EN 17975:2025

(Main)Maintenance - Risk control processes of energies and fluids risks in maintenance activities - Guidance

Maintenance - Risk control processes of energies and fluids risks in maintenance activities - Guidance

This document provides users with guidance that help manage risks related to energies & fluids during maintenance activities on items when in use. It is the responsibility of each employer, according to the terms commonly used in the company, to:

- Set out the correlation between the processes described in this document and standard practices,

- Define the roles and responsibilities of the people involved in the energies & fluids lockout process.

This document refers to concepts, definitions, rules, recommendations, and best practices taken from national and international documents (lockout/tagout - "administrative lockout" - Lockout/Tagout (LOTO) - Safe isolation) that cover activities to ensure the safety of workers with respect to energies & fluids.

This document deals with the prevention of energy & fluid (e.g. powders, gases, liquids, etc.) related risks; it is noted that some are covered by specific regulations or standards, such as the electrical risk. Environmental issues related to energies & fluids are not in the scope of this document. Danger associated with energies & fluids can be direct (e.g. contact, absorption, etc.) or indirect by reaction (e.g. mixing, heating, etc.). The scope includes all fluids because they can be intrinsically dangerous or become dangerous.

The recommendations given in this document have been drawn up with a view to ensure the safety and health of workers around hazardous energies & fluids, and situations when they are conducting actions related to maintenance, settings or changing formats, regardless of the type of activity.

The recommendations relate to activities carried out on items. They are applied before, during and after the operation to:

- The energies & fluids supplied, contained, transported, or released by items, products,

- Risks related to the presence of hazardous energies & fluids for the worker and the surrounding personal.

This document is a methodological guideline within the maintenance standards.

NOTE Particular cases such as risks of lack of presence of vital elements for the worker (e.g. breathable air) are in the scope but will not be detailed.

Instandhaltung - Verfahren zur Kontrolle der Risiken von Energien und Fluide bei Instandhaltungsmaßnahmen - Leitfaden

Dieses Dokument bietet einen Leitfaden für Anwendende, der dazu beiträgt, mit Risiken im Zusammenhang mit Energien und Fluiden bei Instandhaltungsarbeiten an in Betrieb befindlichen Objekten umzugehen. Entsprechend den im Unternehmen üblicherweise verwendeten Begriffen trägt jeder Arbeitgeber die Verantwortung dafür,

- die Übersteinstimmung zwischen den in diesem Dokument beschriebenen Prozessen und den üblichen Vorgehensweisen zu bestimmen;

- die Aufgaben und Verantwortlichkeiten der an dem Energie- und Fluid-Lockout-Prozess beteiligten Personen festzulegen.

Dieses Dokument stellt Konzepte, Definitionen, Regeln, Empfehlungen und bewährte Vorgehensweisen aus nationalen und internationalen Dokumenten auf (Lockout/Tagout – „Organisation des Lockouts“ – Lockout/Tagout (LOTO) – sichere Isolierung), die Vorgänge zur Sicherstellung der Arbeitssicherheit in Bezug auf Energien und Fluide abdecken.

Dieses Dokument ist anwendbar auf die Vorbeugung von Risiken, die mit Energien und Fluiden (z. B. Pulver, Gase, Flüssigkeiten usw.) in Zusammenhang stehen; es ist anzumerken, dass einige davon, wie beispielsweise elektrische Risiken, Gegenstand spezifischer Vorschriften oder Normen sind. Mit Energien und Fluiden in Zusammenhang stehende Umweltfragen fallen nicht in den Anwendungsbereich dieses Dokumentes. Die mit Energien und Fluiden verbundenen Gefährdungen können direkt sein (z. B. Kontakt, Absorption usw.) oder indirekt durch Reaktion (z. B. Mischen, Erwärmen usw.). Der Anwendungsbereich umfasst jegliche Fluide, weil sie an sich gefährlich sein oder gefährlich werden können.

Die in diesem Dokument gegebenen Empfehlungen wurden mit dem Ziel erarbeitet, die Sicherheit und Gesundheit des Personals in der Nähe von gefährlichen Energien und Fluiden sowie in Situationen, in denen sie Instandhaltungs-, Einstellungs- oder Formatwechselarbeiten durchführen, sicherzustellen, unabhängig von der Art der Maßnahme.

Die Empfehlungen beziehen sich auf Tätigkeiten, die an Objekten durchgeführt werden. Sie werden vor, während und nach den Vorgängen in Hinblick auf Folgendes angewendet:

- die von/in Objekten und Produkten zugeführten, enthaltenen, transportierten oder freigesetzten Energien und Fluide;

- Risiken für das Personal und die Belegschaft in der Umgebung in Zusammenhang mit gefährlichen Energien und Fluiden.

Bei diesem Dokument handelt es sich um einen methodischen Leitfaden im Rahmen von Instandhaltungsnormen.

ANMERKUNG Spezielle Fälle wie das Risiko des Nichtvorhandenseins lebenswichtiger Elemente für das Personal (z. B. Atemluft) fallen in den Anwendungsbereich, werden jedoch nicht im Einzelnen dargelegt.

Maintenance - Processus de maîtrise des risques liés aux énergies et fluides lors d’opérations de maintenance - Recommandations

Le présent document fournit aux utilisateurs des recommandations visant à maîtriser les risques liés aux énergies et aux fluides, lors des opérations de maintenance sur des biens en cours d’utilisation. En fonction de la terminologie couramment utilisée dans l’entreprise, il est de la responsabilité de chaque employeur :

- d’établir la corrélation entre les processus décrits dans le présent document et les pratiques usuelles ;

- de définir les fonctions et responsabilités des personnes impliquées dans les processus de mise en sécurité des énergies et des fluides.

Le présent document se réfère à des concepts, des définitions, des règles, des recommandations et des bonnes pratiques issus de documents nationaux et internationaux (consignation - « condamnation administrative » - LOTO (condamnation/signalisation) - isolation sûre) qui traitent des opérations de mise en sécurité des intervenants vis‐à‐vis des énergies et des fluides.

Le présent document traite de la prévention des risques liés aux énergies et aux fluides (poudres, gaz et liquides, par exemple) ; il faut noter que certains risques, tels que le risque électrique, sont couverts par des réglementations ou des normes spécifiques. Les enjeux environnementaux liés aux énergies et aux fluides n’entrent pas dans le domaine d’application du présent document. Le danger associé aux énergies et aux fluides peut être direct (par exemple contact, absorption, etc.) ou indirect par réaction (par exemple mélange, échauffement, etc.). Le domaine d’application englobe tous les fluides car ils peuvent être intrinsèquement dangereux ou ils peuvent le devenir.

Les recommandations formulées dans le présent document ont été rédigées dans le but d’assurer la sécurité et de protéger la santé des intervenants évoluant à proximité d’énergies et de fluides dangereux, ainsi que dans les situations où ils réalisent des actions assimilables à de la maintenance, de réglage ou de changement de formats, quelle que soit la nature des activités.

Les recommandations portent sur les opérations réalisées sur des biens. Elles s’appliquent avant, pendant et après l’opération :

- aux énergies et aux fluides fournis, contenus, transportés ou libérés par des biens ou des produits ;

- aux risques liés à la présence d’énergies et de fluides dangereux pour l’intervenant et le personnel évoluant à proximité.

Le présent document est un guide méthodologique entrant dans le cadre des normes de maintenance.

NOTE Les cas particuliers tels que les risques d’absence d’éléments vitaux pour l’intervenant (air respirable, par exemple) entrent dans le domaine d’application mais ne seront pas détaillés.

Vzdrževanje - Procesi obvladovanja tveganj za energijska in fluidna tveganja pri vzdrževalnih dejavnostih - Napotki

Ta dokument vsebuje napotke, ki so uporabnikom v pomoč pri obvladovanju energijskih in fluidnih tveganj pri vzdrževalnih dejavnostih na predmetih, kadar so v uporabi. Vsak delodajalec je v skladu s pogoji, ki se običajno uporabljajo v podjetju, odgovoren za: – določitev povezave med postopki, opisanimi v tem dokumentu, in standardno prakso; – opredelitev vlog in odgovornosti oseb, vključenih v postopek nadzora nad sprostitvijo nevarne energije in iztekanjem tekočin. Ta dokument se navezuje na koncepte, definicije, pravila, priporočila in najboljše prakse iz nacionalnih in mednarodnih dokumentov (zakleni/označi – »administrativno zaklepanje« – varnostni postopek za preprečevanje nenamernega zagona (LOTO) – varna osamitev), ki zajemajo dejavnosti za zagotavljanje varnosti delavcev v zvezi z energijo in tekočinami. Ta dokument obravnava preprečevanje tveganj, povezanih z energijo in tekočinami (npr. prah, plini, tekočine itd.), pri čemer so nekatera od teh tveganj zajeta v posebnih predpisih ali standardih (npr. električno tveganje). Okoljska vprašanja v povezavi z energijo in tekočinami ne spadajo na področje uporabe tega dokumenta. Nevarnost, povezana z energijo in tekočinami, je lahko neposredna (npr. stik, absorpcija itd.) ali posredna zaradi reakcije (npr. mešanje, segrevanje itd.). Področje uporabe vključuje vse tekočine, saj so lahko nevarne same po sebi oziroma to postanejo. Priporočila v tem dokumentu so bila pripravljena z namenom zagotovitve varnosti in zdravja delavcev v bližini nevarne energije in tekočin ter v situacijah, ko izvajajo naloge, povezane z vzdrževanjem, nastavljanjem ali spreminjanjem formatov, ne glede na vrsto dejavnosti. Priporočila se navezujejo na dejavnosti, ki se izvajajo na predmetih. Uporabiti jih je treba pred, med in po opravilu, in sicer za: – energijo in tekočine, ki jih predmeti oziroma izdelki dovajajo, zadržujejo, prenašajo ali sproščajo; – tveganja, povezana s prisotnostjo energije in tekočin, ki so nevarne za delavca in osebje v njegovi bližini. Ta dokument je metodološka smernica v okviru standardov o vzdrževanju. OPOMBA: Posebni primeri, kot so tveganja pomanjkanja ključnih elementov za delavca (npr. zrak za dihanje), spadajo na področje uporabe tega dokumenta, vendar ne bodo podrobno opisani.

General Information

- Status

- Published

- Publication Date

- 03-Jun-2025

- Technical Committee

- CEN/TC 319 - Maintenance

- Drafting Committee

- CEN/TC 319/WG 15 - Safety and maintenance

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 04-Jun-2025

- Due Date

- 22-Apr-2024

- Completion Date

- 04-Jun-2025

Relations

- Effective Date

- 28-Jan-2026

Overview

EN 17975:2025 - Maintenance: Risk control processes of energies and fluids risks in maintenance activities (Guidance) provides practical guidance for managing hazards from energies and fluids (e.g., powders, gases, liquids, mechanical or stored energy) during maintenance, settings and format changes on items that are in use. It is a methodological guideline within maintenance standards that helps employers align internal practices with recognized lockout/tagout (LOTO) and safe isolation concepts. The standard focuses on worker safety during maintenance and excludes environmental impacts and some sector‑specific regulations (for example, dedicated electrical safety rules).

Key topics and technical requirements

- Risk analysis for maintenance tasks: structured approach to identify energy/fluid sources, hazardous phenomena and critical “key points” before, during and after work.

- Energies & fluids lockout processes: definitions and flowcharts for reinforced isolation (RI), standard isolation, neutralization by control systems, and specific provisions for fluid‑related work.

- Lockout/Tagout (LOTO) and safety checks: guidance on sources, locations, identifiers, verification and maintenance of isolations.

- Parent/Child lockout: management rules and examples for hierarchical or interdependent isolations, including software and manual administration.

- Organizational provisions: roles and responsibilities, competence and training, LOCKOUT administration, use of tags and locks, and quality rules for LOTO.

- Supporting tools and annexes: examples of isolation diagrams, pipe isolation categories, mechanical risks, checklists and LOTO form templates.

Practical applications - who uses this standard

EN 17975:2025 is intended for organizations that perform maintenance or facility management and have responsibilities for occupational safety:

- Employers, maintenance managers and supervisors

- Health & safety officers, safety engineers and industrial hygienists

- Facilities management teams and contractors performing on‑site maintenance

- Designers and modification teams integrating LOTO considerations into equipment

Practical uses include:

- Developing or refining site LOTO procedures and Standard Operating Procedures (SOPs)

- Training and competence schemes for personnel responsible for isolations

- Risk assessment of specific maintenance tasks involving hazardous fluids or energies

- Documenting lockout device inventories, administration and removal procedures

Related standards and references

This guidance refers to established national and international concepts for lockout/tagout, administrative lockout, and safe isolation. It complements sector‑specific regulations (for example, detailed electrical safety rules) rather than replacing them.

Keywords: EN 17975:2025, energies and fluids, lockout/tagout, LOTO, maintenance safety, safe isolation, risk control, maintenance standards, occupational safety.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

EN 17975:2025 is a standard published by the European Committee for Standardization (CEN). Its full title is "Maintenance - Risk control processes of energies and fluids risks in maintenance activities - Guidance". This standard covers: This document provides users with guidance that help manage risks related to energies & fluids during maintenance activities on items when in use. It is the responsibility of each employer, according to the terms commonly used in the company, to: - Set out the correlation between the processes described in this document and standard practices, - Define the roles and responsibilities of the people involved in the energies & fluids lockout process. This document refers to concepts, definitions, rules, recommendations, and best practices taken from national and international documents (lockout/tagout - "administrative lockout" - Lockout/Tagout (LOTO) - Safe isolation) that cover activities to ensure the safety of workers with respect to energies & fluids. This document deals with the prevention of energy & fluid (e.g. powders, gases, liquids, etc.) related risks; it is noted that some are covered by specific regulations or standards, such as the electrical risk. Environmental issues related to energies & fluids are not in the scope of this document. Danger associated with energies & fluids can be direct (e.g. contact, absorption, etc.) or indirect by reaction (e.g. mixing, heating, etc.). The scope includes all fluids because they can be intrinsically dangerous or become dangerous. The recommendations given in this document have been drawn up with a view to ensure the safety and health of workers around hazardous energies & fluids, and situations when they are conducting actions related to maintenance, settings or changing formats, regardless of the type of activity. The recommendations relate to activities carried out on items. They are applied before, during and after the operation to: - The energies & fluids supplied, contained, transported, or released by items, products, - Risks related to the presence of hazardous energies & fluids for the worker and the surrounding personal. This document is a methodological guideline within the maintenance standards. NOTE Particular cases such as risks of lack of presence of vital elements for the worker (e.g. breathable air) are in the scope but will not be detailed.

This document provides users with guidance that help manage risks related to energies & fluids during maintenance activities on items when in use. It is the responsibility of each employer, according to the terms commonly used in the company, to: - Set out the correlation between the processes described in this document and standard practices, - Define the roles and responsibilities of the people involved in the energies & fluids lockout process. This document refers to concepts, definitions, rules, recommendations, and best practices taken from national and international documents (lockout/tagout - "administrative lockout" - Lockout/Tagout (LOTO) - Safe isolation) that cover activities to ensure the safety of workers with respect to energies & fluids. This document deals with the prevention of energy & fluid (e.g. powders, gases, liquids, etc.) related risks; it is noted that some are covered by specific regulations or standards, such as the electrical risk. Environmental issues related to energies & fluids are not in the scope of this document. Danger associated with energies & fluids can be direct (e.g. contact, absorption, etc.) or indirect by reaction (e.g. mixing, heating, etc.). The scope includes all fluids because they can be intrinsically dangerous or become dangerous. The recommendations given in this document have been drawn up with a view to ensure the safety and health of workers around hazardous energies & fluids, and situations when they are conducting actions related to maintenance, settings or changing formats, regardless of the type of activity. The recommendations relate to activities carried out on items. They are applied before, during and after the operation to: - The energies & fluids supplied, contained, transported, or released by items, products, - Risks related to the presence of hazardous energies & fluids for the worker and the surrounding personal. This document is a methodological guideline within the maintenance standards. NOTE Particular cases such as risks of lack of presence of vital elements for the worker (e.g. breathable air) are in the scope but will not be detailed.

EN 17975:2025 is classified under the following ICS (International Classification for Standards) categories: 03.080.10 - Maintenance services. Facilities management; 13.100 - Occupational safety. Industrial hygiene. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 17975:2025 has the following relationships with other standards: It is inter standard links to EN 13306:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 17975:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2025

Vzdrževanje - Procesi obvladovanja tveganj za energijska in fluidna tveganja pri

vzdrževalnih dejavnostih - Napotki

Maintenance - Risk control processes of energies and fluids risks in maintenance

activities - Guidance

Instandhaltung - Verfahren zur Kontrolle der Risiken von Energien und Fluide bei

Instandhaltungsaufgaben - Leitfaden

Maintenance - Processus de maîtrise des risques liés aux énergies et fluides lors

d’opérations de maintenance - Recommandations

Ta slovenski standard je istoveten z: EN 17975:2025

ICS:

03.080.10 Vzdrževalne storitve. Maintenance services.

Upravljanje objektov Facilities management

13.100 Varnost pri delu. Industrijska Occupational safety.

higiena Industrial hygiene

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17975

EUROPEAN STANDARD

NORME EUROPÉENNE

May 2025

EUROPÄISCHE NORM

ICS 03.080.10; 13.100

English Version

Maintenance - Risk control processes of energies and

fluids risks in maintenance activities - Guidance

Maintenance - Processus de maîtrise des risques liés Instandhaltung - Verfahren zur Kontrolle der Risiken

aux énergies et aux fluides au cours des opérations de von Energien und Fluide bei Instandhaltungsaufgaben -

maintenance - Recommandations Leitfaden

This European Standard was approved by CEN on 7 April 2025.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17975:2025 E

worldwide for CEN national Members.

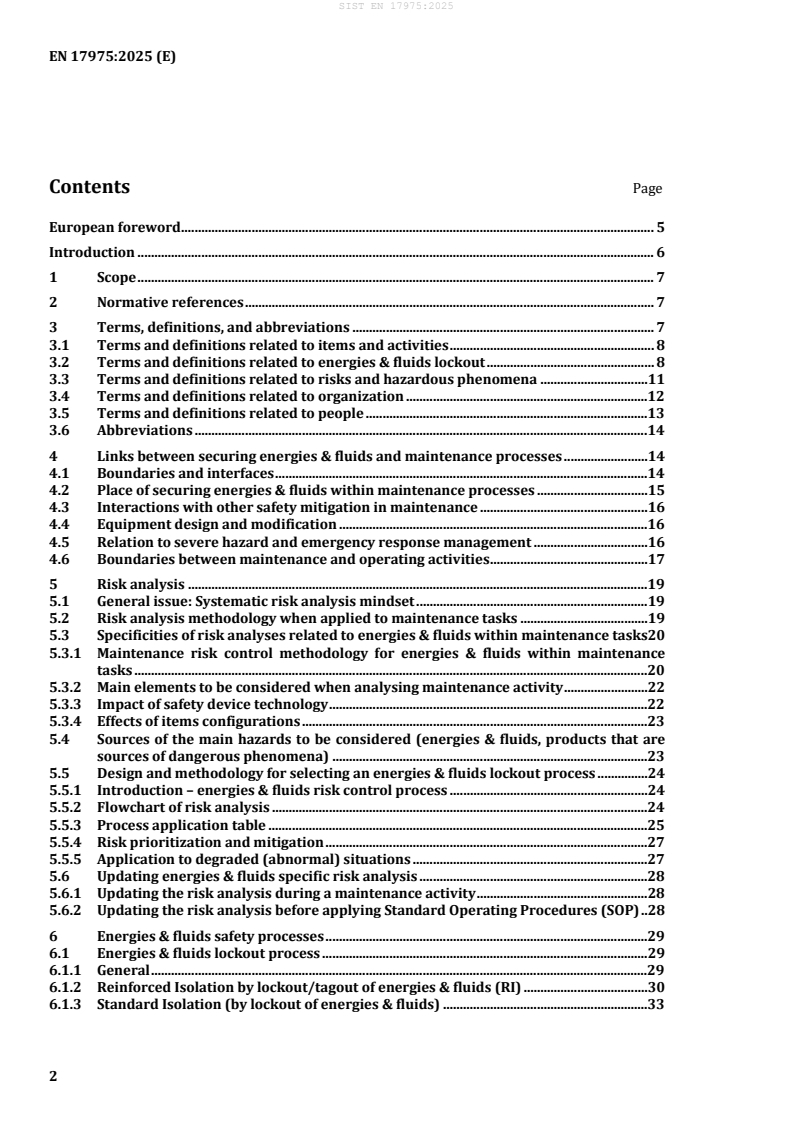

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 7

2 Normative references . 7

3 Terms, definitions, and abbreviations . 7

3.1 Terms and definitions related to items and activities . 8

3.2 Terms and definitions related to energies & fluids lockout . 8

3.3 Terms and definitions related to risks and hazardous phenomena .11

3.4 Terms and definitions related to organization .12

3.5 Terms and definitions related to people .13

3.6 Abbreviations .14

4 Links between securing energies & fluids and maintenance processes .14

4.1 Boundaries and interfaces .14

4.2 Place of securing energies & fluids within maintenance processes .15

4.3 Interactions with other safety mitigation in maintenance .16

4.4 Equipment design and modification .16

4.5 Relation to severe hazard and emergency response management .16

4.6 Boundaries between maintenance and operating activities .17

5 Risk analysis .19

5.1 General issue: Systematic risk analysis mindset .19

5.2 Risk analysis methodology when applied to maintenance tasks .19

5.3 Specificities of risk analyses related to energies & fluids within maintenance tasks 20

5.3.1 Maintenance risk control methodology for energies & fluids within maintenance

tasks .20

5.3.2 Main elements to be considered when analysing maintenance activity .22

5.3.3 Impact of safety device technology .22

5.3.4 Effects of items configurations .23

5.4 Sources of the main hazards to be considered (energies & fluids, products that are

sources of dangerous phenomena) .23

5.5 Design and methodology for selecting an energies & fluids lockout process .24

5.5.1 Introduction – energies & fluids risk control process .24

5.5.2 Flowchart of risk analysis .24

5.5.3 Process application table .25

5.5.4 Risk prioritization and mitigation .27

5.5.5 Application to degraded (abnormal) situations .27

5.6 Updating energies & fluids specific risk analysis .28

5.6.1 Updating the risk analysis during a maintenance activity .28

5.6.2 Updating the risk analysis before applying Standard Operating Procedures (SOP) .28

6 Energies & fluids safety processes .29

6.1 Energies & fluids lockout process .29

6.1.1 General .29

6.1.2 Reinforced Isolation by lockout/tagout of energies & fluids (RI) .30

6.1.3 Standard Isolation (by lockout of energies & fluids) .33

6.1.4 Neutralization of energies & fluids by the control systems . 36

6.1.5 Specific Provisions for activities involving energies & fluids (SP) . 38

6.2 Lockout/Tagout and safety check. 41

6.2.1 Energies & fluids source control . 41

6.2.2 Type . 42

6.2.3 Location . 43

6.2.4 Identifiers and markers . 43

6.2.5 Maintenance . 43

6.3 Compensatory measures and Specific Provisions . 44

6.4 Securing steps . 45

6.4.1 Technical steps – Reinforced and Standard Isolation steps flowchart. 45

6.4.2 Means of checking the removal or neutralization of the energies & fluids . 47

6.4.3 Determining the “key points” . 47

6.4.4 Specific case related to the fitting of plugs . 48

6.5 Specific features of “PARENT/CHILD” energies & fluids lockout . 48

7 Organizational provisions . 49

7.1 Organizational prerequisites . 49

7.2 Organizational provisions . 49

7.3 Quality rules related to energies & fluids lockout . 50

7.4 Energies & fluids competences management and training . 50

7.4.1 Warning . 50

7.4.2 Principle . 50

7.5 LOCKOUT Administration . 51

7.5.1 Principle . 51

7.5.2 Lockout devices . 51

7.5.3 Secure access to handling devices . 51

7.5.4 Procedure for removing locked devices . 51

7.6 Use of tags and locks . 52

7.6.1 Tags memo . 52

7.6.2 Locks management . 53

7.7 Specific features – Design and modification of equipment . 53

7.8 Energies & fluids lockout device identification sheet . 53

7.8.1 General . 53

7.8.2 Content . 53

7.8.3 Validation . 54

7.8.4 Updating . 54

7.8.5 Exclusions . 54

Annex A (informative) Organizational provisions . 55

A.1 Organizational provision . 55

A.2 Organizational quality rules . 58

A.3 Energies & fluids lockout competences, training . 60

A.4 Example: designation of competent people for energies & fluids lockout and

maintenance operations . 62

Annex B (informative) Main elements to be considered when analysing maintenance activity

................................................................................................................................................................... 64

Annex C (informative) Non-exhaustive list of energies & fluids sources and phenomena . 67

C.1 General . 67

C.2 Unexhaustive list of energies and fluids. 67

Annex D (informative) Preparation of energies & fluids lockout steps .71

Annex E (informative) Example of isolation categories for pipes .73

E.1 Isolation categories for pipes .73

E.2 Selection of securing process given the existing setup .73

E.3 Category B types (reinforced isolation) .75

E.4 Category A types (standard isolation) .78

E.5 Examples of practical diagrams for category B (reinforced isolation) .79

E.6 Examples of practical diagrams for category A (standard isolation) .83

Annex F (informative) Mechanical energies & fluids lockout .85

F.1 General .85

F.2 Gravity-related mechanical risks .85

F.3 Mechanical risks caused by actuators .85

F.4 Ventilation-related mechanical risks .86

F.5 Mechanical risks caused by the effects of arching and walls.86

Annex G (informative) Specific rules for PARENT/CHILD energies & fluids lockout processes

....................................................................................................................................................................87

G.1 General .87

G.2 Specific rules for “PARENT/CHILD” .87

G.3 Removal of a “PARENT” energies & fluids lockout .88

G.4 “PARENT/CHILD” energies & fluids lockout .88

G.5 “PARENT” energies & fluids lockout .89

G.6 “CHILD” energies & fluids lockout .90

G.7 Dedicated software management of “PARENT/CHILD” energies & fluids lockout .90

G.8 Management of “PARENT/CHILD” energies & fluids lockout without dedicated

software .91

Annex H (informative) Document examples .92

H.1 Set of document example .92

H.2 LOTO form model example .94

H.3 Tag model example .95

Bibliography .97

European foreword

This document (EN 17975:2025) has been prepared by Technical Committee CEN/TC 319

“Maintenance”, the secretariat of which is held by UNI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by November 2025, and conflicting national standards shall

be withdrawn at the latest by November 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

Many occupational accidents are caused by a failure to manage energy & fluid sources during

maintenance activities and can result in serious impact on people, assets, and activities.

This standard is concerned with occupational safety and how to best control the risks related to energies

& fluids linked to maintenance activities.

The safety and health of workers prior to, and during, maintenance tasks on items involves a series of

practices and procedures aimed at controlling all energy & fluid sources. These practices and procedures

enable a worker to be sure that they can work on an item without any accidental reconnection of energies

or fluids and avoid being exposed to a hazardous working environment.

Depending on the task, items and related risk analysis, the safety of workers is based on the individual or

combined implementation of the following specific processes for each energy & fluid:

— Reinforced Isolation by lockout/tagout of energies & fluids (RI);

— Standard Isolation by lockout of energies & fluids (SI);

— Neutralization of energies & fluids by the control systems (N);

— Specific Provisions for activities involving energies & fluids (SP).

On its own, reinforced isolation by lockout/tagout of energies & fluids ensures the full protection of

workers. However, the design of existing items or the type of operations does not always enable such an

approach to be applied, which therefore imposes use of one of the three alternative processes set out

below.

Various industrial sectors (for example: chemical, metallurgy, agrifood, energies & fluids production and

power distribution) have adopted their own “energies & fluids lockout” terminologies. Each industry has

defined a formal system for risk analysis and operating procedures for securing each of the energies &

fluids it works with. Depending on the sector, the terms used for “energies & fluids lockout” include, but

are not limited to:

— reinforced lockout/tagout,

— standard lockout/tagout,

— lockout of released energies & fluids,

— LOTO - Lock Out, Tag Out,

— LOTOTO - Lock Out, Tag Out, Try Out (see OSHA 29 CFR 1910.147),

— administrative lockout,

— etc.

1 Scope

This document provides users with guidance that help manage risks related to energies & fluids during

maintenance activities on items when in use. It is the responsibility of each employer, according to the

terms commonly used in the company, to:

— Set out the correlation between the processes described in this document and standard practices,

— Define the roles and responsibilities of the people involved in the energies & fluids lockout process.

This document refers to concepts, definitions, rules, recommendations, and best practices taken from

national and international documents (lockout/tagout – “administrative lockout” – Lockout/Tagout

(LOTO) – Safe isolation) that cover activities to ensure the safety of workers with respect to energies &

fluids.

This document deals with the prevention of energy & fluid (e.g. powders, gases, liquids, etc.) related risks;

it is noted that some are covered by specific regulations or standards, such as the electrical risk.

Environmental issues related to energies & fluids are not in the scope of this document. Danger associated

with energies & fluids can be direct (e.g. contact, absorption, etc.) or indirect by reaction (e.g. mixing,

heating, etc.). The scope includes all fluids because they can be intrinsically dangerous or become

dangerous.

The recommendations given in this document have been drawn up with a view to ensure the safety and

health of workers around hazardous energies & fluids, and situations when they are conducting actions

related to maintenance, settings or changing formats, regardless of the type of activity.

The recommendations relate to activities carried out on items. They are applied before, during and after

the operation to:

— The energies & fluids supplied, contained, transported, or released by items, products,

— Risks related to the presence of hazardous energies & fluids for the worker and the surrounding

personal.

This document is a methodological guideline within the maintenance standards.

NOTE Particular cases such as risks of lack of presence of vital elements for the worker (e.g. breathable air) are

in the scope but will not be detailed.

2 Normative references

The following documents are referred to in the text in such a way that some or all their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated

references, the last edition of the referenced document (including any amendments) applies.

EN 13306, Maintenance — Maintenance terminology

3 Terms, definitions, and abbreviations

For the purposes of this document, the terms and definitions given in EN 13306, and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1 Terms and definitions related to items and activities

3.1.1

item

part, component, device, subsystem, functional unit, equipment or system that can be individually

described and considered

Note 1 to entry: In the context of this standard, we consider as items things that are commonly called installations,

process line, machinery, items, production line, plant, working equipment, etc.

[SOURCE: EN 13306:2017, 3.1, modified – modification of note to entry 1 and removal of notes to entry

2 and 3]

3.1.2

release

authorization for a temporary transfer of responsibility from the operating officer to the operation

manager within the scope indicated in the release document

Note 1 to entry: The release, for works, testing, etc. is an authorization given to a works officer, test officer, etc. in

order to work on disabled items or items in use.

3.2 Terms and definitions related to energies & fluids lockout

3.2.1

energies & fluids supplied to items

energies & fluids supplied to the items by external sources

Note 1 to entry: Energies and fluids can be necessary for items' operation.

3.2.2

contained energies & fluids

internal, stored, residual or converted energies & fluids

3.2.3

lockout/tagout

LOTO

lockout/tagout is a process which contains different steps of securing energies & fluids

placement of a lockout device on an energies & fluids isolating device, in accordance with an

established procedure, ensuring that the energies & fluids isolating device and the equipment being

controlled cannot be operated until the lockout device is removed

placement of a tagout device on an energies & fluids isolating device, in accordance with an

established procedure, to indicate that the energies & fluids isolating device and the equipment being

controlled should not be operated until the tagout device is removed

[SOURCE: OSHA CPL 02-00-147]

3.2.4

lockout/tagout/try-out

LOTOTO

LOTO improvement highlighting the phase of verification of absence of energies & fluids (Try-Out step)

before any intervention

3.2.5

process

set of interrelated or interacting activities that use inputs to deliver an intended result

Note 1 to entry: In the context of this standard, items perform processes that use energies & fluids.

[SOURCE: EN ISO 9000:2015, 3.4.1]

3.2.6

energies & fluids lockout

all activities and measures related to energies & fluids, hazardous products or the removal of vital

elements that ensure the safety of maintenance workers during their activities on, or near to, items or

within their working environment

Note 1 to entry: Securing should combine various processes that are specific to each energy & fluid listed in this

document, through:

— Reinforced isolation by lockout/tagout of energies & fluids (RI);

— Standard isolation by lockout of energies & fluids (SI);

— Neutralization of energies & fluids by the control systems (N);

— Specific provisions for activities involving energies & fluids (SP).

In addition to the processes listed above, collective, and individual protections or organizational measures

(procedures, requirements, working methods, permits-to-work, etc.) enable the maintenance worker to carry out

activities whilst controlling the risks.

Note 2 to entry: See the list of energies in Annex C “Non-exhaustive list of energies & fluids sources and

phenomena”.

3.2.7

reinforced isolation by lockout/tagout of energies & fluids

RI

process that results in the removal – by separation or by a combination of isolating and opening devices

(e.g. valve, tap, etc.) – of all energies & fluids where the presence, accidental retention, unintended

appearance does not have hazardous consequences for workers, the environment, and items

Note 1 to entry: Depending on the energies & fluids present, bleed, discharge, release, clean-up, or mechanical

blocking activities could be necessary.

Note 2 to entry: The RI process involves all the activities and provisions that enable an item to be secured and kept

secure, so that the workers can conduct their maintenance activities.

3.2.8

standard isolation by lockout of energies & fluids

SI

process that results in the removal – by locking in position a single or double isolating device – of all

energies & fluids where the presence, accidental retention, unexpected appearance does not have

hazardous consequences for workers, the environment, and items

Note 1 to entry: Depending on the energies & fluids present, bleed, discharge or release activities should be

necessary.

Note 2 to entry: The SI process involves all the activities and provisions that enable an item to be secured, so that

the workers can conduct their maintenance activities.

Note 3 to entry: It is important to monitor the efficiency of isolation throughout the intervention (no leaks or leaks

controlled).

3.2.9

neutralization of energies & fluids by the control systems

N

process that, through design of the control systems, shuts down an item of equipment so that a list of pre-

determined tasks can be conducted in safety

Note 1 to entry: The control systems fulfilling safety functions meet reliability requirements, considering the risk

of failures. The design rules are defined in the design standards (EN 60204-1, EN ISO 13849-1 and EN IEC 62061).

Note 2 to entry: Based on risk assessments, various performance levels are determined with control system

architectures adapted to the level of risk.

Note 3 to entry: Securing through control systems addresses risks related to the energies & fluids supplied to the

item. Additional measures should be implemented to interrupt or reduce contained energies & fluids.

3.2.10

specific provisions for activities involving energies & fluids

SP

process that results in the implementation of organizational or technical measures enabling observation,

diagnostics, testing activities and work on settings for the item in service to be carried out safely, with

energies & fluids present

3.2.11

separate

action of creating an interruption through a combination of systems, specific systems, or the temporary

removal of an element of the system to permanently guarantee a lack of energies & fluids between the

item and each of the energies & fluids present

Note 1 to entry: Terminology related to the process of reinforced isolation by lockout/tagout of energies & fluids.

Note 2 to entry: Shared terminology, applicable to all energies & fluids.

3.2.12

isolate

action of creating an interruption through an action and/or a system to manage a lack of energies & fluids

between the item and each of the energies & fluids present for a given period

Note 1 to entry: Terminology related to the process of standard isolation by lockout of energies & fluids.

3.2.13

lockout

placement of a lockout device on an energies & fluids isolating device, in accordance with an established

procedure, ensuring that the energies & fluids isolating device and the equipment being controlled cannot

be operated until the lockout device is removed

3.2.14

lockout device

strong mechanical element used to maintain the energies & fluids lockout components in a given position

Note 1 to entry: The removal of the lockout device should only be performed as part of a removal procedure by an

authorized person.

Note 2 to entry: To remove the device, dedicated equipment defined in the procedure shall be used (example: a key

or another equivalent system).

3.2.15

tagout

placement of a tagout device on an energies & fluids isolating device, in accordance with an established

procedure, to indicate that the energies & fluids isolating device and the equipment being controlled

should not be operated until the tagout device is removed

3.2.16

try-out

actions related to the verification of the absence of energy or fluids

3.3 Terms and definitions related to risks and hazardous phenomena

3.3.1

hazard and hazardous phenomena

potential source of harm

[SOURCE: EN ISO 12100:2010, 3.6, modified – removal of notes to entry]

Note 1 to entry: Although the occupational risk is the main stake, risks to consider might be also damages to

population, assets, and environment.

3.3.2

risk

combination of the probability of occurrence of harm and the severity of that harm

[SOURCE: EN ISO 12100:2010, 3.12]

3.3.3

risk analysis

process implemented to understand the type of a risk and to determine the level of risk

Note 1 to entry: The risk analysis provides the foundation for assessing the risk and the decisions related to dealing

with the risk.

Note 2 to entry: The risk analysis includes an estimation of the risk.

[SOURCE: ISO 31000:2009, 2.21]

3.3.4

risk assessment

process comparing the results of the risk analysis with risk criteria, in order to determine if the risk

and/or its scale are acceptable or tolerable

Note 1 to entry: The risk assessment helps with decision-making on how to deal with the risk.

Note 2 to entry: Risk control, used in this standard, is defined below.

[SOURCE: ISO 31000:2009, 2.24]

3.3.5

risk control

risk control processes are operational steps that control the risks « on the field »

Note 1 to entry: The standard is not explaining more general risk management issues – it would duplicate risk

management systems standards.

3.4 Terms and definitions related to organization

3.4.1

lockout procedure

organizational procedure setting out the rules for fitting and removing component lockout devices as part

of energies & fluids lockout

3.4.2

energies & fluids lockout device identification sheet

document identifying the energies & fluids and the energies & fluids lockout devices for the items in

question

Note 1 to entry: It lists all the energies & fluids of the item in question (supplied, contained and residual energies

& fluids).

Note 2 to entry: It lists the energies & fluids separation, isolation and dissipation devices marked beforehand using

tags (see Annex F).

Note 3 to entry: It lists the energies & fluids separation, isolation, and dissipation activities with the reference of

the relevant handling sheet.

3.4.3

operating procedure for energies & fluids control

document determining the type and order of the various states and handling activities involved

neutralising energies & fluids during an operation on an item

Note 1 to entry: The operating procedure considers all the energies & fluids and defines, as per requirements, the

initial state and expected final state of the position of the valves.

Note 2 to entry: Depending on the complexity of the items, it should refer to the application of several handling

operation sheets.

3.4.4

handling operation sheet

document, specific to a type of energies & fluids that indicates the type, the state and order of the actions

to be carried out for the process of reinforced isolation by lockout/tagout of energies & fluids or standard

isolation by lockout of energies & fluids

Note 1 to entry: Several handling operation sheets should be grouped together within a single document.

3.4.5

work-permit

document issued by the employer providing formal authorization to carry out an operation, after a risk

analysis and definition of the prevention and protection measures

Note 1 to entry: Work-permit is also commonly known as work authorization.

3.4.6

energies & fluids lockout certificate

document delivered before work begins formalising the securing of all the energies & fluids for an item

3.4.7

energies & fluids lockout proficiency certificate

document through which the employer formally recognised an employee's ability to secure the energies

& fluids of an item

3.4.8

degraded situations

abnormal use of equipment, caused by a technical, human, or organizational failure or deviation

(e.g. incorrect use of standard operating procedure)

3.5 Terms and definitions related to people

3.5.1

employer

person or legal entity who employs members of staff and has authority over them

3.5.2

plant manager

person who is responsible for an operating site, and is accountable of the whole site safety (responsible

authority)

Note 1 to entry: This responsibility can be subdivided and delegated.

3.5.3

ordering party

person or legal entity that has the authority to contract a service provider to perform activities in relation

to an order

3.5.4

operations manager

person in charge of managing operating activities (operation, surveillance, maintenance, etc.) for an item

3.5.5

lockout/tagout officer

person capable of analysing the risks and defining the actions to be taken on the energies & fluids, in

order to carry out or have carried out the process of reinforced isolation by lockout/tagout of energies &

fluids or the process of standard isolation by lockout of energies & fluids

3.5.6

lockout officer

person capable of analysing the risks and defining the actions to be taken on the energies & fluids, in

order to carry out or have carried out the process of standard isolation by lockout of energies & fluids

3.5.7

lockout/tagout manager

person in charge of coordinating the actions of the lockout/tagout officer and the lockout officer and

ensuring that all the energies & fluids lockout devices have been put in place for an item

3.5.8

maintainer

person performing a maintenance activity

3.5.9

works officer

person in charge of managing works

3.5.10

activity officer

person in charge of managing interventions and, where appropriate, carrying them out

3.5.11

operator

person in charge of carrying out an operation

3.5.12

test officer

person in charge of managing tests; he/she takes the measures needed to ensure his/her own safety and

that of any third parties involved during tests

3.5.13

safety supervisor

person with the knowledge required to monitor one or more people during completion of an operation

in accordance with given instructions, as a compensatory measure

3.6 Abbreviations

ALARP As Low As Reasonably Practicable

ATEX Atmosphere Explosive

CMMS Computerized Maintenance Management System

HSE Health, Safety and Environment

SOP Standard Operation Procedure

UPS Uninterruptible Power Supply

4 Links between securing energies & fluids and maintenance processes

4.1 Boundaries and interfaces

This standard only applies to professional activities.

This standard interfaces with the notions of HSE (Health, Safety and Environment) risk control,

mentioned in EN 13460:2009, Annex B (work permit within work order).

This standard focuses on “Maintenance” activities, which will be defined and distinguished from design

and production management activities using EN 17007 and EN 13306.

Risks not directly related to energies & fluids during maintenance activities will not be considered, for

example: fall from height, level fall, handling cuts. Principle safety management issues are covered by

safety standards, this document covers the very specific risk analysis within maintenance activities,

related to hazardous energies & fluids.

This standard does not supersede existing standards that cover specific risks, in particular but not

exclusively:

— Operations on electrical structures and installations in the surrounding area (best covered by

EN 50110-1),

— Working in confined spaces,

— Radioactivity, ionising radiations,

— The design of equipment as defined in the “Machinery directive” 2006/42/EC and the “Pressure

Equipment Directive” 2014/68/EU.

This document has not been written to deal with items (reminder: item can be a set of items; item can be

a single equipment up to a whole item – see definition chapter) that are subject to very specific

requirements and are submitted to specific regulations or standards because of the major risks they may

present (e.g. nuclear item or viruses in a laboratory).

In the event of decommissioning of items, utilities, networks, or processes working equipment, etc., this

final stage of the service life of the item could require specific additional procedures not included in this

document.

4.2 Place of securing energies & fluids within maintenance processes

This standard focuses on the specific risks related to energies & fluids during maintenance tasks. This

standard relates to the maintenance processes described in EN 17007. It concerns more particularly the

following processes:

— “Ensure personal health and safety to individuals and preserve environment in maintenance”

(referenced as HSE process in EN 17007),

— The processes for carrying out the maintenance tasks; and more especially the process “Act

preventively and/or correctively on the items to maintain” (referenced as ACT process in EN 17007):

— Rank the events,

— Prepare for the tasks,

— Set in order the tasks,

— Schedule the tasks,

— Begin the scheduled tasks,

— Perform the maintenance tasks,

— Finish the tasks.

As shown in Figure 1, the core of this standard is the risk analysis step and the choice of the appropriate

risk control process (Reinforced isolation, standard isolation, neutralization etc. described later in this

document) for each energy & fluid.

Maintenance processes shall include activities dedicated to HSE risks control. It is then a support for HSE

risk control within maintenance processes.

It also relates with the maintenance workflow and work order information and purpose described

in EN 13460:2009, Annexes B and C.

4.3 Interactions with other safety mitigation in maintenance

An efficient and controlled maintenance activity (in terms of quality and HSE risks) shall be properly

planned. This planning shall identify and manage all the risks control related to the activity and define

the appropriate prevention and protection tasks.

The risk analysis phase related to maintenance activities, in the broadest sense, should integrate energies

& fluids issues. This is relevant because there are harmful i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...