EN 1463-1:2009

(Main)Road marking materials - Retroreflecting road studs - Part 1: Initial performance requirements

Road marking materials - Retroreflecting road studs - Part 1: Initial performance requirements

This European Standard specifies the initial performance requirements and laboratory test methods for retroreflecting road studs intended for use as permanent and temporary road marking materials.

Straßenmarkierungsmaterialien - Markierungsknöpfe - Teil 1: Anforderungen im Neuzustand

Diese Europäische Norm legt die Produktanforderungen an und die Prüfverfahren für retroreflektierende

Markierungsknöpfe im Neuzustand fest, die als dauerhafte oder vorübergehende Straßenmarkierungsmaterialien

verwendet werden sollen.

Produits de marquage routier - Plots rétroréfléchissants - Partie 1 : Spécifications des performances initiales

La présente Norme européenne spécifie les exigences initiales de performance et les méthodes d’essai en laboratoire des plots rétroréfléchissants utilisés comme matériaux de marquage routier temporaires ou permanents.

Materiali za označevanje vozišča - Odsevniki - 1. del: Lastnosti novih odsevnikov

General Information

- Status

- Withdrawn

- Publication Date

- 24-Mar-2009

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 226 - Road equipment

- Drafting Committee

- CEN/TC 226/WG 2 - Horizontal road signs

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 22-Dec-2021

- Completion Date

- 09-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 01-Apr-2009

- Effective Date

- 01-Apr-2009

- Effective Date

- 24-Jun-2015

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 1463-1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Road marking materials - Retroreflecting road studs - Part 1: Initial performance requirements". This standard covers: This European Standard specifies the initial performance requirements and laboratory test methods for retroreflecting road studs intended for use as permanent and temporary road marking materials.

This European Standard specifies the initial performance requirements and laboratory test methods for retroreflecting road studs intended for use as permanent and temporary road marking materials.

EN 1463-1:2009 is classified under the following ICS (International Classification for Standards) categories: 93.080.20 - Road construction materials; 93.080.30 - Road equipment and installations. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1463-1:2009 has the following relationships with other standards: It is inter standard links to EN 1463-1:1997, EN 1463-1:1997/A1:2003, EN 1463-1:2021, EN 1463-2:2000. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1463-1:2009 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/111. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1463-1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Straßenmarkierungsmaterialien - Markierungsknöpfe - Teil 1: Anforderungen im NeuzustandProduits de marquage routier - Plots rétroréfléchissants - Partie 1 : Exigences initiales de performanceRoad marking materials - Retroreflecting road studs - Part 1: Initial performance requirements93.080.20Materiali za gradnjo cestRoad construction materialsICS:Ta slovenski standard je istoveten z:EN 1463-1:2009SIST EN 1463-1:2009en,de01-julij-2009SIST EN 1463-1:2009SLOVENSKI

STANDARDSIST EN 1463-1:1999/A1:2004SIST EN 1463-1:19991DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1463-1March 2009ICS 93.080.20Supersedes EN 1463-1:1997

English VersionRoad marking materials - Retroreflecting road studs - Part 1:Initial performance requirementsProduits de marquage routier - Plots rétroréfléchissants -Partie 1 : Exigences initiales de performanceStraßenmarkierungsmaterialien - Markierungsknöpfe - Teil1: Anforderungen im NeuzustandThis European Standard was approved by CEN on 17 February 2009.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre:

Avenue Marnix 17,

B-1000 Brussels© 2009 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1463-1:2009: ESIST EN 1463-1:2009

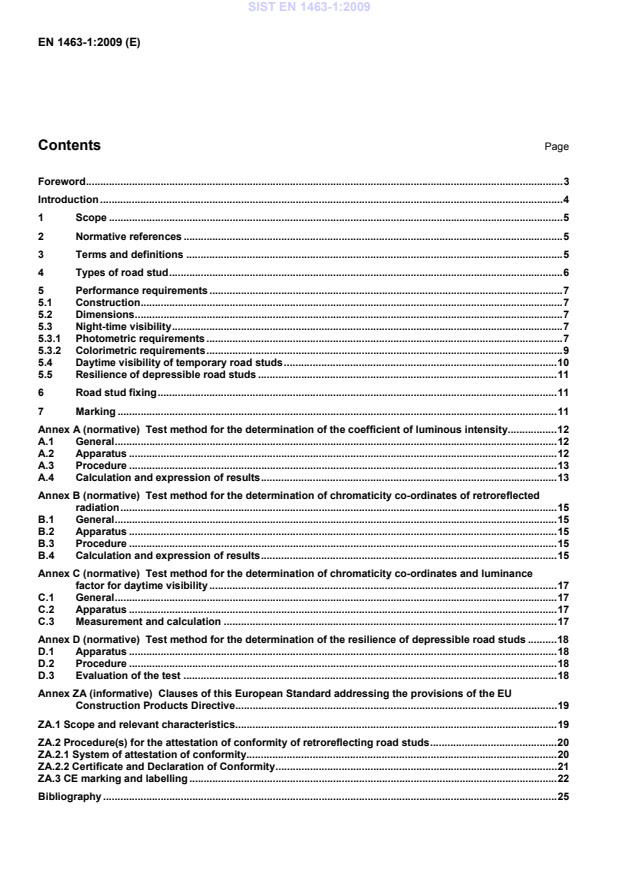

Test method for the determination of the coefficient of luminous intensity. 12 A.1 General . 12 A.2 Apparatus . 12 A.3 Procedure . 13 A.4 Calculation and expression of results . 13 Annex B (normative)

Test method for the determination of chromaticity co-ordinates of retroreflected radiation . 15 B.1 General . 15 B.2 Apparatus . 15 B.3 Procedure . 15 B.4 Calculation and expression of results . 15 Annex C (normative)

Test method for the determination of chromaticity co-ordinates and luminance factor for daytime visibility . 17 C.1 General . 17 C.2 Apparatus . 17 C.3 Measurement and calculation . 17 Annex D (normative)

Test method for the determination of the resilience of depressible road studs . 18 D.1 Apparatus . 18 D.2 Procedure . 18 D.3 Evaluation of the test . 18 Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive . 19 ZA.1 Scope and relevant characteristics. 19 ZA.2 Procedure(s) for the attestation of conformity of retroreflecting road studs . 20 ZA.2.1 System of attestation of conformity. 20 ZA.2.2 Certificate and Declaration of Conformity . 21 ZA.3 CE marking and labelling . 22 Bibliography . 25 SIST EN 1463-1:2009

In Mandate M/111, there is a clear requirement for durability in use. In order to meet this requirement,

EN 1463-1 specifies, in Annex ZA Table ZA.1, the standard EN 1463-2 (Road test performance specifications).

However, in the current Table ZA.1, the classes S0 and R0 (no performance determined) are included (just as a way to reflect the result of the mentioned durability test, which requires 1-year of road exposure for the applicant studs) and some notified bodies have interpreted this as meaning that it is not required to test to EN 1463-2 and consequently CE marks are being granted without durability being tested. However, in other cases, the mentioned test has been carried out; therefore, both types of road studs are now in the market granting a “well different” class of CE-marking.

In order to rectify this unsatisfactory situation it is proposed to amend the requirement for “R” to become R1 to R4 - i.e. eliminating R0, which might have caused the confusion, and thus meaning that a road test has to be carried out and the requirement for durability is met. In addition, it is also proposed that the requirement for “S” is deleted as this is not necessary to also have this to ensure durability is tested. SIST EN 1463-1:2009

1 Scope This European Standard specifies the initial performance requirements and laboratory test methods for retroreflecting road studs intended for use as permanent and temporary road marking materials.

2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1463-2:2000, Road marking materials – Retroreflecting road studs – Part 2: Road test performance specifications

ISO 10526, CIE standard illuminants for colorimetry

ISO 10527, CIE standard colorimetric observers

CIE publication No. 054.2-2001, Retroreflection: Definition and measurement

IEC/CIE publication No. 017.4-1987, International lighting vocabulary, 4th ed. (Joint publication IEC/CIE)

3 Terms and definitions For the purposes of this European Standard, the terms and definitions in CIE publication 17.4:1987 apply together with the following.

3.1 retroreflecting road stud (called “road stud” in this standard) horizontal guiding device that reflects incident light by means of retroreflectors (see 3.2) in order to warn, guide or inform road users

NOTE

Retroreflecting road studs may be constructed in either one or more integral parts and may be bonded to, anchored within or embedded within the road surface. The retroreflecting portion may be unidirectional or bidirectional, depressible or non depressible. This device may be either permanent (type P) or temporary (type T). 3.2

retroreflector device which reverses the direction of visible light striking it and returns it along a path substantially parallel to its original path

NOTE It may be made of glass (type 1), plastic (type 2) or plastic with an abrasion resistant surface (type 3). It may have a reflective coating at the back. 3.3

non depressible road stud substantially rigid road stud not designed to deform under the passage of traffic (type A)

3.4

depressible road stud road stud designed to have one or more parts which deform under traffic and recover to their original geometry after removal of the traffic load (type B)

3.5

bonded road stud

road stud fixed to the road surface using an adhesive applied to the stud and/or to the road surface at the time of installation

self-adhesive road stud

road stud precoated with adhesive

NOTE An adhesion enhancer (see 3.7) may be required under some climatic conditions. 3.7

adhesion enhancer

additional coating on the load bearing surface of the road stud or on the road surface which improves the performance of the adhesive bond

3.8

anchored road stud

road stud fixed to the road surface using an anchor or spigot

NOTE The anchor(s) or spigot(s) may be an extension of the road stud body or a separate part(s) supplied for the purpose. The principal load bearing interface of the road stud and the road is between the surface of the road and the underside of the road stud. 3.9

embedded road stud

road stud fixed into a prepared cavity of an appropriate dimension cut into the road surface

NOTE The principal load bearing interface of the road stud and the road is between a downward facing surface of the road stud and an upward facing surface of the cavity. 4 Types of road stud Road studs are classified in this European Standard in accordance with Tables 1, 2 and 3.

Table 1 - Classification of road studs by use

Use TypePermanent road stud 1) P Temporary road stud 2) T 1) Provides night-time warning guidance and information to road users.

2) Provides daytime and night-time warning guidance and information to the road user by stimulating the use of three senses. It is received visually and can be heard and felt through the rumble effect. Temporary road studs are used only at road construction/maintenance sites.

Table 2 - Classification of road studs by reflector

Reflector TypeGlass 1 Plastic 2 Plastic with abrasion resistant layer 3 NOTE

The abrasion resistant layer is applied on the surface exposed to traffic.

Table 3 - Classification of road studs by design

Design TypeNon depressible road stud A Depressible road stud B

5 Performance requirements 5.1 Construction For safety reasons the enveloping profile of the road studs shall not present any sharp edges to traffic.

If the road stud consists of two or more parts, each replaceable part shall be removable only with a tool recommended by the manufacturer.

5.2 Dimensions The height of that part of a road stud designed to be above the road surface shall be as follows:

- class H 0 -

no performance determined;

- class H 1 -

up to 18 mm;

- class H 2 -

from more than 18 mm to 20 mm;

- class H 3 -

from more than 20 mm to 25 mm.

NOTE Class H 0 road studs are not intended to be subjected to traffic load.

Maximum horizontal dimensions of that part of a road stud which is exposed to traffic after installation are classified as follows:

- class HD 0 -

no performance determined;

- class HD 1 -

in the direction of travel: length 250 mm, width 190 mm;

- class HD 2 -

in the direction of travel: length 320 mm, width 230 mm.

NOTE Class HD 0 road studs are intended for use when other functional needs of the road stud are required (e.g. to be snowploughed). Minimum horizontal dimensions of that part of a temporary road stud which is exposed to traffic after installation are classified as follows:

-

class HDT 0

-

no performance determined;

-

class HDT 1

-

in the direction of travel: length 35 mm, width 84 mm;

-

class HDT 2

-

in the direction of travel: length 75 mm, width 90 mm.

5.3 Night-time visibility 5.3.1 Photometric requirements 5.3.1.1 Permanent road stud

When tested in accordance with Annex A, each retroreflective face of the road stud shall have a coefficient of luminous intensity (R) as classified (see Table 4) multiplied by the appropriate colour factor given in Table 5.

-

class PRP 0

-

no performance determined;

-

class PRP 1

-

not less than given in Table 4.

Table 4 - Class PRP 1 - Minimum R values for type 1, type 2 and type 3 road studs as new

Entrance angle ββββH ββββV = 0° Observation angleαααα Min. Rmcd · lx-1

Type

1 2 3 ± 15° 2° 2 2,5 1,5 ± 10° 1° 10 25 10 ± 5° 0,3 ° 20 220 150

Table 5 - Colour factors for the retroreflectors of road studs

Colour Colour factorWhite 1,0 Yellow 0,6 Amber 0,5 Red 0,2 Green 0,2

5.3.1.2 Temporary road studs

When tested in accordance with Annex A, each retroreflective face of the road stud shall have a coefficient of luminous intensity (R) as classified (see Tables 6 to 8) multiplied by the appropriate colour factor given in Table 5:

-

class PRT 0

-

no performance determined;

-

class PRT 1

-

not less than Table 6;

-

class PRT 2

-

not less than Table 7;

-

class PRT 3

-

not less than Table 8.

The minimum R values for type 1, type 2 and type 3 road studs, as new, are given in Tables 6 to 8.

Table 6 - Class PRT 1 - Minimum R values for type 1, type 2 and type 3 read studs as new

Entrance angleββββH ββββV = 0° Observation angle αααα Min. Rmcd · lx-1

Type

1 2 3 ± 15° 2° 2 2,5 1,5 ± 10° 1° 10 25 10 ± 5° 0,3 ° 20 220 150

Table 7 - Class PRT 2 - Minimum R values for type 1, type 2 and type 3 road studs as new

Entrance angleββββH ββββV = 0° Observation angle αααα Min. Rmcd · lx-1

Type

1 2 3 ± 15° 2° 1,4 2,0 1,4 ± 10° 1° 7 10 7 ± 5° 0,3 ° 13 60 40 SIST EN 1463-1:2009

Table 8 - Class PRT 3 - Minimum R values for type 1, type

2 and type 3 road studs as new

Entrance angle ββββH ββββV = 0° Observation angle αααα Min. Rmcd · lx-1

Type

1 2 3 ± 10° 1° 7 10 7 ± 5° 0,3 ° 13 60 40

5.3.1.3 Interpretation of the results

A road stud shall not be considered to fail the photometric requirements if the measured coefficient of luminous intensity at any one position of measurement is less than the values specified in Tables 4 or 6 to 8, multiplied by the respective colour factor given in Table 5 provided that:

a) the value is not less than 80 % of the specified minimum; and

b) the average of the left (-) and right (+) measurements for the specific angle is greater than the specified minimum.

5.3.2 Colorimetric requirements

When tested in accordance with Annex B, the retroreflected radiation of a road stud shall be classified as follows and have chromaticity co-ordinates that lie within the permitted regions defined in Table 9.

- class

NCR 0

-

no performance determined;

- class

NCR 1

-

as specified in Table 9.

Measurements shall be carried out in accordance with ISO 10526 and ISO 10527 (2° visual field) and with an entrance angle βV = 0°, βH = 5° and an observation angle of α = 0,3°.

Colour Pointxy White (uncoloured) 1 2 3 4 5 0,390 0,440 0,500 0,500 0,420 0,410 0,440 0,440 0,390 0,370 Yellow 1 2 3 4 0,539 0,530 0,580 0,589 0,460 0,460 0,410 0,410 Amber 1 2 3 4 0,549 0,543 0,590 0,605 0,450 0,450 0,395 0,395 Red 1 2 3 4 0,665 0,645 0,721 0,735 0,335 0,335 0,259 0,265 Green 1 2 3 4 0,030 0,228 0,321 0,302 0,385 0,351 0,493 0,692 NOTE 1

If two of the points lie on the spectrum locus line, they shall not be connected by a straight line but shall, in this case, be joined by the boundary of the spectrum locus.

NOTE 2

The night-time colours of retroreflective materials are at present being studied by the International Commission on Illumination (CIE TC 2.19). The limits given in this table are therefore of a provisional nature. It is proposed that these will be revised once TC 2.19 has completed its work.

5.4 Daytime visibility of temporary road studs

When tested in accordance with Annex C and using the measuring geometry 45/0 the road stud body shall have chromaticity coordinates that lie within the permitted regions defined in Table 10 and shall have the minimum luminance factor given in Table 10. Daytime visibility is classified as follows:

- class DCR 0

-

no performance determined;

- class DCR 1

-

as specified in Table 10.

Table 10 - Corner points of chromaticity regions and minimum luminance factor for temporary road stud bodies as new - class DCR 1 Colour PointxyLuminance factor ββββ White 1 2 3 4 0,350 0,300 0,290 0,340 0,360 0,310 0,320 0,370

≥ 0,75 Fluorescent green-yellow 1 2 3 4 0,380 0,320 0,380 0,460 0,620 0,540 0,480 0,540

≥ 0,75 Yellow 1 2 3 4 0,522 0,470 0,427 0,465 0,477 0,440 0,483 0,534

≥ 0,45

5.5 Resilience of depressible road studs When tested in accordance with Annex D depressible road studs shall show no breakdown of the depressing action and no permanent deformation of such an extent that the retroreflecting part is permanently obscured, even partially. 6 Road stud fixing All road studs shall be laid in accordance with the manufacturer’s instructions.

Removal of temporary road studs shall be possible without damage to the road surface and with a minimum of residue. 7 Marking All road studs shall be clearly and permanently marked. The following information shall be on the road stud or the packaging or the accompanying commercial documents using a hierarchical method in that order:

a) name or identifying mark of the manufactu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...