EN 16728:2016

(Main)LPG equipment and accessories - Transportable refillable LPG cylinders other than traditional welded and brazed steel cylinders - Periodic inspection

LPG equipment and accessories - Transportable refillable LPG cylinders other than traditional welded and brazed steel cylinders - Periodic inspection

This European Standard specifies procedures for periodic inspection and testing, for transportable refillable LPG cylinders with a water capacity from 0,5 l up to and including 150 l.

This European Standard is applicable to the following:

- welded steel LPG cylinders manufactured to an alternative design and construction, see EN 14140 or equivalent standard;

- welded aluminium LPG cylinders, see EN 13110 or equivalent standard;

- composite LPG cylinders, see EN 14427 or equivalent standard;

- over-moulded cylinders designed and manufactured according to EN 1442 or EN 14140, see Annex F.

NOTE The requirements of RID/ADR take precedence over those of this Standard in the case of cylinders complying with that regulation, including pi marked cylinders.

This European Standard does not apply to cylinders permanently installed in vehicles.

Flüssiggas-Geräte und Ausrüstungsteile - Ortsbewegliche, wiederbefüllbare Flaschen für Flüssiggas (LPG), ausgenommen geschweißte und hartgelötete Stahlflaschen - Wiederkehrende Inspektion

Diese Europäische Norm legt Verfahren für die wiederkehrende Inspektion und Prüfung von ortsbeweglichen, wiederbefüll¬baren Flaschen für Flüssiggas (LPG) mit einem Fassungsraum von 0,5 l bis einschließlich 150 l fest.

Diese Europäische Norm gilt für:

- geschweißte Flaschen aus Stahl für Flüssiggas (LPG), die mit alternativer Gestaltung und Konstruktion hergestellt wurden, siehe EN 14140 oder eine gleichwertige Norm;

- geschweißte Flaschen aus Aluminium für Flüssiggas (LPG), siehe EN 13110 oder eine gleichwertige Norm;

- Flüssiggasflaschen aus Verbundwerkstoff, siehe EN 14427 oder eine gleichwertige Norm;

- umformte Flaschen, gestaltet und hergestellt nach EN 1442 oder EN 14140, siehe Anhang F.

ANMERKUNG Für Flaschen, die den Vorschriften der/des RID/ADR entsprechen sowie für Flaschen mit der Kennzeichnung "pi", haben die in der/dem RID/ADR angegebenen Anforderungen Vorrang gegenüber den Anforderungen in der vorliegenden Norm.

Diese Europäische Norm gilt nicht für Flaschen, die dauerhaft in Fahrzeugen eingebaut sind.

Équipements pour GPL et leurs accessoires - Bouteilles transportables et rechargeables pour GPL autres que celles en acier soudé et brasé - Contrôle périodique

Cette Norme européenne spécifie des modes opératoires pour des contrôles et des essais périodiques pour des bouteilles pour GPL transportables et rechargeables d’une capacité en eau comprise entre 0,5 et 150 l.

Cette Norme s’applique aux éléments suivants :

- bouteilles pour GPL, en acier soudé, fabriquées selon une conception et fabrication différentes, voir l'EN 14140 ou une Norme équivalente ;

- bouteilles pour GPL, en aluminium soudé, voir l'EN 13110 ou une Norme équivalente ;

- bouteilles pour GPL, en matériau composite, voir l'EN 14427 ou une Norme équivalente ;

- bouteilles surmoulées conçues et fabriquées conformément à l'EN 1442 ou l'EN 14140, voir l'Annexe F.

La présente Norme européenne ne s’applique pas aux bouteilles installées en permanence dans des véhicules.

Oprema in pribor za utekočinjeni naftni plin (UNP) - Premične, ponovno polnljive plinske jeklenke za UNP, ki niso varjene in trdo spajkane - Periodična kontrola

Ta evropski standard določa postopke za periodične preglede in preskušanje premičnih, ponovno polnljivih jeklenk za utekočinjeni naftni plin (LPG) z vodno kapaciteto od 0,5 l do vključno 150 l.

Ta evropski standard se uporablja za:

– varjene jeklenke za LPG z alternativno zasnovo in konstrukcijo (glej EN 14140 ali enakovreden standard);

– varjene aluminijaste jeklenke za LPG (glej EN 13110 ali enakovredni standard);

– kompozitne jeklenke za LPG (glej EN 14427 ali enakovredni standard);

– prelite jeklenke, zasnovane in izdelane v skladu s standardom EN 1442 ali EN 14140 (glej dodatek F).

Ta evropski standard se ne uporablja za jeklenke, trajno nameščene v vozila.

General Information

- Status

- Withdrawn

- Publication Date

- 08-Mar-2016

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 286 - Liquefied petroleum gas equipment and accessories

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 13-Jun-2018

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 18-Jan-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 10028-7:2016 - Flat products made of steels for pressure purposes - Part 7: Stainless steels - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 16728:2016 is a standard published by the European Committee for Standardization (CEN). Its full title is "LPG equipment and accessories - Transportable refillable LPG cylinders other than traditional welded and brazed steel cylinders - Periodic inspection". This standard covers: This European Standard specifies procedures for periodic inspection and testing, for transportable refillable LPG cylinders with a water capacity from 0,5 l up to and including 150 l. This European Standard is applicable to the following: - welded steel LPG cylinders manufactured to an alternative design and construction, see EN 14140 or equivalent standard; - welded aluminium LPG cylinders, see EN 13110 or equivalent standard; - composite LPG cylinders, see EN 14427 or equivalent standard; - over-moulded cylinders designed and manufactured according to EN 1442 or EN 14140, see Annex F. NOTE The requirements of RID/ADR take precedence over those of this Standard in the case of cylinders complying with that regulation, including pi marked cylinders. This European Standard does not apply to cylinders permanently installed in vehicles.

This European Standard specifies procedures for periodic inspection and testing, for transportable refillable LPG cylinders with a water capacity from 0,5 l up to and including 150 l. This European Standard is applicable to the following: - welded steel LPG cylinders manufactured to an alternative design and construction, see EN 14140 or equivalent standard; - welded aluminium LPG cylinders, see EN 13110 or equivalent standard; - composite LPG cylinders, see EN 14427 or equivalent standard; - over-moulded cylinders designed and manufactured according to EN 1442 or EN 14140, see Annex F. NOTE The requirements of RID/ADR take precedence over those of this Standard in the case of cylinders complying with that regulation, including pi marked cylinders. This European Standard does not apply to cylinders permanently installed in vehicles.

EN 16728:2016 is classified under the following ICS (International Classification for Standards) categories: 23.020.30 - Pressure vessels, gas cylinders; 23.020.35 - Gas cylinders. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16728:2016 has the following relationships with other standards: It is inter standard links to EN 1440:2008+A1:2012, EN 16728:2016+A1:2018, ISO 16269-6:2014, EN 837-3:1996, EN ISO 15995:2021, EN 14894:2021, EN ISO 14245:2021, EN 10028-7:2016, EN 14912:2022, EN 14140:2014, EN 14427:2014, EN 196-1:1994, EN 837-1:1996, EN 13110:2022, EN 1442:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16728:2016 is associated with the following European legislation: EU Directives/Regulations: 2008/68/EC, 94/55/EC, 96/49/EC, 96/86/EC, 96/87/EC; Standardization Mandates: M/086. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16728:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Flüssiggas-Geräte und Ausrüstungsteile - Ortsbewegliche, wiederbefüllbare Flaschen für Flüssiggas (LPG), ausgenommen geschweißte und hartgelötete Stahlflaschen - Wiederkehrende InspektionÉquipements pour GPL et leurs accessoires - Bouteilles transportables et rechargeables pour GPL autres que celles en acier soudé et brasé - Contrôle périodiqueLPG equipment and accessories - Transportable refillable traditional LPG cylinders other than traditional welded and brazed steel cylinders - Periodic inspection23.020.35Plinske jeklenkeGas cylindersICS:Ta slovenski standard je istoveten z:EN 16728:2016SIST EN 16728:2016en,fr,de01-junij-2016SIST EN 16728:2016SLOVENSKI

STANDARDSIST EN 1440:2008+A1:20121DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16728

March

t r s x ICS

t uä r t rä u r Supersedes EN

s v v rã t r r z ªA sã t r s tEnglish Version

LPG equipment and accessories æ Transportable refillable LPG cylinders other than traditional welded and brazed steel cylinders æ Periodic inspection Équipements pour GPL et leurs accessoires æ Bouteilles transportables et rechargeables pour GPL autres que celles en acier soudß et brasß æ Contrôle pßriodique

FlüssiggasæGeräte und Ausrüstungsteile æ Ortsbeweglicheá wiederbefüllbare Flaschen für hartgelötete Stahlflaschen æ Wiederkehrende Inspektion This European Standard was approved by CEN on

t January

t r s xä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey andUnited Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s x CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s x y t zã t r s x ESIST EN 16728:2016

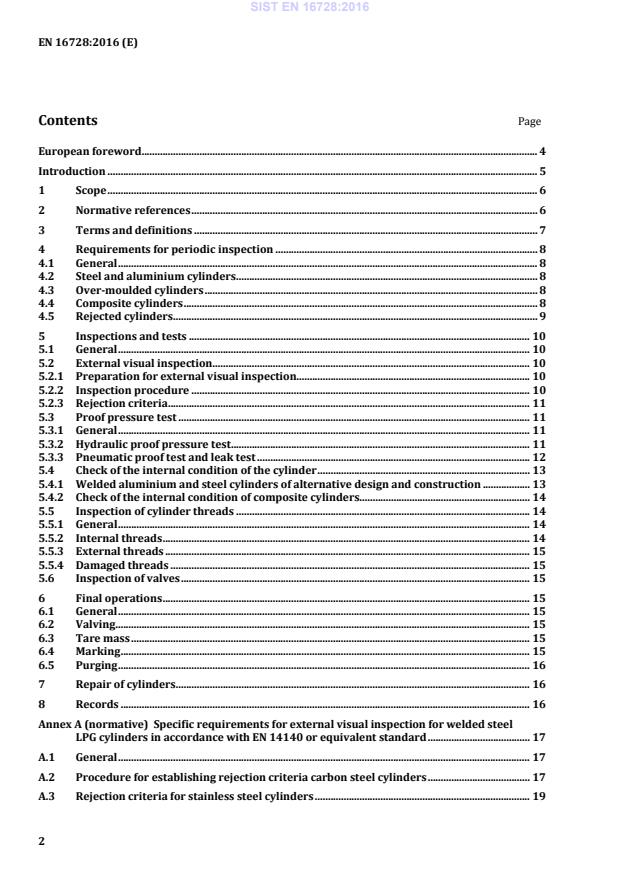

Page European foreword . 4 Introduction . 5 1 Scope . 6 2 Normative references . 6 3 Terms and definitions . 7 4 Requirements for periodic inspection . 8 4.1 General . 8 4.2 Steel and aluminium cylinders . 8 4.3 Over-moulded cylinders . 8 4.4 Composite cylinders . 8 4.5 Rejected cylinders . 9 5 Inspections and tests . 10 5.1 General . 10 5.2 External visual inspection . 10 5.2.1 Preparation for external visual inspection. 10 5.2.2 Inspection procedure . 10 5.2.3 Rejection criteria . 11 5.3 Proof pressure test . 11 5.3.1 General . 11 5.3.2 Hydraulic proof pressure test. 11 5.3.3 Pneumatic proof test and leak test . 12 5.4 Check of the internal condition of the cylinder . 13 5.4.1 Welded aluminium and steel cylinders of alternative design and construction . 13 5.4.2 Check of the internal condition of composite cylinders . 14 5.5 Inspection of cylinder threads . 14 5.5.1 General . 14 5.5.2 Internal threads . 14 5.5.3 External threads . 15 5.5.4 Damaged threads . 15 5.6 Inspection of valves . 15 6 Final operations . 15 6.1 General . 15 6.2 Valving . 15 6.3 Tare mass . 15 6.4 Marking . 15 6.5 Purging . 16 7 Repair of cylinders . 16 8 Records . 16 Annex A (normative)

Specific requirements for external visual inspection for welded steel LPG cylinders in accordance with EN 14140 or equivalent standard . 17 A.1 General . 17 A.2 Procedure for establishing rejection criteria carbon steel cylinders . 17 A.3 Rejection criteria for stainless steel cylinders . 19 SIST EN 16728:2016

Specific requirements for external visual inspection of welded aluminium LPG cylinders . 22 Annex C (normative)

Specific requirements for visual inspection of composite LPG cylinders . 25 C.1 Establishment of rejection criteria . 25 C.1.1 General . 25 C.1.2 Procedure . 25 C.2 Examples of rejection criteria . 25 C.2.1 Cylinders without a metallic liner . 25 C.2.2 Cylinders with a metallic liner . 30 Annex D (informative)

Conditions for 15-year periodic inspection interval of welded steel cylinders manufactured before 1st January 2015 . 33 D.1 General . 33 D.2 Concept of control. 33 D.3 Conditions . 33 Annex E (informative)

Guidance on conditions for 10-year periodic inspection interval of composite cylinders . 35 Annex F (normative)

Specific Periodic inspection procedure for over-moulded cylinders (OMC) . 36 F.1 General . 36 F.1.1 Introduction. 36 F.1.2 Valve . 36 F.1.3 Marking and records . 36 F.2 Periodic inspection . 36 F.2.1 General . 36 F.2.2 External visual inspection . 37 F.2.2.1 General . 37 F.2.2.2 Sampling . 37 F.2.2.2.1 General . 37 F.2.2.2.2 Peeling and corrosion test . 37 F.2.2.2.3 Adhesion tests of the polyurethane material . 38 F.2.2.3 Test frequency . 38 F.2.3 Burst test . 38 F.2.4 Rejection criteria and annual production sampling . 38 F.2.5 Periodic inspection tests reports and records . 40 F.3 Lifetime . 40 Annex G (informative)

Example of an Over-Moulded Cylinder . 42 Bibliography . 44 SIST EN 16728:2016

European foreword This document (EN 16728:2016) has been prepared by Technical Committee CEN/TC 286 “Liquefied petroleum gas equipment and accessories”, the secretariat of which is held by NSAI. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by September 2016, and conflicting national standards shall be withdrawn at the latest by September 2016. Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights. This document in conjunction with EN 1440:2016 supersedes EN 1440:2008+A1:2012 and deals with the periodic inspection requirements for transportable refillable LPG cylinders that are not covered by EN 1440. This document has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association. This European Standard has been submitted for reference into the RID [1] and the technical annexes of the ADR [2]. NOTE These regulations take precedence over any clause of this standard. It is emphasized that RID/ADR are being revised regularly at intervals of two years which may lead to temporary non- compliances with the clauses of this standard. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 16728:2016

— External visual inspection as described in 5.2 and Annex A; — Proof pressure test (hydraulic proof pressure test or, with the agreement of the competent authority, a pneumatic proof test and leak test) as described in 5.3; — Internal condition check as described in 5.4.1 and Annex A; — Inspection of threads as described in 5.5; — Inspection of valves as described in 5.6. Welded steel cylinders in conformance with EN 14140 or equivalent standard – manufactured before 1st January 2015. — 10 years; or — 15 years with the agreement of the competent authority and under the conditions of Annex D. Welded aluminium cylinders. 10 years — External visual inspection as described in 5.2 and Annex B; — Proof pressure tests (hydraulic proof pressure test or, with the agreement of the competent authority, a pneumatic proof test and leak test) as described in 5.3; — Internal condition check as described in 5.4.1; — Inspection of threads as described in 5.5; — Inspection of valves as described in 5.6. Composite cylinders As determined by the competent authority. Guidance for 10 year periodic inspection interval described in Annex E. — External visual inspection as described in 5.2 and Annex C; — Proof pressure test (hydraulic proof pressure test or, with the agreement of the competent authority, a pneumatic proof test and leak test) as described in 5.3; — Internal condition check as described in 5.4.2; — Inspection of threads as described in 5.5; — Inspection of valves as described in 5.6. Over-moulded cylinders Annex F provides specific additional inspection requirements with destructive tests with an interval of maximum 3 years after putting in service and thereafter every 5 years. — External visual inspection as described in F.2.2; — Burst Tests as described in F.2.3; — Internal condition check as described in 5.4; — Inspection of threads as described in 5.5 — Inspection of valves as described in 5.6. SIST EN 16728:2016

at the base of the cylinder;

the junction between the cylindrical shell and the foot-ring;

the junction between the cylindrical shell and the valve guard or shroud;

the cylindrical shell and the valve guard or shroud; and

hidden corrosion e.g. under handles, applying the criteria for rejection given in Annex A and

Annex B as appropriate. c) other defects (e.g. depressed bung or fire damage), while applying the criteria for rejection given in Annex A and Annex B as appropriate; d) integrity of all permanent attachments including protective casing where relevant; and SIST EN 16728:2016

Specific requirements for external visual inspection for welded steel LPG cylinders in accordance with EN 14140 or equivalent standard A.1 General Where applicable, the protective casing shall be removed prior to inspection. The owner of the cylinder (or their authorized representative) shall provide a written scheme to the periodic inspection station, which contains acceptance/rejection criteria for the physical and material defects and heat damage to the cylinder. The procedure for establishing the acceptance/rejection criteria is described in A.2. These criteria shall be at least those established by the manufacturer, taking into account the design conditions of the cylinder, e.g. wall thickness, material, protective casing. The procedure and the records of the test results shall be witnessed and assessed by a competent authority. The descriptions of defects for carbon steel cylinders are shown in Table A.1, Table A.2 and Table A.3. The descriptions of defects for stainless steel cylinders are shown in Table A.4, Table A.5 and Table A.6. A.2 Procedure for establishing rejection crite

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...