IEC 61189-2-721:2015

(Main)Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 2-721: Test methods for materials for interconnection structures - Measurement of relative permittivity and loss tangent for copper clad laminate at microwave frequency using a split post dielectric resonator

Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 2-721: Test methods for materials for interconnection structures - Measurement of relative permittivity and loss tangent for copper clad laminate at microwave frequency using a split post dielectric resonator

IEC 61189-2-721:2015 outlines a way to determine the relative permittivity and loss tangent (also called dielectric constant and dissipation factor) of copper clad laminates at microwave frequencies (from 1,1 GHz to 20 GHz) using a split post dielectric resonator (SPDR). IEC 61189-2-721:2015 is applicable to copper clad laminates and dielectric base materials.

Methodes d'essai pour les matériaux éléctriques, les cartes imprimées et autres structures d'interconnexion et ensembles - Partie 2-721: Méthodes d'essai des matériaux pour structures d'interconnexion - Mesure de la permittivité relative et de la tangente de perte pour les stratifiés recouverts de cuivre en hyperfréquences à l'aide d'un résonateur diélectrique en anneaux fendus

L'IEC 61189-2-721:2015 présente un moyen de déterminer la permittivité relative et la tangente de perte, également appelées constante diélectrique et facteur de dissipation des stratifiés recouverts de cuivre en hyperfréquences (de 1,1 GHz à 20 GHz) à l'aide d'un résonateur diélectrique en anneaux fendus (SPDR). l'IEC 61189-2-721:2015 s'applique aux stratifiés recouverts de cuivre et aux matériaux de base diélectriques.

General Information

- Status

- Published

- Publication Date

- 28-Apr-2015

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 10 - TC 91/WG 10

- Current Stage

- PPUB - Publication issued

- Start Date

- 29-Apr-2015

- Completion Date

- 31-May-2015

Overview

IEC 61189-2-721:2015 is an international standard published by the International Electrotechnical Commission (IEC) that specifies test methods for determining key electrical properties of copper clad laminates (CCLs) used in interconnection structures. The standard focuses on measuring the relative permittivity (dielectric constant) and loss tangent (dissipation factor) of these materials at microwave frequencies ranging from 1.1 GHz to 20 GHz. The measurement technique employs a split post dielectric resonator (SPDR), an advanced test fixture that ensures highly accurate characterization of dielectric materials critical for high-frequency electronic applications.

This standard is integral for manufacturers, designers, and quality control specialists working with copper clad laminates and dielectric base materials in printed circuit boards (PCBs) and other electronic interconnection assemblies. Accurate electrical property data at microwave frequencies is essential for optimizing signal integrity, minimizing electromagnetic losses, and ensuring device reliability.

Key Topics

Test Specimens and Preparation

Guidance is provided on specimen size, preparation, thickness measurement, and marking to ensure consistency and repeatability in testing results.Test Equipment Requirements

The standard outlines use of equipment including vector network analyzers (VNAs), SPDR test fixtures, micrometers, circulating ovens, and temperature-controlled test chambers for precise measurement conditions.Measurement Procedures

Detailed steps cover:- Preconditioning of specimens

- Room temperature testing

- Variable temperature testing

- Calibration and connection of test fixtures to VNAs

- Resonance frequency and quality factor (Q-factor) determination with and without specimens

- Calculation methods for extracting relative permittivity and loss tangent from measurements

Temperature Influence

Procedures to assess dielectric properties at different temperatures allow for evaluation of material behavior under operational environmental variations.Accuracy and Reporting

Recommendations for maintaining equipment, ensuring measurement accuracy, and reporting results comprehensively for industry use.

Applications

IEC 61189-2-721:2015 is essential in industries where microwave frequency performance of PCBs and interconnection structures impacts the overall product effectiveness. Typical applications include:

High-Frequency PCB Manufacturing

Ensuring copper clad laminates meet dielectric specifications critical for RF and microwave circuits.Telecommunications Equipment

Evaluation of materials used in antenna feeds, waveguides, and microwave modules.Aerospace and Defense Electronics

Testing materials destined for radar, satellite communication systems, and high-reliability electronics requiring stringent dielectric performance.Automotive Radar and Sensor Systems

Characterization of laminates used in advanced driver-assistance and autonomous vehicle technology.

Utilizing the SPDR measurement technique facilitates the selection and qualification of substrate materials that optimize signal transmission, minimize losses, and enhance device longevity.

Related Standards

Professionals working with IEC 61189-2-721:2015 should consider other related standards to complement this test method:

IEC 61189 series – Comprehensive test methods for electrical materials and printed boards, covering a wide range of electrical and mechanical properties.

IPC-4101 – Specification for base materials used in rigid and multi-layer PCBs, addressing materials’ electrical and mechanical performance.

ISO/IEC 17025 – General requirements for the competence of testing and calibration laboratories, ensuring quality in material testing.

IEEE standards on dielectric measurements – Relevant for advanced testing and characterization of dielectric materials at high frequencies.

By adhering to IEC 61189-2-721:2015 and related international guidelines, manufacturers and researchers can accurately measure and optimize copper clad laminates for critical microwave frequency applications, ensuring performance and reliability in advanced electronic assemblies.

Keywords: IEC 61189-2-721, relative permittivity, loss tangent, dielectric constant, dissipation factor, copper clad laminate, split post dielectric resonator, microwave frequency testing, PCB materials testing, interconnection structures, vector network analyzer, microwave dielectric measurement, high-frequency laminates.

Buy Documents

IEC 61189-2-721:2015 - Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 2-721: Test methods for materials for interconnection structures - Measurement of relative permittivity and loss tangent for copper clad laminate at microwave frequency using a split post dielectric resonator Released:4/29/2015

Frequently Asked Questions

IEC 61189-2-721:2015 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 2-721: Test methods for materials for interconnection structures - Measurement of relative permittivity and loss tangent for copper clad laminate at microwave frequency using a split post dielectric resonator". This standard covers: IEC 61189-2-721:2015 outlines a way to determine the relative permittivity and loss tangent (also called dielectric constant and dissipation factor) of copper clad laminates at microwave frequencies (from 1,1 GHz to 20 GHz) using a split post dielectric resonator (SPDR). IEC 61189-2-721:2015 is applicable to copper clad laminates and dielectric base materials.

IEC 61189-2-721:2015 outlines a way to determine the relative permittivity and loss tangent (also called dielectric constant and dissipation factor) of copper clad laminates at microwave frequencies (from 1,1 GHz to 20 GHz) using a split post dielectric resonator (SPDR). IEC 61189-2-721:2015 is applicable to copper clad laminates and dielectric base materials.

IEC 61189-2-721:2015 is classified under the following ICS (International Classification for Standards) categories: 31.180 - Printed circuits and boards. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61189-2-721:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61189-2-721 ®

Edition 1.0 2015-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Test methods for electrical materials, printed boards and other interconnection

structures and assemblies –

Part 2-721: Test methods for materials for interconnection structures –

Measurement of relative permittivity and loss tangent for copper clad laminate

at microwave frequency using split post dielectric resonator

Méthodes d'essai pour les matériaux électriques, les cartes imprimées et autres

structures d'interconnexion et ensembles –

Partie 2-721: Méthodes d'essai des matériaux pour structures d'interconnexion –

Mesure de la permittivité relative et de la tangente de perte pour les stratifiés

recouverts de cuivre en hyperfréquences à l'aide d'un résonateur diélectrique

en anneaux fendus

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 15

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 60 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

15 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 60 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 61189-2-721 ®

Edition 1.0 2015-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Test methods for electrical materials, printed boards and other interconnection

structures and assemblies –

Part 2-721: Test methods for materials for interconnection structures –

Measurement of relative permittivity and loss tangent for copper clad laminate

at microwave frequency using split post dielectric resonator

Méthodes d'essai pour les matériaux électriques, les cartes imprimées et autres

structures d'interconnexion et ensembles –

Partie 2-721: Méthodes d'essai des matériaux pour structures d'interconnexion –

Mesure de la permittivité relative et de la tangente de perte pour les stratifiés

recouverts de cuivre en hyperfréquences à l'aide d'un résonateur diélectrique

en anneaux fendus

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.180 ISBN 978-2-8322-2648-3

– 2 – IEC 61189-2-721:2015 © IEC 2015

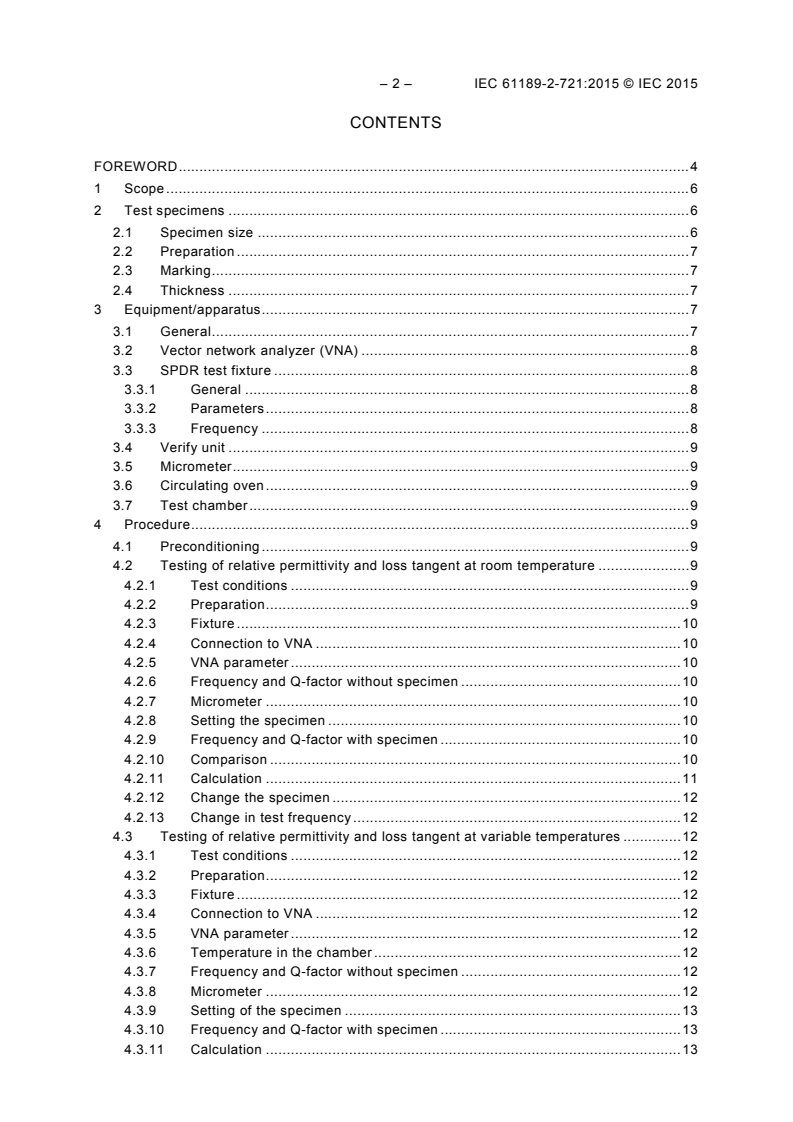

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Test specimens . 6

2.1 Specimen size . 6

2.2 Preparation . 7

2.3 Marking . 7

2.4 Thickness . 7

3 Equipment/apparatus . 7

3.1 General . 7

3.2 Vector network analyzer (VNA) . 8

3.3 SPDR test fixture . 8

3.3.1 General . 8

3.3.2 Parameters . 8

3.3.3 Frequency . 8

3.4 Verify unit . 9

3.5 Micrometer . 9

3.6 Circulating oven . 9

3.7 Test chamber . 9

4 Procedure . 9

4.1 Preconditioning . 9

4.2 Testing of relative permittivity and loss tangent at room temperature . 9

4.2.1 Test conditions . 9

4.2.2 Preparation . 9

4.2.3 Fixture . 10

4.2.4 Connection to VNA . 10

4.2.5 VNA parameter . 10

4.2.6 Frequency and Q-factor without specimen . 10

4.2.7 Micrometer . 10

4.2.8 Setting the specimen . 10

4.2.9 Frequency and Q-factor with specimen . 10

4.2.10 Comparison . 10

4.2.11 Calculation . 11

4.2.12 Change the specimen . 12

4.2.13 Change in test frequency . 12

4.3 Testing of relative permittivity and loss tangent at variable temperatures . 12

4.3.1 Test conditions . 12

4.3.2 Preparation . 12

4.3.3 Fixture . 12

4.3.4 Connection to VNA . 12

4.3.5 VNA parameter . 12

4.3.6 Temperature in the chamber . 12

4.3.7 Frequency and Q-factor without specimen . 12

4.3.8 Micrometer . 12

4.3.9 Setting of the specimen . 13

4.3.10 Frequency and Q-factor with specimen . 13

4.3.11 Calculation . 13

4.3.12 Options . 13

4.3.13 Thermal coefficient . 13

4.3.14 Change in test frequency . 14

5 Report . 14

5.1 At room temperature . 14

5.2 At variable temperature . 14

6 Additional information . 14

6.1 Accuracy . 14

6.2 Maintenance . 14

6.3 Matters to be attended . 15

6.4 Additional information concerning fixtures and results . 15

6.5 Additional information on K (ε ,h) and p . 15

ε r es

Annex A (informative) Example of test fixture and test result . 16

A.1 Example of test fixture . 16

A.2 Example of test result . 16

Annex B (informative) Additional information on K (ε ,h) and p . 19

ε r es

Bibliography . 22

Figure 1 – Scheme of SPDR test fixture . 6

Figure 2 – Component diagram of test system . 8

Figure 3 – Scheme of the change of resonance frequency with or without the

specimen . 10

Figure A.1 – Test fixture . 16

Figure A.2 – Relative permittivity versus frequency (laminate of Dk 3,8 and thickness

0,51 mm) . 17

Figure A.3 – Loss tangent versus frequency (laminate of Dk 3,8 and thickness

0,51 mm) . 17

Figure A.4 – Curve of relative permittivity and loss tangent at variable temperatures

(laminate of Dk 3,8 and thickness 0,51 mm) . 18

Figure B.1 – K (ε ,h) versus relative permittivity at different sample thicknesses . 19

ε r

Figure B.2 – Distribution of the electric field of the split dielectric resonator (side view

of the dielectric resonators) . 20

Figure B.3 – Distribution of the electric field of the split dielectric resonator (top view

between the dielectric resonators) . 21

Figure B.4 – p versus relative permittivity at different sample thicknesses . 21

es

Table 1 – Specimen dimensions . 7

Table 2 – SPDR test fixture’s parameter . 9

Table B.1 – Results of measurements of different materials using a 10 GHz SPDR. 20

– 4 – IEC 61189-2-721:2015 © IEC 2015

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

TEST METHODS FOR ELECTRICAL MATERIALS, PRINTED BOARDS AND

OTHER INTERCONNECTION STRUCTURES AND ASSEMBLIES –

Part 2-721: Test methods for materials for interconnection structures –

Measurement of relative permittivity and loss tangent for copper clad

laminate at microwave frequency using split post dielectric resonator

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61189-2-721 has been prepared by IEC technical committee 91:

Electronics assembly technology.

The text of this standard is based on the following documents:

FDIS Report on voting

91/1246/FDIS 91/1258/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

A list of all parts in the IEC 61189 series, published under the general title Test methods for

electrical materials, printed boards and other interconnection structures and assemblies, can

be found on the IEC website.

Future standards in this series will carry the new general title as cited above. Titles of existing

standards in this series will be updated at the time of the next edition.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 61189-2-721:2015 © IEC 2015

TEST METHODS FOR ELECTRICAL MATERIALS, PRINTED BOARDS AND

OTHER INTERCONNECTION STRUCTURES AND ASSEMBLIES –

Part 2-721: Test methods for materials for interconnection structures –

Measurement of relative permittivity and loss tangent for copper clad

laminate at microwave frequency using split post dielectric resonator

1 Scope

This part of IEC 61189 outlines a way to determine the relative permittivity (ε ) and loss

r

δ) (also called dielectric constant (Dk) and dissipation factor (Df)) of copper clad

tangent (tan

laminates at microwave frequencies (from 1,1 GHz to 20 GHz) using a split post dielectric

resonator (SPDR).

This part of IEC 61189 is applicable to copper clad laminates and dielectric base materials.

2 Test specimens

2.1 Specimen size

The size of the specimen shall be larger than the internal diameter D of the metal enclosures,

and the maximum thickness of the specimen shall be smaller than the distance h between

g

the metal enclosures of the fixture. (See Figure 1.)

Z

Support

D

Dielectric resonators

Coupling loop

Sample

d

r

Metal enclosure

IEC

Key

h distance between the metal enclosures of the fixture;

g

D internal diameter of the metal enclosures;

L internal height of the metal enclosures;

d diameter of the dielectric resonator;

r

h thickness of the dielectric resonator.

r

Figure 1 – Scheme of SPDR test fixture

h

g

h

r

L

Three specimens for the test at room temperature and one specimen for the test at variable

temperatures are required for each SPDR test fixture for this test. Table 1 shows the

supported specimen dimensions.

Table 1 – Specimen dimensions

SPDR test fixture’s nominal

Supported specimen sizes Maximum thickness of specimens

frequency

GHz mm mm

1,1 150 × 150 6,0

3 3,0

80 × 80

5 to 6 2,0

80 × 80

9 to 10 80 × 80 0,9

13 to 16 50 × 35 0,6

18 to 20 0,5

15 × 15

If applicable, a specimen size different from those given in Table 1 can be used. For example,

specimen size “130 mm × 130 mm” can be used for 1,1 GHz.

2.2 Preparation

Copper clad laminates shall have all copper cladding removed by etching, and shall be

thoroughly cleaned.

2.3 Marking

Mark each specimen in the upper left corner with an engraving pencil or other suitable method.

2.4 Thickness

Within the limits of the test fixture, the thicker the specimen is, the less error occurs in the

measurements. Thin specimen can be stacked up to a minimum of 0,4 mm to improve

measurement accuracy.

NOTE Air gaps between the sample and fixture do not affect the measurement.

3 Equipment/apparatus

3.1 General

The component diagram of the test system is shown in Figure 2.

– 8 – IEC 61189-2-721:2015 © IEC 2015

Room temperature test

Variable temperature test

VNA

VNA

Environmental test chamber

SPDR test fixture

Sample

SPDR test fixture

Sample

IEC

Figure 2 – Component diagram of test system

3.2 Vector network analyzer (VNA)

The following values are required:

a) The frequency range of VNA shall be 500 MHz to 20 GHz.

b) The dynamic range of VNA shall be more than 60 dB.

3.3 SPDR test fixture

3.3.1 General

Figure 1 shows the scheme of SPDR test fixture.

3.3.2 Parameters

Table 2 shows the typical relationship between the SPDR test fixture’s nominal frequency and

h and D.

g

3.3.3 Frequency

For different test frequencies, use a corresponding SPDR test fixture of nominal frequency.

Table 2 – SPDR test fixture’s parameter

SPDR test fixture’s nominal frequency D h

g

GHz mm mm

1,1 120 6,0

3 50 3,0

5 to 6 30 2,0

9 to 10 22 0,9

13 to 16 15 0,6

18 to 20 10 0,5

3.4 Verify unit

The verify unit includes the following:

a) Standard reference sample, for example, single-crystal quartz or equivalent sample.

b) A calibration assembly of VNA.

3.5 Micrometer

Micrometer with 0,001 mm resolution (or better).

3.6 Circulating oven

+5

Circulating oven with stabilized temperature at 105 °C.

−2

3.7 Test chamber

For the environmental test chamber for variable temperature testing the following

requirements apply:

a) Temperature ranges: –125 °C to +110 °C, other temperature range is as agreed between

user and supplier.

b) Temperature accuracy-set point to actual: ±1 °C.

4 Procedure

4.1 Preconditioning

All specimens shall be conditioned at (23 ± 2) °C and (50 ± 5) % RH for at least 24 h prior to

testing. However, if a specimen has recently been etched or exposed to excessive moisture, it

+5

should be dried in an air-circulating oven for 2 h at 105 °C and then conditioned at the

−2

condition as mentioned above.

4.2 Testing of relative permittivity and loss tangent at room temperature

4.2.1 Test conditions

The ambient test temperature should be (23 ± 2) °C. The variation should not exceed 1 °C

during the test.

4.2.2 Preparation

Allow at least 30 min for the VNA to warm up and stabilize.

– 10 – IEC 61189-2-721:2015 © IEC 2015

4.2.3 Fixture

Select an SPDR test fixture in accordance with the test frequency. The specimen size and

thickness shall comply with the requirements specified in Table 1. For example, if the test

frequency is 10 GHz, a SPDR test fixture with 10 GHz nominal frequency should be selected.

The supported specimen size is 80 mm × 80 mm and the maximum thickness of specimens is

no more than 0,9 mm.

4.2.4 Connection to VNA

Connect the SPDR test fixture to the VNA. The test fixture shall be kept horizontal.

4.2.5 VNA parameter

Set the VNA parameters according to the manufacturer's instructions and the nominal

frequency of the SPDR fixture.

4.2.6 Frequency and Q-factor without specimen

Measure the resonance frequency (f ) and Q-factor (Q ) values of the empty resonator.

0 0

4.2.7 Micrometer

Utilize a micrometer to measure the thickness of the specimen and record as h.

4.2.8 Setting the specimen

Insert the specimen into the test fixture. The side with marking is face up and the edge of this

side has to be aligned with the fixture edge.

4.2.9 Frequency and Q-factor with specimen

Measure the resonance frequency (f ) and Q-factor (Q ) of the resonator containing the

s s

specimen.

4.2.10 Comparison

The scheme of the change of resonance frequency with or without the specimen is shown in

Figure 3.

Empty resonator

Resonator containing

the specimen

f f

S 0

Resonance frequency

IEC

Figure 3 – Scheme of the change of resonance frequency

with or without the specimen

Resonance amplitude

4.2.11 Calculation

4.2.11.1 General

Calculation of relative permittivity and loss tangent at room temperature.

Relative permittivity and loss tangent at room temperature shall be calculated as follows. It is

recommended to use the computer software provided by the equipment supplier for

calculation.

4.2.11.2 Relative permittivity

The relative permittivity (ε ) shall be calculated according to Equation (1).

r

f − f

0 s

ε = 1+ (1)

r

hf K (ε ,h)

0 ε r

where

ε is relative permittivity;

r

h is the thickness of the specimen under test, in mm;

f is the resonant frequency of the empty SPDR;

f is the resonant frequency of the resonator with the dielectric specimen;

s

K (ε h) is a function of ε and h. For a fixed resonant cavity, its physical parameters (size,

ε r, r

dielectric resonators ε ) should have been identified. K (ε h) is pre-computed and

r ε r,

tabulated by electromagnetic field simulation with the strict Rayleigh-Ritz method.

Put the empty SPDR frequency (f ), the resonant frequency with dielectric

specimen (f ) and the thickness of the specimen (h) under test into Equation (1).

s

Enter a similar arbitrary value of the relative permittivity of the sample, and use a

successive approximation algorithm. After several iterations, end the calculation

when the relative error of the last two calculated relative permittivities is less than

0,1 %. The last calculated data is taken as the relative permittivity of the specimen.

Some additional information is shown in Annex B.

4.2.11.3 Loss tangent

The loss tangent shall be calculated according to Equation (2).

−1 −1 −1

(Q − Q − Q )

S DR C

tanδ = (2)

p

es

where

tanδ is the loss tangent;

is the unloaded Q-factor of a resonant fixture containing the specimen;

Q

s

Q is the Q-factor depending on metal losses for the resonant fixture containing the

c

specimen;

Q is the Q-factor depending on dielectric losses in the dielectric posts for the fixture

DR

containing the specimen;

p is the electromagnetic energy filling factor of the specimen. After identifying the

es

physical parameters of the resonant cavity, the electromagnetic energy filling factor

p can be determined by electromagnetic field simulation. For a fixed resonant

es

cavity, p is a constant value. Some additional information is showed in Annex B.

es

– 12 – IEC 61189-2-721:2015 © IEC 2015

4.2.12 Change the specimen

Measure the two remaining specimens by repeating steps 4.2.6 through 4.2.11.

4.2.13 Change in test frequency

If another test frequency is selected, change the SPDR test fixture in accordance with the test

frequency. Then repeat steps 4.2.3 through 4.2.12.

4.3 Testing of relative permittivity and loss tangent at variable temperatures

4.3.1 Test conditions

The ambient test temperature should be (23 ± 2) °C. The variation should not exceed 1 °C

during the test.

4.3.2 Preparation

Allow at least 30 min for the VNA to warm up.

4.3.3 Fixture

Select an SPDR test fixture in accordance with the test frequency. The specimen size and

thickness shall comply with the requirements specified in Table 1. For example, if the test

frequency is 10 GHz, an SPDR test fixture with 10 GHz nominal frequency should be selected.

The supported specimen size is 80 mm × 80 mm and the maximum thickness of the specimen

is no more than 0,9 mm.

4.3.4 Connection to VNA

Connect the SPDR test fixture to the VNA. The test fixture shall be kept in a horizontal

position in the test chamber.

4.3.5 VNA parameter

Set the VNA parameters according to the manufacturer's instructions and the nominal

frequency of the SPDR fixture.

4.3.6 Temperature in the chamber

Adjust the test temperature of the test chamber. After reaching the set temperature (T), hold it

for at least 15 min.

4.3.7 Frequency and Q-factor without specimen

Measure the resonance frequency f (T) and Q-factor Q (T) of the empty resonator.

0 0

The resonance peak should be between –40 dB and –45 dB; adjust the position of the

coupling loops to achieve this whilst ensuring their position is symmetrical.

When measuring the Q-factor, the frequency span of the VNA should be adjusted such that it

is between 110 % and 200 % of the full width at half maximum of the resonant curve.

4.3.8 Micrometer

Use a micrometer to measure the thickness of the specimen, and record as h.

4.3.9 Setting of the specimen

The environmental test chamber shall be returned to room temperature. Insert the specimen

into the test fixture. The side with marking is face up and the edge of this side has to be

aligned with the fixture edge.

4.3.10 Frequency and Q-factor with specimen

Repeat step 4.3.6. Measure the resonance frequency f (T) and Q-factor Q (T) of the resonator

s s

with the specimen at temperature T.

When measuring the Q-factor, the frequency span of the VNA should be adjusted such that it

is between 110 % and 200 % of the full width at half maximum of the resonant curve.

4.3.11 Calculation

Follow step 4.2.11 and calculate the value of the relative permittivity Dk(T) and the loss

tangent Df(T) at temperature T.

4.3.12 Options

If another test temperature is selected, repeat steps 4.3.6 through 4.3.11.

4.3.13 Thermal coefficient

4.3.13.1 General

Thermal coefficient of relative permittivity and thermal coefficient of loss tangent.

4.3.13.2 Relative permittivity

The thermal coefficient of the relative permittivity ε (brief for TCε ) is the change rate of the

r r

–6

relative permittivity per temperature change. The unit of TCε is 10 /°C. Generally, the

r

relative permittivity of a specimen at its base temperature T of 23 °C is used as the base

ref

relative permittivity Dk(T ). For temperature T, TCε shall be calculated according to Equation

ref r

(3).

Dk(T ) − Dk(T )

ref

TCε = (3)

r

( ) ( )

T − T × Dk T

ref ref

where

–6

TCε is the thermal coefficient of ε , 10 /°C;

r r

T is the test temperature, in °C;

T is the base temperature, in °C;

ref

Dk(T) is the relative permittivity at temperature T

;

Dk(T ) is the relative permittivity at temperature T .

ref ref

4.3.13.3 Loss tangent

The Thermal coefficient of tanδ (TC tanδ) is the change rate of the loss tangent per

–6

temperature (every increase or decrease 1 °C). The unit of TC tanδ is 10 /°C. Generally, the

loss tangent of the specimen at base temperature T of 23 °C is used as the base loss

ref

tangent Df(T ). For temperature T, TC tanδ is calculated according to Equation (4).

ref

Df (T ) − Df (T )

ref

TC tanδ =

(4)

(T − T )× Df (T )

ref ref

– 14 – IEC 61189-2-721:2015 © IEC 2015

where

TC tanδ is thermal coefficient of tanδ, in ppm/°C;

T is the test temperature, in °C;

T is the base temperature, in °C;

ref

Df(T) is the loss tangent at temperature T;

Df(T ) is the loss tangent at temperature T .

ref ref

4.3.14 Change in test frequency

If another test frequency is selected, change the SPDR test fixture in accordance with the test

frequency. Then repeat steps 4.3.3 through 4.3.13.

5 Report

5.1 At room temperature

For room temperature tests, report the following:

a) test environment (temperature, humidity);

b) test frequency;

c) the values and the average values of the relative permittivity and loss tangent at test

frequency;

d) the preconditioning of the specimen;

e) any anomalies in the test or variations from this test method.

5.2 At variable temperature

For variable temperature tests, report the following:

a) test temperature (T) and base temperature (T );;

ref

b) test frequency;

c) Dk(T)and Df(T)at test temperature (T);

d) TCε and TC tanδ;

r

e) Dk(T ) and Df(T );

ref ref

f) if more than one test temperature is necessary, report the curve diagram of the relative

permittivity and loss tangent in accordance with the temperature variation;

g) the preconditioning of the specimen;

h) any anomalies in the test or variations from this test method.

6 Additional information

6.1 Accuracy

Accuracy of measurements of a sample of thickness h.

Permittivity measurement: ∆ε/ε = ±(0,0015+∆h/h).

−5

Loss tangent: ∆tanδ = ±2 × 10 or ±0,03 tanδ whichever is higher.

6.2 Maintenance

Clean the test heads, standard materials and fixtures regularly.

6.3 Matters to be attended

To prevent damage to the test fixture because of the variable temperature tests, verify the

test system regularly with a standard reference sample. For example, single-crystal quartz is

used as the standard reference sample of thickness 0,4 mm. The deviation of the relative

permittivity measurement between the test result and the nominal value of the standard

reference sample shall be less than ±0,7 %, while the deviation of the loss tangent shall be

−5

less than ±2 × 10 .

6.4 Additional information concerning fixtures and results

An example of a test fixture and test result is shown in Annex A.

6.5 Additional information on K (ε ,h) and p

ε r es

Some additional information on K (ε ,h) and p is shown in Annex B.

ε r es

– 16 – IEC 61189-2-721:2015 © IEC 2015

Annex A

(informative)

Example of test fixture and test result

A.1 Example of test fixture

Figure A.1 shows a picture of an SPDR fixture at 5 GHz. Utilize a 3,5 mm female-to-female

adapter to connect the coaxial cable and the SPDR test fixture.

An SPDR fixture has a coupling loop on both ends to adjust the coupling coefficient. The

maximum thickness of the specimen of this fixture is 2 mm.

Coupling loop

Marking

Coupling loop

IEC

Figure A.1 – Test fixture

A.2 Example of test result

Figure A.2 and Figure A.3 show the typical measurement of relative permittivity and loss

ε

tangent at microwave frequencies (from 1,1 GHz to 19 GHz) for a copper clad laminate of

r

3,8. Figure A.4 shows the curve diagram of relative permittivity and loss tangent at variable

temperatures (from −125 °C to 110 °C) for a copper clad laminate of ε 3,8.

r

4,0

DK 3,8

3,9

3,8

3,7

3,6

3,5

0 2 4 6 8 10 12 14 16 18 20

Frequency, GHz

IEC

Figure A.2 – Relative permittivity versus frequency

(laminate of Dk 3,8 and thickness 0,51 mm)

0,010

Df

0,009

0,008

0,007

0 2 4 6 8 10 12 14 16 18 20

Frequency, GHz

IEC

Figure A.3 – Loss tangent versus frequency

(laminate of Dk 3,8 and thickness 0,51 mm)

Loss tangent

Relative permittivity

– 18 – IEC 61189-2-721:2015 © IEC 2015

3,92 0,014

0,012

3,88

0,010

3,84

0,008

0,006

3,80

0,004

Dk

3,76

0,002

Df

3,72 0,000

−150 −100 −50 0 50 100 150

Temperature, °C

IEC

Figure A.4 – Curve of relative permittivity and loss tangent

at variable temperatures (laminate of Dk 3,8 and thickness 0,51 mm)

Relative permittivity

Loss tangent

Annex B

(informative)

Additional information on K (ε ,h) and p

ε r es

By definition K (ε ,h) function values are specified for a given resonant fixture and with fixed

ε r

values ε and h as follows:

r

f − f

0 s

K (ε ,h) = (B.1)

ε r

(ε −1)hf

r 0

The function K (ε ,h) is computed and tabulated for every specific SPDR. Exact resonant

ε r

frequencies and the resulting values of K (ε ,h) are computed for a number of ε and h and

ε r r

tabulated. Interpolation has been used to compute K (ε ,h) for any other values of ε and h.

ε r r

The initial value of K (ε ,h) in the permittivity evaluation using Equation (1) is taken to be the

ε r

same as its corresponding value for a given h and ε = 1. Subsequent values of K (ε ,h) are

r ε r

found for the subsequent dielectric constant values obtained in the iterative procedure.

Because K (ε ,h) is a slowly varying function of ε and h, the iterations using Equation (1)

ε r r

converge rapidly. Figure B.1 shows K (ε ,h) versus relative permittivity at different sample

ε r

thicknesses for a 10 GHz SPDR.

12,6

h = 0,1 mm

12,5

h = 0,3 mm

12,4

h = 0,5 mm

12,3

h = 0,7 mm

h = 0,9 mm

12,2

12,1

2 4 6 8 10 12 14

ε

r

IEC

Figure B.1 – K (ε ,h) versus relative permittivity at

ε r

different sample thicknesses

By definition the p value is specified for a given resonant fixture and with fixed values ε′

es r

and h as follows:

′ ′

p = hε K (ε ,h) (B.2)

es r 1 r

K (ε ,h)

ε r

– 20 – IEC 61189-2-721:2015 © IEC 2015

where

ε′ is the relative permittivity;

r

h is the thickness of the specimen, mm;

K (ε′ ,h) is a function of ε′ and h.

1 r r

The Rayleigh-Ritz method permits to compute the p value for a given resonant structure.

es

ε′ .

These parameters have been computed for a number of h and

r

For a 10 GHz SPDR with resonant structure D = 16,5 mm, L = 9 mm, d = 8 mm, h = 1 mm, h

r r g

= 1 mm and a relative permittivity of a dielectric resonator = 38, the distribution of the electric

field component E in the split dielectric resonator operating at a nominal frequency (without

sample) of 10 GHz is shown in Figure B.2 and Figure B.3.

Figure B.4 shows p versus relative permittivity at different sample thicknesses.

es

For a 10 GHz SPDR with different samples, the parameters are shown in Table B.1.

Table B.1 – Results of measurements of

different materials using a 10 GHz SPDR

Thickness

Material

Dk Df p K (ε h) Q Q

es ε r, c DR

mm

–4 5

2,05 0,000 3 0,3 8,3 × 10 12,477 > 10 16 000 PTFE

–3 5

3,0 0,003 0 0,3 12,412 16 000 Low-Dk FR4

1,2 × 10 > 10

–3 5

3,8 0,009 0 0,3 3 × 10 12,364 > 10 16 000 Low-loss FR4

–3 5

4,5 0,015 0 0,3 4,2 × 10 12,332 > 10 16 000 Halogen-free FR4

IEC

Figure B.2 – Distribution of the electric field of the split dielectric resonator

(side view of the dielectric resonators)

IEC

Figure B.3 – Distribution of the electric field of the split dielectric resonator

(top view between the dielectric resonators)

h = 0,8 mm

0,1

h = 0,4 mm

0,01

h = 0,2 mm

h = 0,1 mm

-3

-4

0 20 40 60 80 100

Relative permittivity

IEC

Figure B.4 – p versus relative permittivity at different sample thicknesses

es

p

es

– 22 – IEC 61189-2-721:2015 © IEC 2015

Bibliography

[1] Nishikawa, T.; Wakino, K.; Tanaka, H.; Ishikawa, Y., "Dielectric Resonator Method for

Nondestructive Measurement of Comp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...