IEC 61249-2-38:2008

(Main)Materials for printed boards and other interconnecting structures - Part 2-38: Reinforced base materials, clad and unclad - Non-halogenated epoxide woven E-glass laminate sheets of defined flammability (vertical burning test), copper-clad for lead-free assembly

Materials for printed boards and other interconnecting structures - Part 2-38: Reinforced base materials, clad and unclad - Non-halogenated epoxide woven E-glass laminate sheets of defined flammability (vertical burning test), copper-clad for lead-free assembly

IEC 61249-2-38:2008 gives requirements for properties of di-functional non-halogenated epoxide woven E-glass laminate sheet 0,05 mm up to 3,2 mm, of defined flammability (vertical burning test), copper-clad. The glass transition temperature is defined to be 120 °C minimum.

Matériaux pour circuits imprimés et autres structures d'interconnexion - Partie 2-38: Matériaux de base renforcés, plaqués et non plaqués - Feuilles stratifiées en tissu de verre de type E époxyde non halogénées, plaquées cuivre, d'inflammabilité définie (essai de combustion verticale) pour les assemblages sans plomb

La CEI 61249-2-38:2008 fournit des exigences concernant les propriétés des feuilles stratifiées en tissu de verre de type E époxyde non halogénées difonctionnelles, plaquées cuivre, d'inflammabilité définie (essai de combustion verticale) et ayant une épaisseur comprise entre 0,05 mm et 3,2 mm. La température de transition vitreuse a été définie comme devant être de 120 °C au minimum.

General Information

- Status

- Published

- Publication Date

- 26-Nov-2008

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 4 - TC 91/WG 4

- Current Stage

- PPUB - Publication issued

- Start Date

- 27-Nov-2008

- Completion Date

- 31-Dec-2008

Overview

The IEC 61249-2-38:2008 standard specifies the requirements for non-halogenated epoxide woven E-glass laminate sheets used as reinforced base materials in printed boards and other interconnecting structures. These laminates are copper-clad and designed for lead-free assembly processes, addressing modern environmental and manufacturing demands. The standard covers sheet thicknesses ranging from 0.05 mm to 3.2 mm and mandates a minimum glass transition temperature (Tg) of 120 °C, ensuring thermal robustness.

This international standard by the International Electrotechnical Commission (IEC) focuses on materials exhibiting defined flammability characteristics tested via the vertical burning test. It emphasizes consistent electrical, mechanical, and thermal performance properties critical for high-reliability electronics manufacturing.

Key Topics

Material Composition

- Di-functional non-halogenated epoxide resin system for environmental safety.

- Woven E-glass reinforcement ensuring mechanical strength and thermal stability.

- Copper foil cladding compatible with lead-free solder assembly.

Flammability Requirements

- Defined vertical burning test to verify fire resistance characteristics.

- Non-halogenated composition reduces hazardous halogen emissions in case of fire.

Thermal Properties

- Minimum glass transition temperature (Tg) of 120 °C for consistent performance under thermal stress.

- Thermal resistance and decomposition temperature parameters to support durability.

Mechanical and Electrical Performance

- Specifications for laminate thickness, flatness (bow and twist), and dimensional stability.

- Copper foil bond strength and punchability for manufacturing reliability.

- Electrical properties such as dielectric constant and insulation resistance suitable for printed circuit boards (PCBs).

Quality Assurance and Compliance

- Defined procedures for qualification, inspection, and certification ensuring conformance.

- Inclusion of safety data sheets and regulatory compliance documentation.

- Packaging and marking guidelines to maintain product integrity during transport and handling.

Applications

IEC 61249-2-38:2008 materials are primarily used in:

- Printed Circuit Boards (PCBs) manufacturing that demand high flame retardance and thermal resilience.

- Lead-free assembly processes adhering to RoHS and WEEE directives for reduced environmental impact.

- High-reliability electronic devices such as computers, telecommunications equipment, industrial controls, and consumer electronics.

- Multilayer PCB fabrication where laminate stability, electrical insulation, and mechanical robustness are critical.

- Interconnecting structures requiring materials that maintain performance under thermal cycling and mechanical stresses.

By adopting these standards, PCB manufacturers can ensure standardized base materials that facilitate consistent product quality, reduce manufacturing defects, and enhance device safety and longevity.

Related Standards

- IEC 61249 Series – Covering various materials for printed boards and interconnecting structures, including reinforced base materials with different resin systems and flame retardance classes.

- IPC-4101 – Specifications for base materials used in rigid and multilayer printed boards.

- UL 94 – Flammability standards for plastic materials used in devices and appliances, complementing IEC’s vertical burning test parameters.

- RoHS Directive – Restriction of hazardous substances in electric and electronic equipment, underlining the importance of non-halogenated materials.

- ISO/IEC Guides – Frameworks for standard development, quality assurance, and conformity assessment relevant to IEC publications.

For manufacturers and engineers sourcing copper-clad, non-halogenated epoxide woven E-glass laminates for printed boards, IEC 61249-2-38:2008 provides an authoritative reference ensuring compliance with international safety, environmental, and performance standards. Understanding and applying this standard supports the production of environmentally friendly, high-quality electronic assemblies meeting the demands of modern electronics industries.

IEC 61249-2-38:2008 - Materials for printed boards and other interconnecting structures - Part 2-38: Reinforced base materials, clad and unclad - Non-halogenated epoxide woven E-glass laminate sheets of defined flammability (vertical burning test), copper-clad for lead-free assembly

Frequently Asked Questions

IEC 61249-2-38:2008 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Materials for printed boards and other interconnecting structures - Part 2-38: Reinforced base materials, clad and unclad - Non-halogenated epoxide woven E-glass laminate sheets of defined flammability (vertical burning test), copper-clad for lead-free assembly". This standard covers: IEC 61249-2-38:2008 gives requirements for properties of di-functional non-halogenated epoxide woven E-glass laminate sheet 0,05 mm up to 3,2 mm, of defined flammability (vertical burning test), copper-clad. The glass transition temperature is defined to be 120 °C minimum.

IEC 61249-2-38:2008 gives requirements for properties of di-functional non-halogenated epoxide woven E-glass laminate sheet 0,05 mm up to 3,2 mm, of defined flammability (vertical burning test), copper-clad. The glass transition temperature is defined to be 120 °C minimum.

IEC 61249-2-38:2008 is classified under the following ICS (International Classification for Standards) categories: 31.180 - Printed circuits and boards. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61249-2-38:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61249-2-38

Edition 1.0 2008-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Materials for printed boards and other interconnecting structures –

Part 2-38: Reinforced base materials, clad and unclad – Non-halogenated

epoxide woven E-glass laminate sheets of defined flammability (vertical burning

test), copper-clad for lead-free assembly

Matériaux pour circuits imprimés et autres structures d'interconnexion –

Partie 2-38: Matériaux de base renforcés, plaqués et non plaqués – Feuilles

stratifiées en tissu de verre de type E époxyde non halogénées, plaquées cuivre,

d’inflammabilité définie (essai de combustion verticale) pour les assemblages

sans plomb

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61249-2-38

Edition 1.0 2008-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Materials for printed boards and other interconnecting structures –

Part 2-38: Reinforced base materials, clad and unclad – Non-halogenated

epoxide woven E-glass laminate sheets of defined flammability (vertical burning

test), copper-clad for lead-free assembly

Matériaux pour circuits imprimés et autres structures d'interconnexion –

Partie 2-38: Matériaux de base renforcés, plaqués et non plaqués – Feuilles

stratifiées en tissu de verre de type E époxyde non halogénées, plaquées

cuivre, d’inflammabilité définie (essai de combustion verticale) pour les

assemblages sans plomb

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

S

CODE PRIX

ICS 31.180 ISBN 978-2-88910-460-4

– 2 – 61249-2-38 © IEC:2008

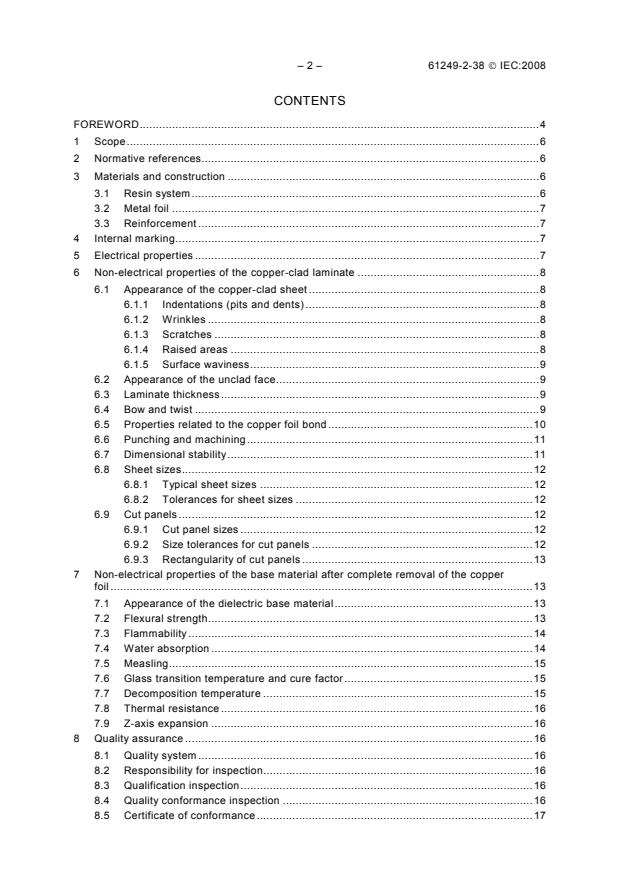

CONTENTS

FOREWORD.4

1 Scope.6

2 Normative references.6

3 Materials and construction .6

3.1 Resin system.6

3.2 Metal foil .7

3.3 Reinforcement .7

4 Internal marking.7

5 Electrical properties .7

6 Non-electrical properties of the copper-clad laminate .8

6.1 Appearance of the copper-clad sheet .8

6.1.1 Indentations (pits and dents) .8

6.1.2 Wrinkles .8

6.1.3 Scratches .8

6.1.4 Raised areas .8

6.1.5 Surface waviness.9

6.2 Appearance of the unclad face.9

6.3 Laminate thickness.9

6.4 Bow and twist .9

6.5 Properties related to the copper foil bond.10

6.6 Punching and machining.11

6.7 Dimensional stability.11

6.8 Sheet sizes.12

6.8.1 Typical sheet sizes .12

6.8.2 Tolerances for sheet sizes .12

6.9 Cut panels .12

6.9.1 Cut panel sizes .12

6.9.2 Size tolerances for cut panels .12

6.9.3 Rectangularity of cut panels .13

7 Non-electrical properties of the base material after complete removal of the copper

foil.13

7.1 Appearance of the dielectric base material.13

7.2 Flexural strength.13

7.3 Flammability .14

7.4 Water absorption .14

7.5 Measling.15

7.6 Glass transition temperature and cure factor.15

7.7 Decomposition temperature .15

7.8 Thermal resistance .16

7.9 Z-axis expansion .16

8 Quality assurance .16

8.1 Quality system .16

8.2 Responsibility for inspection.16

8.3 Qualification inspection.16

8.4 Quality conformance inspection .16

8.5 Certificate of conformance.17

61249-2-38 © IEC:2008 – 3 –

8.6 Safety data sheet.17

9 Packaging and marking.17

10 Ordering information .17

Annex A (informative) Engineering information .18

Annex B (informative) Common laminate constructions.20

Annex C (informative) Guideline for qualification and conformance inspection.22

Bibliography .23

Table 1 – Electrical properties .7

Table 2 – Nominal thickness and tolerance of metal-clad laminate.9

Table 3 – Bow and twist .10

Table 4 – Pull-off and peel strength .11

Table 5 – Dimensional stability .12

Table 6 – Size tolerance for cut panels .12

Table 7 – Rectangularity of cut panels .13

Table 8 – Flexural strength.14

Table 9 – Flammability .14

Table 10 – Water absorption .14

Table 11 – Measling.15

Table 12 – Glass transition temperature and cure factor .15

Table 13 – Decomposition temperature .15

Table 14 – Thermal resistance .16

Table 15 – Z-axis expansion.16

– 4 – 61249-2-38 © IEC:2008

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MATERIALS FOR PRINTED BOARDS

AND OTHER INTERCONNECTING STRUCTURES –

Part 2-38: Reinforced base materials, clad and unclad –

Non-halogenated epoxide woven E-glass laminate sheets

of defined flammability (vertical burning test),

copper-clad for lead-free assembly

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61249-2-38 has been prepared by IEC technical committee 91:

Electronics assembly technology.

The text of this standard is based on the following documents:

FDIS Report on voting

91/812/FDIS 91/834/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

61249-2-38 © IEC:2008 – 5 –

A list of all parts of the IEC 61249 series, under the general title Materials for printed boards

and other interconnecting structures, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until the

maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 61249-2-38 © IEC:2008

MATERIALS FOR PRINTED BOARDS

AND OTHER INTERCONNECTING STRUCTURES –

Part 2-38: Reinforced base materials, clad and unclad –

Non-halogenated epoxide woven E-glass laminate sheets

of defined flammability (vertical burning test),

copper-clad for lead-free assembly

1 Scope

This part of IEC 61249 gives requirements for properties of di-functional non-halogenated

epoxide woven E-glass laminate sheet 0,05 mm up to 3,2 mm, of defined flammability (vertical

burning test), copper-clad. The glass transition temperature is defined to be 120 °C minimum.

Its flame resistance is defined in terms of the flammability requirements of 7.3.

Some property requirements may have several classes of performance. The class desired

should be specified on the purchase order otherwise the default class of material will be

supplied.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 61189-2:2006, Test methods for electrical materials, printed boards and other

interconnection structures and assemblies – Part 2: Test method for interconnection structures

IEC 61249-5-1:1995, Materials for interconnection structures – Part 5 : Sectional specification

set for conductive foils and films with and without coatings – Section 1: Copper foils (for the

manufacture of copper-clad base materials)

ISO 9000, Quality management systems – Fundamentals and vocabulary

ISO 11014-1, Safety data sheet for chemical products – Part 1: Content and order of sections

ISO 14001, Environmental management systems – Requirements with guidance for use

3 Materials and construction

The sheet consists of an insulating base with metal-foil bonded to one side or both.

3.1 Resin system

Majority di-functional non-halogenated epoxide, modified non-halogenated epoxide, woven E-

glass laminate with a glass transition temperature of 120 °C minimum. The flammability rating

is achieved through the use of non-halogenated flame retardants reacted into the polymer.

Inorganic fillers may be used. Contrast agents may be added to enhance processing such as

automated optical inspection (AOI).

61249-2-38 © IEC:2008 – 7 –

-

The maximum total halogens contained in the resin plus reinforcement matrix is 1 500 × 10

6 -6 -6

with a maximum chlorine of 900 × 10 and maximum bromine being 900 × 10 .

Its flame resistance is defined in terms of the flammability requirements of 7.3.

3.2 Metal foil

Copper as specified in IEC 61249-5-1, copper foil (for the manufacture of copper-clad

materials). The preferred foils are electro-deposited of defined ductility.

3.3 Reinforcement

Woven E-glass as specified in the future IEC 61249-6-3, Woven E-glass fabric (for the

manufacture of prepreg and copper clad materials).

4 Internal marking

Not specified.

5 Electrical properties

The electrical property requirements are shown in Table 1.

Table 1 – Electrical properties

Test method

Property Requirements

(IEC 61189-2)

Resistance of foil 2E12 As specified in IEC 61249-5-1

Surface resistance after damp heat

while in the humidity chamber 2E03 ≥10 000 MΩ

(optional)

Surface resistance after damp heat

2E03

≥50 000 MΩ

and recovery

Volume resistivity after damp heat

while in the humidity chamber 2E04 ≥5 000 MΩm

(optional)

Volume resistivity after damp heat and

2E04 ≥10 000 MΩm

recovery

Relative permittivity after damp heat

2E10

≤5,4

and recovery (1 MHz)

Dissipation factor after damp heat and

2E10

≤0,035

recovery (1 MHz)

Electric strength (only for material

2E11 ≥30 kV/mm

thickness less than 0,5 mm)

Arc resistance 2E14

≥60 s

Dielectric breakdown (only for material

2E15 ≥40 kV

thicknesses ≥0,5mm)

Surface resistance at 125 °C 2E07 ≥1 000 MΩ

2E07

Volume resistivity at 125 °C ≥1 000 MΩm

– 8 – 61249-2-38 © IEC:2008

6 Non-electrical properties of the copper-clad laminate

6.1 Appearance of the copper-clad sheet

The copper-clad face shall be substantially free from defects that may have an impact on the

material´s fitness for use for the intended purpose.

For the following specific defects the requirements given shall apply when inspection is made

in accordance with IEC 61189-2 method 2M18.

6.1.1 Indentations (pits and dents)

The size of an indentation, usually the length, shall be determined and given a point value to be

used as measure of the quality.

Point value for each

Size

mm indentation

0,13 – 0,25 1

0,26 – 0,50 2

0,51 – 0,75 4

0,76 – 1,00 7

Over 1,00 30

The total point count for any 300 mm × 300 mm area shall be calculated to determine the class

of the material.

Class A 29 maximum

Class B 17 maximum

Class C 5 maximum

Class D 0

Class X To be agreed upon by user and supplier

The required class of material shall be specified in the purchase order. Class A applies unless

otherwise specified.

6.1.2 Wrinkles

There shall be no wrinkles in the copper surface.

6.1.3 Scratches

Scratches deeper than 20 % of the nominal thickness of the foil thickness are not permitted.

Scratches with a depth less than 5 % of the nominal thickness of the foil shall not be counted

unless this depth is 10 μm or more.

Scratches with a depth between 5 % and 20 % of the nominal thickness of the foil are

permitted to a total length of 100 mm for a 300 mm × 300 mm area.

6.1.4 Raised areas

Raised areas are usually impressions in the press plates used during manufacture but may

also be caused by blisters or inclusions of foreign particles under the foil.

Raised areas caused by blisters or inclusions are not permitted.

61249-2-38 © IEC:2008 – 9 –

Raised areas being impressions of defects in press plates are permitted to the following extent:

Class A and X material maximum height 15 μm and maximum length 15 mm;

Class B and C material maximum height 8 μm and maximum length 15 mm;

Class D material maximum height 5 μm and maximum length 15 mm.

6.1.5 Surface waviness

When examined in accordance with test method 2M12 of IEC 61189-2, the surface waviness in

both the machine and cross machine direction shall not exceed 7 μm.

6.2 Appearance of the unclad face

The unclad face of single side clad sheet shall have the natural appearance resulting from the

curing process. Small irregularities in colour are permitted. The gloss of the unclad face shall

be that given by the press plate or release foil used. Variations of gloss due to the impact of

pressure of gases released during the curing are permitted.

6.3 Laminate thickness

The laminate thickness may be ordered to include or exclude the copper foil contribution as

specified in the purchase order. As a general rule, laminates less than 0,8 mm are measured

excluding copper and laminates greater or equal to 0,8 mm are measured including copper. If

the copper-clad laminate is tested in accordance with test method 2D01 of IEC 61189-2, the

thickness shall not depart from the nominal thickness by more than the appropriate value

shown in Table 2. The fine tolerances shall apply unless the other tolerances are ordered.

Table 2 – Nominal thickness and tolerance of metal-clad laminate

Nominal thickness excluding Nominal thickness including Tolerance requirements

metal foil (material intended metal foil (material intended

±mm

for multilayer boards) for single or double sided boards)

Coarse Fine Extra fine

mm mm

0,03 0,02 0,01

≥0,05 ≤ 0,10

0,04 0,03 0,02

>0,10 ≤ 0,15

0,05 0,04 0,03

>0,15 ≤ 0,30

0,08 0,05 0,04

>0,30 ≤ 0,50

0,09 0,06 0,05

>0,50 ≤ 0,80

0,13 0,09 0,07

≥0,80 ≤ 1,00

>0,80 ≤ 1,00

0,17 0,11 0,08

>1,00 ≤ 1,30

>1,00 ≤ 1,30

0,20 0,13 0,10

>1,30 ≤ 1,70

0,23 0,15 0,12

>1,70 ≤ 2,10

0,25 0,18 0,15

>2,10 ≤ 2,60

0,30 0,20 0,15

>2,60 ≤ 3,20

The thickness and tolerances do not apply to the outer 25 mm of the trimmed master sheet or

the outer 13 mm of the cut-to-size panel as manufactured and delivered by the supplier. At no

point shall the thickness vary from the nominal by a value greater than 125 % of the specified

tolerance.

6.4 Bow and twist

When the copper-clad laminate is tested in accordance with test method 2M01 of IEC 61189-2

the bow and twist shall not exceed the values given in Table 3.

– 10 – 61249-2-38 © IEC:2008

Table 3 – Bow and twist

Requirements

Nominal Panel dimension

Test method %

Property thickness longest side

(IEC 61189-2)

mm mm Copper foil on Copper foil on

one side both sides

Bow and 2M01 ≥0,8 ≤ 1,3 ≤350 ≤2,0 ≤1,5

twist

>350 ≤500 ≤1,8 ≤1,3

>500 ≤1,5 ≤1,0

>1,3 < 1,7 ≤350 ≤1,5 ≤1,0

>350 ≤500 ≤1,3 ≤0,8

>500 ≤1,0 ≤0,5

≥1,7 ≤ 3,2 ≤350 ≤1,0 ≤0,5

>350 ≤500 ≤0,8 ≤0,4

>500 ≤0,5 ≤0,3

NOTE The requirements for bow and twist apply only to one sided copper-clad laminates with maximum foil

thickness of 105 μm (915 g/m ) and double sided copper-clad laminates with maximum foil thickness difference of

70 μm (610 g/m ).

Requirements for laminates with copper foil configurations beyond these limits are subject to agreement between

purchaser and supplier.

6.5 Properties related to the copper foil bond

Pull-off and peel strength requirements are shown in Table 4. These requirements apply to

copper foil with a normal profile depth. In the case of low or very low profile copper foil, the

requirements shall be at least 50 % of that shown in Table 4 as a minimum.

61249-2-38 © IEC:2008 – 11 –

Table 4 – Pull-off and peel strength

Test method

Property Requirements

(IEC 61189-2)

Pull-off strength 2M05

≥25 N

Thickness of the copper foil

≤12 μm 18 μm 35 μm ≥70 μm

2 2

2 2

(152 g/m ) (305 g/m )

(≤101 g/m ) (≥610 g/m )

Peel strength after 2M14 ≥0,7 N/mm ≥0,9 N/mm ≥1,2 N/mm ≥1,6 N/mm

heat shock of 20 s

No blistering nor delamination

Peel strength after dry 2M15

≥0,7 N/mm ≥0,9 N/mm ≥1,2 N/mm ≥1,6 N/mm

o

heat 125 C

No blistering nor delamination

Peel strength after 2M06

exposure to solvent

vapour. Solvents as

≥0,7 N/mm ≥0,9 N/mm ≥1,2 N/mm ≥1,6 N/mm

agreed upon between

purchaser and supplier

No blistering nor delamination

Peel strength after 2M16

≥0,6 N/mm ≥0,8 N/mm ≥1,0 N/mm ≥1,2 N/mm

simulated plating

No blistering nor delamination

Peel strength at high 2M17

temperature

Not specified ≥0,7 N/mm ≥0,9 N/mm ≥1,1 N/mm

o

Temperature 125 C

(optional)

Blistering after 20 s heat 2C05

No blistering nor delamination

shock

NOTE In case of difficulty due to breakage of the foil or reading range of the force measuring device, the

measurement of peel strength at high temperature may be carried out using conductor widths of more than 3 mm.

6.6 Punching and machining

Punching is not applicable. The laminate shall, in accordance with the manufacturer’s

recommendations, be capable of being sheared or drilled. Delamination at the edges due to the

shearing process is permissible, provided that the depth of delamination is not larger than the

thickness of the base material. Delamination at the edges of drilled holes due to the drilling

process is not permissible. Drilled holes shall be capable of being through-plated with no

interference from any exudations into the hole.

6.7 Dimensional stability

The dimensional stability requirements are shown in Table 5. When specimens are tested in

accordance to IEC 61189-2, 2X02, the observed tolerance shall be as specified in Table 5. The

nominal dimensional stability value shall be as agreed upon between user and vendor. The

tolerance range around the agreed upon nominal thickness shall be range B unless otherwise

specified on the purchase order.

The choice of the glass fabrics in the construction of the laminate has a significant impact on

dimensional stability. Examples of typical constructions used in printed board applications can

be found in Annex B.

Class A performance shall apply unless otherwise noted on the purchase order.

– 12 – 61249-2-38 © IEC:2008

Table 5 – Dimensional stability

Test method Requirements

Property Class

(IEC 61189-2) ppm

Dimensional stability 2X02 A

±300

B

±200

C ±100

X As agreed upon between user and supplier

6.8 Sheet sizes

6.8.1 Typical sheet sizes

Sheet sizes are matters of agreement between purchaser and supplier. However the

recommended sizes are listed below:

– 915 mm × 1 220 mm;

– 1 065 mm × 1 155 mm;

– 1 065 mm × 1 280 mm;

– 1 000 mm × 1 000 mm;

– 1 000 mm × 1 200 mm.

6.8.2 Tolerances for sheet sizes

+20

The size of sheet delivered by the supplier shall not deviate more that mm from the ordered

size.

6.9 Cut panels

6.9.1 Cut panel sizes

Cut panel sizes shall be, when delivered, in accordance with the purchaser’s specification.

6.9.2 Size tolerances for cut panels

For panels cut to size according to the purchaser’s specification, the following tolerances for

length and width shall apply as shown in Table 6. Tolerances indicated as normal shall be in

effect unless otherwise specified by in the purchasing specification.

Table 6 – Size tolerance for cut panels

Tolerance requirements

Panel size

± mm

mm

Normal Close

2,0 0,5

≤300

2,0 0,8

>300 ≤600

2,0 1,6

>600

NOTE The specified tolerances include all deviations caused by cutting the panels.

61249-2-38 © IEC:2008 – 13 –

6.9.3 Rectangularity of cut panels

For panels cut to size according to the purchaser’s specification, the following requirements for

rectangularity shall apply as shown in Table 7. Tolerance indicated as normal shall be in effect

unless otherwise specified in the purchasing specification.

Table 7 – Rectangularity of cut panels

Requirements

Test method

mm/m

Property

(IEC 61189-2)

Normal Close

Rectangularity of cut panels 2M23 ≤3 ≤2

7 Non-electrical properties of the base material after complete removal of the

copper foil

7.1 Appearance of the dielectric base material

The etched specimens shall be inspected to verify that no surface or subsurface imperfections

of the dielectric material exceed those shown below. The panels shall be inspected using an

optical aid apparatus which provides a minimum magnification of 4X.

Referee inspection shall be conducted at 10X magnification. Lighting conditions of inspection

shall be appropriate to the material under inspection or as agreed upon between user and

supplier.

Surface and subsurface imperfections (such as weave texture, resin starvation, voids, foreign

inclusions) shall be acceptable provided that the imperfections meet the following:

• the reinforcement fibres are not cut or exposed;

• the foreign inclusions are not conductive;

• the imperfections do not propagate as a result of thermal stress;

• the foreign inclusions are translucent;

• opaque foreign fibres are less than 15 mm in length and average no more than one per

300 mm × 300 mm area;

• opaque foreign inclusions other than fibres shall not exceed 0,50 mm. Opaque foreign

inclusions less than 0,15 mm shall not be counted. Opaque foreign inclusions between

0,50 mm and 0,15 mm shall average no more than two spots per 300 mm × 300 mm area;

• voids (sealed voids or surface void) have a longest dimension less than 0,075 mm and

there should not be more than three voids in a 3,5 mm diameter circle.

7.2 Flexural strength

When the laminate is tested in accordance with test method 2M20 of IEC 61189-2 the flexural

strength shall be as shown in Table 8.

– 14 – 61249-2-38 © IEC:2008

Table 8 – Flexural strength

Test method

Property Requirements

(IEC 61189-2)

Flexural strength 2M20

Length direction

≥400 N/mm

Cross direction 2

≥300 N/mm

(applicable to sheets ≥1,0 mm in thickness)

Flexural strength

Length direction Not specified

Elevated temperature

(applicable to sheets ≥1,0 mm in thickness)

7.3 Flammability

When the laminate is tested in accordance with test method 2C08 (thickness ≥0,05 mm ≤

0,3 mm) or 2C06 (thickness >0,3 mm ≤ 3,2 mm) of IEC 61189-2, the flammability shall be as

shown in Table 9.

The performance labelled V-0 shall apply unless otherwise noted on the purchase order.

Table 9 – Flammability

Test method

Property Requirements

(IEC 61189-2)

Flammability

Designation

2C06

V-0

Flaming combustion time after each application of the flame for each

≤10 s

test specimen.

Total flaming combustion time for the 10 flame applications for each set

of five specimens.

≤50 s

Glowing combustion time after the second removal of the test flame.

Flaming or glowing combustion up to the holding clamp.

≤30 s

Dripping flaming particles that ignite the tissue paper

None

None

7.4 Water absorption

When the laminate is tested in accordance with test method 2N02 of IEC 61189-2, the

maximum water absorption shall be as shown in Table 10.

Table 10 – Water absorption

Test method Thickness Requirements

Property

mm

(IEC 61189-2) %

2N02

≥0,05 < 0,20 ≤2,00

Water absorption

≥0,20 < 0,30 ≤1,50

≥0,30 < 0,40 ≤1,20

≥0,40 < 0,50 ≤1,00

61249-2-38 © IEC:2008 – 15 –

Test method Thickness Requirements

Property

(IEC 61189-2) mm %

≥0,50 < 0,60 ≤0,80

≥0,60 < 0,80 ≤0,70

≥0,80 < 1,00 ≤0,50

≥1,00 < 1,20 ≤0,50

≥1,20 < 1,60 ≤0,40

≥1,60 < 2,00 ≤0,25

≥2,00 < 2,40 ≤0,20

≥2,40 < 3,20 ≤0,20

7.5 Measling

When the laminate is tested in accordance with test method 2N01 of IEC 61189-2, the

presence of measles allowed shall be as shown in Table 11.

Table 11 – Measling

Test method

Property Requirements

(IEC 61189-2)

Measling 2N01 No measling on three specimens. If one out of three

specimens fails, the test has to be repeated.

No measling on three specimens of the second test is

permitted.

No blistering or delamination on any of the three

specimens is permitted.

7.6 Glass transition temperature and cure factor

The requirements for glass transition temperature and cure factor are found in Table 12.

Table 12 – Glass transition temperature and cure factor

Test method

Property Requirements

(IEC 61189-2)

Glass transition temperature 2M10 or 2M11

≥120 °C

Cure factor 2M03 ≥0,96

7.7 Decomposition temperature

The requirements for decomposition temperature are found in Table 13.

Table 13 – Decomposition temperature

Test method

Property Requirements

(IEC 61189-2)

Decomposition temperature (5 % 2MXX

≥310°C

weight loss from 50 °C)

– 16 – 61249-2-38 © IEC:2008

7.8 Thermal resistance

The requirements for thermal resistance are found in Table 14. The specimen shall not have

copper foil on any layer.

Table 14 – Thermal resistance

Test method

Property Requirements

(IEC 61189-2)

T260 2MXX

≥30 min

T288 ≥5 min

T300 TBD

7.9 Z-axis expansion

The requirements for Z-axis expansion are found in Table 15.

Table 15 – Z-axis expansion

Test method

Property Requirements

(IEC 61189-2)

Z-axis alpha 1 2MXX -6 /

≤60 × 10 °C

-6

Z-axis alpha 2

≤300 × 10 / °C

Z-axis % 50 °C to 260 °C 4,0 % maximum

8 Quality assurance

8.1 Quality system

The supplier shall operate a quality system, ISO 9000 or similar, to support quality

conformance inspection.

The supplier shall operate a management system for environmental control, ISO 14000 or

similar, to support environmental considerations.

8.2 Responsibility for inspection

The supplier is responsible for all the inspections of the manufactured material. The purchaser

or an appointed third party may audit this inspection.

8.3 Qualification inspection

Laminates furnished under this standard shall be qualified. Qualification testing shall be

performed to demonstrate the manufacturer’s ability to meet the requirements of this standard.

Qualification testing shall be conducted at a laboratory in compliance with IEC laboratory

requirements. A list of the normal qualification tests can be found in Annex C. The

manufacturer shall retain on file the data which supports that the materials meet this standard

and shall be readily available for review upon request.

8.4 Quality conformance inspection

The supplier shall operate a quality plan to assure product conformance to this standard. Such

a quality plan, when appropriate, should utilize statistical methods rather than lot-by-lot

inspection. It is the responsibility of the supplier, based on the quality plan, to determine the

frequency of test to assure conforming products. In the absence of a quality plan or supporting

data, the testing regime shall be as outlined in Annex C.

61249-2-38 © IEC:2008 – 17 –

A combination of the following techniques may be used to show compliance with the

requirements which can be used to reduce the frequency of testing. The data supporting the

reduction of testing frequency shall be available for review upon request.

• In process parameter control

• In process inspection

• Periodic final inspection

• Final lot inspection

8.5 Certificate of conformance

The supplier shall, on request from the purchaser, issue a certificate of conformance to this

standard in electronic or paper format.

8.6 Safety data sheet

A safety data sheet in accordance with ISO 11014-1 shall be available for products

manufactured and delivered in compliance with this standard.

9 Packaging and marking

If not otherwise specified in the purchase order, laminate sheets shall be marked with the

manufacturer's designation and lot number. Marking shall remain legible during normal

handling but be readily removable prior to use of the material.

Cut-to-size panels shall be identified by marking on the package.

Laminates comprised of asymmetric copper configurations shall be marked on the side of

heaviest copper weight.

Sheets and panels shall be packaged in a manner which will provide adequate protection

against corrosion, deterioration and physical damage during shipment and storage.

Packages shall be marked in a manner to clearly identify the contents.

10 Ordering information

Order shall include the following details:

a) A reference to this specification

b) Type of material (see scope and 7.3)

c) Size, thickness and copper cladding

d) Class of indentations if other than “A” (see 6.1.1).

e) Class of raised areas if other than “A” (see 6.1.4).

f) Class of thickness tolerance if other than “fine” (see 6.3).

g) Class of dimensional stability if other than “A” (see 6.7).

h) Class of panel size tolerance if other than “normal” (see 6.9.2).

i) Request for certification if applicable (see 8.5)

– 18 – 61249-2-38 © IEC:2008

Annex A

(informative)

Engineering information

A.1 General

Information in this annex does not detail material property requirements. The information is

intended as a guideline for design and engineering purposes. Users of this standard are

encouraged to supply information to be included in the annex.

Materials according to this standard show the properties and data as listed in Clause A.2 to

Clause A.7.

A.2 Chemical properties

• Resistance against chemicals

A.3 Electrical properties

• Comparative tracking index 175 – 250 V

A.4 Flammability properties

• Needle flame test

• Oxygen index 45 %

A.5 Mechanical properties

• Compressive strength (flatwise) 400 N/mm

• Compressive strength (edgewise) 240 N/mm

• Hardness at room temperature 200 (Rockwell M)

• Modulus of elasticity, flexural (warp) 1,9 × 10 N/mm

• Modulus of elasticity, flexural (weft) 1,5 × 10 N/mm

• Modulus of elasticity, tensile (warp) 1,7 × 10 N/mm

• Modulus of elasticity, tensile (weft) 1,4 × 10 N/mm

• Poisson’s ratio 0,12 - 0,16

• Shear strength 148 N/mm

• Young’s modulus 22 GPa

61249-2-38 © IEC:2008 – 19 –

A.6 Physical properties

• Density 1,85 g/cm

A.7 Thermal properties

–6

• Coefficient of thermal expansion (

–6

• Coefficient of thermal expansion (

• Specific heat capacity 1,25 kJ/kg ⋅ °C

• Thermal conductivity 0,3 W/m ⋅ °C

• UL temperature index (mechanical) 130 °C

• UL temperature index (electrical) 130 °C

• Maximum operating temperature (MOT) 130 °C

– 20 – 61249-2-38 © IEC:2008

Annex B

(informative)

Common laminate constructions

Nominal thickness

Common construction

mm

0,075 1 080

0,080 2 × 106

0,100

2 × 106

0,100 2 113

0,100 2 116

0,125 2 116

0,125 2 165

0,125

2 × 1 080

0,15 2 157

0,15 2 165

0,16 1 500

0,18 7 628

0,18 1 500

0,20 2 × 2 113

0,20

2 × 2 116

0,20 7 628

0,25

2 × 2 116

0,25

2 × 2 165

0,26 1 080/2 116/1 080

0,30

2 × 2 157

0,30 2 × 2 165

0,30 2 116/2 112/2 116

0,30

1 080/7 628/1 080

0,36

2 × 7 628

0,37 2 113/7 628/2 113

0,38 1 500/1 080/1 500

0,41 7 628/1 080/7 628

0,43 2116/7628/2116

0,45

3 × 1 500

0,46 7 628/2 112/7 628

0,48 7 628/2 116/7 628

0,51 7 628/2 165/7 628

0,51 1 080/2 × 7 628/1 080

0,54

3 × 7 628

0,61

3 × 7 628/1 080

0,61 2 116/2 × 7 628/2 116

0,66

7 628

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...