EN 13463-5:2011

(Main)Non-electrical equipment intended for use in potentially explosive atmospheres - Part 5: Protection by constructional safety 'c'

Non-electrical equipment intended for use in potentially explosive atmospheres - Part 5: Protection by constructional safety 'c'

1.1 This European Standard specifies the requirements for the design and construction of non-electrical equipment, intended for use in potentially explosive atmospheres, protected by the type of protection Constructional Safety "c".

1.2 This European Standard supplements the requirements in EN 13463-1, the contents of which also apply in full to equipment constructed in accordance with this European Standard.

1.3 The type of ignition protection described in the standard can be used either on its own or in combination with other types of ignition protection to meet the requirements for equipment of Group I, category M2 or Group II, categories 1 and 2 depending on the ignition hazard assessment in EN 13463-1. Type of ignition protection "c" is not applicable for Group I for M1. These requirements are specified in EN 50303.

NOTE Most category 3 equipment, only needs to meet the requirements of EN 13463-1, but some category 3 equipment may have to meet the requirements of European Standard for some of the ignition sources identified in the ignition hazard assessment.

Nicht-elektrische Geräte für den Einsatz in explosionsgefährdeten Bereichen - Teil 5: Schutz durch konstruktive Sicherheit 'c'

Diese Europäische Norm legt die Anforderungen an den Aufbau und die Konstruktion von nichtelektrischen

Geräten fest, die in explosionsgefährdeten Bereichen eingesetzt werden sollen und durch die

Schutzart Konstruktive Sicherheit „c“ geschützt sind.

1.2 Diese Europäische Norm ergänzt die Anforderungen von EN 13463-1, deren Inhalt insgesamt auch für

Geräte gilt, deren Konstruktion der vorliegenden Europäische Norm entspricht.

1.3 Um die Anforderungen an Geräte der Gruppe I, Kategorien M2 oder der Gruppe II, Kategorien 1 und 2

entsprechend der Bewertung der Zündgefahr in EN 13463-1 zu erfüllen, kann die in der Norm beschriebene

Zündschutzart entweder einzeln oder in Verbindung mit anderen Zündschutzarten verwendet werden. Die

Zündschutzart 'c' gilt nicht für Gruppe I, Kategorie M1. Diese Anforderungen sind in EN 50303 festgelegt.

ANMERKUNG Die meisten Geräte der Kategorie 3 brauchen nur die Anforderungen von EN 13463-1 zu erfüllen,

jedoch kann es sein, dass einige Geräte der Kategorie 3 die Anforderungen der vorliegenden Europäische Norm an einige

der in der Bewertung der Zündgefahr bezeichneten Zündquellen erfüllen müssen.

Appareils non électriques destinés à être utilisés en atmosphères explosibles - Partie 5: Protection par sécurité de construction 'c'

La présente Norme européenne spécifie les exigences relatives à la conception et à la construction des

appareils non électriques, destinés à être utilisés dans les atmosphères explosibles et protégés par le mode de

protection Sécurité par construction ‘c’.

1.2 La présente Norme européenne complète les exigences de l’EN 13463-1, dont le contenu s’applique

également dans sa totalité aux appareils construits conformément à cette Norme européenne.

1.3 Le mode de protection contre l’inflammation décrit dans la norme peut être utilisé soit seul, soit en

combinaison avec d’autres modes de protection contre l’inflammation pour répondre aux exigences des

appareils de la Catégorie M2 du Groupe I ou des Catégories 1 et 2 du Groupe II, en fonction de l’évaluation

du risque d’inflammation selon l’EN 13463-1. Le mode de protection contre l’inflammation ‘c’ ne s’applique

pas à la Catégorie M1 du Groupe I. Ces exigences sont spécifiées dans l’EN 50303.

NOTE La plupart des appareils de Catégorie 3 n’ont besoin de satisfaire qu’aux exigences de l’EN 13463-1, mais les

exigences de la présente Norme européenne peuvent s’appliquer à certains appareils de Catégorie 3 pour quelques

sources d’inflammation identifiées dans l’évaluation du risque d’inflammation.

Neelektrična oprema za uporabo v potencialno eksplozivnih atmosferah - 5. del: Zaščita s konstrukcijsko varnostjo “c”

1.1 Ta evropski standard določa zahteve za načrtovanje in konstrukcijo neelektrične opreme, namenjene uporabi v potencialno eksplozivnih atmosferah, zaščiteno z vrsto zaščite konstrukcijska varnost »c«.

Ta standard dopolnjuje zahteve iz EN 13463-1, vsebina katerih velja v celoti tudi za opremo, konstruirano v skladu s tem standardom.

1.3 Oprema, ki je v skladu z ustrezno točko tega standarda, izpolnjuje zahteve za naslednje kategorije:

Skupina opreme I, Kategorija M2;

Skupina opreme II, Kategorija 2 G ali 2D;

Skupina opreme II Kategorija 1G ali 1D.

OPOMBA: Zahteve za Skupino I, Kategorijo opreme M1 so podane v EN 50303, ki določa zahteve za električno in neelektrično opremo.

1.4 Tip zaščite pred vžigom, opisan v tem standardu, se lahko uporabi samostojno ali v kombinaciji z drugimi tipi zaščite pred vžigom, da so izpolnjene zahteve za opremo Skupine I, kategorij M1 in M2 ali skupine II, kategorij 1 in 2, odvisno od ocene nevarnosti za vžig v EN 13463-1.

General Information

- Status

- Withdrawn

- Publication Date

- 19-Jul-2011

- Withdrawal Date

- 08-Feb-2026

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 06-Apr-2016

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 23-Jul-2011

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN ISO 19353:2019 - Safety of machinery - Fire prevention and fire protection (ISO 19353:2019) - Effective Date

- 28-Jan-2026

- Effective Date

- 13-Apr-2016

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 13463-5:2011 is a standard published by the European Committee for Standardization (CEN). Its full title is "Non-electrical equipment intended for use in potentially explosive atmospheres - Part 5: Protection by constructional safety 'c'". This standard covers: 1.1 This European Standard specifies the requirements for the design and construction of non-electrical equipment, intended for use in potentially explosive atmospheres, protected by the type of protection Constructional Safety "c". 1.2 This European Standard supplements the requirements in EN 13463-1, the contents of which also apply in full to equipment constructed in accordance with this European Standard. 1.3 The type of ignition protection described in the standard can be used either on its own or in combination with other types of ignition protection to meet the requirements for equipment of Group I, category M2 or Group II, categories 1 and 2 depending on the ignition hazard assessment in EN 13463-1. Type of ignition protection "c" is not applicable for Group I for M1. These requirements are specified in EN 50303. NOTE Most category 3 equipment, only needs to meet the requirements of EN 13463-1, but some category 3 equipment may have to meet the requirements of European Standard for some of the ignition sources identified in the ignition hazard assessment.

1.1 This European Standard specifies the requirements for the design and construction of non-electrical equipment, intended for use in potentially explosive atmospheres, protected by the type of protection Constructional Safety "c". 1.2 This European Standard supplements the requirements in EN 13463-1, the contents of which also apply in full to equipment constructed in accordance with this European Standard. 1.3 The type of ignition protection described in the standard can be used either on its own or in combination with other types of ignition protection to meet the requirements for equipment of Group I, category M2 or Group II, categories 1 and 2 depending on the ignition hazard assessment in EN 13463-1. Type of ignition protection "c" is not applicable for Group I for M1. These requirements are specified in EN 50303. NOTE Most category 3 equipment, only needs to meet the requirements of EN 13463-1, but some category 3 equipment may have to meet the requirements of European Standard for some of the ignition sources identified in the ignition hazard assessment.

EN 13463-5:2011 is classified under the following ICS (International Classification for Standards) categories: 13.230 - Explosion protection. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13463-5:2011 has the following relationships with other standards: It is inter standard links to EN 13463-5:2003, EN 60529:1991, EN 13463-1:2009, EN 1127-2:2014, EN ISO 284:2025, EN 1127-1:2019, EN ISO 5359:2014, EN 13501-1:2007+A1:2009, EN 13463-6:2005, EN ISO 4414:2010, EN 13237:2024, EN ISO 4413:2010, EN ISO 19353:2019, EN ISO 80079-37:2016, EN 1755:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13463-5:2011 is associated with the following European legislation: EU Directives/Regulations: 2014/34/EU, 94/9/EC; Standardization Mandates: M/BC/CEN/92/46. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13463-5:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Nicht-elektrische Geräte für den Einsatz in explosionsgefährdeten Bereichen - Teil 5: Schutz durch Konstruktive Sicherheit 'c'Appareils non électriques destinés à être utilisés en atmosphères explosibles - Partie 5: Protection par sécurité de construction 'c'Non-electrical equipment intended for use in potentially explosive atmospheres - Part 5: Protection by constructional safety 'c'13.230Varstvo pred eksplozijoExplosion protectionICS:Ta slovenski standard je istoveten z:EN 13463-5:2011SIST EN 13463-5:2011en,fr,de01-oktober-2011SIST EN 13463-5:2011SLOVENSKI

STANDARDSIST EN 13463-5:20041DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13463-5

July 2011 ICS 13.230 Supersedes EN 13463-5:2003English Version

Non-electrical equipment intended for use in potentially explosive atmospheres - Part 5: Protection by constructional safety 'c'

Appareils non électriques destinés à être utilisés en atmosphères explosibles - Partie 5: Protection par sécurité de construction 'c'

Nicht-elektrische Geräte für den Einsatz in explosionsgefährdeten Bereichen - Teil 5: Schutz durch konstruktive Sicherheit 'c' This European Standard was approved by CEN on 11 June 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13463-5:2011: ESIST EN 13463-5:2011

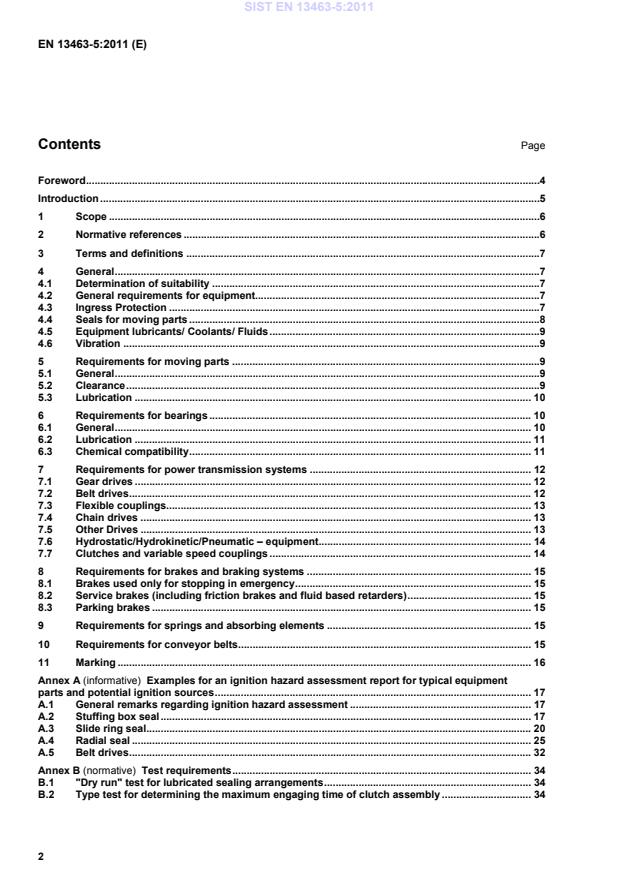

Examples for an ignition hazard assessment report for typical equipment parts and potential ignition sources . 17A.1General remarks regarding ignition hazard assessment . 17A.2Stuffing box seal . 17A.3Slide ring seal . 20A.4Radial seal . 25A.5Belt drives . 32Annex B (normative)

Test requirements . 34B.1"Dry run" test for lubricated sealing arrangements . 34B.2Type test for determining the maximum engaging time of clutch assembly . 34SIST EN 13463-5:2011

Significant technical changes between this European Standard and EN 13463-5:2003 . 36Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 94/9/EC . 39Bibliography . 41 Tables Table A.1 — Stuffing box seal . 18Table A.2 — Slide ring seal . 21Table A.3 — Radial seal . 26Table A.4 — Belt drives . 33Table C.1 — Significant changes between this European Standard and EN 13463-5:2003 . 36Table ZA.1 — Correspondence between this European Standard and Directive 94/9 EC . 39 SIST EN 13463-5:2011

EN ISO 4413, Hydraulic fluid power - General rules and safety requirements for systems and their components (ISO 4413:2010)

EN ISO 4414, Pneumatic fluid power - General rules and safety requirements for systems and their components (ISO 4414:2010)

Furthermore, it shall also have been determined that, by enhancing or increasing the safety of certain vulnerable parts, the required level of protection is ensured against the possibility of ignition sources occurring. 4.2 General requirements for equipment All parts shall be capable of functioning in conformity with the operational parameters established by the manufacturer throughout their expected lifetime. They shall be sufficiently firm and durable to withstand the mechanical and thermal stresses to which they are intended to be subjected.

This also applies to interconnecting parts of equipment including joints (e.g. cemented, soldered or welded joints). 4.3 Ingress Protection 4.3.1 General The degree of ingress protection (IP) provided by the outer enclosures of equipment depends upon its intended duty and the type of environment it is designed to be used in. An appropriate rating, according to IP category 1, as specified in 13.4 of EN 60529:1991, shall be determined as part of the ignition hazard assessment (see 4.1) and shall be able to prevent foreign objects and/or water entering the equipment which could: 1) Increase the probability of ignition, by for example, allowing combustible dust, with a lower ignition temperature than the potentially explosive atmosphere, to form a layer on hot internal components or parts of the equipment; and/or 2) make contact with moving parts, resulting in the creation of an effective ignition source. SIST EN 13463-5:2011

NOTE An enclosure can be required for other safety reasons, e.g. IP 2X to prevent parts of the body coming into contact with rotating parts. 4.4 Seals for moving parts 4.4.1 Unlubricated gaskets, seals, sleeves, bellows and diaphragms

Unlubricated gaskets, seals, sleeves, bellows and diaphragms shall not become an effective ignition source, e.g. If there is a risk of mechanically generated sparks which can become an effective ignition source, light metals shall not be used (see EN 13463-1). NOTE Sleeves made e.g. of elastomeric material, PTFE or similar material, graphite and ceramics might be suitable. Non-metallic materials shall be resistant to distortion and degradation without reducing the effectiveness of explosion protection (see EN 13463-1). 4.4.2 Stuffing box seals (packed glands) Stuffing-box seals (packed glands) shall only be used if a temperature rise above the permitted maximum surface temperature can be excluded. NOTE Otherwise a device to monitor temperatures and switch off equipment should be applied (see EN 13463-6). 4.4.3 Lubricated seals Seals which normally require the presence of a replenishable lubricant to prevent hot surfaces occurring at their interface with equipment parts a) shall be designed to ensure the sufficient presence of lubricant; or

b) shall be protected by one of the following means: 1) provision of an effective means to monitor the continued presence of the lubricant; or 2) provision of a temperature detection device to warn of increasing temperatures; or SIST EN 13463-5:2011

NOTE 1 In the case of parts protected by fluids see EN 13463-8. NOTE 2 See 4.6, Note 2 for the precautions which may be adopted for the purpose of expected malfunction. SIST EN 13463-5:2011

Where equipment is designed to process liquids as part of its duties and the presence of the process liquid is essential for the purpose of lubrication, cooling, quenching, or ignition prevention, this shall be stated in the instructions for safe use, as required by EN 13463-1. The instructions for safe use shall state the correct way for bringing a self priming pump in operation. 6 Requirements for bearings 6.1 General Bearings are basically divided into three types, sliding plane motion, sliding rotary motion and rolling element. When assessing bearings, as part of the ignition hazard assessment required by EN 13463-1, the following (which is not a definitive list) shall be taken into account: the bearing shall be designed for the equipment’s intended duty e.g. speed, temperature, loading and variations of speed and loading; the bearing’s basic rated life. As described in ISO 281 for rolling element bearings. (see also Note 1 below); the proper fit of the bearings in their housing and on the shaft (tolerances, roundness and surface quality), taking into consideration the vertical and axial loads on the bearing with respect to shaft and housing; the correct alignment of the bearings; the axial and radial loading of the bearings caused by thermal expansion of the shaft and the housing under the most severe operating conditions; protection of the bearing from ingress of unintended liquids and solids, if necessary to avoid premature failure; protection of the bearing from electrical currents, including stray circulating currents (which can cause, for example, incendive sparking, or spark erosion leading to premature failure, at the point of contact between the ball and ball race of a ball bearing). If bearings act as an insulator, constructive measures, e.g. earthing or bonding, shall be taken, so that the isolation of parts of the equipment is avoided (see EN 13463-1:2009, 6.7.2); the provision of adequate lubrication, according to the lubricating regime necessary for the type of bearing (e.g. for sliding bearings, boundary lubrication, mixed film, or full film hydrodynamic lubrication are the most commonly used regimes); SIST EN 13463-5:2011

The requirements of 5.3 apply. 6.3 Chemical compatibility

Bearings shall be made of materials resistant to the liquids, or vapours, in which they are intended to be used. Similarly, the material used in the construction of the bearing, including any bearing cages, shall be resistant to any liquids or solvents which can come into contact with them. Particular attention shall be given to the possibility of swelling of non-metallic parts. Where liquids or vapours can dissolve in the lubricant of the bearings, the lubricant shall remain "fit for purpose" even in this condition. SIST EN 13463-5:2011

b) synchronous (timing) belt drives, with positive interaction between belt teeth and pulley grooves such that friction heat build up does not normally occur. 7.2.2 Power transmission belts shall not be capable of developing an incendive electrostatic discharge during operation, see Annex B for conductivity criteria and measurement requirements. NOTE 1 ISO 1813 - friction belt drives, and ISO 9563 - synchronous belt drives, specify methods of measuring belt electrical resistance, and give resistance values intended for use where belt drives work in explosive atmospheres. However, the state of the art is set out in CLC/TR 50404. The Technical Report particularly gives advice on the use of belt drives for particular categories and explosive atmospheres.

Where the electrical resistance of a belt is known to increase over time in normal service, the manufacturer shall specify a time period for re-testing or replacement of the belt.

NOTE 2 Whilst conductive of electrostatic charges, belts should not be considered a suitable earth path between the drive and driven pulleys, for lower voltage potentials.

7.2.3 For drives which could cause surfaces to exceed the maximum surface temperature if the belt becomes slack or slips on the pulley, the correct belt tension shall be maintained. NOTE Devices used to ensure correct belt tension can also serve to detect broken belts. 7.2.4 With drives which could cause surfaces to exceed the maximum temperature if they run out of alignment, true alignment shall be maintained (see 7.2.3). NOTE A correctly designed and installed belt drive, operating near the limit of its capability, may produce surface temperatures in normal running of up to: Friction drives

50 K above ambient Synchronous drives

25 K above ambient. Temperature rises greater than the above will likely reduce the working life of belts. 7.2.5 The supporting frame, chassis, or structure, of equipment containing belt(s) shall be constructed of electrically conducting material and shall be so arranged as to provide a leakage path to earth for any static electricity which occurs on the belt(s). The frame, chassis or structure includes the driving pulley or drum and any idler pulleys or rollers associated with the belt drive. Specific electrical bonding between the separate parts and earth shall be provided where the electrical resistance of the leakage path to earth exceeds 1 MΩ. SIST EN 13463-5:2011

7.3 Flexible couplings 7.3.1 When operated within their design parameters, flexible couplings shall not generate hot surfaces, which exceed the permitted maximum surface temperature, nor disintegrate in a way which would create the risk of an ignition source, through for example contact between moving metal parts. Manufacturers shall define the design parameters using established calculation methods or testing.

NOTE Suitable calculation methods are given in DIN 740-2. 7.3.2 Flexible couplings shall be of a design and built of materials such as to exclude the possibility of an incendive electrostatic discharge. NOTE This does not necessitate an electrical conductive path (through the flexible coupling) between the coupled shafts unless specified as necessary to complete an earth path from other parts of the coupled machinery. 7.3.3 Where flexible couplings employing non-metallic elements are used to separate metallic components which could otherwise contact and cause incendive sparks, user instructions shall specify the installation and maintenance procedures needed to prevent metal/metal contact during normal use. 7.3.4 Flexible couplings designed to accommodate shaft misalignment shall be installed such that misalignment does not exceed the manufacturers’ maximum values, with due regard to any foreseeable movement or flexure of machinery after installation. In particular, the bores in the hubs shall be sufficiently accurate to ensure concentric running of coupling hubs, and of appropriate diameter tolerance to help ensure secure and accurate shaft fixing. 7.3.5 The manufacturers instructions for safe use shall include maximum torque, maximum rotational speed, limits on angular and linear alignment deviations, the temperature rise of polymeric or metal spring components during normal operation at the limiting parameters, and any other information necessary for safe use. 7.4 Chain drives Chain drives shall comply with the requirements of Clause 5.

Chain drives operating at speeds greater than 1 m/s, and containing a potential ignition source (identified by the ignition hazard assessment required by EN 13463-1), shall be fitted with means to ensure continuous positive engagement of the chain with its associated sprocket. Where this is not possible, it shall be fitted with a device that removes the driving power to the drive sprocket in the event of the chain breaking, becoming disengaged, or slackening beyond a limit specified by the information for use (see EN 13463-6). 7.5 Other Drives Other drives shall fulfil the requirements set out in Clause 5. SIST EN 13463-5:2011

NOTE 1 For Group I equipment this can be achieved by using a liquid with a fire resistance rating of at least "2", when tested in accordance with the "Community of Six Spray ignition Test" and a persistence of flame not exceeding 30 s, when tested in accordance with the "Wick test", as described in 3.1.1 and 3.2 of the European Safety and Health Commission for Mining and Other Extractive Industries (SHCMOEI) document - Requirements and tests applicable to fire-resistant hydraulic fluids used for power transmission and control (Hydrostatic and Hydrokinetic)", 1994 [1].

NOTE 2 National legislation in member states can require the use of different fire resistant fluids in certain hydraulic systems. 7.6.6 Air compressors used for pneumatic equipment shall: incorporate a filter on the intake system to prevent the ingress of dust or similar foreign material into the parts where compression takes place; contain only lubricants which are resistant to carbonisation. NOTE 1 Carbonisation of compressor lubricant (caused by exposure to elevated temperatures) results in the formation of oily carbon deposits in the compressor delivery which can cause it to overheat and explode. NOTE 2 For fluids operating at high pressure (e.g. inside compressors) allowance should be made for the fact that the ignition temperature is lowered by increased operating pressure. 7.7 Clutches and variable speed couplings 7.7.1 Clutches and couplings, shall be arranged or monitored (see EN 13463-6) so that no fixed or moving part that is exposed to the potentially explosive atmosphere exceeds the maximum surface temperature of the equipment. In the case of plastic or other non-metallic parts of a clutch or coupling, their material or arrangement shall exclude the possibility of an incendive electrostatic discharge. NOTE Examples of the above types of clutch and coupling are friction plate clutches, bell type centrifugal clutches, fluid couplings and scoop-controlled fluid couplings. 7.7.2 During the period of full engagement, there shall be no slipping, or similar relative movement between the input and output mechanisms likely to cause a hot surface exceeding the maximum surface temperature. NOTE The above requirements can be achieved by one or more of the following preventative methods (see EN 13463-6): SIST EN 13463-5:2011

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...