IEC 62321-3-4:2023

(Main)Determination of certain substances in electrotechnical products - Part 3-4: Screening - Phthalates in polymers of electrotechnical products by high performance liquid chromatography with ultraviolet detector (HPLC-UV), thin layer chromatography (TLC) and thermal desorption mass spectrometry (TD-MS)

Determination of certain substances in electrotechnical products - Part 3-4: Screening - Phthalates in polymers of electrotechnical products by high performance liquid chromatography with ultraviolet detector (HPLC-UV), thin layer chromatography (TLC) and thermal desorption mass spectrometry (TD-MS)

IEC 62321-3-4:2023 specifies procedures for the screening of di-isobutyl phthalate (DIBP), di-n-butyl phthalate (DBP), benzyl butyl phthalate (BBP), di-(2-ethylhexyl) phthalate (DEHP) in polymers of electrotechnical products by using high performance liquid chromatography with ultraviolet detector (HPLC-UV), thin layer chromatography (TLC) and thermal desorption mass spectrometry (TD-MS).

High performance liquid chromatography with ultraviolet detector (HPLC-UV), thin layer chromatography (TLC) and thermal desorption mass spectrometry (TD-MS) techniques are described in the normative part of this document. Fourier transform infrared spectroscopy (FT-IR) is described in the informative annexes of this document.

Détermination de certaines substances dans les produits électrotechniques - Partie 3-4: Détection - Phtalates dans les polymères des produits électrotechniques par chromatographie en phase liquide à haute performance avec détecteur d'ultraviolets (HPLC-UV), par chromatographie sur couche mince (CCM) et par spectrométrie de masse par désorption thermique (TD-MS)

IEC 62321-3-4:2023 spécifie des modes opératoires pour le criblage du phtalate de di-isobutyle (DIBP), du phtalate de di-n-butyle (DBP), du phtalate de benzyle et de butyle (BBP), du phtalate de bis (2-éthylhexyle) (DEHP) dans les polymères de produits électrotechniques en utilisant la chromatographie liquide à haute performance avec détecteur ultraviolet (HPLC-UV), la chromatographie sur couche mince (TLC) et la spectrométrie de masse par désorption thermique (TD-MS).

Les techniques de chromatographie liquide à haute performance avec détecteur ultraviolet (CLHP-UV), chromatographie sur couche mince (CCM) et spectrométrie de masse par désorption thermique (TD-MS) sont décrites dans la partie normative du présent document. La spectroscopie infrarouge à transformée de Fourier (FT-IR) est décrite dans les annexes informatives du présent document.

General Information

- Status

- Published

- Publication Date

- 02-May-2023

- Technical Committee

- TC 111 - Environmental standardization for electrical and electronic products and systems

- Drafting Committee

- WG 3 - TC 111/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 03-May-2023

- Completion Date

- 19-May-2023

Overview

IEC 62321-3-4:2023 is an international standard developed by the International Electrotechnical Commission (IEC) that specifies screening procedures for detecting phthalates in polymers of electrotechnical products. These phthalates include di-isobutyl phthalate (DIBP), di-n-butyl phthalate (DBP), benzyl butyl phthalate (BBP), and di-(2-ethylhexyl) phthalate (DEHP). The standard focuses on reliable screening methods using High Performance Liquid Chromatography with Ultraviolet Detector (HPLC-UV), Thin Layer Chromatography (TLC), and Thermal Desorption Mass Spectrometry (TD-MS).

Adopted in 2023, IEC 62321-3-4 provides standardized analytical techniques essential for compliance verification, quality control, and environmental safety assessments. It supports manufacturers, testing laboratories, and regulators in consistent detection and quantification of phthalate content in electrical and electronic equipment polymers.

Key Topics

Screening Phthalates in Polymers

The standard outlines procedures for identifying key phthalates in polymeric materials used within electrotechnical products.Analytical Techniques

- HPLC-UV: Provides separation and quantification of phthalates by liquid chromatography paired with ultraviolet detection.

- Thin Layer Chromatography (TLC): Offers a rapid screening tool using chromatographic separation on thin layers with visualization methods.

- Thermal Desorption Mass Spectrometry (TD-MS): Enables direct measurement of phthalates with high sensitivity through thermal desorption coupled with mass spectrometry detection.

Quality Assurance and Control

The standard details precision, sensitivity, and reliability assessment methods to ensure accurate and repeatable results.Sampling and Sample Preparation

Guidelines for sampling electrotechnical polymer products and preparing samples before analysis are clearly defined.Informative Annexes

Additional techniques such as Fourier Transform Infrared Spectroscopy (FT-IR) are included in annexes for supplementary screening information and validation.

Applications

IEC 62321-3-4:2023 is critical for stakeholders involved in electrotechnical product manufacturing and testing, as it facilitates:

Regulatory Compliance

Helps manufacturers verify that their products meet international and regional restrictions on phthalates, supporting compliance with environmental directives like RoHS and REACH.Material Safety and Environmental Health

Enables consistent monitoring of harmful substances, reducing environmental and health risks associated with phthalate exposure.Quality Control in Production

Assists quality assurance teams in identifying phthalate concentrations during polymer selection and product development processes.Testing Laboratories

Provides laboratories with standardized methods to perform reliable screening tests, ensuring harmonized global testing practices.Product Certification

Assists certification bodies in verifying the absence or regulated levels of phthalates in electrical and electronic equipment.

Related Standards

IEC 62321 Series

IEC 62321 encompasses the determination of various hazardous substances in electrotechnical products, including metals and brominated flame retardants. Part 3-4 focuses specifically on phthalate screening methods.RoHS Directive Compliance Testing Standards

Provides methodologies pertinent to compliance verification under the Restriction of Hazardous Substances directive.IEC 62321-3-1:2013

Covers screening methods for brominated flame retardants; often used in conjunction with Part 3-4 when comprehensive chemical testing is required.Testing and Analytical Standards for Polymers

Related ISO and IEC documents provide complementary procedures on polymer characterization and safety evaluation.

Keywords: IEC 62321-3-4, phthalates, electrotechnical products, polymers, HPLC-UV, thin layer chromatography, thermal desorption mass spectrometry, screening methods, di-isobutyl phthalate, di-n-butyl phthalate, benzyl butyl phthalate, di-(2-ethylhexyl) phthalate, environmental compliance, RoHS testing, IEC standards, polymer analysis, hazardous substances detection.

Buy Documents

IEC 62321-3-4:2023 - Determination of certain substances in electrotechnical products - Part 3-4: Screening - Phthalates in polymers of electrotechnical products by high performance liquid chromatography with ultraviolet detector (HPLC-UV), thin layer chromatography (TLC) and thermal desorption mass spectrometry (TD-MS)

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

IEC 62321-3-4:2023 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Determination of certain substances in electrotechnical products - Part 3-4: Screening - Phthalates in polymers of electrotechnical products by high performance liquid chromatography with ultraviolet detector (HPLC-UV), thin layer chromatography (TLC) and thermal desorption mass spectrometry (TD-MS)". This standard covers: IEC 62321-3-4:2023 specifies procedures for the screening of di-isobutyl phthalate (DIBP), di-n-butyl phthalate (DBP), benzyl butyl phthalate (BBP), di-(2-ethylhexyl) phthalate (DEHP) in polymers of electrotechnical products by using high performance liquid chromatography with ultraviolet detector (HPLC-UV), thin layer chromatography (TLC) and thermal desorption mass spectrometry (TD-MS). High performance liquid chromatography with ultraviolet detector (HPLC-UV), thin layer chromatography (TLC) and thermal desorption mass spectrometry (TD-MS) techniques are described in the normative part of this document. Fourier transform infrared spectroscopy (FT-IR) is described in the informative annexes of this document.

IEC 62321-3-4:2023 specifies procedures for the screening of di-isobutyl phthalate (DIBP), di-n-butyl phthalate (DBP), benzyl butyl phthalate (BBP), di-(2-ethylhexyl) phthalate (DEHP) in polymers of electrotechnical products by using high performance liquid chromatography with ultraviolet detector (HPLC-UV), thin layer chromatography (TLC) and thermal desorption mass spectrometry (TD-MS). High performance liquid chromatography with ultraviolet detector (HPLC-UV), thin layer chromatography (TLC) and thermal desorption mass spectrometry (TD-MS) techniques are described in the normative part of this document. Fourier transform infrared spectroscopy (FT-IR) is described in the informative annexes of this document.

IEC 62321-3-4:2023 is classified under the following ICS (International Classification for Standards) categories: 01.110 - Technical product documentation; 13.020.01 - Environment and environmental protection in general; 29.100.01 - Components for electrical equipment in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62321-3-4:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62321-3-4 ®

Edition 1.0 2023-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Determination of certain substances In electrotechnical products –

Part 3-4: Screening – Phthalates in polymers of electrotechnical products by

high performance liquid chromatography with ultraviolet detector (HPLC-UV),

thin layer chromatography (TLC) and thermal desorption mass spectrometry

(TD-MS)

Détermination de certaines substances dans les produits électrotechniques –

Partie 3-4: Détection – Phtalates dans les polymères des produits

électrotechniques par chromatographie en phase liquide à haute performance

avec détecteur d'ultraviolets (HPLC-UV), par chromatographie sur couche mince

(CCM) et par spectrométrie de masse par désorption thermique (TD-MS)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Découvrez notre puissant moteur de recherche et consultez

webstore.iec.ch/advsearchform gratuitement tous les aperçus des publications. Avec un

La recherche avancée permet de trouver des publications IEC abonnement, vous aurez toujours accès à un contenu à jour

en utilisant différents critères (numéro de référence, texte, adapté à vos besoins.

comité d’études, …). Elle donne aussi des informations sur les

projets et les publications remplacées ou retirées. Electropedia - www.electropedia.org

Le premier dictionnaire d'électrotechnologie en ligne au monde,

IEC Just Published - webstore.iec.ch/justpublished

avec plus de 22 300 articles terminologiques en anglais et en

Restez informé sur les nouvelles publications IEC. Just

français, ainsi que les termes équivalents dans 19 langues

Published détaille les nouvelles publications parues.

additionnelles. Egalement appelé Vocabulaire

Disponible en ligne et une fois par mois par email.

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC Products & Services Portal - products.iec.ch

IEC 62321-3-4 ®

Edition 1.0 2023-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Determination of certain substances In electrotechnical products –

Part 3-4: Screening – Phthalates in polymers of electrotechnical products by

high performance liquid chromatography with ultraviolet detector (HPLC-UV),

thin layer chromatography (TLC) and thermal desorption mass spectrometry

(TD-MS)

Détermination de certaines substances dans les produits électrotechniques –

Partie 3-4: Détection – Phtalates dans les polymères des produits

électrotechniques par chromatographie en phase liquide à haute performance

avec détecteur d'ultraviolets (HPLC-UV), par chromatographie sur couche mince

(CCM) et par spectrométrie de masse par désorption thermique (TD-MS)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 01.110; 13.020.01; 29.100.01 ISBN 978-2-8322-6853-7

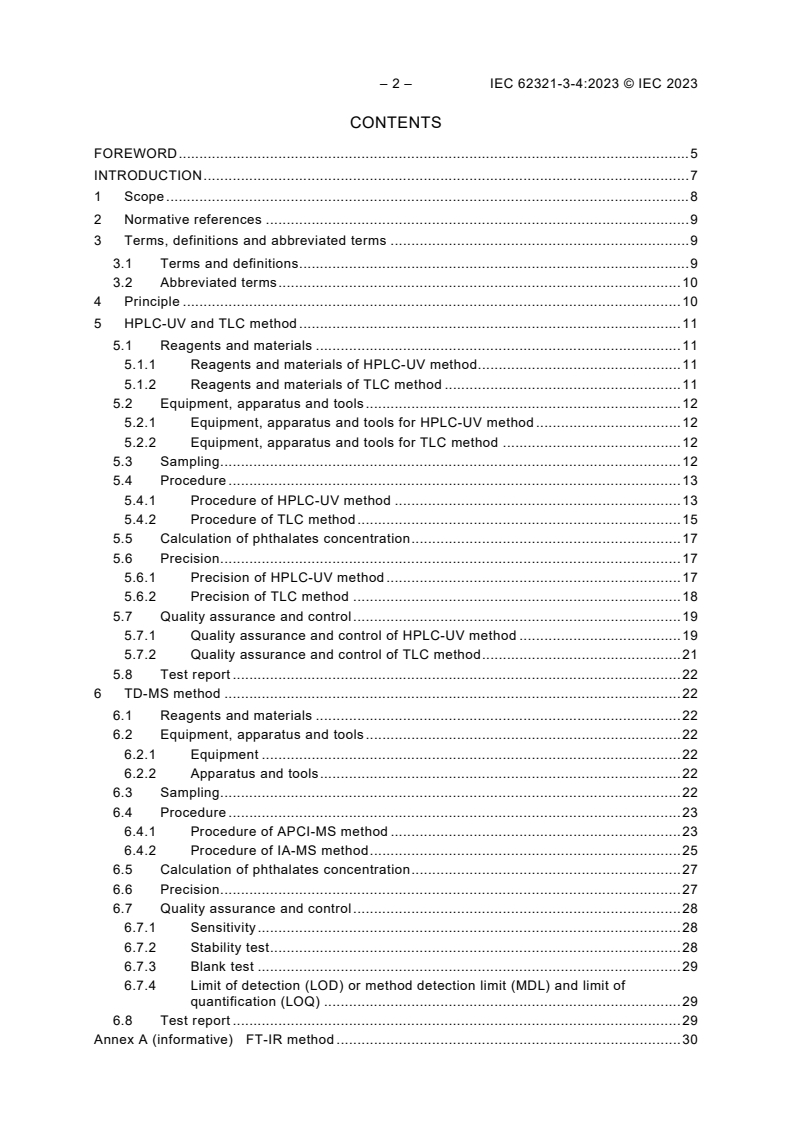

– 2 – IEC 62321-3-4:2023 © IEC 2023

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 9

3 Terms, definitions and abbreviated terms . 9

3.1 Terms and definitions . 9

3.2 Abbreviated terms . 10

4 Principle . 10

5 HPLC-UV and TLC method . 11

5.1 Reagents and materials . 11

5.1.1 Reagents and materials of HPLC-UV method . 11

5.1.2 Reagents and materials of TLC method . 11

5.2 Equipment, apparatus and tools . 12

5.2.1 Equipment, apparatus and tools for HPLC-UV method . 12

5.2.2 Equipment, apparatus and tools for TLC method . 12

5.3 Sampling. 12

5.4 Procedure . 13

5.4.1 Procedure of HPLC-UV method . 13

5.4.2 Procedure of TLC method . 15

5.5 Calculation of phthalates concentration . 17

5.6 Precision . 17

5.6.1 Precision of HPLC-UV method . 17

5.6.2 Precision of TLC method . 18

5.7 Quality assurance and control . 19

5.7.1 Quality assurance and control of HPLC-UV method . 19

5.7.2 Quality assurance and control of TLC method . 21

5.8 Test report . 22

6 TD-MS method . 22

6.1 Reagents and materials . 22

6.2 Equipment, apparatus and tools . 22

6.2.1 Equipment . 22

6.2.2 Apparatus and tools . 22

6.3 Sampling. 22

6.4 Procedure . 23

6.4.1 Procedure of APCI-MS method . 23

6.4.2 Procedure of IA-MS method . 25

6.5 Calculation of phthalates concentration . 27

6.6 Precision . 27

6.7 Quality assurance and control . 28

6.7.1 Sensitivity . 28

6.7.2 Stability test . 28

6.7.3 Blank test . 29

6.7.4 Limit of detection (LOD) or method detection limit (MDL) and limit of

quantification (LOQ) . 29

6.8 Test report . 29

Annex A (informative) FT-IR method . 30

A.1 Principle . 30

A.2 Reagents and materials . 32

A.3 Apparatus . 32

A.4 Sampling. 33

A.5 Procedure . 33

A.5.1 Sample preparation . 33

A.5.2 Instrumental parameters . 33

A.5.3 Calibration . 33

A.6 Calculation of phthalates concentration . 34

A.7 Precision . 34

A.8 Quality assurance and control . 35

A.9 Test report . 35

Annex B (informative) Details of analysis by TLC method . 36

B.1 Separation by TLC . 36

B.2 Detection by image analysis. 36

B.3 Re-measurement . 38

Annex C (informative) Examples of spectrums and chromatograms at suggested

conditions . 41

C.1 FT-IR spectrum . 41

C.2 HPLC-UV chromatogram . 41

C.3 TLC chromatogram . 42

C.4 APCI-MS mass spectrum . 42

C.5 IA-MS mass spectrum . 43

Annex D (informative) Commercially available reference materials and solutions

considered suitable for the suggested methods . 44

Annex E (informative) Flowchart of test methods . 45

Annex F (informative) Commonly used phthalates. 46

Annex G (informative) Results of international inter-laboratory study 3-4 (IIS 3-4). 47

Bibliography . 51

Figure 1 – Polymer samples in glass vials with acetonitrile (tightened with sealing tape) . 15

Figure A.1 – Phthalate analysis in polymers (check) . 31

Figure A.2 – Phthalate analysis in polymers with pre-treatment . 31

Figure B.1 – Usage of TLC plate (20 cm × 10 cm) . 36

Figure B.2 – Set-up of camera-equipment for TLC (inside of darkroom) . 37

Figure B.3 – TLC chromatogram . 38

Figure B.4 – Separation by re-measurement conditions (in case of pattern a)) . 39

Figure B.5 – Peak shift affected by large amount of DEHA . 39

Figure B.6 – TLC re-measurement by standard addition method (in case of pattern b)) . 40

Figure C.1 – Spectrum of FT-IR . 41

Figure C.2 – Chromatogram of HPLC-UV . 41

Figure C.3 – Developed TLC plate exposed to UV light of 254 nm . 42

Figure C.4 – Image processed TLC chromatogram of Figure C.3 . 42

Figure C.5 – Mass spectrums of APCI-MS . 43

Figure C.6 – Mass spectrums of IA-MS . 43

Figure E.1 – Flowchart for screening step and verification test step . 45

– 4 – IEC 62321-3-4:2023 © IEC 2023

Table 1 – Standard mixture solution concentrations . 13

Table 2 – Measurement conditions of HPLC-UV . 14

Table 3 – Standard mixture solution concentrations . 15

Table 4 – Measurement conditions of TLC . 16

Table 5 – IIS 3-4 Repeatability and reproducibility of HPLC-UV . 18

Table 6 – IIS 3-4 Repeatability and reproducibility of TLC . 19

Table 7 – Measurement conditions of APCI-MS . 24

Table 8 – Measurement conditions of IA-MS . 26

Table 9 – IIS 3-4 Repeatability and reproducibility of TD-MS . 28

Table A.1 – IIS 3-4 Repeatability and reproducibility of FT-IR . 34

Table B.1 – Conditions of photography . 37

Table B.2 – Range of Rf values of target phthalates . 38

Table D.1 – Example list of commercially available reference materials . 44

Table F.1 – Example list of commonly used phthalates in products . 46

Table G.1 – Formulation of samples. 47

Table G.2 – Statistical data for HPLC-UV . 48

Table G.3 – Statistical data for TLC . 49

Table G.4 – Statistical data for TD-MS . 50

Table G.5 – Statistical data for FT-IR . 50

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

DETERMINATION OF CERTAIN SUBSTANCES

IN ELECTROTECHNICAL PRODUCTS –

Part 3-4: Screening – Phthalates in polymers of electrotechnical

products by high performance liquid chromatography with ultraviolet

detector (HPLC-UV), thin layer chromatography (TLC) and thermal

desorption mass spectrometry (TD-MS)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 62321-3-4 has been prepared IEC technical committee 111: Environmental standardization

for electrical and electronic products and systems. It is an International Standard.

The text of this International Standard is based on the following documents:

Draft Report on voting

111/695/FDIS 111/701/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

– 6 – IEC 62321-3-4:2023 © IEC 2023

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts in the IEC 62321 series, published under the general title Determination of

certain substances in electrotechnical products, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

INTRODUCTION

The widespread use of electrotechnical products has drawn increased attention to their impact

on the environment. In many countries all over the world, this has resulted in the adaptation of

regulations affecting wastes, substances and energy use of electrotechnical products.

The use of certain substances (e.g. lead (Pb), cadmium (Cd), polybrominated diphenyl ethers

(PBDEs) and specific phthalates) in electrotechnical products is a source of concern in current

and proposed regional legislation.

The purpose of the IEC 62321 series is therefore to provide test methods that will allow the

electrotechnical industry to determine the levels of certain substances of concern in

electrotechnical products on a consistent global basis.

This first edition of IEC 62321-3-4 introduces a new part in the IEC 62321 series.

Appropriate test methods are required in order to facilitate the monitoring of the contents of

certain substances in affected materials. Faced with the enormous task of testing a diversity of

electronic and electric equipment, the industry adopted the concept of 'screening' in order to

reduce the amount of testing. As defined in IEC 62321-1:2013, 3.1.10, "…screening is an

analytical procedure to determine the presence or absence of substances in the representative

part or section of a product, relative to the value or values chosen as the criterion for presence,

absence or further testing". Executed as a predecessor to any other test analysis of the product,

the main objective of screening is to quickly, expediently, inexpensively and preferably in a non-

destructive manner, determine whether the screened product:

– contains a certain substance at a concentration significantly higher than its value accepted

as criterion, and therefore can be rejected as being above the threshold;

– contains a certain substance at a concentration significantly lower than its value accepted

as criterion, and therefore can be considered below the threshold;

– contains a certain substance at a concentration so close to the value accepted as criterion

that when all possible errors of measurement and safety factors and measurement

uncertainty are considered, no conclusive decision can be made about the absence or

presence of substance and, therefore, a follow-up action can be required, such as another,

more specific or more precise and accurate analysis.

WARNING – Persons using this document should be familiar with normal laboratory practice.

This document does not purport to address all of the safety problems, if any, associated with

its use. It is the responsibility of the user to establish appropriate safety and health practices

and to ensure compliance with any national regulatory conditions.

– 8 – IEC 62321-3-4:2023 © IEC 2023

DETERMINATION OF CERTAIN SUBSTANCES

IN ELECTROTECHNICAL PRODUCTS –

Part 3-4: Screening – Phthalates in polymers of electrotechnical

products by high performance liquid chromatography with ultraviolet

detector (HPLC-UV), thin layer chromatography (TLC) and thermal

desorption mass spectrometry (TD-MS)

1 Scope

This part of IEC 62321 specifies procedures for the screening of di-isobutyl phthalate (DIBP),

di-n-butyl phthalate (DBP), benzyl butyl phthalate (BBP), di-(2-ethylhexyl) phthalate (DEHP) in

polymers of electrotechnical products by using high performance liquid chromatography with

ultraviolet detector (HPLC-UV), thin layer chromatography (TLC) and thermal desorption mass

spectrometry (TD-MS).

High performance liquid chromatography with ultraviolet detector (HPLC-UV), thin layer

chromatography (TLC) and thermal desorption mass spectrometry (TD-MS) techniques are

described in the normative part of this document. Fourier transform infrared spectroscopy

(FT-IR) is described in the informative annexes of this document.

The HPLC-UV and TLC techniques are suitable for screening and semi-quantitative analysis of

DIBP, DBP, BBP and DEHP in polymers that are used as parts in electrotechnical products

above 300 mg/kg.

Theu TD-MS technique is suitable for screening and semi-quantitative analysis of DIBP, DBP,

BBP and DEHP in polymers that are used as parts in electrotechnical products above 300 mg/kg.

The FT-IR technique is suitable for preliminary screening of total phthalates (DIBP, DBP, BBP,

DEHP and so forth) in polymers that are used as parts in electrotechnical products above

50 000 mg/kg.

These test methods have been evaluated by testing polyethylene (PE), polyvinyl chloride (PVC)

materials containing individual phthalates between 500 mg/kg to 3 000 mg/kg as depicted in

this document. The use of the methods described in this document for other polymer types,

phthalate compounds or concentration ranges other than those specified above has not been

specifically evaluated.

A flow chart is given as an example of how each method included in this document can be used

for screening. The test methods in this document differ from those given in IEC 62321-8 [1] in

that not all phthalates in this scope are separated from each other. Detectable combinations

are DIBP + DBP + BBP and DEHP for the HPLC-UV technique, DIBP + DBP, BBP and DEHP

for the TLC technique and TD-MS technique, total phthalates for the FT-IR technique. FT-IR is

a suitable analytical technique for preliminary screening in the first step of phthalates screening.

These test methods are characterized by a shorter measuring time compared with IEC 62321-8

because all phthalates in this scope are not separated from each other.

NOTE See Annex F for commonly used phthalates in products.

This document has the status of a horizontal publication in accordance with IEC Guide 108 [2].

___________

Numbers in square brackets refer to the Bibliography.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 62321-1:2013, Determination of certain substances in electrotechnical products – Part 1:

Introduction and overview

IEC 62321-2:2021, Determination of certain substances in electrotechnical products – Part 2:

Disassembly, disjointment and mechanical sample preparation

3 Terms, definitions and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1.1

screening

analytical procedure to determine the presence or absence of substances in the representative

part or section of a product, relative to the value or values chosen as the criterion for presence,

absence or further testing

Note 1 to entry: If the screening method produces values that are not conclusive, then additional analysis or other

follow-up actions may be necessary to make a final presence/absence decision.

[SOURCE: IEC 62321-1:2013, 3.1.10]

3.1.2

semi-quantitative

level of accuracy in a measurement amount where the relative uncertainty of the result is

typically 30 % or better at a defined level of confidence of 68 %

[SOURCE: IEC 62321-6:2015, 3.1.1 [3]]

3.1.3

calibrant

calibration standard

substance in solid or liquid form with known and stable concentration(s) of the analyte(s) of

interest used to establish instrument response (calibration curve) with respect to analyte(s)

concentration(s)

– 10 – IEC 62321-3-4:2023 © IEC 2023

3.2 Abbreviated terms

ACN acetonitrile

APCI atmospheric pressure chemical ionization

APCI-MS atmospheric pressure chemical ionization mass spectrometry

BBP benzyl butyl phthalate

CRM certified reference material

DBP di-n-butyl phthalate

DEHP di-(2-ethylhexyl) phthalate

DIBP di-isobutyl phthalate

DIP direct injection probe

DNOP di-n-octyl phthalate

FT-IR Fourier Transform infrared spectroscopy

HPLC-UV high performance liquid chromatography with ultraviolet detector

IA-MS ion attachment mass spectrometry

TLC thin layer chromatography

IS internal standard

LOD limit of detection

LOQ limit of quantification

MDL method detection limit

MS mass spectrometry

PVC polyvinyl chloride

QC quality control

SIM selected ion monitoring

TD-MS thermal desorption mass spectrometry

THF tetrahydrofuran

4 Principle

In the HPLC-UV method, DIBP, DBP, BBP and DEHP are determined using ultrasonic extraction

followed by high-pressure, liquid chromatography separation and ultraviolet detection. Owing

to the peak overlapping of DIBP, DBP and BBP, occurrence of the peak indicates only

qualitative information of possible presence of DIBP, DBP and BBP or a combination of one or

two of either of these phthalates.

The TLC method, as well as the HPLC method, is one of the liquid chromatography methods

and can be performed with simple instruments. In the TLC method, DIBP, DBP, BBP and DEHP

in the polymer are separated by TLC after ultrasonic extraction and detected by image analysis

after photography under UV light. DIBP and DBP are detected as sum peaks because it is

difficult to separate them by TLC.

TD-MS techniques use a thermal desorption system directly connected to mass spectrometry

with ionization systems such as an atmospheric pressure chemical ionization or ion attachment

to screen for the presence of DIBP, DBP, BBP and DEHP in polymers. This method allows for

the direct analysis of a polymer sample without pre-treatment process. For example:

+

– The APCI-MS method has an ion source that attaches H to target molecules by a corona

discharge under atmospheric pressure and is coupled with a furnace stabilized at 330 °C

and a sample heater. The sample heater is programmed to heat up to 230 °C to thermally

desorb sample molecules. The thermally desorbed sample molecules (M) form adducts

+ +

(M + H ) with H in the reaction and are analysed by a mass spectrometer via select ion

monitoring.

+ +

– The IA-MS method includes a Li attachment reaction chamber with a Li emitter and is

coupled with a direct injection probe (DIP). The DIP is programmed to heat up to 350 °C to

thermally desorb sample molecules. The thermally desorbed sample molecules (M) form

+ +

adducts (M + Li ) with Li in the reaction chamber and those adducts are analysed by a

mass spectrometer via select ion monitoring.

Therefore, target molecules with the same molecular weight such as DBP and DIBP, DEHP and

Di-n-octyl phthalate (DNOP) are detected as sum peaks by TD-MS techniques.

The principle of phthalate detection by FT-IR can be referenced in Annex A.

These test methods are based on the concept of performance. Apparatus, sampling and

calibration are specified in this document in relatively general terms. It is the responsibility of

the user to document all procedures developed in the laboratory that uses the test methods

described in this document. The user shall establish a written procedure for all cases denoted

in the test methods described in this document by the term "work instructions". A flowchart is

provided in Annex E as an example of how these methods can be used for screening.

5 HPLC-UV and TLC method

5.1 Reagents and materials

5.1.1 Reagents and materials of HPLC-UV method

All chemicals shall be tested for contamination and blank values prior to application, as follows:

a) methanol (HPLC grade, purity greater than a volume fraction of 99,7 %);

b) THF (HPLC grade, purity greater than a volume fraction of 99,7 %);

c) ethanol (HPLC grade, purity greater than a volume fraction of 99,7 %);

d) ultrapure water (HPLC grade);

e) standard mixture solution or reference polymer materials as calibrants:

one contains approximately 1 000 mg/kg of phthalates.

NOTE Commercially available reference materials are listed in Annex D.

5.1.2 Reagents and materials of TLC method

All chemicals shall be tested for contamination and blank values prior to application, as follows:

a) acetonitrile;

b) methanol;

c) standard mixture solution or reference polymer materials as calibrants:

one contains approximately 1 000 mg/kg of phthalates;

NOTE Commercially available reference materials are listed in Annex D.

– 12 – IEC 62321-3-4:2023 © IEC 2023

5.2 Equipment, apparatus and tools

5.2.1 Equipment, apparatus and tools for HPLC-UV method

The following equipment shall be used for the analysis:

a) high-performance liquid chromatography (HPLC) system equipped with a UV or PDA/UV

detector, auto sampler, pump and column oven;

b) analytical balance capable of measuring accurately to 0,000 1 g (0,1 mg);

c) ultrasonic bath (capable of heating above 50 °C);

The following equipment should be used for sample preparation as necessary:

d) cryogenic grinding or milling with liquid N cooling.

The following items shall be used for the analysis:

e) column;

f) glass vials for HPLC-UV;

g) glass vials for extraction (40 ml volume is recommended);

h) volumetric flask;

i) adjustable pipettes;

j) paper filters, medium-fast filtration, general laboratory use.

NOTE The size of the required glass vial for HPLC depends on the instrument.

5.2.2 Equipment, apparatus and tools for TLC method

The following equipment shall be used for the analysis:

a) ultrasonic bath (capable of heating above 60 °C);

b) analytical balance (capable of measuring accurately to 0,000 1 g (0,1 mg));

c) TLC plate (stationary phase C18, size 20 cm × 20 cm, cut in half to 20 cm × 10 cm);

d) TLC developing chamber;

e) UV lamp (λ = 254 nm, 2 units required);

f) digital camera (with UV lens filter for ultraviolet adsorption as optional);

g) clamp (for fixing UV lamps and a camera);

h) desktop darkroom.

The following items shall be used for the analysis:

a) glass vials for extraction (4 ml volume is recommended);

d) capillary (capacity 1 µl);

c) volumetric flask;

d) adjustable pipettes or micro syringes;

e) scissors or cutter knife.

5.3 Sampling

Unless otherwise specified in this document, the sampling procedure described in IEC 62321-2

shall be referred to.

All items used in the samples preparation for measurements shall be shown to be free of

contamination, specific for the analytes of this TLC method. This means that all grinding

materials, solvents, fluxes, etc. shall not contain detectable quantities of phthalates (DIBP, DBP,

BBP, and DEHP).

Tools used in the handling of samples shall be chosen to minimize contamination by the

analytes of this TLC test method as well as by any other elements or species. The procedures

which will be used for cleaning different tools shall not introduce any contaminants.

5.4 Procedure

5.4.1 Procedure of HPLC-UV method

5.4.1.1 Sample preparation

5.4.1.1.1 General

Sample preparation requires clean glassware (e.g. single use items) to avoid cross

contamination.

5.4.1.1.2 Polymer sample

a) Cryogenic grinding with liquid N cooling is recommended to achieve a particle size under

1 mm.

b) Weigh 150 mg ± 20 mg of the sample and transfer it into a glass vial for extraction. Record

the mass to the nearest 0,1 mg.

c) Transfer 5 ml of THF to the vial.

d) Tightly cap the sample vial. Place it in an ultrasonic bath (50 °C) and sonicate for 60 min

until the sample has dissolved. A small piece of adhesive tape may be used to prevent the

cap from loosening due to vibration.

e) After the sample is dissolved, allow the vial to cool to ambient temperature.

f) Accurately add 10 ml of ethanol dropwise into the vial to precipitate the sample matrix.

g) Allow the polymer to settle or filter the mixture through a paper filter made of hydrophilic

polytetrafluoroethylene.

5.4.1.1.3 Standard solution

Whenever possible, the solvent used for the HPLC sample and standard solutions shall be the

same to avoid any potential solvent effects.

The standard mixture solutions of phthalates given in Table 1 are used for calibration. A

reference polymer material which concentration is approximately 1 000 mg/kg can be used for

preparing the standard stock solution. When using reference polymer materials, the standard

mixture solution shall be prepared in accordance with 5.4.1.1.2.

Table 1 – Standard mixture solution concentrations

No. DIBP DBP BBP DEHP

10 µg/ml 10 µg/ml 10 µg/ml 10 µg/ml

(equivalent to (equivalent to (equivalent to (equivalent to

1 000 mg/kg) 1 000 mg/kg) 1 000 mg/kg) 1 000 mg/kg)

5.4.1.2 Instrumental parameters

Different conditions can be necessary to optimize a specific HPLC-UV system to achieve

effective determination of phthalates and meet the requirements of 5.7.1 (Quality assurance

and control).

– 14 – IEC 62321-3-4:2023 © IEC 2023

The following parameters given in Table 2 have been found suitable and are provided as an

example. For every measurement the peaks for each phthalate shall be identified by the

retention times with the standard stock solution. Deviation of retention times shall not exceed

±5 % within a batch.

NOTE See Annex C for examples of chromatogram at suggested conditions.

Table 2 – Measurement conditions of HPLC-UV

Liquid (mobile) phase 95 % methanol / 5 % water (volume fraction)

C18 stationary phase, 150 mm in length and 4,6 mm in diameter, 5 μm particle

Stationary (column) phase

size or equivalent

Measurement conditions

Run time 15 min

Flow rate 1,0 ml/min

Wavelength 254 nm

Injection volume 10 µl

Column temperature 40 °C ± 2 °C

NOTE In the measurement conditions described in this Table 2, examples of retention time of each phthalate are

for DIBP/DBP/BBP: 2,5 min to 3,5 min, for DEHP: 5,5 min to 6,0 min.

5.4.1.3 Calibration

The HPLC-UV method shall be calibrated taking into account interference effects and any other

effects that influence the determination of the peak area.

To produce calibration straight lines, the peak area is plotted against the absolute amount (ng)

of each phthalate.

A slope of a one-point calibration curve is calculated by using Equation (1).

a = A / m (1)

where

a is the slope of the calibration curve;

A is the peak area of each phthalate in the standard mixture solution or the extract of reference

polymer material;

m is the absolute amount of each phthalate in the standard mixture solution or the extract of

referenced polymer material (ng).

The calibration curve is specified by using Equation (2):

y =ax

(2)

where

y is the peak area of each phthalate in the sample;

x is the absolute amount of each phthalate in the sample (ng);

a is the slope of the calibration curve calculated by Equation (1).

5.4.2 Procedure of TLC method

5.4.2.1 Sample preparation

5.4.2.1.1 General

Sampl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...