EN 13104:2009

(Main)Railway applications - Wheelsets and bogies - Powered axles - Design method

Railway applications - Wheelsets and bogies - Powered axles - Design method

This standard:

1) defines the forces and moments to be taken into account with reference to masses, traction and braking

conditions;

2) gives the stress calculation method for axles with outside axle journals;

3) specifies the maximum permissible stresses to be assumed in calculations for steel grade EA1N defined

in EN 13261;

4) describes the method for determination of the maximum permissible stresses for other steel grades;

5) determines the diameters for the various sections of the axle and recommends the preferred shapes and

transitions to ensure adequate service performance.

This standard is applicable to:

6) solid and hollow powered axles for railway rolling stock;

7) solid and hollow non-powered axles of motor bogies;

8) solid and hollow non-powered axles of locomotives3;

9) axles defined in EN 13261;

10) all gauges4.

This standard is applicable to axles fitted to rolling stock intended to run under normal European conditions.

Before using this standard, if there is doubt as to whether the railway operating conditions are normal, it is

necessary to determine whether an additional design factor has to be applied to the maximum permissible

stresses. The calculation of wheelsets for special applications (e.g. tamping/lining/levelling machines) may be

made according to this standard only for the load cases of free-running and running in train formation. This

standard does not apply to workload cases. They are calculated separately.

For light rail and tramway applications, other standards or documents agreed between the customer and

supplier may be applied.

Bahnanwendungen - Radsätze und Drehgestelle - Treibradsatzwellen - Konstruktionsverfahren

Diese Europäische Norm:

- gibt Kräfte und Momente an, die aufgrund der Massenwirkungen, Antriebs- und Bremsbedingungen zu berücksichtigen sind;

- gibt das Verfahren zur Spannungsberechnung außengelagerter Radsatzwellen an;

- legt die höchstzulässigen Spannungen für den Stahl der Güte EA1N fest, die in die Berechnung einzu¬setzen sind nach EN 13261;

- beschreibt die Vorgehensweise zur Ermittlung der höchstzulässigen Spannungen für andere Stähle;

- bestimmt die Durchmesser der verschiedenen Wellenabschnitte. Die bevorzugten Formen und Über¬gänge werden definiert, um ein sicheres Betriebsverhalten zu erreichen.

Diese Norm gilt für:

- angetriebene Radsätze von rollendem Eisenbahnmaterial mit Voll- und Hohlwellen;

- Laufradsätze mit Voll- und Hohlwellen von Motordrehgestellen;

- Laufradsätze mit Voll- und Hohlwellen von Lokomotiven );

- Radsätzen nach EN 13261;

- alle Spurweiten ).

Diese Norm ist anwendbar für Radsatzwellen für Rollendes Material, das für den Einsatz unter üblichen Betriebs¬bedingungen, wie sie in Europa herrschen, vorgesehen ist. Wenn Zweifel bestehen, ob die Betriebsbedingungen üblich sind, ist es notwendig vor Anwendung dieser Norm zu entscheiden, ob ein zusätzlicher Konstruktionsfaktor für die maximal zulässigen Spannungen angewendet werden muß. Die Berechnung von Radsätzen für besondere Anwendungsfälle (z. B. Oberbauricht- und -stopfmaschinen) kann entsprechend der vorliegenden Norm aus¬schließlich für die Lastfälle Eigenfahrt und Fahrt im Zugverband durchgeführt werden. Diese Norm gilt nicht für Arbeitslastfälle. Sie werden separat berechnet.

Applications ferroviaires - Essieux montés et bogies - Essieux-axes moteurs - Méthode de conception

La présente norme :

- définit les forces et moments à prendre en compte en fonction des masses, de la traction et du freinage ;

- donne la méthode de calcul des contraintes dans les essieux-axes à fusées extérieures ;

- prescrit les contraintes maximales admissibles à prendre en compte dans les calculs pour la nuance d'acier EA1N définie dans l’EN 13261;

- décrit la méthode de détermination des contraintes maximales admissibles pour les autres nuances d'acier ;

- permet de calculer les diamètres des différentes parties de l'essieu-axe et recommande les formes et raccordements les mieux adaptés pour garantir une bonne tenue mécanique en service.

La présente norme est applicable :

- aux essieux-axes moteurs pleins et creux du matériel roulant ferroviaire ;

- aux essieux-axes porteurs pleins et creux des bogies moteurs ;

- aux essieux-axes porteurs pleins et creux des locomotives ) ;

- aux essieux-axes définis par l’EN 13261;

- à tous les écartements de voie ).

La présente norme est applicable aux essieux-axes destinés aux matériels roulant dans des conditions d'exploitation normale européenne. Avant l’utilisation de cette norme et en cas de doutes sur la normalité des conditions d’exploitation, il est impératif d’établir la nécessité d’appliquer un coefficient de sécurité supplémentaire, aux contraintes admissibles maximales. Les calculs d’essieux pour des applications spéciales (par exemple bourreuses, niveleuses, dresseuses) peuvent être menés selon la présente norme, pour les cas de charge véhicule isolé, hors séquence de travail et véhicule incorporé dans un train. Cette norme ne s’applique pas aux cas de charges de travail. Ceux-ci sont calculés séparément.

Pour les véhicules légers et les tramways, d’autres normes ou documents acceptés entre client et fournisseur peuvent être utilisés.

Železniške naprave - Kolesne dvojice in podstavni vozički - Pogonske osi - Konstrukcijska metoda

General Information

- Status

- Withdrawn

- Publication Date

- 03-Mar-2009

- Withdrawal Date

- 19-Oct-2010

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 2/WG 11 - Wheels - Wheelsets

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 20-Oct-2010

- Completion Date

- 20-Oct-2010

Relations

- Effective Date

- 08-Jun-2022

- Merged Into

EN 13104:2009+A1:2010 - Railway applications - Wheelsets and bogies - Powered axles - Design method - Effective Date

- 18-Jan-2023

- Amended By

EN 13104:2009/FprA1 - Railway applications - Wheelsets and bogies - Powered axles - Design method - Effective Date

- 12-Dec-2009

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

EN 13104:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Wheelsets and bogies - Powered axles - Design method". This standard covers: This standard: 1) defines the forces and moments to be taken into account with reference to masses, traction and braking conditions; 2) gives the stress calculation method for axles with outside axle journals; 3) specifies the maximum permissible stresses to be assumed in calculations for steel grade EA1N defined in EN 13261; 4) describes the method for determination of the maximum permissible stresses for other steel grades; 5) determines the diameters for the various sections of the axle and recommends the preferred shapes and transitions to ensure adequate service performance. This standard is applicable to: 6) solid and hollow powered axles for railway rolling stock; 7) solid and hollow non-powered axles of motor bogies; 8) solid and hollow non-powered axles of locomotives3; 9) axles defined in EN 13261; 10) all gauges4. This standard is applicable to axles fitted to rolling stock intended to run under normal European conditions. Before using this standard, if there is doubt as to whether the railway operating conditions are normal, it is necessary to determine whether an additional design factor has to be applied to the maximum permissible stresses. The calculation of wheelsets for special applications (e.g. tamping/lining/levelling machines) may be made according to this standard only for the load cases of free-running and running in train formation. This standard does not apply to workload cases. They are calculated separately. For light rail and tramway applications, other standards or documents agreed between the customer and supplier may be applied.

This standard: 1) defines the forces and moments to be taken into account with reference to masses, traction and braking conditions; 2) gives the stress calculation method for axles with outside axle journals; 3) specifies the maximum permissible stresses to be assumed in calculations for steel grade EA1N defined in EN 13261; 4) describes the method for determination of the maximum permissible stresses for other steel grades; 5) determines the diameters for the various sections of the axle and recommends the preferred shapes and transitions to ensure adequate service performance. This standard is applicable to: 6) solid and hollow powered axles for railway rolling stock; 7) solid and hollow non-powered axles of motor bogies; 8) solid and hollow non-powered axles of locomotives3; 9) axles defined in EN 13261; 10) all gauges4. This standard is applicable to axles fitted to rolling stock intended to run under normal European conditions. Before using this standard, if there is doubt as to whether the railway operating conditions are normal, it is necessary to determine whether an additional design factor has to be applied to the maximum permissible stresses. The calculation of wheelsets for special applications (e.g. tamping/lining/levelling machines) may be made according to this standard only for the load cases of free-running and running in train formation. This standard does not apply to workload cases. They are calculated separately. For light rail and tramway applications, other standards or documents agreed between the customer and supplier may be applied.

EN 13104:2009 is classified under the following ICS (International Classification for Standards) categories: 01.075 - Character symbols; 45.040 - Materials and components for railway engineering; 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13104:2009 has the following relationships with other standards: It is inter standard links to EN 13104:2001, EN 13104:2009+A1:2010, EN 13104:2009/FprA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13104:2009 is associated with the following European legislation: EU Directives/Regulations: 2001/16/EC, 2008/57/EC, 96/48/EC; Standardization Mandates: M/275, M/334. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13104:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Bahnanwendungen - Radsätze und Drehgestelle - Treibradsatzwellen - KonstruktionsverfahrenApplications ferroviaires - Essieux montés et bogies - Essieux-axes moteurs - Méthode de conceptionRailway applications - Wheelsets and bogies - Powered axles - Design method45.040Materiali in deli za železniško tehnikoMaterials and components for railway engineeringICS:Ta slovenski standard je istoveten z:EN 13104:2009SIST EN 13104:2009en,fr01-junij-2009SIST EN 13104:2009SLOVENSKI

STANDARDSIST EN 13104:20041DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13104March 2009ICS 45.040Supersedes EN 13104:2001

English VersionRailway applications - Wheelsets and bogies - Powered axles -Design methodApplications ferroviaires - Essieux montés et bogies -Essieux-axes moteurs - Méthode de conceptionBahnanwendungen - Radsätze und Drehgestelle -Treibradsatzwellen - KonstruktionsverfahrenThis European Standard was approved by CEN on 26 December 2008.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre:

Avenue Marnix 17,

B-1000 Brussels© 2009 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13104:2009: ESIST EN 13104:2009

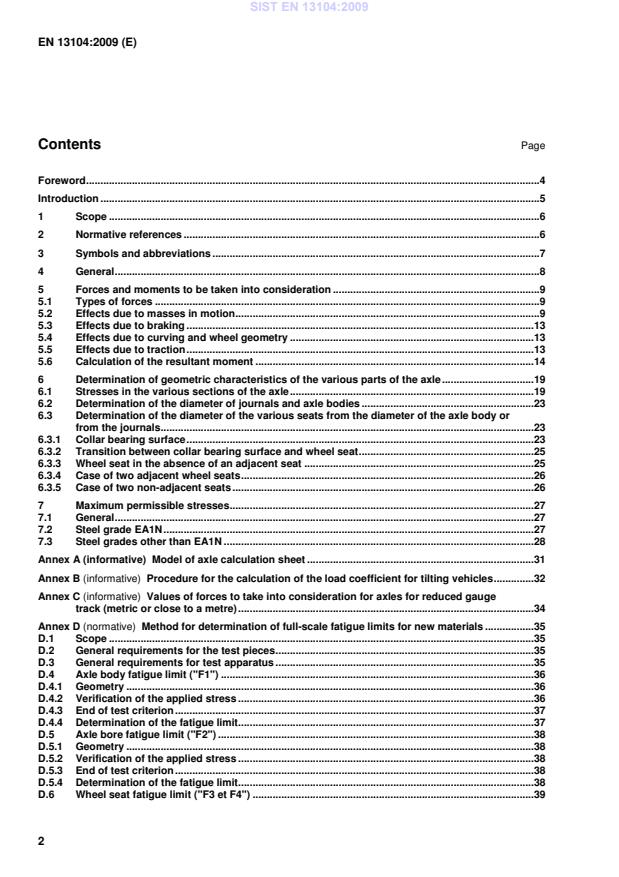

Steel grade EA1N.27 7.3

Steel grades other than EA1N.28 Annex A (informative)

Model of axle calculation sheet.31 Annex B (informative)

Procedure for the calculation of the load coefficient for tilting vehicles.32 Annex C (informative)

Values of forces to take into consideration for axles for reduced gauge track (metric or close to a metre).34 Annex D (normative)

Method for determination of full-scale fatigue limits for new materials.35 D.1 Scope.35 D.2 General requirements for the test pieces.35 D.3 General requirements for test apparatus.35 D.4 Axle body fatigue limit ("F1").36 D.4.1 Geometry.36 D.4.2 Verification of the applied stress.36 D.4.3 End of test criterion.37 D.4.4 Determination of the fatigue limit.37 D.5 Axle bore fatigue limit ("F2").38 D.5.1 Geometry.38 D.5.2 Verification of the applied stress.38 D.5.3 End of test criterion.38 D.5.4 Determination of the fatigue limit.38 D.6 Wheel seat fatigue limit ("F3 et F4").39 SIST EN 13104:2009

Relationship between this European Standard and the Essential Requirements of EU Directive 96/48/EC amended by Directive 2004/50/EC.42 Annex ZB (informative)

Relationship between this

European

Standard and the Essential Requirements of EU Directive 2001/16/EC amended by EU Directive 2004/50/EC.43 Bibliography.44

Introduction Railway axles were among the first train components to give rise to fatigue problems.

Many years ago, specific methods were developed in order to design these axles. They were based on a feedback process from the service behaviour of axles combined with the examination of failures and on fatigue tests conducted in the laboratory, so as to characterize and optimize the design and materials used for axles. A European working group under the aegis of UIC1 started to harmonize these methods at the beginning of the 1970s. This led to an ORE2 document applicable to the design of trailer stock axles, subsequently incorporated into national standards (French, German, Italian). This method was successfully extrapolated in France for the design of powered axles and the French standard also applies to such axles. Consequently this method was converted into a UIC leaflet.

The bibliography lists the relevant documents used for reference purposes. The method described therein is largely based on conventional loadings and applies the beam theory for the stress calculation. The shape and stress recommendations are derived from laboratory tests and the outcome is validated by many years of operations on the various railway systems. This standard is based largely on this method which has been improved and its scope enlarged.

1 UIC : Union Internationale des Chemins de fer. 2 ORE: Office de Recherches et d'Essais de l'UIC. SIST EN 13104:2009

1 Scope This standard: 1) defines the forces and moments to be taken into account with reference to masses, traction and braking conditions; 2) gives the stress calculation method for axles with outside axle journals; 3) specifies the maximum permissible stresses to be assumed in calculations for steel grade EA1N defined in

EN 13261; 4) describes the method for determination of the maximum permissible stresses for other steel grades; 5) determines the diameters for the various sections of the axle and recommends the preferred shapes and transitions to ensure adequate service performance. This standard is applicable to: 6) solid and hollow powered axles for railway rolling stock; 7) solid and hollow non-powered axles of motor bogies; 8) solid and hollow non-powered axles of locomotives3; 9) axles defined in EN 13261; 10) all gauges4. This standard is applicable to axles fitted to rolling stock intended to run under normal European conditions. Before using this standard, if there is doubt as to whether the railway operating conditions are normal, it is necessary to determine whether an additional design factor has to be applied to the maximum permissible stresses. The calculation of wheelsets for special applications (e.g. tamping/lining/levelling machines) may be made according to this standard only for the load cases of free-running and running in train formation. This standard does not apply to workload cases. They are calculated separately. For light rail and tramway applications, other standards or documents agreed between the customer and supplier may be applied. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 13260:2009, Railway applications – Wheelsets and bogies – Wheelsets – Product requirements

EN 13261:2009, Railway applications – Wheelsets and bogies – Axles – Product requirements

3 In France, the interpretation of the term "locomotive" includes locomotives, locomoteurs or locotracteurs. 4 If the gauge is not standard, certain formulae need to be adapted. SIST EN 13104:2009

rail 2)(21gmm+ 0P N Vertical static force per journal when the wheelset is loaded symmetrically 21gm 1P N Vertical force on the more heavily-loaded journal 2P N Vertical force on the less heavily-loaded journal 'P N Proportion of P braked by any mechanical braking system

1Y N Wheel/rail horizontal force perpendicular to the rail on the side of the more heavily- loaded journal 2Y N Wheel/rail horizontal force perpendicular to the rail on the side of the less heavily-loaded journal H N Force balancing the forces 1Y and 2Y 1Q N Vertical reaction on the wheel situated on the side of the more heavily-loaded journal 2Q N Vertical reaction on the wheel situated on the side of the less heavily-loaded journal iF N Forces exerted by the masses of the unsprung elements situated between the two wheels (brake disc(s), gearwheel, etc.) fF N Maximum force input of the brake shoes of the same shoeholder on one wheel or interface force of the pads on one disc xM Nmm Bending moment due to the masses in motion 'xM , 'zM Nmm Bending moments due to braking 'yM Nmm Torsional moment due to braking ''xM, ''zM Nmm

Bending moments due to traction ''yM Nmm

Torsional moment due to traction MX, MZ Nmm

Sum of bending moments MY Nmm

Sum of torsional moments MR Nmm

Resultant moment SIST EN 13104:2009

Average friction coefficient between the wheel and the brake shoe or between the brake pads and the disc s N/mm2 Stress calculated in one section K

Fatigue stress concentration factor R mm Nominal radius of the rolling circle of a wheel bR mm Brake radius d mm Diameter for one section of the axle 'd mm Bore diameter of a hollow axle D mm Diameter used for determining K r mm Radius of transition fillet or groove used to determine K S

Security coefficient G

Centre of gravity fLR N/mm2 Fatigue limit under rotating bending up to 107 cycles for unnotched test pieces fER N/mm2 Fatigue limit under rotating bending up to 107 cycles for notched test pieces qa m/s2 Unbalanced transverse acceleration qf

Thrust factor 4 General The major phases for the design of an axle are: a) definition of the forces to be taken into account and calculation of the moments on the various sections of the axle; b) selection of the diameters of the axle body and journals and - on the basis of these diameters - calculation of the diameters for the other parts of the axle; c) the options taken are verified in the following manner: ¾ stress calculation for each section; ¾ comparison of these stresses with the maximum permissible stresses. The maximum permissible stresses are mainly defined by: SIST EN 13104:2009

5.2 Effects due to masses in motion The forces generated by masses in motion are concentrated along the vertical symmetry plane (y, z) (see Figure 1) intersecting the axle centreline.

Figure 1 Unless otherwise defined by the customer, the masses )(21mm+ to be taken into account for the main types of rolling stock are defined in Table 2. For particular applications, e.g. suburban vehicles, other definitions for masses are necessary, in accordance with the specific operating requirements.

Table 2 Type of rolling stock units Mass )(21mm+ Traction units with no passenger accommodation, luggage areas and postal vans

For the axle considered, proportion of the wagon mass under maximum permissible loading in service Traction units including passenger accommodation, luggage areas and postal vans

1 – Main line vehiclesa Mass in service + 1,2 ´ payload, "mass in service" is defined as: the vehicle mass without passengers, tanks full (of water, sand, fuel, etc.); "payload" is defined as the mass of a passenger estimated at 80 kg, including hand luggage;

1 passenger per seat; ¾ 2 passengers per m² in corridors and vestibules; ¾ 2 passengers per attendant compartment; ¾ 300 kg per m2 in luggage compartments.

2 – Suburban vehiclesa, b Mass in service + 1,2 ´ payload, "mass in service" is defined as the vehicle mass without passengers, tanks full (of water, sand, fuel, etc.); "payload" is defined as the mass of a passenger, which is estimated at 70 kg (little or no luggage); ¾ 1 passenger per seat; ¾ 3 passengers per m² in corridor areas; ¾ 4 or 5 passengers per m² in vestibule areas b; ¾ 300 kg per m2 in luggage compartments. a The payloads to be taken into account to determine the mass of the mainline and suburban vehicles broadly reflect the normal operating conditions of the member railways of the International Union of Railways (UIC). If the operating conditions differ significantly, these masses may be modified, for example, by increasing or decreasing the number of passengers per m² in corridors and vestibules. b These vehicles are sometimes associated with classes of passenger travel, i.e. 1st or 2nd class. The bending moment xM in any section is calculated from forces 1P, 2P, 1Q, 2Q, 1Y, 2Y and iF as shown in Figure 2. It represents the most adverse condition for the axle, i.e.: ¾ asymmetric distribution of forces; ¾ the direction of the forces iF due to the masses of the unsprung components selected in such a manner that their effect on bending is added to that due to the vertical forces; ¾ the value of the forces iFresults from multiplying the mass of each unsprung component by 1 g.

Key G – centre of gravity of vehicle

Figure 2 Table 3 shows the values of the forces calculated from1m. The formulae coefficient values are applicable to standard gauge axles and classical suspension. For very

different gauges, metric gauge for example, or a new system of suspension, tilting system for example, other values shall be considered (see Annexes B and C). Table 3 For all wheelsets defined in the scope of this standard gmbhP111)/0875,0625,0(+= gmbhP112)/0875,0625,0(-= gmY1135,0= gmY12175,0= gmYYH121175,0=-= For all wheelsets

)]2()()()([21ii21211ysFRYYsbPsbPsQi---+--+=

])()()([21ii21122yFRYYsbPsbPsQi-----+=

Between loading plane and running surface yPMx1=

Between running surfaces )()(111iixysbyFRYsbyQyPM-+--++--=

iF: force(s) on the left of the section considered

General outline of xM

variations

a For a non-symmetric wheelset, the calculations shall be carried out after applying the load alternately to the two journals to determine the worst case.

Figure 3 ¾ the bending component 'xM is due to the vertical forces parallel to the z axis; ¾ the bending component 'zM is due to the horizontal forces parallel to the x axis; ¾ the torsional component 'yM is directed along the axle centreline (y axis); it is due to the forces applied tangentially to the wheels. The components 'xM , 'yM and 'zM are shown in Table 6 for each method of braking. If several methods of braking are superimposed, the values corresponding to each method shall be added. For example, forces and moments due to electric braking or regenerative braking shall be added. NOTE If other methods of braking are used, the forces and moments to be taken into account can be obtained on the basis of the same principles as those shown in Table 6. Special attention should be paid to the calculation of the 'xM component, which is to be added directly to the xM component representing masses in motion. 5.4 Effects due to curving and wheel geometry For an unbraked wheelset, the torsional moment 'yM is equal to 0,2 PR to account for possible differences in wheel diameters and the effect of passing through curves.

For a braked wheelset, these effects are included in the effects due to braking.

5.5 Effects due to traction The forces generated in the axle from the transmission of the driving torque under constant adhesion conditions can normally be neglected. Calculation and experience have shown that the bending moments ''xM and ''zM, and torsional moment ''yM, are smaller than those generated by braking. Traction and braking moments do not occur simultaneously. SIST EN 13104:2009

The axle design should also take into account the instantaneous loss of traction, e.g. short-circuit overload.

Where traction control systems adopt a technique to maintain the tractive effort at the limit of adhesion, any resultant controlled oscillations about the mean driving torque shall be considered in determining the magnitude of the torsional moment ''yM.

For some applications, when driving torque is very high in starting conditions, and when they occur very often, the calculation shall be done as follows: a) taking into account the effects described in 5.2, 5.3 and 5.4; b) with the following starting conditions: 1) effects due to masses in motion given by Table 5; 2) effects due to starting driving torque. The effect of the conditions defined in b 1) and b 2) shall be combined.

The most severe conditions between a) and b) have to be used to define the axle.

Table 5

Starting forces gmP1155,0= gmP1255,0= gmY1110,0= gmY1205,0= gmH105,0=

5.6 Calculation of the resultant moment In every section, the maximum stresses are calculated from the resultant moment MR(see the following note), which is equal to:

222MZMYMXMR++= where MX, MYand MZare the sums of the various components due to masses in motion and braking:

'xxMMMX+= 5 'yMMY= 5 'zMMZ= 5

5 The values 'xM, yM', zM' may be replaced respectively by ''xM, ''yM and ''zM if the moments due to traction are greater than the moments due to braking. SIST EN 13104:2009

32232dMZMXnps+= The value of the shear stress is the following (torsion of beams with a circular section):

316dMYtps= As a result, the two principal stresses 1s and 2s are obtained as:

24221tnnssss++=24222tnnssss+-= Since the normal stress has a much higher absolute value (10 to 20 times) than the shear stress, the diameter of the largest Mohr's circle is selected (21ss- in this case) as a check of the value assumed ford.

22232t221MYMZMXd324++p=s+s=s-s=s As a result, the definition of a resultant moment is:

222MZMYMXMR++= SIST EN 13104:2009

M’x = 0,3Ff G y M’x = 0,3Ff G (b – s) M’x = Ff G y M’x = Ff G (b – s)

a b

a b b b M’x

M’z = Ff (0,3 + G )y M’z = Ff (0,3 + G )(b – s) M’z = Ff (1 + G )y M’z = Ff (1 + G )(b – s)

a a

M’z

M’y

M’y = 0

M’y = 0,3P’R c d

M’y = 0

M’y = 0,3P’R c d

Two brake discs mounted on the axle Two brake discs attached to the wheel hub f

Components M’x, M’z, M’y Between loading plane and running surface Between running surfaces and disc Between discs Between loading plane and running surface Between running surfaces

M’x = Ff G y M’x = Ff G (b – s + yi) M’x = Ff G y M’x = Ff G (b – s + yi)

b b b b M’x

M’z = Ff GyRRb M’z = Ff G RRb (b – s) M’z = Ff GyRRb M’z = Ff G (b – s) RRb

b b b b M’z

M’y M’y = 0 RPMy''3,0= d e

M’y = 0,3 P’R d, e M’y = 0 M’y = 0,3 P’R

d, e

M’x = Ff G ()ybysbi2-+

M’x = Ff G ()()ybbysbi-+-22 M’x = b21Ff G y (b+s-yi) M’x = Ff G()()ybbysbi-+-22

b b b b M’x

Between loading planes and running surface Between running surfaces

M’z = 21Ff GyRRb M’z =21Ff GRRb(b – s) M’z = 21Ff GyRRb M’z = 21Ff G (b – s) RRb M’z

Between loading planes and running surface Between running surfaces

M’y M’y = 0 M’y = 0,3 P’R M’y = 0 M’y = 0,3 P’R

d, e

d, e SIST EN 13104:2009

for brake blocks: 1,0= for cast iron blocks; 17,0= for all blocks with low-friction coefficient excluding cast iron; 25,0= for all blocks with high-friction coefficient excluding cast iron.

for brake pads: 35,0=. c This value was obtained from experimental tests and corresponds to a braking force difference between the two wheels producing a force difference tangential to the wheels and equates to '3,0P. It includes the torsional moment as specified in 5.3. d 'P is the proportion of P braked with the method of braking considered. e By convention, the torsional moment between running surfaces is selected at the value of RP'3,0. It includes the torsional moment due to braking and the torsional moment as specified in 5.4. f When the disc is mounted on the wheel web, then 0=iy 6 Determination of geometric characteristics of the various parts of the axle 6.1 Stresses in the various sections of the axle On any section of the axle with d as diameter, the stress6 to be taken into account is the following: ¾ for a solid axle (see Figure 4a): 332dMRKps´´= 7 ¾ for a hollow axle (see Figure 4b): ¾ on the outer surface:

)(324'4dddMRK-´´´=ps ¾ in the bore:

)(324'4'dddMRK-´´´=ps

6 In the case of a conical wheel seat, the stress is calculated for the section where the resultant moment is the highest and the diameter of this section is taken to be equal to the lower diameter of the wheel seat. 7 Kis a fatigue stress concentration factor . SIST EN 13104:2009

Figure 4a)

Figure 4b)

In a cylindrical part situated on the surface of a solid or hollow axle and in the bore of a hollow axle, the fatigue stress concentration factor Kis equal to 1. However, each change in section produces a stress increment, the

maximum value of which can be found:

at the bottom of a transition between two adjacent cylindrical parts with different diameters; ¾ at the groove bottom. NOTE Where a compound transition radius is used, it is recommended that the critical section is not located at the intersection between two radii.

If this situation occurs, consideration of the stress at the intersection of each radius in the compound transition radius i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...