EN 287-1:2004

(Main)Qualification test of welders - Fusion welding - Part 1: Steels

Qualification test of welders - Fusion welding - Part 1: Steels

This European Standard defines the qualification test of welders for the fusion welding of steels.

It provides a set of technical rules for a systematic qualification test of the welder, and enables such qualifications to be uniformly accepted independently of the type of product, location and examiner/examining body.

When qualifying welders, the emphasis is placed on the welders ability to manually manipulate the electrode/ welding torch/ welding blowpipe and thereby producing a weld of acceptable quality.

The welding processes referred to in this European Standard include those fusion welding processes which are designated as manual or partly mechanized welding. It does not cover fully mechanized and automated welding processes (see EN 1418).

Prüfung von Schweißern - Schmelzschweißen - Teil 1: Stähle

Diese Europäische Norm definiert die Schweißerprüfung für das Schmelzschweißen von Stählen.

Sie stellt eine Reihe technischer Regeln für systematische Prüfungen von Schweißern auf und ermöglicht so, dass solche Qualifizierungen unabhängig von der Art des Erzeugnisses, des Ortes und des Prüfers/der Prüfstelle einheitlich akzeptiert werden.

Wenn Schweißer qualifiziert werden, liegt der Schwerpunkt auf der Fähigkeit des Schweißers, den Elektroden-halter/die Schweißpistole/den Schweißbrenner so zu handhaben, dass damit eine Schweißung von zulässiger Qualität erzeugt wird.

Die Schweißprozesse nach dieser Norm schließen nur solche Schweißprozesse ein, die als Handschweißen oder teilmechanisches Schweißen bezeichnet werden. Sie schließen nicht die vollmechanischen und automatischen Schweißprozesse ein (siehe EN 1418).

Epreuve de qualification des soudeurs - Soudage par fusion - Partie 1 : Aciers

La présente Norme européenne définit l'épreuve de qualification des soudeurs pour le soudage par fusion des aciers.

Elle fournit un ensemble de règles techniques pour l'épreuve de qualification systématique des soudeurs, et permet à de telles qualifications d'être acceptées uniformément, indépendamment du type de produit, du lieu et de l'examinateur ou de l'organisme d'examen.

Lors de la qualification des soudeurs, l'accent est porté sur l'aptitude du soudeur à guider manuellement l'électrode, la torche ou le chalumeau de soudage pour produire une soudure de qualité acceptable.

Les procédés de soudage concernés par la présente Norme européenne sont les procédés de soudage par fusion désignés en tant que, manuels ou semi-automatiques. Elle ne traite pas des procédés de soudage totalement mécanisés et automatisés (voir l'EN 1418).

Preskušanje varilcev - Talilno varjenje - 1. del: Jekla

General Information

- Status

- Withdrawn

- Publication Date

- 02-Mar-2004

- Withdrawal Date

- 12-Jul-2011

- Technical Committee

- CEN/TC 121 - Welding

- Drafting Committee

- CEN/TC 121/SC 4 - Quality management in the field of welding

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 13-Jul-2011

- Completion Date

- 13-Jul-2011

- Directive

- 87/404/EEC - Simple pressure vessels

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 16-Jul-2011

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 13831:2007 - Closed expansion vessels with built in diaphragm for installation in water - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

EN 287-1:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Qualification test of welders - Fusion welding - Part 1: Steels". This standard covers: This European Standard defines the qualification test of welders for the fusion welding of steels. It provides a set of technical rules for a systematic qualification test of the welder, and enables such qualifications to be uniformly accepted independently of the type of product, location and examiner/examining body. When qualifying welders, the emphasis is placed on the welders ability to manually manipulate the electrode/ welding torch/ welding blowpipe and thereby producing a weld of acceptable quality. The welding processes referred to in this European Standard include those fusion welding processes which are designated as manual or partly mechanized welding. It does not cover fully mechanized and automated welding processes (see EN 1418).

This European Standard defines the qualification test of welders for the fusion welding of steels. It provides a set of technical rules for a systematic qualification test of the welder, and enables such qualifications to be uniformly accepted independently of the type of product, location and examiner/examining body. When qualifying welders, the emphasis is placed on the welders ability to manually manipulate the electrode/ welding torch/ welding blowpipe and thereby producing a weld of acceptable quality. The welding processes referred to in this European Standard include those fusion welding processes which are designated as manual or partly mechanized welding. It does not cover fully mechanized and automated welding processes (see EN 1418).

EN 287-1:2004 is classified under the following ICS (International Classification for Standards) categories: 25.160.10 - Welding processes. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 287-1:2004 has the following relationships with other standards: It is inter standard links to EN 287-1:1992/A1:1997, EN 287-1:1992, EN 287-1:2011, EN 14341:2006, EN 14015:2004, EN 14276-1:2006+A1:2011, EN 12952-6:2011, EN 474-1:2006+A1:2009, EN 474-1:2006+A3:2013, CEN/TR 13445-101:2015, EN 13831:2007, EN 13709:2010, EN 1092-1:2007, EN 3-8:2006, EN 287-6:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 287-1:2004 is associated with the following European legislation: EU Directives/Regulations: 2009/105/EC, 2009/105//EC, 305/2011, 87/404/EEC, 89/106/EEC, 97/23/EC; Standardization Mandates: M/071, M/111, M/BC/CEN/86/6. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 287-1:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Qualification test of welders - Fusion welding - Part 1: SteelsPreskušanje varilcev - Talilno varjenje - 1. del: JeklaEpreuve de qualification des soudeurs - Soudage par fusion - Partie 1 : AciersPrüfung von Schweißern - Schmelzschweißen - Teil 1: StähleTa slovenski standard je istoveten z:EN 287-1:2004SIST EN 287-1:2004en25.160.10Varilni postopki in varjenjeWelding processesICS:SLOVENSKI

STANDARDSIST EN 287-1:200401-junij-2004

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 287-1March 2004ICS 25.160.10Supersedes EN 287-1:1992English versionQualification test of welders - Fusion welding - Part 1: SteelsEpreuve de qualification des soudeurs - Soudage parfusion - Partie 1 : AciersPrüfung von Schweißern - Schmelzschweißen - Teil 1:StahlThis European Standard was approved by CEN on 2 January 2004.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 287-1:2004: E

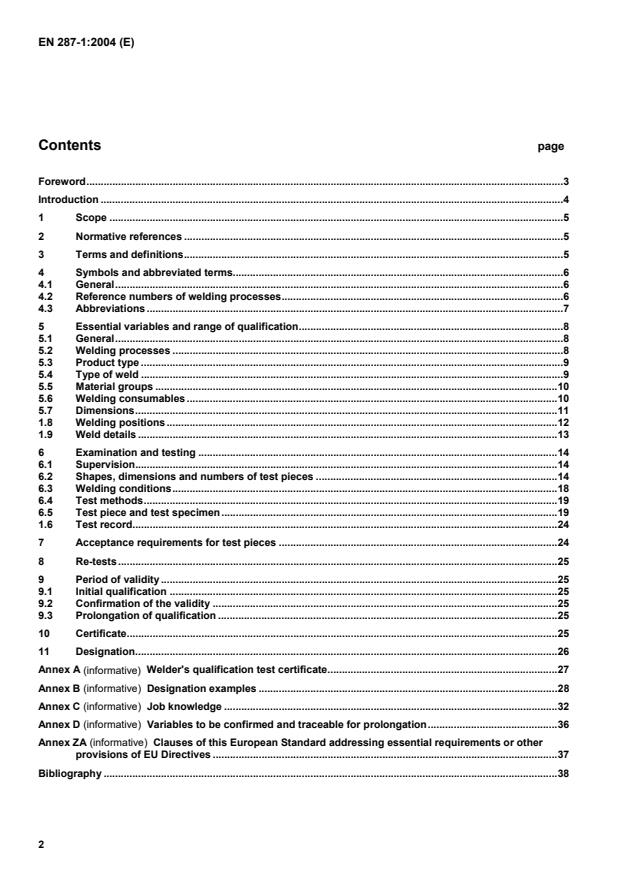

Welder's qualification test certificate.27Annex B (informative)

Designation examples.28Annex C (informative)

Job knowledge.32Annex D (informative)

Variables to be confirmed and traceable for prolongation.36Annex ZA (informative)

Clauses of this European Standard addressing essential requirements or otherprovisions of EU Directives.37Bibliography.38

1)The word "pipe" alone or in combination, is used to mean "pipe", "tube" or "hollow section".

t1for welding process 2:t = t2according to Table 4t = t1 + t2welding process 1only for welding ofthe root area5.3 Product typeThe qualification test shall be carried out on plate or pipe. The following criteria are applicable:a) welds in pipes, outside pipe diameter D > 25 mm, cover welds in plates;b) welds in plates cover welds in pipe:¾ of outside pipe diameter D ³ 150 mm, for welding positions PA, PB and PC;¾ of outside pipe diameter D ³ 500 mm, for all welding positions.5.4 Type of weldThe qualification test shall be carried out as butt or fillet weld. The following criteria are applicable:a) butt welds cover butt welds in any type of joint except branch connections (see also 5.4 c));b) in cases where the majority of work is fillet welding, the welder shall also be qualified by an appropriate filletwelding test; in cases where the majority of work is butt welding, butt welds qualify fillet welds;c) butt welds in pipes without backing qualify branch connections with an angle ³ 60° and the same range ofqualification as in Tables 1 to 8. For a branch weld the range of qualification is based on the outside pipediameter of the branch;d) for applications where the type of weld cannot be qualified by means of either a butt or fillet weld test then aspecific test piece should be used to qualify the welder, e.g. branch connection.

ofthe test piece1.11.21.49.19.2 + 9.31.1, 1.2, 1.4X––––––––––––1.3XXXX–––––X––X2XXXX–––––X––X3XXXX–––––X––X4XXXXXXXX–X––X5XXXXXXXX–X––X6XXXXXXXX–X––X7XXXXXXXX–X––X8––––––––X–XX–9.1XXXX–––––X––X99.2 + 9.3X–––––––––X––10––––––––X–XX–11XX––––––––––XaMaterial group according to CR ISO 15608.KeyXindicates those material groups for which the welder is qualified.–indicates those material groups for which the welder is not qualified.5.6 Welding consumablesQualification with filler metal, e.g. with welding processes 141, 15 and 311, qualifies for welding without filler metalbut not vice versa.The ranges of qualification for welding consumables are given in Table 3.

´ tcFor oxy-acetylene welding (311): 3 mm to 1,5

´ tTable 5 — Range of qualification for outside pipe diameter aDimension in millimetresOutside pipe diameter of test pieceDRange of qualificationD £ 25D to 2 ´ DD > 25³ 0,5 ´ D (25 mm min.)aFor structural hollow sections, D is the dimension of the smaller side.Table 6 — Range of qualification of material thickness of test piece for fillet weldsaDimension in millimetresMaterial thickness of test piecetRange of qualificationt < 3t to 3t

3³ 3aSee also Table 9.5.8 Welding positionsThe range of qualification for each welding position is given in Table 7. The welding positions and symbols refer toEN ISO 6947.The test pieces shall be welded in accordance with the nominal angles of the welding positions according toEN ISO 6947.The welding positions J-L045 and H-L045 for pipes qualify for all pipe angles.Welding two pipes with the same outside pipe diameter, one in welding position PF and one in welding position PC,also covers the range of qualification of a pipe welded in welding position H-L045.Welding two pipes with the same outside pipe diameter, one in welding position PG and one in welding positionPC, also covers the range of qualification of a pipe welded in welding position J-L045.Outside pipe diameters D ³ 150 mm can be welded in two welding positions (PF or PG 2/3 of circumference, PC1/3 of circumference) using only one test piece.

Weldingpositionof testpiecePAPB b

PCPD bPEPF(Plate)PF(Pipe)PG(Plate)PG(Pipe)H-L045J-L045PAXX–––––––––PB bXX–––––––––PCXXX––––––––PD bXXXXXX–––––PEXXXXXX–––––PF(Plate)XX–––X–––––PF(Pipe)XX–XXXX––––PG(Plate)–––––––X–––PG(Pipe)XX–XX––XX––H-L045XXXXXXX––X–J-L045XXXXX––XX–XaAdditionally the requirements of 5.3 and 5.4 shall be observed.bWelding position PB and PD are only used for fillet welds (see 5.4 b)) and can only qualify fillet welds in other welding positions.KeyXindicates those welding positions for which the welder is qualified.–indicates those welding positions for which the welder is not qualified.5.9 Weld detailsDepending on the weld details, the ranges of qualification are shown in Tables 8 and 9.When welding with process 311 a change from rightward welding to leftward welding and vice versa requires a newqualification test.Table 8 — Range of qualification for weld details on butt weldsRange of qualificationWeld details of test piecesingle-side welding /welding without backing(ss nb)single-side welding /welding with backing(ss mb)welding from both sides(bs)single-side welding /welding withoutbacking (ss nb)XXXsingle-side welding /welding withbacking (ss mb)–XXwelding from both sides (bs)–XXKeyXindicates those welds for which the welder is qualified.–indicates those welds for which the welder is not qualified.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...