EN 16864:2017

(Main)Building hardware - Mechatronic padlocks - Requirements and test methods

Building hardware - Mechatronic padlocks - Requirements and test methods

This European Standard specifies requirements for performance and testing of mechatronic padlocks (MPs) and their keys and/or electronic keys.

It establishes categories of use based on performance tests and grades of security based on design requirements and on performance tests that simulate attack. If the design incorporates mechanical security means in addition to the mechatronic means, these are also tested.

This European Standard does not cover any other element of a security system, other than those directly involved in the control of a padlock.

This European Standard does not cover the physical testing of multi-function devices such as Smartphones that may be used as part of the control system.

Schlösser und Baubeschläge - Mechatronische Hangschlösser - Anforderungen und Prüfverfahren

Diese Europäische Norm legt Anforderungen an die Leistung und Prüfung von mechatronischen Hangschlössern (MH) und deren Schlüsseln und/oder elektronischen Schlüsseln fest.

Sie legt auf Leistungsprüfungen basierende Gebrauchsklassen sowie Sicherheitsklassen fest, die auf Konstruktionsanforderungen und Leistungsprüfungen beruhen, die Angriffe simulieren. Sofern die Konstruktion zusätzlich zu den mechatronischen Vorrichtungen mechanische Schutzvorrichtungen enthält, werden auch diese geprüft.

Die vorliegende Europäische Norm behandelt keine weiteren Elemente eines Sicherheitssystems als die¬jenigen, die unmittelbar mit der Bedienung eines Hangschlosses verbunden sind.

Diese Europäische Norm deckt nicht die physikalische Prüfung von Multifunktionsgeräten wie z. B. Smartphones ab, die als Teil des Kontrollsystems genutzt werden können.

Quincaillerie pour le bâtiment - Cadenas mécatroniques - Exigences et méthodes d'essai

La présente Norme européenne spécifie les exigences de performance et d'essai des cadenas mécaniques (MP) et de leurs clés et/ou de leurs clés électroniques.

Elle définit des catégories d'utilisation basées sur des essais de performance et des niveaux de sécurité basés sur des exigences de conception et sur des essais de performance simulant une effraction. Si la conception intègre des dispositifs de sécurité mécanique, en complément de dispositifs mécatroniques, ces dispositifs sont également soumis à essai.

La présente Norme européenne ne couvre aucun élément d’un système de sécurité autre que ceux directement mis en jeu dans la manoeuvre d’un cadenas.

La présente Norme européenne ne traite pas de l'essai physique des dispositifs multi-fonctionnels tels que les smartphones, qui peuvent être utilisés comme éléments du système de contrôle.

Stavbno okovje - Mehatronske obešanke - Zahteve in preskusne metode

Ta evropski standard določa zahteve za delovanje in preskušanje mehatronskih obešank (MP) ter njihovih ključev in/ali elektronskih ključev.

Določa kategorije uporabe na podlagi preskusov delovanja in varnostne stopnje na podlagi zahtev glede zasnove in preskusov delovanja, ki simulirajo napad. Če načrtovanje poleg mehatronskih sredstev zajema tudi mehanska varnostna sredstva, se te tudi preskusi.

Ta evropski standard ne zajema drugih elementov varnostnega sistema, ki niso neposredno vključeni v nadzor obešanke.

Ta evropski standard ne zajema fizičnega preskušanja večfunkcijskih naprav, kot so pametni

General Information

- Status

- Published

- Publication Date

- 19-Sep-2017

- Withdrawal Date

- 30-Mar-2018

- Technical Committee

- CEN/TC 33 - Doors, windows, shutters and building hardware

- Drafting Committee

- CEN/TC 33/WG 4 - Building hardware

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 08-Mar-2023

- Completion Date

- 09-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 12320:2012 - Building hardware - Padlocks and padlock fittings - Requirements and test methods - Effective Date

- 28-Jan-2026

Overview

EN 16864:2017 - Building hardware - Mechatronic padlocks - Requirements and test methods is a European Standard published by CEN that defines performance, testing and classification for mechatronic padlocks (MPs) and their electronic keys. The standard specifies functional, environmental and mechanical requirements, establishes use categories and security grades, and sets repeatable test methods that simulate attack (both mechanical and electronic) to verify resistance and durability. EN 16864:2017 focuses strictly on elements directly involved in padlock control and does not cover broader security systems or testing of multi‑function consumer devices (e.g., smartphones).

Key topics and requirements

- Scope and definitions: Clear terms for MPs, electronic keys, audit trail, whitelist, mean time to compromise (MTC), spoofing, brute‑force and dictionary attacks.

- Categories of use and security grades: MPs are classified by performance tests (operation, key strength, environmental resistance) and by attack resistance (design and simulated attacks).

- Mechanical and mechatronic tests: Includes torque, key/knob operation, shackle pull, twist and cut tests, impact, drilling and sawing resistance. Test rigs and tool sets are defined for reproducibility.

- Environmental tests: Vibration, shock, cold/heat, damp heat and corrosion resistance are specified to assess durability in real conditions.

- Electronic security tests: Requirements for electronic code variation, resistance to spoofing, brute‑force and cryptographic attacks, time‑zone and audit‑trail functionality, and electronic key robustness.

- Marking and documentation: Requirements for manufacturer marking and information to support correct selection and installation.

- Reproducible test procedures: Detailed sampling, assessment and pass/fail criteria to ensure consistent certification across laboratories.

Applications and who uses this standard

EN 16864:2017 is applicable to:

- Manufacturers of mechatronic padlocks for product design, quality control and market compliance.

- Independent test laboratories that certify padlocks to European performance and security grades.

- Security consultants, procurement teams and facility managers selecting padlocks for access control, asset protection, transport, storage and site security.

- Architects and specifiers integrating secure locking hardware into building designs.

- Regulators and certification bodies assessing conformity with European norms.

Practical benefits include verified attack resistance, predictable lifecycle behavior in harsh environments, clear security grading for procurement, and standardized test evidence for claims about audit trail, time‑based access and electronic key resilience.

Related standards (if applicable)

EN 16864 references and complements other standards used in testing and conformity:

- EN 12320:2012 (padlocks - mechanical performance)

- EN 1670:2007 (corrosion resistance)

- EN 60068 series (environmental testing: vibration, shock, temperature, humidity)

- EN 60529 (IP protection ratings)

- Relevant EN/ISO screw and drill standards used in test setups

Keywords: EN 16864:2017, mechatronic padlocks, padlock testing, security grades, electronic keys, audit trail, attack resistance, building hardware.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 16864:2017 is a standard published by the European Committee for Standardization (CEN). Its full title is "Building hardware - Mechatronic padlocks - Requirements and test methods". This standard covers: This European Standard specifies requirements for performance and testing of mechatronic padlocks (MPs) and their keys and/or electronic keys. It establishes categories of use based on performance tests and grades of security based on design requirements and on performance tests that simulate attack. If the design incorporates mechanical security means in addition to the mechatronic means, these are also tested. This European Standard does not cover any other element of a security system, other than those directly involved in the control of a padlock. This European Standard does not cover the physical testing of multi-function devices such as Smartphones that may be used as part of the control system.

This European Standard specifies requirements for performance and testing of mechatronic padlocks (MPs) and their keys and/or electronic keys. It establishes categories of use based on performance tests and grades of security based on design requirements and on performance tests that simulate attack. If the design incorporates mechanical security means in addition to the mechatronic means, these are also tested. This European Standard does not cover any other element of a security system, other than those directly involved in the control of a padlock. This European Standard does not cover the physical testing of multi-function devices such as Smartphones that may be used as part of the control system.

EN 16864:2017 is classified under the following ICS (International Classification for Standards) categories: 91.190 - Building accessories. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16864:2017 has the following relationships with other standards: It is inter standard links to EN 60068-2-6:2008, EN 60068-2-27:2009, EN 60068-2-30:2005, EN IEC 61000-4-2:2025, EN IEC 60068-2-1:2025, EN 60529:1991, EN IEC 60068-2-2:2025, EN ISO 15482:1999, EN ISO 10666:1999, EN ISO 15483:1999, EN ISO 15481:1999, EN ISO 12217-2:2002, EN 1670:2007, EN ISO 15480:2019, EN 12320:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16864:2017 is associated with the following European legislation: EU Directives/Regulations: 89/106/EEC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16864:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stavbno okovje - Mehatronske obešanke - Zahteve in preskusne metodeSchlösser und Baubeschläge - Mechatronische Hangschlösser - Anforderungen und PrüfverfahrenQuincaillerie du bâtiment - Cadenas mécatroniques - Exigences et méthodes d'essaiBuilding hardware - Mechatronic padlocks - Requirements and test methods91.190Stavbna opremaBuilding accessoriesICS:Ta slovenski standard je istoveten z:EN 16864:2017SIST EN 16864:2017en,fr,de01-november-2017SIST EN 16864:2017SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16864

September

t r s y ICS

{ sä s { r English Version

Building hardware æ Mechatronic padlocks æ Requirements and test methods Quincaillerie pour le bâtiment æ Cadenas mécatroniques æ Exigences et méthodes d 5essai

Schlösser und Baubeschläge æ Mechatronische Hangschlösser æ Anforderungen und Prüfverfahren This European Standard was approved by CEN on

s s May

t r s yä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s y CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s x z x vã t r s y ESIST EN 16864:2017

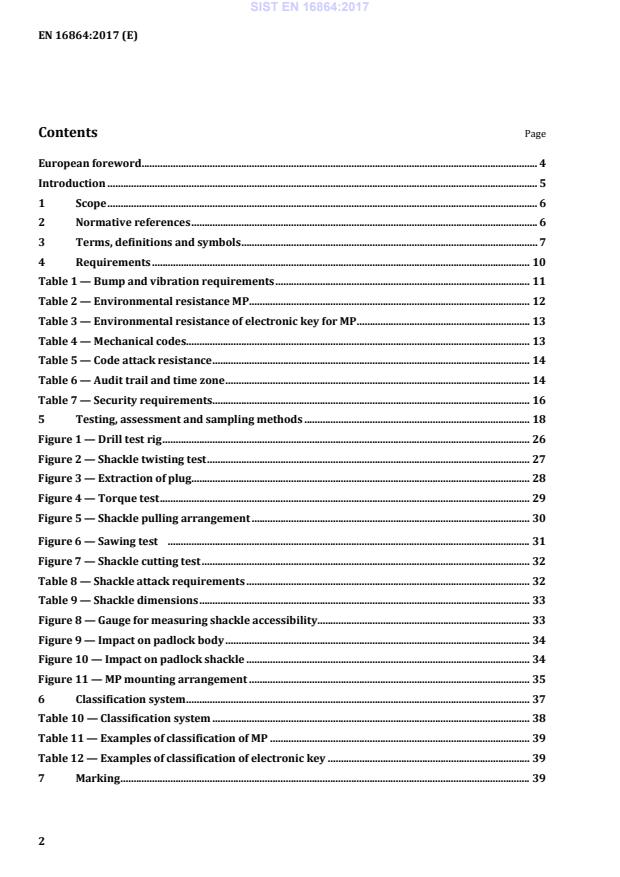

Tool sets for attack resistance tests . 40 Table A.1 . 40 Table A.2 . 41 Table A.3 . 42 Annex B (normative)

Table of test procedures . 43 Table B.1 — Test procedures for MP . 43 Table B.2 — Test procedures for electronic keys . 44 Bibliography . 45

MP independent locking device comprising a body, a code mechanism, a locking mechanism and a shackle. The code mechanism includes an electronic component that interfaces with mechatronic detaining elements after verification 3.1.18 plug part of a mechatronic padlock that can be moved when the proper key is used 3.1.19 steps cuts in the surface of a bit or blade which operate the mechanical code elements 3.1.20 time zone degree of functionality intended to provide security by limiting the time that a valid credential will operate the MP SIST EN 16864:2017

%), without loss of function. 4.2.5 Bump requirements The MP and its electronic keys shall be able to withstand bumps typical of daily usage. The MP shall conform to the requirements given in Table 1. Compliance is checked by the test methods given in 5.4.3. 4.2.6 Vibration requirements The MP and its electronic keys shall be able to withstand vibrations typical of daily usage. The MP and its electronic key shall conform to the requirements given in Table 1. Compliance is checked by the test methods given in 5.4.4 The MP shall remain secured during the test and shall operate normally afterwards.5.4.4. SIST EN 16864:2017

Test clause Grade 0 1 2 3 4 4.5.1 Protection of MP against water - 5.7.2 - - Yes IPX4 Yes IPX5 Yes IPX6 4.5.2 Dry heat - 5.7.3 -

ª w w ¹ Cá 16 h

ª w w ¹ Cá 16 h

ª w w ¹ Cá 16 h

ª x w ¹ Cá 16 h 4.5.2 Cold - 5.7.4 -

ª w ¹ Cá 16h

ª w ¹ Cá 16 h

«10° C, 16 h

«25° C, 16 h 4.5.3 Damp heat (cyclic) - 5.7.5 - - -

ª w w ¹ Cá 6 cycles

ª w w ¹ Cá 6 cycles SIST EN 16864:2017

Test clause Grade 0 1 2 3 4 4.5.2

Dry heat - 5.7.3 -

ª w w ¹ Cá 16 h

ª w w ¹ Cá 16 h

ª w w ¹ Cá 16 h

ª x w ¹ Cá 16 h 4.5.2

Cold - 5.7.4 -

ª w ¹ Cá 16 h

ª w ¹ Cá 16 h

«10° C, 16 h

«25° C, 16 h 4.5.3

Damp heat (cyclic) - 5.7.5 - - - -

ª w w ¹ Cá 6 cycles 4.5.4 Resistance of electronic key against water - 5.7.6 - - Yes Yes Yes 4.6 Key related security 4.6.1 Minimum number of effective mechanical code variations For classification of mechanical code variation (5th character of Table 10), the minimum number of effective mechanical code variations of the MP shall be as specified in Table 4. Table 4 — Mechanical codes Mechanical codes Correlation with EN 12320:2012 Grade 0: - no grade Grade 1: 300 grade 1 Grade 2: 1000 grade 2 Grade 3: 2500 grade 3 Grade 4: 5 000 grade 4 Grade 5: 10 000 grade 5 Grade 6: 20 000 grade 6 Compliance is checked by the test method of 5.8.2. NOTE Grade 0 includes MPs without mechanical code variations. For a MP having a mechanical locking feature, the maximum number of steps on the same level shall be 60 %, maximum two adjacent and a minimum of three levels. 4.6.2 Non-interpassing of keys with just one interval effective differ When tested in accordance with 5.2 it shall not be possible to operate the padlock with keys differing from the correct key by one interval, i.e. the next closest key. The next closest key shall be defined by the manufacturer according to its key coding system. Compliance is checked by the test method of 5.7.5. 4.6.3 Direct coding on key Direct key coding shall not be visibly marked on electronic keys. SIST EN 16864:2017

parameter Grade Unit 1 2 3 4 5 6 4.6.1 Minimum number of effective key differs 5.8.2 n 300 1 000 2 500 5 000 10 000 20 000 - 4.6.2 Non-interpassing of keys with just one interval differ - Torque on key 5.8.3 M1 1 1 1,5 1,5 1,5 1,5 Nm 4.8.1 Key retained in open position

yes / no - - - yes yes yes

4.8.2 Resistance to drilling of padlock body, shackle and staple 5.11.2 t - - - 2 4 8 min SIST EN 16864:2017

1 200 2 500 Nm 4.8.4 Resistance to force on cylinder plug or locking mechanism 5.11.4 F1 - - 4 5 10 15 kN 4.8.5 Torque resistance applied with electronic dummy key- 5.11.5 M2 - - 4 or key break 5 or key break

7 or key break 7 or key break Nm 4.8.6 Resistance to torque on cylinder plug or locking mechanism 5.11.6 M2 - 2,5 5 15 20 30 Nm 4.8.7 Resistance to pulling of shackle 5.11.7 F2 3 5 15 30 70 100 kN 4.8.8 Resistance to sawing of padlock body, and shackle 5.11.8 t - - - 2 4 8 min 4.8.9 Resistance to cutting of shackle 5.11.9 F3 6 15 25 45 70

100 kN 4.8.10 Resistance to impact on padlock body and shackle at low temperature 5.11.10 T m h D - - - - - - - - - 20 1 250 800 10 - 20 3 050 1 000 12 - 40 6 550 1 400 16 - 40 7 150 1 500 20 °C g mm mm 4.8.11 Manual attack, toolsets according to the ANNEX A 5.11.11 t

- - - 3 5 10 min 4.8.12 Attack by vibrations 5.11.12 t No requirements 3 5 min 4.8.13 Increased voltage attack test 5.11.13 Voltage No requirements Normal supply voltage

ª

x V by a max. of 600 mA Normal supply voltage

ª

v z V by a max. of 600 mA V 4.8.14

Electrostatic discharge attack test

5.11.14 Contact Air 8 15 8 21 8 21 kV 4.8.15 Magnetic field attack test 5.11.15 t No requirements 2 2 min NOTE Classification is in six grades where grade 1 has the lowest requirement. NOTE Grade 1 represents the requirements of 4.2 Category of use. 4.9 Requirements for product information An MP and its electronic keys manufactured to this European Standard shall have clear and detailed instructions in its product documentation and/or product information for its commissioning operation and maintenance. SIST EN 16864:2017

ª s w ¹C and

ª u r ¹Cä The environment shall be free from draughtsä — Instruments with an accuracy of 1,5 % of measured values, or better, shall be used for measurements in accordance with these test methods. — All cycle testing equipment shall include means of recording the number of cycles attained. SIST EN 16864:2017

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...