EN 613:2021

(Main)Independent closed-fronted gas-fired type B11, type C11, type C31 and type C91 heaters

Independent closed-fronted gas-fired type B11, type C11, type C31 and type C91 heaters

This document specifies the requirements and test methods for the construction, safety, marking and rational use of energy.

This document is applicable to types B11AS, B11BS, B11CS, C11, C31 and C91 appliances (see 4.2) and those that:

— are closed-fronted;

— incorporate a natural draught burner;

— are connected directly to an open flue or to a device to evacuate the products of combustion (open-flued appliances, balanced-flued appliances);

— are wall mounted, free-standing or built-in;

— have a nominal heat input not exceeding 20 kW (based on the net calorific value).

This document is not applicable to:

— open fronted appliances as specified in EN 13278:2013;

— decorative fuel effect appliances as specified in EN 509:1999/A1:2003;

— catalytic combustion appliances;

— appliances in which the supply of combustion air and/or evacuation of products of combustion is achieved by mechanical means as specified in EN 1266:2002;

— ducted-air appliances;

— appliances installed by means of a closure plate (see 3.3.3.3).

Matters related to quality assurance systems, tests during production and to certificates of conformity of auxiliary devices are not dealt with by this standard.

Raumheizer mit geschlossener Vorderseite für gasförmige Brennstoffe der Geräte Art B11, Art C11, Art C31 und Art C91

Dieses Dokument legt Anforderungen und Prüfverfahren für Bau, Sicherheit, Kennzeichnung und rationelle Energienutzung fest.

Dieses Dokument ist anzuwenden für Geräte der Arten B11AS, B11BS, B11CS, C11 und C31 und C91 (siehe 4.2) und die:

— eine geschlossene Vorderseite;

— einen atmosphärischen Brenner;

— direkt oder mittels Zwischenstücks an einem offenen Schornstein oder an eine Einrichtung zur Abführung der Abgase angeschlossen sind (Geräte mit offener Verbrennung, Geräte mit Luftabgassystem (LAS));

— an der Wand befestigt, freistehend oder eingebaut sind;

— eine Nennwärmeleistung kleiner oder gleich 20 kW (bezogen auf den Heizwert) haben.

Dieses Dokument ist nicht anzuwenden für:

— Geräte mit offener Verbrennungskammer nach EN 13278:2013;

— Geräte mit dekorativem Brennstoffeffekt nach EN 509:1999/A1:2003;

— Geräte mit katalytischer Verbrennung;

— Geräte bei denen die Zufuhr von Verbrennungsluft und/oder die Ableitung von Abgasen durch mechanische Mittel nach EN 1266:2002 erfolgt;

— Luftgeräte mit Kanalanschluss;

— Geräte, die mit einer Verschlussplatte installiert werden (siehe 3.3.3.3).

Fragen im Zusammenhang mit Qualitätssicherung, Kontrollprüfungen während der Produktion und Konformitätszertifikate von Hilfsgeräten werden nicht in dieser Norm behandelt.

Appareils de chauffage indépendants à foyer fermé utilisant les combustibles gazeux de types B11, C11, C31 et C91

Le présent document spécifie les exigences et méthodes d’essais pour la construction, la sécurité, le marquage et l’utilisation rationnelle de l’énergie.

La présente norme s’applique aux appareils de types B11AS, B11BS, B11CS, C11, C31 et C91 (voir Paragraphe 4.2) et ceux :

⎯ à foyer fermé ;

⎯ comportant un brûleur atmosphérique ;

⎯ raccordés directement à un conduit ou à un dispositif d’évacuation des produits de combustion (appareils pour conduits à tirage naturel, appareils à ventouse) ;

⎯ posés, fixés au mur ou encastrés ;

⎯ ayant un débit calorifique nominal inférieur ou égal à 20 kW (sur le pouvoir calorifique inférieur).

Le présent document ne s’applique pas :

⎯ aux appareils à foyer ouvert, comme ceux spécifiés dans l’EN 13278:2013;

⎯ aux appareils à effet décoratif, comme ceux spécifiés dans l’EN 509 :1999+A1 :2013;

⎯ aux appareils à combustion catalytique ;

⎯ aux appareils dans lesquels l’amenée d’air comburant et/ou l’évacuation des produits de combustion est effectuée par un moyen mécanique comme spécifié dans l’EN 1266 :2002;

⎯ aux appareils de distribution d’air par gaine ;

⎯ aux appareils installés au moyen d’une plaque de fermeture (voir 3.3.3.3).

Les points relatifs aux systèmes d’assurance qualité, aux essais en production et aux certificats de conformité aux équipements auxiliaires ne sont pas traités dans la présente norme.

Plinski grelniki z zaprtim kuriščem tipov B11, C11, C31 in C91

Plinski grelniki z zaprtim kuriščem tipov B11, C11, C31 in C91

Independent closed-fronted gas-fired type B11, type C11, type C31 and type C91 heaters

Osnova: EN 613:2021

ICS: 97.100.20

Ta dokument določa zahteve in preskusne metode za izdelavo, varnost, označevanje in racionalno rabo energije.

Ta standard se uporablja za aparate na plin tipov B11, C11, C31 in C91 ter:

– aparate z zaprtim kuriščem;

– aparate, ki vključujejo gorilnik z naravnim vlekom;

– aparate, ki so neposredno povezani z odprto odvodno cevjo ali z napravo za odvajanje produktov zgorevanja (aparati z odprto odvodno cevjo, tlačno izravnani aparati);

– stenske, prostostoječe ali vgrajene aparate;

– aparate z nazivno vhodno toplotno močjo, ki ne presega 20 kW (glede na neto kalorično vrednost).

Ta dokument se ne uporablja za:

– aparate z odprtim kuriščem iz standarda EN 13278;

– plinske aparate z dekorativnim plamenom iz standarda EN 509;

– aparate s katalitičnim izgorevanjem;

– aparate, v katerih se dovajanje zgorevalnega zraka in/ali odvajanje produktov zgorevanja doseže z mehanskimi sredstvi, kot je določeno v standardu EN 1266;

– aparate z vodenim zrakom;

– aparate, vgrajene z zapiralno ploščo (glej točko 3.3.3.3).

Ta standard ne obravnava vsebine, ki se navezuje na sisteme zagotavljanja kakovosti, preskuse med proizvodnjo in potrdila o skladnosti pomožnih naprav.

General Information

- Status

- Published

- Publication Date

- 21-Dec-2021

- Withdrawal Date

- 29-Jun-2022

- Technical Committee

- CEN/TC 62 - Independent gas-fired space heaters

- Drafting Committee

- CEN/TC 62/WG 3 - Chairman's Advisory Group

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 22-Dec-2021

- Due Date

- 23-Feb-2021

- Completion Date

- 22-Dec-2021

Relations

- Effective Date

- 29-Dec-2021

- Effective Date

- 29-Dec-2021

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 613:2021 (EN 613:2021) sets the requirements and test methods for independent closed-fronted gas-fired heaters of types B11 (including B11AS, B11BS, B11CS) and C11, C31, C91. The standard covers construction, safety, marking and the rational use of energy for appliances that:

- are closed-fronted and incorporate a natural draught burner;

- are connected to an open flue or a combustion-products evacuation device (open-flued or balanced-flued);

- are wall-mounted, free-standing or built-in; and

- have a nominal heat input ≤ 20 kW (net calorific value).

Exceptions include open-fronted appliances (EN 13278), decorative fuel-effect appliances (EN 509), catalytic combustion appliances, mechanically ventilated combustion/evacuation systems (EN 1266), ducted-air appliances, and appliances installed using a closure plate. Quality assurance, production-line testing and auxiliary-device conformity certificates are outside its scope.

Key topics and technical requirements

The standard provides prescriptive coverage and test methodologies for:

- Appliance construction: gas circuit, burners, ignition and flame supervision systems, controls and safety devices.

- Operational safety: soundness of gas and combustion-product circuits, spillage monitoring, flame stability and ignition behavior.

- Thermal performance: heat input measurement, working-surface temperatures and overall appliance efficiency testing.

- Pressure and regulation: requirements and test methods for pressure regulators and gas pressure test points.

- Marking and instructions: mandatory labelling, user and installation instructions for safe operation and energy-efficient use.

- Test methods and annexes: detailed procedures (e.g., hood test for type B appliances - Annex A), smoke-number determination (Annex C), NOx conversion calculations (Annex E) and leakage measurement arrangements (Annex G).

Normative cross-references include EN 437 (test gases & appliance categories), EN 60335 series (electrical safety), EN 88-1 (pressure governors) and other gas-appliance related standards.

Practical applications - who uses EN 613

- Manufacturers and product designers - to design and verify closed-fronted gas heaters meet European safety and performance requirements.

- Test laboratories and certification bodies - to perform type testing, combustion and leakage tests according to standardized methods.

- Regulatory authorities and market surveillance - to assess conformity with safety and marking obligations.

- Installers and technical service - to understand appliance classification, installation limits and user information requirements.

- Energy and compliance engineers - to evaluate appliance efficiency and rational energy use.

Related standards

- EN 437 (Test gases - categories)

- EN 60335-1 / EN 60335-2-102 (electrical safety for appliances)

- EN 1266 (mechanical combustion/evacuation) - referenced as exclusion

- EN 13278, EN 509 - referenced for excluded appliance types

Keywords: SIST EN 613, EN 613, closed-fronted gas heaters, B11 C11 C31 C91, natural draught burners, gas heater safety, test methods, appliance marking, energy efficiency.

Frequently Asked Questions

EN 613:2021 is a standard published by the European Committee for Standardization (CEN). Its full title is "Independent closed-fronted gas-fired type B11, type C11, type C31 and type C91 heaters". This standard covers: This document specifies the requirements and test methods for the construction, safety, marking and rational use of energy. This document is applicable to types B11AS, B11BS, B11CS, C11, C31 and C91 appliances (see 4.2) and those that: — are closed-fronted; — incorporate a natural draught burner; — are connected directly to an open flue or to a device to evacuate the products of combustion (open-flued appliances, balanced-flued appliances); — are wall mounted, free-standing or built-in; — have a nominal heat input not exceeding 20 kW (based on the net calorific value). This document is not applicable to: — open fronted appliances as specified in EN 13278:2013; — decorative fuel effect appliances as specified in EN 509:1999/A1:2003; — catalytic combustion appliances; — appliances in which the supply of combustion air and/or evacuation of products of combustion is achieved by mechanical means as specified in EN 1266:2002; — ducted-air appliances; — appliances installed by means of a closure plate (see 3.3.3.3). Matters related to quality assurance systems, tests during production and to certificates of conformity of auxiliary devices are not dealt with by this standard.

This document specifies the requirements and test methods for the construction, safety, marking and rational use of energy. This document is applicable to types B11AS, B11BS, B11CS, C11, C31 and C91 appliances (see 4.2) and those that: — are closed-fronted; — incorporate a natural draught burner; — are connected directly to an open flue or to a device to evacuate the products of combustion (open-flued appliances, balanced-flued appliances); — are wall mounted, free-standing or built-in; — have a nominal heat input not exceeding 20 kW (based on the net calorific value). This document is not applicable to: — open fronted appliances as specified in EN 13278:2013; — decorative fuel effect appliances as specified in EN 509:1999/A1:2003; — catalytic combustion appliances; — appliances in which the supply of combustion air and/or evacuation of products of combustion is achieved by mechanical means as specified in EN 1266:2002; — ducted-air appliances; — appliances installed by means of a closure plate (see 3.3.3.3). Matters related to quality assurance systems, tests during production and to certificates of conformity of auxiliary devices are not dealt with by this standard.

EN 613:2021 is classified under the following ICS (International Classification for Standards) categories: 97.100.20 - Gas heaters. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 613:2021 has the following relationships with other standards: It is inter standard links to EN 613:2000, EN 613:2000/A1:2003, EN 60730-1:2016, EN 60529:1991/A2:2013, EN IEC 60730-2-9:2019/A1:2019, EN 60335-1:2012/A2:2019, EN 60335-2-102:2016, EN 10305-1:2016, EN 751-1:1996, EN 298:2012, EN 751-2:1996, EN 1106:2010, EN 126:2012, EN 125:2010+A1:2015, EN 161:2011+A3:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 613:2021 is associated with the following European legislation: EU Directives/Regulations: 2016/426; Standardization Mandates: M/BC/CEN/89/6. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 613:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-april-2022

Nadomešča:

SIST EN 613:2002

SIST EN 613:2002/A1:2004

Plinski grelniki z zaprtim kuriščem tipov B11, C11, C31 in C91

Independent closed-fronted gas-fired type B11, type C11, type C31 and type C91

heaters

Konvektions-Raumheizer für gasförmige Brennstoffe der Geräte Art B11, Art C11, Art

C31 und Art C91

Appareils de chauffage indépendants à foyer fermé utilisant les combustibles gazeux de

types B11, C11, C31 et C91

Ta slovenski standard je istoveten z: EN 613:2021

ICS:

97.100.20 Plinski grelniki Gas heaters

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 613

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2021

EUROPÄISCHE NORM

ICS 97.100.20 Supersedes EN 613:2000

English Version

Independent closed-fronted gas-fired type B11, type C11,

type C31 and type C91 heaters

Appareils de chauffage indépendants à foyer fermé Konvektions-Raumheizer für gasförmige Brennstoffe

utilisant les combustibles gazeux de types B11, C11, der Geräte Art B11, Art C11, Art C31 und Art C91

C31 et C91

This European Standard was approved by CEN on 12 April 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 613:2021 E

worldwide for CEN national Members.

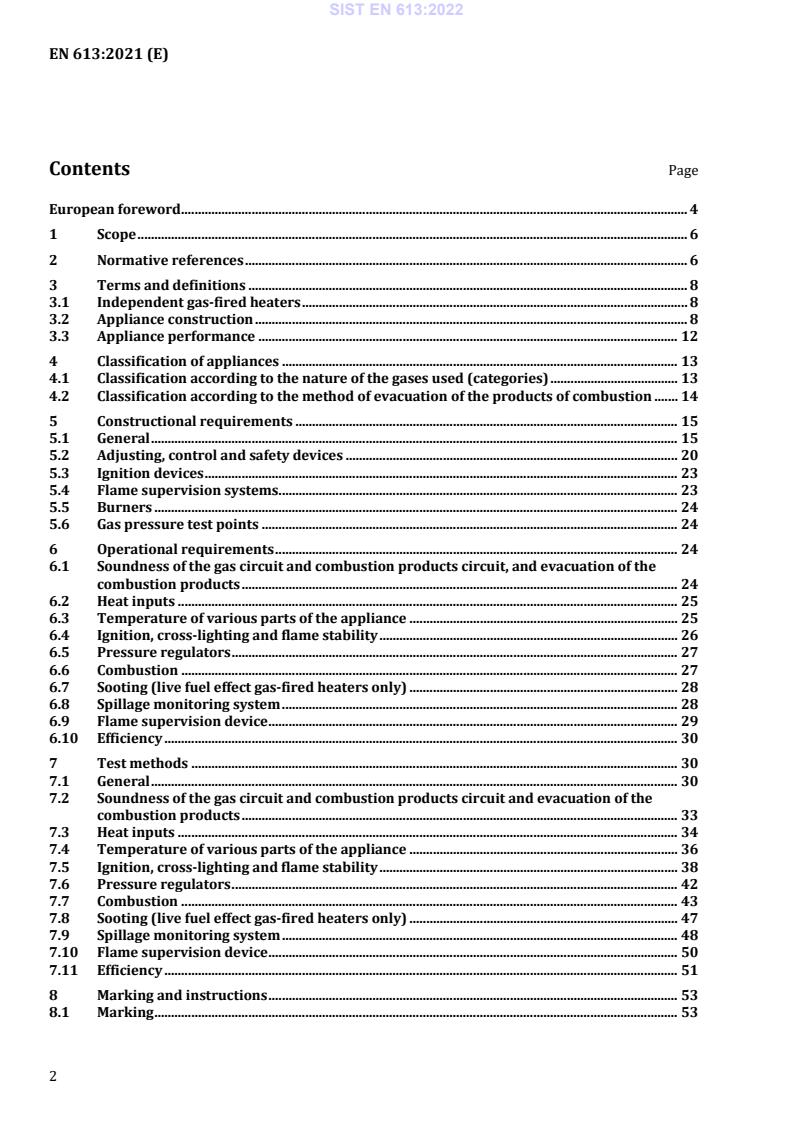

Contents Page

European foreword . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 8

3.1 Independent gas-fired heaters . 8

3.2 Appliance construction . 8

3.3 Appliance performance . 12

4 Classification of appliances . 13

4.1 Classification according to the nature of the gases used (categories) . 13

4.2 Classification according to the method of evacuation of the products of combustion . 14

5 Constructional requirements . 15

5.1 General . 15

5.2 Adjusting, control and safety devices . 20

5.3 Ignition devices . 23

5.4 Flame supervision systems. 23

5.5 Burners . 24

5.6 Gas pressure test points . 24

6 Operational requirements . 24

6.1 Soundness of the gas circuit and combustion products circuit, and evacuation of the

combustion products . 24

6.2 Heat inputs . 25

6.3 Temperature of various parts of the appliance . 25

6.4 Ignition, cross-lighting and flame stability . 26

6.5 Pressure regulators . 27

6.6 Combustion . 27

6.7 Sooting (live fuel effect gas-fired heaters only) . 28

6.8 Spillage monitoring system . 28

6.9 Flame supervision device . 29

6.10 Efficiency . 30

7 Test methods . 30

7.1 General . 30

7.2 Soundness of the gas circuit and combustion products circuit and evacuation of the

combustion products . 33

7.3 Heat inputs . 34

7.4 Temperature of various parts of the appliance . 36

7.5 Ignition, cross-lighting and flame stability . 38

7.6 Pressure regulators . 42

7.7 Combustion . 43

7.8 Sooting (live fuel effect gas-fired heaters only) . 47

7.9 Spillage monitoring system . 48

7.10 Flame supervision device . 50

7.11 Efficiency . 51

8 Marking and instructions . 53

8.1 Marking . 53

8.2 Instructions . 56

Annex A (normative) Hood test method (type B appliances) . 71

Annex B (informative) Gas designations in force in the various EU countries . 75

Annex C (normative) Apparatus for the determination of the smoke number . 77

Annex D (informative) Symbols and abbreviations . 78

Annex E (normative) Calculation of conversions of NOx . 79

Annex F (normative) Arrangement for measuring the leakage rate . 80

Annex G (normative) Special national conditions . 81

Bibliography . 82

European foreword

This document (EN 613:2021) has been prepared by Technical Committee CEN/TC 62 “Independent

gas-fired space heaters”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2022, and conflicting national standards shall be

withdrawn at the latest by June 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 613:2000.

The main changes compared to EN 613:2000 are the following:

• Clause 1 – the Scope has been extended to cover type C and type C appliances;

31 91

• Clause 3.2 – all terms and definitions related to gas in EN 613:2000, cl. 3.2, have been deleted and

replaced by reference to EN 437;

• EN 613:2000, Clauses 3.4 and 3.5 – have been deleted;

• EN 613:2000, Clause 3.6 – has been deleted;

• Clause 4.1 – original replaced by reference to EN 437;

• Clause 4.2 – classification extended to type C and type C appliances;

31 91

• EN 613:2000, Clauses 5.1.1.4, 5.2.7 and 5.6 – have been deleted;

• Clauses 7.1.1 and 7.1.2 – original replaced by reference to EN 437;

• Clause 6.2.2.2 and 7.2.2.2 – have been extended to cover type C and type C appliances;

31 91

• Clause 6.5.2.3 and 7.5.4 – have been extended to cover type C and type C appliances;

31 91

• Clause 7.1.5.3 – has been extended to cover type C and type C appliances;

31 91

• Clause 7.5.2 – has been extended to cover type C and type C appliances

31 91

• Clause 7.7.1.2 and 7.7.3.3 – have been extended to cover type C and type C appliances;

31 91

• Clause 7.11.1.3 – has been extended to cover type C and type C appliances;

31 91

• EN 613:2000, Annexes A, B, F and L – have been deleted;

• Annex G – new Annex to cover arrangement for measuring the leakage rate.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

1 Scope

This document specifies the requirements and test methods for the construction, safety, marking and

rational use of energy.

This document is applicable to types B B , B , C , C and C appliances (see 4.2) and those

11AS, 11BS 11CS 11 31 91

that:

— are closed-fronted;

— incorporate a natural draught burner;

— are connected directly to an open flue or to a device to evacuate the products of combustion (open-

flued appliances, balanced-flued appliances);

— are wall mounted, free-standing or built-in;

— have a nominal heat input not exceeding 20 kW (based on the net calorific value).

This document is not applicable to:

— open fronted appliances as specified in EN 13278:2013;

— decorative fuel effect appliances as specified in EN 509:1999/A1:2003;

— catalytic combustion appliances;

— appliances in which the supply of combustion air and/or evacuation of products of combustion is

achieved by mechanical means as specified in EN 1266:2002;

— ducted-air appliances;

— appliances installed by means of a closure plate (see 3.3.3.3).

Matters related to quality assurance systems, tests during production and to certificates of conformity

of auxiliary devices are not dealt with by this standard.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 88-1:2011+A1:2016, Pressure governors for gas appliances for inlet pressure up to 200 mbar

EN 125:2010+A1:2015, Flame supervision devices for gas burning appliances — Thermoelectric flame

supervision devices

EN 126:2012, Multifunctional controls for gas burning appliances

EN 161:2011+A3:2013, Automatic shut-off valves for gas burners and gas appliances

EN 257:2010, Mechanical thermostats for gas-burning appliances

EN 298:2012, Automatic burner control systems for burners and appliances burning gaseous or liquid

fuels

EN 437:2021, Test gases — Test pressures — Appliance categories

EN 751-1:1996, Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family

gases and hot water — Part 1: Anaerobic jointing compounds

EN 751-2:1996, Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family

gases and hot water — Part 2: Non-hardening jointing compounds

EN 10226-1:2004, Pipe threads where pressure tight joints are made on the threads — Part 1: Taper

external threads and parallel internal threads — Dimensions, tolerances and designation

EN 10226-2:2005, Pipe threads where pressure tight joints are made on the threads — Part 2: Taper

external threads and taper internal threads — Dimensions, tolerances and designation

EN 1106:2010, Manually operated taps for gas burning appliances

EN 10305-1:2016, Steel tubes for precision applications — Technical delivery conditions — Part 1:

Seamless cold drawn tubes

EN 23166:1993, Codes for the representation of names of countries (ISO 3166:1993)

EN ISO 3166-1:2020, Codes for the representation of names of countries and their subdivisions — Part 1:

Country Codes (ISO 3166-1:2020)

EN 60335-1:2012/A2:2019, Household and similar electrical appliances — Part 1: Safety. General

requirements

EN 60335-2-102:2016, Household and similar electrical appliances — Safety — Part 2-102: Particular

requirements for gas, oil and solid-fuel burning appliances having electrical connections

EN 60529:1991/A2:2013, Degrees of protection provided by enclosures (IP code)

EN IEC 60730-2-9:2019/A1:2019, Automatic electrical controls — Part 2-9: Particular requirements for

temperature sensing control

EN 60730-1:2016, Automatic electrical controls — Part 1: General requirements

ISO 7-1:1994, Pipe threads where pressure-tight joints are made on the threads — Part 1: Dimensions,

tolerances and designation

EN ISO 228-1:2003, Pipe threads where pressure-tight joints are not made on the threads — Part 1:

Dimensions, tolerances and designation (ISO 228-1:2000)

CR 1404:1994, Determination of emissions from appliances burning gaseous fuels during type-testing

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 437 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1 Independent gas-fired heaters

3.1.1

closed-fronted appliance

appliance which does not have exposed flames or exposed incandescent areas

Note 1 to entry: Access to the flame is prevented by a panel made of glass, metal or a suitable material.

Note 2 to entry: Type C1 and type C3 appliances are room-sealed appliances.

3.1.2

forced gas-fired heater

appliance that incorporates a fan and thus allows an acceleration of the circulation of the air in contact

with the heating body

Note 1 to entry: Such an appliance is designed to discharge heated air directly into the room in which the

appliance is installed.

3.1.3

live fuel effect gas-firedheater

appliance which has a visual flame effect

3.1.4

working surfaces

area of the appliance that generates and emits heat

Note 1 to entry: Examples of working surfaces include fire bricks, refractories, imitation fuel, fire fronts, fire

baskets, burners, burner trays and bracketry.

3.1.5

convection fan

device to assist in the distribution of heated air

3.2 Appliance construction

3.2.1 The gas circuit

3.2.1.1

inlet connection

part of the appliance intended to be connected to the gas supply

3.2.1.2

mechanical joint

connection device assuring soundness in an assembly of several parts, generally of metal

Note 1 to entry: For example the following:

— cone seat joints;

— flat joints;

— metal to metal joints.

3.2.1.3

gas circuit

part of an appliance that conveys or contains the gas between the appliance gas inlet connection and the

burner(s)

3.2.1.4

gas restrictor

non-adjustable device which is placed in the gas circuit so as to create a pressure drop and thus reduce

the gas pressure at the burner to a predetermined value for a given supply pressure and rate

3.2.1.5

gas rate adjuster

component intended to set the gas rate to each burner at a predetermined value according to the supply

conditions

Note 1 to entry: The adjustment can be progressive (screw adjuster) or discontinuous (changing restrictors).

Note 2 to entry: The adjuster of an adjustable governor is regarded as a gas rate adjuster.

Note 3 to entry: The action of setting this device is called 'setting the gas rate'.

3.2.1.6

gas rate control

component allowing the user to open or close the gas supply to one or more burners

Note 1 to entry: It may also be used to adjust the gas rate of certain burners to a predetermined value, called the

'reduced rate'. This device can be a 'tap'.

3.2.1.7

injector

component that admits the gas into a burner, where the section of the outlet orifice is fixed

3.2.1.8

start gas

initial quantity of gas ignited to give a flame which is used to ignite the main burner

Note 1 to entry: It can be discharged through a separate ignition burner or part of the main burner.

3.2.2 Burner

3.2.2.1

main burner

burner that provides the primary thermal function of the appliance

3.2.2.2

pilot burner

burner intended to light the main burner and that supplements the main burner in providing a thermal

function of the appliance

3.2.2.2.1

permanent pilot

pilot burner that operates continuously throughout the whole period that the appliance is in use,

independent of the main burner, and has to be extinguished by manual intervention

3.2.2.2.2

non-permanent pilot

pilot burner that is extinguished automatically when there is no heat demand

3.2.2.2.3

fixed primary aeration restrictor

non-adjustable device which limits the supply of primary air to a burner

3.2.3 Combustion products circuit

3.2.3.1

flue outlet

part of a type B appliance that connects with a flue to evacuate the products of combustion

3.2.3.2

draught diverter

device placed in the combustion product's circuit to reduce the influence of flue-pull and to minimize

the effect of down-draught on the burner flame stability and combustion

3.2.3.3

closure plate

non-combustible plate used to cover and seal the front plane of a builder's opening, or fireplace

opening, such that when the appliance is installed, any air flowing from the room into the flue does so in

accordance with the design requirements of the appliance

Note 1 to entry: This plate contains an aperture through which the flue outlet spigot of the appliance projects

into the cavity of the builder's opening, or fireplace recess, but is not connected to the flue.

Note 2 to entry: The plate can be a separate component, or an integral part of the appliance, e.g. the back panel,

but in either case it is to be considered as part of the appliance.

3.2.3.4

builder's opening

enclosure constructed to accommodate fireplace components

3.2.3.5

fireplace opening

aperture formed in the face of the builder's opening, the fireplace recess or fire surround if fitted

3.2.3.6

fireplace recess

recess formed by the inclusion of fireplace components in the builder's opening

3.2.4 Auxiliary equipment

3.2.4.1

pressure governor

device that maintains, within a fixed range, a constant downstream pressure, independent of the

upstream pressure and/or the gas rate

3.2.4.2

ignition device

device that ignites one or more burners

3.2.4.3

flame supervision device

device that senses the absence or presence of a flame

3.2.4.4

combustion products discharge safety device

device that automatically shuts off the gas supply to the main burner, and perhaps to the ignition

burner, when there is unacceptably high spillage of combustion products from the draught diverter

3.2.4.5

atmosphere sensing device

device that reacts to the lack of oxygen in the surrounding atmosphere

3.2.4.6

control knob

component designed to be moved by hand in order to operate an appliance control (tap, thermostat,

etc.)

3.2.4.7

programming unit

unit which reacts to signals from control and safety devices, gives control commands, controls the start-

up sequence, supervises the burner operation and causes controlled shut-down, and if necessary safety

shut-down and lock-out

Note 1 to entry: The programming unit follows a predetermined sequence of actions and always operates in

conjunction with a flame detector device.

3.2.4.8

flame detector device

device by which the presence of a flame is detected and signalled

Note 1 to entry: It can consist of a flame sensor, an amplifier and a relay for signal transmission. These parts,

with the possible exception of the actual flame sensor, may be assembled in a single housing for use in conjunction

with a programming unit.

3.2.4.9

automatic burner system

burner system in which, when starting from the completely shut-down condition, the gas is ignited and

the flame is detected and proved and the main gas valve(s) is actuated without manual intervention

3.2.4.10

restart interlock

device which prevents the restoration of the gas supply to the main burner, or to the main burner and

ignition burner, until the end of the extinction delay time

3.3 Appliance performance

3.3.1 Gas rates

3.3.1.1

nominal heat input

Q

n

value of the heat input declared in the technical specification

Note 1 to entry: Unit: kilowatt (kW).

3.3.2 Gas combustion

3.3.2.1

flame stability

state of the flames resting in a stable manner on the burner ports or the flame contact area provided by

the design with no flame lift or light-back

3.3.2.2

flame lift

phenomenon characterized by the total or partial lifting of the base of the flame from the burner port or

the flame contact area provided by the design

3.3.2.3

light-back

phenomenon characterized by the entry of a flame into the body of a burner

3.3.2.4

light-back at the injector

phenomenon characterized by ignition of the gas at the injector, either as a result of the flame entering

the burner or by the propagation of a flame around the outside of the burner

3.3.2.5

sooting

phenomenon characterized by deposits of soot on the surfaces of parts of the appliance in contact with

the products of combustion or with the flame, or as particulate matter in the combustion products

3.3.2.6

yellow tipping

phenomenon characterized by the appearance of yellow colouring at the top of the blue cone of an

aerated flame

3.3.3

safety time

interval between the ignition burner gas valve, the start gas valve or main gas valve, as applicable, being

energized and the ignition burner gas valve, start gas valve or main gas valve, as applicable, being de-

energized if the flame detector signals the absence of a flame

3.3.4

extinction delay time

time that elapses between the disappearance of the flame and the interruption of the gas supply

3.3.5

ignition delay time

time that elapses between ignition of the supervised flame and the moment when the closure element is

held open by the flame signal

Note 1 to entry: This applies to a thermoelectric flame supervision device.

3.3.6

thermal equilibrium

operating state of the appliance, corresponding to a particular setting of the input, in which the flue gas

temperature does not change by more than ± 2 K over a period of 10 min

3.3.7

controlled shutdown

process by which a control device (on the appliance or external to it) causes the gas supply to the main

burner to be stopped immediately

3.3.8

safety shutdown

process which is initiated immediately in response to the signal from a limiting device or sensor and

which causes any burner to shut down

3.3.9

non-volatile lockout

shutdown condition so that a start can only be accomplished by a manual reset

3.3.10

volatile lockout

shutdown condition so that a start can be accomplished by restoration of the electrical supply after its

loss

3.3.11

smoke number

qualitative scale of the soot emission

4 Classification of appliances

4.1 Classification according to the nature of the gases used (categories)

4.1.1 Classification of gases

Gases are classified into three families, possibly divided into groups as a function of the Wobbe index in

accordance with the values given in EN 437:2021, Table 1.

4.1.2 Appliance categories

Appliance are classified into categories defined according to the gases and the pressures for which they

are designed as given in EN 437:2021, 6.1.

4.2 Classification according to the method of evacuation of the products of combustion

Appliances are classified into types according to the method of evacuation of the products of

combustion and of admission of the combustion air:

• Type B: An appliance intended to be connected to a flue which evacuates the products of

combustion to the outside of the room containing the appliance. The combustion air is drawn

directly from the room.

• Type B : A type B appliance incorporating a draught diverter.

• For the purposes of this standard a type B appliance is an appliance that is connected directly or

by means of an adaptor to a flue.

• Type B : A natural draught type B appliance designed for a natural draught flue, which includes

11 1

Type B Type B and Type B appliances.

11AS, 11BS 11CS

• Type B : A type B appliance fitted with an atmospheric sensing device to prevent the release of

11AS 11

combustion products in a dangerous quantity into the room under abnormal draught conditions.

• Type B : A type B appliance fitted with a combustion products discharge safety device to

11BS 11

prevent the release of combustion products in dangerous quantities into the room under abnormal

draught conditions.

• Type B : A type B appliance not fitted with an atmosphere sensing device or combustion

11CS 11

products discharge safety device, but is constructed to prevent the release of combustion products

in dangerous quantities into the room under abnormal draught conditions.

• Type C: An appliance in which the combustion circuit (air supply, combustion chamber, heat

exchanger, and evacuation of the combustion products) is sealed with respect to the room in which

the appliance is installed.

• Type C : A type C appliance that is designed for connection via its ducts to its horizontal terminal,

which at the same time admits fresh air to the burner and discharges the products of combustion to

the outside through orifices which are either concentric or close enough together to come under

the same wind conditions.

• Type C : A natural draught type C appliance.

11 1

• Type C : A type C appliance that is designed for connection via its ducts to a vertical terminal, which

at the same time admits fresh air to the burner and discharges the products of combustion to the

outside through orifices that are either concentric or close enough together to come under the same

wind conditions.

• Type C : A natural draught type C appliance.

31 3

• Type C : A type C appliance that is designed for connection via its flue duct to a vertical terminal

and via its inlet duct to an existing vertical duct. The terminal at the same time admits fresh air to

the burner and discharges the products of combustion to the outside through orifices that are

either concentric or close enough to come under similar wind conditions.

• Type C : A natural draught type C appliance.

91 9

5 Constructional requirements

5.1 General

5.1.1 Conversion to different gases

5.1.1.1 General

In accordance with the categories (see 4.1), the only acceptable modifications and/or adjustments when

converting from a gas of one group or family to another group or family and/or for adapting to a

different gas distribution pressures, are given in 5.1.1.2 to 5.1.1.3 for each appliance category.

For type B appliances, when the operation of atmosphere sensing devices depends upon the

11AS

characteristics of the gas (including pressure), a change of the complete atmosphere sensing device is

required when converting from a gas of one family to a gas of another family, or from one pressure or

pressure couple to another within the third family, if this is specified in the instructions for installation,

use and servicing.

5.1.1.2 Category I

• Categories I ,I ,I , I : Modification and/or adjustment of the appliance is not applicable.

2H 2L 2E 2E+

• Category I : No modification and/or adjustment of the appliance except for replacement of the

3+

injectors or restrictors in order to convert from one pressure couple to another (e.g. 28 mbar to

30 mbar/37 mbar < = > 50 mbar/67 mbar). Exchange of fixed primary aeration restrictor when

changing from one pressure couple to another or from one pressure to another within a pressure

couple is permitted.

• Category I , I : No modification and/or adjustment of the appliance with respect to a change of

3P 3B/P

gas. For a change of pressure range, replacement of injectors, and adjustment of gas rates and

exchange of fixed primary aeration restrictor is permitted.

5.1.1.3 Category II

5.1.1.3.1 Appliance categories designed for use on gases of the first and second families

The following modifications and/or adjustments are permitted but only when converting from a gas of

one family to a gas of another family:

a) adjustment of the gas rate with, if necessary, a change of injectors, restrictors or governor;

b) replacement of a burner assembly;

c) replacement of complete ignition burners or some of its parts;

d) exchange of fixed primary aeration restrictor.

If the appliance is intended to function without an operational governor for use with gases of the second

family, it is obligatory to put the governor out of service in these circumstances (see 5.2.6).

It is obligatory to put gas rate adjusters out of service for use with gases of the second family.

5.1.1.3.2 Appliance categories designed for use on gases of the second and third families

The following modifications and/or adjustments are permitted but only when converting from a gas of

one family to a gas of another family:

a) adjustment of the gas rate with, if necessary, a change of injectors, restrictors or governor;

b) replacement of a burner assembly;

c) replacement of complete ignition burner or some of its parts;

d) exchange of the fixed primary aeration restrictor.

The governor shall be put out of service where this is required in accordance with the requirements of

5.2.6.

Gas rate adjusters shall be put out of service in accordance with requirements of 5.2.2.

The following modifications and/or adjustments are permitted when changing from one pressure

couple to another or from one pressure range to another:

1) replacement of the injectors or restrictors in order to convert from one pressure couple to another

within the third family (e.g. 28 mbar to 30 mbar/37 mbar < = > 50 mbar/67 mbar).

2) exchange of fixed primary aeration restrictor when changing from one pressure couple to another

or from one pressure to another within a pressure couple is permitted.

For a change of pressure range in the case of appliance categories using third family gases without a

pressure couple (i.e. “3P” and “3B/P”), replacement of injectors, adjustment of the gas rates and

exchange of fixed primary aeration restrictor is permitted.

5.1.2 Materials and method of construction

The quality and thickness of the materials used in the construction of the appliance, and the method of

assembling the various parts, shall be such that the constructional, functional and operational

characteristics do not alter during a reasonable life under normal conditions of installation, use and

maintenance. This includes the gas carrying components which shall be of metallic or non-metallic

material but suitable for the type of gas for which the appliance is approved, this includes the gas

carrying and flue carrying components.

When the appliance is installed according to the instructions for installation, use and servicing and

national installation requirements, all components shall withstand the mechanical, chemical and

thermal conditions to which they might be subjected during use.

Sheet metal parts in contact with products of combustion and not made of corrosion-resistant material

shall be coated with an effective protection against corrosion, e.g. enamel.

Asbestos or materials containing asbestos shall not be used.

If condensation is produced at the start-up and/or during the normal operation of the appliance, it shall

not cause a deterioration in the construction of the appliance and/or materials used so as to affect the

safety of the appliance. The design of an appliance shall be such that condensate cannot drip outside of

the appliance.

5.1.3 Accessibility for use and maintenance

Any control placed in the gas circuit shall be arranged so that it can be adjusted, maintained or

exchanged.

Removable parts shall be so designed or marked that they are easy to reassemble correctly in

accordance with the instructions for installation, use and servicing and difficult to reassemble

incorrectly. Removable parts shall be so designed or marked that they are easy to reassemble correctly

in accordance with the instructions for installation, use and servicing and any incorrect assembly shall

be obvious.

It shall be possible to complete all the operations of removal and reassembly of parts which the user has

to carry out in the course of routine maintenance as explained in the instructions for installation, use

and servicing, without the aid of a tool.

Removable parts shall be dismountable for maintenance by a service engineer using tools in common

use, such as a screwdriver or a spanner.

For a type C , C and C appliances, the soundness of the combustion circuit shall be maintained

11 31 91

after reassembly and, if required, after replacing the sealing gasket following cleaning or maintenance

operations.

An appliance shall be capable of being fixed securely. The instructions for installation, use and servicing

shall give relevant and precise information.

When the combustion circuit of an appliance incorporates a door which is required to be opened or a

panel which is required to be removed, it shall be difficult to close the door or replace the panel

incorrectly.

If the above operation does not require the use of a tool, this operation shall not be obvious and the

procedure shall be specified in the instructions for use and servicing (see 8.2.2).

In the case where a special tool is supplied by the manufacturer, this tool shall be removable once the

above operation has been completed.

5.1.4 Connections

5.1.4.1 Appliance inlet connection

The appliance inlet connection shall conform to the soundness requirements specified in 6.1.1.

The appliance inlet connection shall be one of the following types:

a) a thread conforming to EN 10226-1:2004. In this case the end of the gas inlet connection shall have

a flat annular surface at least 3 mm wide for thread sizes 1/2" and 3/8" and at least 2,5 mm wide

for thread size 1/4", to allow the interposition of a sealing washer. When the end of the gas inlet

connection has a thread of nominal size 1/2", it shall be possible to insert a gauge of 12,3 mm

diameter to a depth of at least 4 mm;

b) a thread conforming to ISO 7-1:1994 and EN ISO 228-1:2003;

c) a compression fitting with dimensions compatible with the steel tube dimensions conforming to

EN 10305-1:2016;

d) a straight tube at least 30 mm long, the end of which is cylindrical, smooth and clean, to allow

connection by means of a compression fitting as specified in c);

e) a cone seat union.

Other connections are possible if the soundness requirements of 6.1.1 are met.

5.1.4.2 Access to the inlet connection

The position of the connection shall be such that connection to the gas supply can be made easily with

tools in common use.

5.1.5 Soundness of the gas circuit

The joints, sealing compounds and sealing materials used in the construction of the appliance, and the

method of assembling the various parts, shall be such that the constructional, functional and

operational characteristics do not alter significantly during a reasonable life under normal conditions of

installation, use and maintenance. This includes the gas carrying components. Sealing materials for

metallic threaded joints in gas circuit shall be in accordance with EN 751-1:1996 (for anaerobic jointing

compounds) or EN 751-2:1996 Class B (for non-hardening jointing compounds) for the threads in

compliance with EN 10226-1:2004 (Threaded joints using taper external threads and parallel internal

threads) (Threaded joints using taper external threads and taper internal threads) and

EN 10226-2:2005 (Threaded joints using taper external threads and taper internal threads).

Holes for screws, studs, etc., intended for the assembly of components shall not open into the gasways.

Brackets for supporting components shall not be interposed in any gas-carrying joints.

The soundness of components and assemblies connected to the gas circuit and likely to be dismantled

for routine maintenance at the consumer's premises, with the exception of taps and cocks, shall be

ensured by means of mechanical joints, e.g. metal to metal joints, O-ring joints or packing, but excluding

the use of any sealing compound such as tape, mastic or paste. Sealing compounds may be used for

permanent threaded assemblies and injectors and grease for taps and cocks. The sealing material shall

remain effective under normal conditions of appliance use.

The soundness of the gas circuit assemblies shall not be achieved by means of soft solder for which the

lowest temperature of the melting range, after application, is less than 450 °C.

The soundness of the gas circuit shall conform to 6.1.1.

5.1.6 Soundness of the combustion circuit

5.1.6.1 Type B appliances

The soundness of an appliance up to the draught-diverter shall be effected by mechanical means only,

with the exception of those parts which do not require to be disconnected for routine maintenance,

which may be joined with mastic or paste in such a way that permanent soundness is ensured under

normal conditions of use.

Parts which can be removed for routine maintenance shall be so designed and arranged that soundness

is ensured after reassembly.

5.1.6.2 Type C , C and C appliances

11 31 91

The soundness of the heating body and of the connection of an appliance to the combustion air inlet and

the products outlet ducts shall be effected by mechanical means only.

However, those parts of the assembly which do not require to be dismantled for routine maintenance

may be joined with mastic or paste in such a way that permanent soundness is ensured under normal

conditions of use.

The construction of the whole assembly shall ensure soundness in relation to the room in which an

appliance is installed.

Parts which can be removed for routine maintenance shall be so designed and arranged that soundness

is ensured after reassembly.

5.1.6.3 Built-in appliances

If an appliance is supplied in several sub-groups which have to be assembled on installation, it shall be

possible to carry out this operation without ambiguity when assembling in accordance with the

instructions for installation, use and servicing. If a special tool is required it shall be supplied by the

manufacturer.

Any components or materials necessary to assemble these sub-groups shall be supplied by the

manufacturer.

5.1.7 Supply of combustion air and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...