EN 14831:2005

(Main)Fasteners - Tightening performance - Torque/Angle simplified test method

Fasteners - Tightening performance - Torque/Angle simplified test method

This European standard specifies a test method for fasteners with ISO metric thread from M6 to M16 and with property classes 8.8 to 12.9 for bolts and screws and with property classes 8 to 12 for nuts, to check their tightening performance in the elastic range.

It applies to steel fasteners with an ISO metric thread according to ISO 68-1.

It applies to fasteners having a friction coefficient from 0,06 up to and including 0,18. For higher values of friction coefficients, the dispersion of test results increases and the test method should not be applied. For lower values friction of coefficients, which are for very specific applications and require special lubrication, this standard does not apply.

This comparative test method can be used to monitor stability of a production process (such as coating, lubrication, shot-blasting) or to compare various production manufacturing lots. It can also be used to detect fasteners, which are out of specification.

NOTE This simplified test method has been developed to avoid systematic use of more complex procedures.

In case of dispute the torque/tension test method according to EN ISO 16047 is the referee test.

This standard does not apply for assessment of fasteners in actual assembly conditions; it does not allow the measurement of operating friction coefficients.

Verbindungselemente - Anziehverhalten - Vereinfachtes Drehmoment/Drehwinkel-Verfahren

Dieses Dokument legt ein Prüfverfahren für Verbindungselemente mit metrischem ISO-Gewinde von M6 bis M16 für Schrauben der Festigkeitsklassen 8.8 bis 12.9 und für Muttern der Festigkeitsklassen 8 bis 12 zur Prüfung ihres Anziehverhaltens im elastischen Bereich fest.

Es gilt für Verbindungselemente aus Stahl mit metrischem ISO-Gewinde nach ISO 68-1.

Es gilt für Verbindungselemente mit einer Reibungszahl von 0,06 bis einschließlich 0,18. Bei höheren Reibungszahlwerten nimmt die Streuung der Prüfergebnisse zu und das Prüfverfahren sollte nicht angewendet werden. Dieses Dokument gilt nicht für niedrigere Reibungszahlen, die für sehr spezifische Anwendungsfälle vorgesehen sind und die eine besondere Schmierung erfordern.

Dieses vergleichende Prüfverfahren kann zur Überprüfung der Gleichmäßigkeit eines Fertigungsprozesses (z. B. Aufbringen eines Überzuges, Schmierung, Kugelstrahlen) oder zum Vergleichen von unterschiedlichen Herstellungslosen angewendet werden. Es kann auch zum Erkennen von Verbindungselementen eingesetzt werden, die nicht den Festlegungen entsprechen.

ANMERKUNG Dieses vereinfachte Prüfverfahren wurde entwickelt, um die systematische Anwendung von umfangreicheren Verfahren zu vermeiden.

Im Streitfall dient der Drehmoment/Vorspannkraft-Versuch nach EN ISO 16047 als Schiedsprüfung.

Dieses Dokument ist nicht anwendbar für die Bewertung von Verbindungselementen im tatsächlichen Montagezustand; die Messung der im Betrieb auftretenden Reibungszahlen ist nicht möglich.

Eléments de fixation - Aptitude au serrage - Méthode d'essai simplifiée Couple/Angle

La présente Norme européenne spécifie une méthode d'essai applicable aux éléments de fixation à filetage

métrique ISO, de diamètres M6 à M16, de classes de qualité 8.8 à 12.9 pour les vis et de classes de qualité 8

à 12 pour les écrous, permettant de vérifier leur aptitude au serrage dans le domaine élastique.

Elle s'applique aux éléments de fixation en acier à filetage métrique ISO conforme à l'ISO 68-1.

Elle s'applique aux éléments de fixation ayant un coefficient de frottement de 0,06 à 0,18 inclus. Pour des

coefficients de frottement supérieurs, la dispersion des résultats d'essai est plus importante et il convient de

ne pas appliquer cette méthode d'essai. La présente norme ne s'applique pas pour des coefficients de

frottement inférieurs qui correspondent à des applications très spécifiques et nécessitent une lubrification

spéciale.

La présente méthode d'essai comparative peut être utilisée pour contrôler la stabilité d'un procédé de

production (tel que l'application d'un revêtement, la lubrification, le grenaillage) ou pour comparer différents

lots fabriqués. Elle peut également être utilisée pour détecter des éléments de fixation en dehors des

spécifications prévues.

NOTE La présente méthode d'essai simplifiée a été élaborée afin d�éviter l'utilisation systématique de procédures

plus complexes.

En cas de litige, la méthode d'essai de couple/tension conforme au prEN ISO 16047 constitue l'essai de

référence.

La présente norme ne s'applique pas pour l'évaluation d�éléments de fixation dans des conditions

d'assemblage réelles ; elle ne permet pas de mesurer les coefficients de frottement réels.

Vezni elementi – Karakteristika privijanja - Poenostavljen preskus navora/zasuka

General Information

- Status

- Published

- Publication Date

- 12-Apr-2005

- Withdrawal Date

- 30-Oct-2005

- Technical Committee

- CEN/TC 185 - Threaded and nonthreaded mechanical fasteners and accessories

- Drafting Committee

- CEN/TC 185/WG 9 - Torque/angle test method

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 16-Apr-2023

- Completion Date

- 04-Feb-2026

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 14831:2005 - Fasteners: Tightening performance - Torque/Angle simplified test method (CEN) defines a comparative laboratory test for checking the tightening behaviour of steel ISO‑metric threaded fasteners (M6–M16). The method targets bolts, screws and nuts in specified property classes (bolts/screws 8.8–12.9; nuts 8–12) and is intended to verify tightening performance in the elastic range. It is a simplified torque/angle procedure for production monitoring and lot comparison - not a replacement for full assembly testing or for measuring operating friction coefficients.

Key topics and requirements

- Scope & limits: ISO metric thread according to ISO 68‑1; thread sizes M6–M16; applicable friction coefficient range 0.06–0.18. Outside this range the method is not recommended.

- Comparative test purpose: Monitor process stability (coating, lubrication, shot‑blasting), compare manufacturing lots, and detect out‑of‑spec fasteners.

- Reference (referee) test: In case of dispute the torque/tension method EN ISO 16047 is the referee test.

- Apparatus and accuracy:

- Torque wrench with uncertainty ±2%.

- Angle measurement accuracy ±2° or ±2% of measured value.

- Test fixture includes a hardened tightening block (≥50 HRC) and bearing washer (≥200 HV, Ra ≤1.6).

- Test procedure basics:

- Use new reference fasteners and bearing parts for each test.

- Apply a specified pretorque (example values: M6=3 Nm, M8=6 Nm, M10=15 Nm, M12=25 Nm, M14=35 Nm, M16=60 Nm).

- Tighten continuously to a calibrated test angle θ and record final torque.

- Ambient test range: 10 °C – 35 °C.

- Typical sample size: 10 fasteners unless agreed otherwise.

- Output: Torque at specified angle is compared to control limits; annexes provide calibration and control‑limit determination procedures.

Applications and users

Who benefits:

- Fastener manufacturers - routine production quality control and lot comparison.

- Coating and lubrication process engineers - monitor process effects on tightening performance.

- Quality assurance/inspection labs - quick screening for non‑conforming lots.

- OEMs and procurement teams - acceptance testing for delivered fasteners (comparative basis). Practical uses include detecting coating or lubrication variability, validating manufacturing stability, and screening batches before assembly.

Related standards

- EN ISO 16047 - Torque/clamp‑force testing (referee method)

- EN ISO 898‑1 / EN 20898‑2 - Mechanical property classes for bolts and nuts

- ISO 965‑2, EN ISO 7093‑1, EN ISO 4759‑3 - threads, washers and tolerances referenced by EN 14831

EN 14831:2005 is a practical, simplified torque/angle method for comparative testing of ISO metric fasteners in production and QC environments; it is not intended for in‑service assembly evaluation.

Frequently Asked Questions

EN 14831:2005 is a standard published by the European Committee for Standardization (CEN). Its full title is "Fasteners - Tightening performance - Torque/Angle simplified test method". This standard covers: This European standard specifies a test method for fasteners with ISO metric thread from M6 to M16 and with property classes 8.8 to 12.9 for bolts and screws and with property classes 8 to 12 for nuts, to check their tightening performance in the elastic range. It applies to steel fasteners with an ISO metric thread according to ISO 68-1. It applies to fasteners having a friction coefficient from 0,06 up to and including 0,18. For higher values of friction coefficients, the dispersion of test results increases and the test method should not be applied. For lower values friction of coefficients, which are for very specific applications and require special lubrication, this standard does not apply. This comparative test method can be used to monitor stability of a production process (such as coating, lubrication, shot-blasting) or to compare various production manufacturing lots. It can also be used to detect fasteners, which are out of specification. NOTE This simplified test method has been developed to avoid systematic use of more complex procedures. In case of dispute the torque/tension test method according to EN ISO 16047 is the referee test. This standard does not apply for assessment of fasteners in actual assembly conditions; it does not allow the measurement of operating friction coefficients.

This European standard specifies a test method for fasteners with ISO metric thread from M6 to M16 and with property classes 8.8 to 12.9 for bolts and screws and with property classes 8 to 12 for nuts, to check their tightening performance in the elastic range. It applies to steel fasteners with an ISO metric thread according to ISO 68-1. It applies to fasteners having a friction coefficient from 0,06 up to and including 0,18. For higher values of friction coefficients, the dispersion of test results increases and the test method should not be applied. For lower values friction of coefficients, which are for very specific applications and require special lubrication, this standard does not apply. This comparative test method can be used to monitor stability of a production process (such as coating, lubrication, shot-blasting) or to compare various production manufacturing lots. It can also be used to detect fasteners, which are out of specification. NOTE This simplified test method has been developed to avoid systematic use of more complex procedures. In case of dispute the torque/tension test method according to EN ISO 16047 is the referee test. This standard does not apply for assessment of fasteners in actual assembly conditions; it does not allow the measurement of operating friction coefficients.

EN 14831:2005 is classified under the following ICS (International Classification for Standards) categories: 21.060.10 - Bolts, screws, studs; 21.060.20 - Nuts. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14831:2005 has the following relationships with other standards: It is inter standard links to EN ISO 7093-1:2000, EN ISO 898-1:2013, EN ISO 16047:2005, EN ISO 9013:2002/A1:2003, EN ISO 4759-3:2016, EN ISO 898-2:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14831:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2005

Vezni elementi – Karakteristika privijanja - Poenostavljen preskus navora/zasuka

Fasteners - Tightening performance - Torque/Angle simplified test method

Verbindungselemente - Anziehverhalten - Vereinfachtes Drehmoment/Drehwinkel-

Verfahren

Eléments de fixation - Aptitude au serrage - Méthode d'essai simplifiée Couple/Angle

Ta slovenski standard je istoveten z: EN 14831:2005

ICS:

21.060.01 Vezni elementi na splošno Fasteners in general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN 14831

NORME EUROPÉENNE

EUROPÄISCHE NORM

April 2005

ICS 21.060.10; 21.060.20

English version

Fasteners - Tightening performance - Torque/Angle simplified

test method

Eléments de fixation - Aptitude au serrage - Méthode Verbindungselemente - Anziehverhalten - Vereinfachtes

d'essai simplifiée Couple/Angle Drehmoment/Drehwinkel-Verfahren

This European Standard was approved by CEN on 3 March 2005.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the Central Secretariat or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the official

versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,

Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2005 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14831:2005: E

worldwide for CEN national Members.

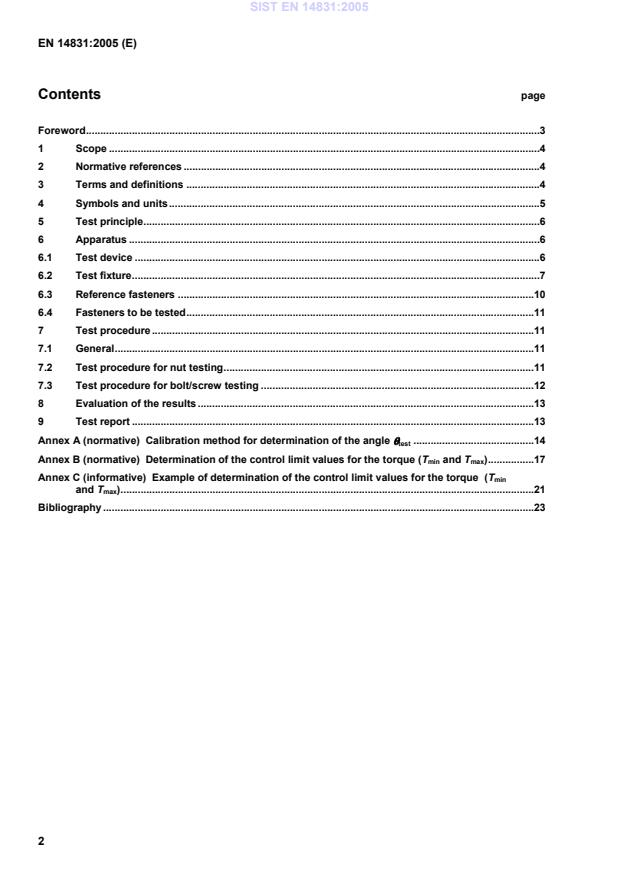

Contents page

Foreword.3

1 Scope .4

2 Normative references .4

3 Terms and definitions .4

4 Symbols and units.5

5 Test principle.6

6 Apparatus .6

6.1 Test device .6

6.2 Test fixture.7

6.3 Reference fasteners .10

6.4 Fasteners to be tested.11

7 Test procedure.11

7.1 General.11

7.2 Test procedure for nut testing.11

7.3 Test procedure for bolt/screw testing .12

8 Evaluation of the results .13

9 Test report .13

Annex A (normative) Calibration method for determination of the angle θθθθ .14

test

Annex B (normative) Determination of the control limit values for the torque (T and T ).17

min max

Annex C (informative) Example of determination of the control limit values for the torque (T

min

and T ).21

max

Bibliography .23

Foreword

This document (EN 14831:2005) has been prepared by Technical Committee CEN/TC 185, “Threaded and

non-threaded mechanical fasteners and accessories”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an identical

text or by endorsement, at the latest by October 2005, and conflicting national standards shall be withdrawn at

the latest by October 2005.

This document includes a Bibliography.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic,

Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland

and United Kingdom.

1 Scope

This document specifies a test method for fasteners with ISO metric thread from M6 to M16 and with property

classes 8.8 to 12.9 for bolts and screws and with property classes 8 to 12 for nuts, to check their tightening

performance in the elastic range.

It applies to steel fasteners with an ISO metric thread according to ISO 68-1.

It applies to fasteners having a friction coefficient from 0,06 up to and including 0,18. For higher values of

friction coefficients, the dispersion of test results increases and the test method should not be applied. For

lower values friction of coefficients, which are for very specific applications and require special lubrication, this

document does not apply.

This comparative test method can be used to monitor stability of a production process (such as coating,

lubrication, shot-blasting) or to compare various production manufacturing lots. It can also be used to detect

fasteners, which are out of specification.

NOTE This simplified test method has been developed to avoid systematic use of more complex procedures.

In case of dispute the torque/tension test method according to EN ISO 16047 is the referee test.

This document does not apply for assessment of fasteners in actual assembly conditions; it does not allow the

measurement of operating friction coefficients.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

EN 20898-2, Mechanical properties of fasteners — Part 2: Nuts with specified proof load values — Coarse

thread (ISO 898-2:1992).

EN ISO 898-1, Mechanical properties of fasteners made of carbon steel and alloy steel — Part 1: Bolts,

screws and studs (ISO 898-1:1999).

EN ISO 4759-3, Tolerances for fasteners — Part 3: Plain washers for bolts, screws and nuts — Product

grades A and C (ISO 4759-3:2000).

EN ISO 7093-1, Plain washers — Large series — Part 1: Product grade A (ISO 7093-1:2000).

EN ISO 16047, Fasteners — Torque/clamp force testing (ISO 16047:2005).

ISO 965-2, ISO general purpose metric screw threads — Tolerances — Part 2: Limits of sizes for general

purpose external and internal screw threads — Medium quality.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

manufacturing lot

quantity of fasteners of a single designation including product grade, property class and size, manufactured

from bar, wire, rod or flat product from a single cast, processed through the same or similar steps at the same

time or over a continuous time period through the same heat treatment and/or coating process, if any

NOTE 1 Same heat treatment or coating process means:

for a continuous process, the same treatment cycle without any setting modification;

for a discontinuous process, the same treatment cycle for identical consecutive loads (batches).

NOTE 2 The manufacturing lot may be split into a number of manufacturing batches for processing purposes and then

reassembled into the same manufacturing lot.

[Adapted from EN ISO 15330:1999]

3.2

coating process cycle

a sequence of surface preparation and/or coating application during a period of time where operating

parameters including temperature, concentration, surface area, current density, or any other parameter which

may affect the mechanical and/or performance properties of the fasteners are set and maintained

3.3

heat treatment cycle

a sequence of heat treatment over a defined period of time where operating parameters such as temperature,

atmosphere, pressure, retention time, or any other parameter which may affect the mechanical or

performance properties of the fasteners are set and maintained

4 Symbols and units

d Nominal diameter of the bolt, screw or nut, mm

d External diameter of the bearing part, mm

e

d Diameter of the clearance hole (block or bearing part/washer, mm)

h

d Outside diameter of the bearing face of the bolt, screw or nut, mm

w

D Diameter of bearing surface under nut or bolt head for friction (see EN ISO 16047)

b

d Basic pitch diameter, mm

F Force

F Clamping force corresponding to T in correlation with µ , N

p, max p min

F Clamping force corresponding to T in correlation with µ , N

p, min p max

F Clamping force corresponding to T , N

p

p

F Maximum clamping force, N

test, max

F Minimum clamping force, N

test, min

F Nominal clamping force, N

test

H Height of the tightening block, mm

h Thickness of the bearing part, mm

L Side dimension of the tightening block, mm

L Clamping length, mm

c

n Number of tested bolts, screws or nuts.

P Pitch of the thread, mm

r Mean effective radius of the bearing face, mm

m

T Torque

T Mean torque for calibration, Nm

T Maximum torque value, Nm

max

T Minimum torque value, Nm

min

T Pretorque, Nm

p

T Torque corresponding to F , Nm

test test

θ Angle of rotation

θ Angle value measured between T and T in degrees

test p test

µ Upper limit of the specified range of friction coefficient

max

µ Lower limit of the specified range of friction coefficient

min

5 Test principle

The principle of this test is to apply a specified clamping force to the bolt/screw by rotating the fastener

(bolt/screw or nut) to be tested under reference conditions.

After applying a pretorque the fastener to be tested is tightened to a specified test angle.

The final torque is monitored and compared to a specified torque range.

6 Apparatus

6.1 Test device

The torque wrench shall be able to apply a tightening torque within the uncertainty of ± 2 % of the value to be

measured. The uncertainty of angle measurement shall be ± 2 ° or ± 2 % of the measured value, whichever is

greater.

6.2 Test fixture

6.2.1 General

The test fixture includes a tightening block and a bearing part, see Figure 1.

a) Nut testing b) Bolt/screw testing

Key

1 Tightening block

2 Bearing part

3 Nut to be tested

4 Reference bolt/screw

5 Bolt/screw to be tested

6 Reference nut

Figure 1 — Test fixture

The reference fastener and the bearing part/washer shall not rotate during the test. Any device used to

prevent rotation shall not intrude into the bearing face of the fastener to be tested.

6.2.2 Tightening block

The tightening block shall be made of steel quenched and tempered to a hardness equal to or above 50 HRC.

It shall be dry and clean.

The bearing surface shall be uncoated.

Dimensions of the tightening block see Figure 2 and Table 1.

Dimensions in millimetres

Figure 2 — Tightening block

Table 1 — Dimensions of tightening block

Dimensions in milimetres

Thread of the

fastener to be

M6 M8 M10 M12 M14 M16

tested

d

L 50 ± 0,5

min. 6,40 8,40 10,50 13,00 15,00 17,00

d

h

max. 6,55 8,55 10,65 13,18 15,18 17,18

H for

nom

25 25 35 35 50 50

testing nuts

H for

nom

screws (fully 9,00 12,00 15,00 18,00 21,00 24,00

threaded)

l H for bolts (partially threaded)

nom

30 25

50 25

35 35

35 35

60 45

45 45 38

70 50

80 60 60 50 50

90 65 60

100 78 78

110 85

120 95

140 110

6.2.3 Bearing part/washer

The bearing part/washer shall be taken from a single manufacturing lot. They shall be free of burrs, uncoated,

dry and clean. The hardness of the bearing part shall be 200 HV minimum and the hardness class of the

washe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...