (length of cable or

accessory) to check that the component meets the specified requirements

3.2.2

sample test

test carried out by the manufacturer on samples of complete cable, or components taken from

a complete cable or accessory, at a specified frequency, so as to verify that the finished

product meets the specified requirements

3.2.3

type test

test carried out before supplying, on a general commercial basis, a type of cable system, in

order to demonstrate satisfactory performance characteristics to meet the intended

application

Note 1 to entry: Once successfully completed, these tests need not be repeated, unless changes are made in the

cable or accessory with respect to materials, manufacturing process, design or design electrical stress levels,

which might adversely change the performance characteristics.

3.2.4

prequalification test

PQ test

test carried out before supplying, on a general commercial basis, a type of cable system, in

order to demonstrate satisfactory long term performance of the complete cable system

Note 1 to entry: The PQ test need only be carried out once unless there is a substantial change in the cable

system with respect to material, manufacturing process, design or design electrical stress levels.

Note 2 to entry: A substantial change is defined as that which might adversely affect the performance of the cable

system. The supplier should provide a detailed case, including test evidence, if modifications are introduced, which

are claimed not to constitute a substantial change.

3.2.5

electrical test after installation

test carried out to demonstrate the integrity of the cable system as installed

3.2.6

development test

test carried out on test objects to characterize the properties and performance of elements of

the cable system or of selected materials and material combinations

3.3 Other definitions

3.3.1

cable system

cable with installed accessories including components used for thermo-mechanical restraint of

systems limited to those used for terminations and joints only

3.3.2

nominal electrical stress

using nominal dimensions and constant material

electrical stress calculated at U

characteristics

Note 1 to entry: See 4.1.

3.3.3

test object

object which is a cable length or an accessory to be subjected to testing

3.3.4

return cable

cable, which is typically a low/medium voltage DC cable used for the return current in

monopolar operation of HVDC schemes.

Note 1 to entry: A return cable can either be connected over the full length between the converters or can only be

connected for part of the length connecting a converter to an electrode station

3.3.5

transmission cable

cable which is a high voltage cable of a monopolar or bipolar scheme, and which is connected

to the HV terminal at the DC side of the converter

3.3.6

test loop

cable loop which is a combination of series connected test objects simultaneously under test

SEE: Figure 1.

3.3.7

line commutated converter

LCC

converter system that has the feature of changing voltage polarity on the cable system when

the direction of power flow is reversed

Note 1 to entry: See IEC 60633.

Note 2 to entry: This note 2 only applies to the French language

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...