EN 14179-1:2005

(Main)Glass in building - Heat soaked thermally toughened soda lime silicate safety glass - Part 1: Definition and description

Glass in building - Heat soaked thermally toughened soda lime silicate safety glass - Part 1: Definition and description

This European Standard specifies the heat soak process system together with tolerances flatness, edgework, fragmentation and physical and mechanical characteristics of monolithic flat heat soaked thermally toughened soda lime silicate safety glass for use in buildings.

Information on curved heat soak thermally toughened soda lime silicate safety glass is given in Annex B, but this product does not form part of this European Standard.

Other requirements, not specified in this European Standard, can apply to heat soaked thermally toughened soda lime silicate safety glass which is incorporated into assemblies, e.g. laminated glass or insulating units, or undergo an additional treatment, e.g. coating. The additional requirements are specified in the appropriate product standard. Heat soak thermally toughened soda lime silicate safety glass, in this case, does not lose its mechanical or thermal characteristics.

Glas im Bauwesen - Heißgelagertes thermisch vorgespanntes Kalknatron-Einscheibensicherheitsglas - Teil 1: Definition und Beschreibung

Diese Europäische Norm legt das Heißlagerungsprozess-System sowie die Toleranzen, Geradheit, Kantenbearbei-tung,

das Bruchverhalten und physikalische und mechanische Eigenschaften von einscheibigem, flachem heißge-lagertem

thermisch vorgespanntem Kalknatron-Einscheibensicherheitsglas für die Verwendung im Bauwesen fest.

Anhang B enthält Angaben zu gebogenem heißgelagertem thermisch vorgespanntem Kalknatron-Einscheiben-sicherheitsglas,

dieses Produkt ist aber nicht Bestandteil dieser Europäischen Norm.

An heißgelagerte thermisch vorgespannte Kalknatron-Einscheibensicherheitsgläser können andere Anforderun-gen,

die in dieser Europäischen Norm nicht beschrieben sind, gestellt werden, wenn sie Bestandteil von Kombina-tionen

sind, wie z. B. Verbundglas oder Isolierglas, sind oder wenn sie weiterverarbeitet, z. B. beschichtet werden.

Die zusätzlichen Anforderungen sind in den für die Fertigprodukte zutreffenden Normen festgelegt. In diesem Fall

wird heißgelagertes thermisch vorgespanntes Kalknatron-Einscheibensicherheitsglas seine mechanischen

und/oder thermischen Eigenschaften nicht verlieren.

Verre dans la construction - Verre de silicate sodo-calcique de sécurité trempé et traité Heat Soak - Partie 1: Définition et description

Le présent document spécifie le système fonctionnel de stabilisation thermique ainsi que les tolérances, la planéité, la finition des chants, la fragmentation et les caractéristiques physiques et mécaniques du verre plat monolithique de silicate sodo-calcique de sécurité trempé thermiquement et traité Heat Soak dans la construction.

L'Annexe B fournit des informations relatives au verre bombé de silicate sodo-calcique de sécurité trempé thermiquement et traité Heat Soak, mais ce produit ne fait pas partie du présent document.

D'autres exigences, non spécifiées dans le présent document, peuvent s'appliquer au verre de silicate sodo calcique de sécurité trempé thermiquement et traité Heat Soak intégré dans des ensembles, par exemple du verre feuilleté ou des ensembles isolants préfabriqués scellés ou qui subit un traitement supplémentaire, par exemple une couche. Les exigences additionnelles sont spécifiées dans la norme de produit correspondante. Dans ce cas, le verre de silicate sodo-calcique de sécurité trempé thermiquement et traité Heat Soak ne perd pas ses caractéristiques mécaniques ou thermiques.

Steklo v gradbeništvu – HS-preskus kaljenega natrijevega-kalcijevega-silikatnega varnostnega stekla – 1. del: Definicije in opis

General Information

- Status

- Withdrawn

- Publication Date

- 21-Jun-2005

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 129 - Glass in building

- Drafting Committee

- CEN/TC 129/WG 2 - Toughened, heat strengthened and enamelled glass

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 27-Jul-2016

- Completion Date

- 09-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 03-Aug-2016

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 572-2:2012 - Glass in building - Basic soda lime silicate glass products - Part 2: Float glass - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Frequently Asked Questions

EN 14179-1:2005 is a standard published by the European Committee for Standardization (CEN). Its full title is "Glass in building - Heat soaked thermally toughened soda lime silicate safety glass - Part 1: Definition and description". This standard covers: This European Standard specifies the heat soak process system together with tolerances flatness, edgework, fragmentation and physical and mechanical characteristics of monolithic flat heat soaked thermally toughened soda lime silicate safety glass for use in buildings. Information on curved heat soak thermally toughened soda lime silicate safety glass is given in Annex B, but this product does not form part of this European Standard. Other requirements, not specified in this European Standard, can apply to heat soaked thermally toughened soda lime silicate safety glass which is incorporated into assemblies, e.g. laminated glass or insulating units, or undergo an additional treatment, e.g. coating. The additional requirements are specified in the appropriate product standard. Heat soak thermally toughened soda lime silicate safety glass, in this case, does not lose its mechanical or thermal characteristics.

This European Standard specifies the heat soak process system together with tolerances flatness, edgework, fragmentation and physical and mechanical characteristics of monolithic flat heat soaked thermally toughened soda lime silicate safety glass for use in buildings. Information on curved heat soak thermally toughened soda lime silicate safety glass is given in Annex B, but this product does not form part of this European Standard. Other requirements, not specified in this European Standard, can apply to heat soaked thermally toughened soda lime silicate safety glass which is incorporated into assemblies, e.g. laminated glass or insulating units, or undergo an additional treatment, e.g. coating. The additional requirements are specified in the appropriate product standard. Heat soak thermally toughened soda lime silicate safety glass, in this case, does not lose its mechanical or thermal characteristics.

EN 14179-1:2005 is classified under the following ICS (International Classification for Standards) categories: 81.040.20 - Glass in building. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14179-1:2005 has the following relationships with other standards: It is inter standard links to EN 14179-1:2016, EN 572-1:2012+A1:2016, EN 572-4:2012, EN 572-5:2012, EN 1096-1:2012, EN 572-2:2012, EN 14179-2:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14179-1:2005 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/135. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14179-1:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2005

Steklo v gradbeništvu – HS-preskus kaljenega natrijevega-kalcijevega-silikatnega

varnostnega stekla – 1. del: Definicije in opis

Glass in building - Heat soaked thermally toughened soda lime silicate safety glass - Part

1: Definition and description

Glas im Bauwesen - Heißgelagertes thermisch vorgespanntes Kalknatron-

Einscheibensicherheitsglas - Teil 1: Definition und Beschreibung

Verre dans la construction - Verre de silicate sodo-calcique de sécurité trempé et traité

Heat Soak - Partie 1: Définition et description

Ta slovenski standard je istoveten z: EN 14179-1:2005

ICS:

81.040.20 Steklo v gradbeništvu Glass in building

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN 14179-1

NORME EUROPÉENNE

EUROPÄISCHE NORM

June 2005

ICS 81.040.20

English version

Glass in building - Heat soaked thermally toughened soda lime

silicate safety glass - Part 1: Definition and description

Verre dans la construction - Verre de silicate sodo-calcique Glas im Bauwesen - Heißgelagertes thermisch

de sécurité trempé et traité Heat Soak - Partie 1: Définition vorgespanntes Kalknatron-Einscheibensicherheitsglas -

et description Teil 1: Definition und Beschreibung

This European Standard was approved by CEN on 19 May 2005.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the Central Secretariat or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the official

versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,

Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2005 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14179-1:2005: E

worldwide for CEN national Members.

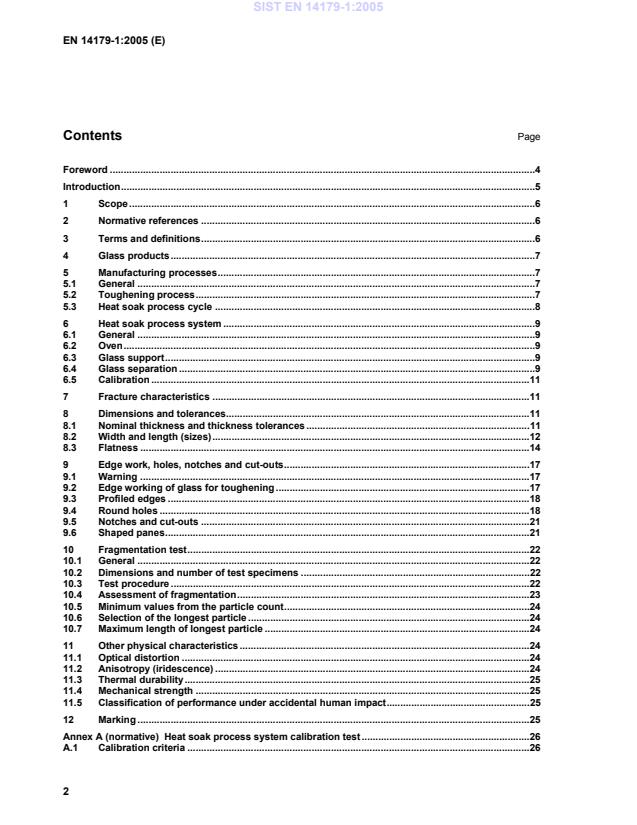

Contents Page

Foreword .4

Introduction.5

1 Scope .6

2 Normative references .6

3 Terms and definitions.6

4 Glass products.7

5 Manufacturing processes.7

5.1 General .7

5.2 Toughening process.7

5.3 Heat soak process cycle .8

6 Heat soak process system .9

6.1 General .9

6.2 Oven.9

6.3 Glass support.9

6.4 Glass separation .9

6.5 Calibration .11

7 Fracture characteristics .11

8 Dimensions and tolerances.11

8.1 Nominal thickness and thickness tolerances.11

8.2 Width and length (sizes).12

8.3 Flatness .14

9 Edge work, holes, notches and cut-outs.17

9.1 Warning .17

9.2 Edge working of glass for toughening .17

9.3 Profiled edges .18

9.4 Round holes .18

9.5 Notches and cut-outs .21

9.6 Shaped panes.21

10 Fragmentation test.22

10.1 General .22

10.2 Dimensions and number of test specimens .22

10.3 Test procedure .22

10.4 Assessment of fragmentation.23

10.5 Minimum values from the particle count.24

10.6 Selection of the longest particle .24

10.7 Maximum length of longest particle .24

11 Other physical characteristics .24

11.1 Optical distortion .24

11.2 Anisotropy (iridescence) .24

11.3 Thermal durability.25

11.4 Mechanical strength .25

11.5 Classification of performance under accidental human impact.25

12 Marking .25

Annex A (normative) Heat soak process system calibration test .26

A.1 Calibration criteria .26

A.2 Loading of oven and position for glass surface temperature measurement .26

A.3 Procedure .27

A.4 Records .27

A.5 Interpretation of the calibration test.28

Annex B (informative) Curved heat soaked thermally toughened soda lime silicate safety glass .37

Annex C (informative) Examples of particle count .38

Foreword

This European Standard (EN 14179-1:2005) has been prepared by Technical Committee CEN/TC 129 “Glass

in building”, the secretariat of which is held by IBN/BIN.

This European Standard shall be given the status of a national standard, either by publication of an identical

text or by endorsement, at the latest by December 2005, and conflicting national standards shall be withdrawn

at the latest by December 2005.

This European Standard has been prepared under a mandate given to CEN by the European Commission

and the European Free Trade Association.

This Part of the European Standard does not stand-alone, it is a part of one standard:

EN 14179-1: Glass in building – Heat soaked thermally toughened soda lime silicate safety glass –

Part 1: Definition and description;

EN 14179-2: Glass in building – Heat soaked thermally toughened soda lime silicate safety glass –

Part 2: Evaluation of conformity/Product standard.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic,

Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland

and United Kingdom.

Introduction

Heat soaked thermally toughened soda lime silicate safety glass has a safer breakage behaviour when

compared with annealed glass. It also has a known level of residual risk of spontaneous breakage arising from

the possible presence of critical nickel sulphide (NiS) inclusions in the thermally toughened soda lime silicate

glass.

NOTE 1 This case deals with extremely large quantities of glass. These quantities are dealt with on a statistical basis.

Therefore it is impossible to select a quantity of heat soaked thermally toughened soda lime silicate safety glass, for a

building, and claim that ‘no break’ by NiS inclusion can occur. The breakage of heat soaked thermally toughened soda

lime silicate safety glass caused by other influences is excluded.[sl1]

When used to offer protection under accidental human impact, heat soaked thermally toughened soda lime

silicate safety glass also should be classified according to EN 12600 (all parts).

NOTE 2 CEN/TC 129/WG 8 is producing standards for the determination of the design strength of glass and is

preparing a design method.

The European Committee for Standardization (CEN) draws attention to the fact that it is claimed that

compliance with this document may involve the use of a patent concerning Heat Soak Tests. CEN takes no

position concerning the evidence, validity and scope of this patent right. The holder of this patent right has

assured CEN that he/she is willing to negotiate licences under reasonable and non-discriminatory terms and

conditions with applicants throughout the world. In this respect, the statement of the holder of this patent right

is registered with CEN. Information may be obtained from:

SAINT-GOBAIN GLASS FRANCE

Les Miroirs – 92096 La Défense Cedex

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights other than those identified above. CEN shall not be held responsible for identifying any or all such

patent rights.

1 Scope

This European Standard specifies the heat soak process system together with tolerances flatness, edgework,

fragmentation and physical and mechanical characteristics of monolithic flat heat soaked thermally toughened

soda lime silicate safety glass for use in buildings.

Information on curved heat soak thermally toughened soda lime silicate safety glass is given in Annex B, but

this product does not form part of this European Standard.

Other requirements, not specified in this European Standard, can apply to heat soaked thermally toughened

soda lime silicate safety glass which is incorporated into assemblies, e.g. laminated glass or insulating units,

or undergo an additional treatment, e.g. coating. The additional requirements are specified in the appropriate

product standard. Heat soak thermally toughened soda lime silicate safety glass, in this case, does not lose its

mechanical or thermal characteristics.

2 Normative references

The following referenced documents are indispensable for the application of this European Standard. For

dated references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

EN 572-1, Glass in building — Basic soda lime silicate glass products — Part 1: Definitions and general

physical and mechanical properties

EN 572-2, Glass in building — Basic soda lime silicate glass products — Pall 2: Float glass

EN 572-4, Glass in building — Basic soda lime silicate glass products — Part 4: Drawn sheet glass

EN 572-5, Glass in building — Basic soda lime silicate glass products — Part 5: Patterned glass

EN 1096-1, Glass in building — Coated glass — Part 1: Definitions and classification

3 Terms and definitions

For the purposes of this European Standard, the following terms and definitions apply.

3.1

heat soaked thermally toughened soda lime silicate safety glass

glass within which a permanent surface compressive stress has been induced in order to give it greatly

increased resistance to mechanical and thermal stress and prescribed fragmentation characteristics and

which has a known level of residual risk of spontaneous breakage due to the presence of critical nickel

sulphide (NiS) inclusions

3.2

level of residual risk

risk of spontaneous breakage of heat soaked thermally toughened soda lime silicate safety glass, on a

statistical basis, due to the presence of critical nickel sulphide inclusions, is no more than one breakage per

400 tonnes of heat soaked thermally toughened soda lime silicate safety glass

3.3

flat heat soaked thermally toughened soda lime silicate safety glass

heat soaked thermally toughened soda lime silicate safety glass that has not been deliberately given a specific

profile during manufacture

3.4

heat soaked enamelled thermally toughened soda lime silicate safety glass

heat soaked thermally toughened soda lime silicate safety glass which has a ceramic frit fired into the surface

during the toughening process. After toughening the ceramic frit becomes an integral part of the glass

NOTE In the UK, this glass is also known as heat soaked opaque thermally toughened soda lime silicate safety glass.

3.5

horizontal toughening

process in which the glass is supported on horizontal rollers

3.6

vertical toughening

process in which the glass is suspended by tongs

4 Glass products

Heat soaked thermally toughened soda lime silicate safety glass shall be made from a monolithic soda lime

silicate glass product generally corresponding to one of the following standards:

soda lime silicate glass according to EN 572-1;

float glass according to EN 572-2;

drawn sheet glass according to EN 572-4;

patterned glass according to EN 572-5;

coated glass according to EN 1096-1.

5 Manufacturing processes

5.1 General

Heat soaked thermally toughened soda time silicate safety glass is manufactured as follows:

Basic soda lime silicate glass products (see Clause 4) are cut to size, shaped and edgeworked (see Clause 9).

The prepared glass panes are then thermally toughened (see 5.2).

The thermally toughened panes are then subjected to the heat soak process cycle.

After manufacture the heat soaked thermally toughened soda lime silicate glass shall comply with the

fragmentation test (see Clause 10) and mechanical strength requirement (see 11.4).

5.2 Toughening process

The cut, shaped and edgeworked glasses are toughened. The horizontal or vertical toughened glass shall

comply with the flatness criteria (see 8.3).

The thermally toughened soda lime silicate glass shall have a level of fragmentation that will ensure that after

the glass has been through the heat soak process, and subsequently tested to the fragmentation test (see

Clause 10), it shall comply with 10.5.

5.3 Heat soak process cycle

5.3.1 General

The heat soak process cycle consists of a heating phase, a holding phase and a cooling phase (see Figure 1).

Key

T glass temperature at any point, °C d ambient temperature

t time, h

a heating phase

1 first glass to reach 280 °C b holding phase

2 last glass to reach 280 °C c cooling phase

Figure 1 — Heat soak process cycle

5.3.2 Heating phase

The heating phase commences with all the glasses at ambient temperature and concludes when the surface

temperature of the last glass reaches 280 °C. The time to reach this temperature is defined in the calibration

process. This time will be dependent on the size of the oven, the amount of glass to be treated, the separation

between glasses and the heating system capacity.

NOTE 1 The glass separation and rate of heating should be controlled to minimise the risk of glass breakage as a

result of thermal stress.

To facilitate economic heating, the air temperature within the oven may exceed 320 °C. However, the glass

surface temperature shall not be allowed to exceed 320 °C. The period of glass surface temperature in excess

of 300 °C shall be minimised.

NOTE 2 When the temperature of the glass exceeds 300 °C, care should be taken to ensure that the properties of the

heat soaked thermally toughened soda lime silicate safety glass are not significantly altered i.e. they continue to meet

Clause 10.

5.3.3 Holding phase

The holding phase commences when the surface temperature of all the glasses has reached a temperature of

280 °C. The duration of the holding phase is 2 h.

Precise oven control is necessary in order to ensure that the glass surface temperature shall be maintained in

the range of 290 °C ± 10 °C during the holding phase.

5.3.4 Cooling phase

The cooling phase commences when the last glass to reach 280 °C has completed its holding phase, i.e.

been held for two hours at 290 °C ± 10 °C. During this phase the glass temperature shall be brought down to

ambient temperature.

The cooling phase can be concluded when the air temperature in the oven reaches 70 °C.

NOTE The rate of cooling should be controlled to minimise the risk of glass breakage as a result of thermal stress.

6 Heat soak process system

6.1 General

The heat soak process system consists of:

oven (see 6.2);

glass support (see 6.3);

separation system (see 6.4).

The oven shall be calibrated, see 6.5 and Annex A, and this determines the method of operation of the heat

soak process system during manufacture of heat soaked thermally toughened soda lime silicate safety glass.

6.2 Oven

The oven shall be heated by convection and shall allow an unhindered air circulation around each glass pane.

In the event of glass breakage the airflow shall not be hindered. The airflow in the oven shall be led parallel to

the glass surfaces.

NOTE The openings for the air ingress/egress should be designed to ensure that fragments of broken glass do not

cause blockages.

6.3 Glass support

Glasses may be supported vertically or horizontally. The glasses shall not be fixed or clamped, they have to

be supported to allow free movement.

NOTE Vertically means true vertical or up to 15° either side of true vertical.

The distance between glasses affects the airflow, heat exchange and the heating time. Glass to glass contact

shall not be allowed.

6.4 Glass separation

The glasses shall be separated in a manner that does not hinder the airflow. The separators shall also not

hinder the airflow e.g. see Figure 2.

Dimensions in millimetres

Figure 2 — Example of a vertical glass support

The minimum separation of the glasses shall be determined during the calibration of the oven, see 6.5 and

Annex A.

NOTE 1 Generally, a minimum separation of 20 mm is recommended (see Figure 3).

NOTE 2 If glasses of very different size are put on the same stillage, they will require greater separation in order to

prevent glass breakage when the furnace is opened alter the heat soak process. The same applies to glasses with holes,

notches and cut-outs.

Figure 3 — Recommend separation between glass

The positioning of the separators, material of the manufacture and their shape shall be specified during the

calibration test of the oven and shall be reproduced during the manufacturing process.

6.5 Calibration

The heat soak system, e.g. oven, glass separation, separators, etc., shall be calibrated, see Annex A.

The calibration shall determine the heating phase of the process, glass separation distance, the positioning,

material and shape of separators, the type and positioning of stillage(s) and define the operating conditions for

use during manufacture.

7 Fracture characteristics

In the event of breakage, heat soaked thermally toughened soda lime silicate safety glass fractures into

numerous small pieces, the edges of which are generally blunt.

NOTE Fragmentation in service does not always correspond to that described in Clause 10, due to restraint from

fixing or reprocessing (e.g. laminating), or due to the cause of fracture.

8 Dimensions and tolerances

8.1 Nominal thickness and thickness tolerances

The nominal thicknesses and thickness tolerances are those given in the relevant product standard (see

Clause 4), some of which are reproduced in Table 1.

Table 1 — Nominal thicknesses and thickness tolerances

Dimensions in millimetres

Thickness tolerances for glass type

Nominal thickness

d

Drawn sheet Patterned Float

±0,2

±0,2

±0,5

±0,2

±0,2

±0,5

±0,2

5 ±0,3 ±0,5

6 ±0,2

±0,3 ±0,5

8 ±0,3

±0,4 ±0,8

±0,3

±0,5 ±1,0

±0,3

±0,6 not manufactured

not manufactured ±0,5

not manufactured

not manufactured not manufactured

±1,0

not manufactured

not manufactured

±1,0

The thickness of a pane shall be determined as for the basic product. The measurement shall be taken at the

centres of the 4 sides, and away from the area of any tong marks (see Figure 6), which may be present.

8.2 Width and length (sizes)

8.2.1 General

When heat soaked thermally toughened soda lime silicate safety glass dimensions are quoted for rectangular

panes, the first dimension shall be the width, B, and the second dimension the length, H, as shown in

Figure 4. It shall be made clear which dimension is the width, B, and which is the length, H, when related to its

installed position.

Figure 4 — Examples of width, B, and length, H, relative to the pane shape

NOTE For heat soaked thermally toughened soda lime silicate safety glass manufactured from patterned glass, the

direction of the pattern should be specified relative to one of the dimensions.

8.2.2 Maximum and minimum sizes

For maximum and minimum sizes, the manufacturer shall be consulted.

8.2.3 Tolerances and squareness

The nominal dimensions for width and length being given, the finished pane shall not be larger than a

prescribed rectangle resulting from the nominal dimensions increased by the tolerance, t, or smaller than a

prescribed rectangle reduced by the tolerance, t. The sides of the prescribed rectangles are parallel to one

another and these rectangles shall have a common centre (see Figure 5). The limits of squareness shall be

determined by the prescribed rectangles. Tolerances are given in Table 2.

Figure 5 — Tolerance limits for dimensions of rectangular panes

Table 2 — Tolerances on width, B, and length, H

Dimensions in millimetres

Tolerance, t

Nominal dimension of side,

nominal glass thickness, nominal glass thickness,

B or H

d ≤≤≤≤ 12 d > 12

≤2 000 ±2,5 (horizontal toughening) ±3,0

±3,0 (vertical toughening)

2 000 < B or H ≤ 3 000 ±3,0 ±4,0

>3 000

±4,0 ±5,0

8.2.4 Edge deformation produced by vertical toughening

The tongs used to suspend the glass during toughening can result in surface depressions, known as tong

marks (see Figure 6). The centres of the tong marks may be situated up to a maximum of 20 mm in from the

edge. A deformation of the edge less than 2 mm can be produced in the region of the tong mark and there can

also be an area of optical distortion. These deformations shall be included in the tolerances in Table 2.

Key

1 deformation

2 up to 20 mm

3 tong mark

4 100 mm radius maximum area of optical distortion

Figure 6 — Tong mark deformation

8.3 Flatness

8.3.1 General

By the very nature of the toughening process, it is not possible to obtain a product as flat as annealed glass.

The difference depends on the nominal thickness, the dimensions and the ratio between the dimensions.

Therefore a distortion known as overall bow may occur. There are two kinds of bow (see Figure 7):

overall or general bow;

local bow.

NOTE 1 Overall bow can, in general, be accommodated by the framing system.

NOTE 2 Local bow needs to be allowed for in the glazing materials and the weather seals. For special requirements

the manufacturers should be consulted.

8.3.2 Measurement of o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...