EN 10083-2:2006

(Main)Steels for quenching and tempering - Part 2: Technical delivery conditions for non alloy steels

Steels for quenching and tempering - Part 2: Technical delivery conditions for non alloy steels

This part of EN 10083, in addition to Part 1, specifies the technical delivery requirements for:

semi-finished products, hot formed, e.g. blooms, billets, slabs (see NOTES 2 and 3 in EN 10083-1:2006, Clause 1),

bars (see NOTE 2 in EN 10083-1:2006, Clause 1),

rod,

wide flats,

hot-rolled strip and sheet/plate,

forgings (see NOTE 2 in EN 10083-1:2006, Clause 1),

manufactured from the direct hardening non alloy steels for quenching and tempering and the non alloy flame and induction hardening steels and supplied in one of the heat treatment conditions given for the different types of products in Table 1, lines 2 to 7, and in one of the surface conditions given in Table 2.

The steels are generally intended for the manufacture of quenched and tempered, flame or induction hardened machine parts, but can also be used in the normalized condition.

The requirements for mechanical properties given in this document are restricted to the sizes given in Table 9 and Table 10.

NOTE This document does not apply for bright steel products. For bright steel products EN 10277-1 and EN 10277-5 apply.

In special cases, variations in these technical delivery requirements or additions to them may be agreed at the time of enquiry and order (see Annex A).

Vergütungsstähle - Teil 2: Technische Lieferbedingungen für unlegierte Stähle

Dieser Teil der EN 10083 enthält in Ergänzung zu Teil 1 die allgemeinen technischen Lieferbedingungen für

- Halbzeug, warmgeformt, zum Beispiel Vorblöcke, Knüppel, Vorbrammen (siehe Anmerkungen 2 und 3 in EN 10083-1:2006, Abschnitt 1),

- Stabstahl (siehe Anmerkung 2 in EN 10083-1:2006, Abschnitt 1),

- Walzdraht,

- Breitflachstahl,

- warmgewalztes Blech und Band,

- Schmiedestücke (siehe Anmerkung 2 in EN 10083-1:2006, Abschnitt 1),

hergestellt aus unlegierten Vergütungsstählen und unlegierten Stählen zum Flamm- und Induktionshärten, welche in einem der für die verschiedenen Erzeugnisformen in Tabelle 1, Zeilen 2 bis 7 angegebenen Wärmebehandlungszustände und in einer der in Tabelle 2 angegebenen Oberflächenausführungen geliefert werden.

Die Stähle sind im Allgemeinen zur Herstellung vergüteter, flamm- oder induktionsgehärteter Maschinenteile vorgesehen, die teilweise auch im normalgeglühten Zustand verwendet werden.

Die Anforderungen an die in dieser Europäischen Norm gegebenen mechanischen Eigenschaften beschränken sich auf die in Tabelle 9 und Tabelle 10 angegebenen Maße.

ANMERKUNG Diese Norm gilt nicht für Blankstahlprodukte. Für Blankstahl gelten die EN 10277-1 und die EN 10277-5.

In Sonderfällen können bei der Anfrage und Bestellung Abweichungen von oder Zusätze zu diesen technischen Lieferbedingungen vereinbart werden (siehe Anhang A).

Aciers pour trempe et revenu - Partie 2: Conditions techniques de livraison des aciers non alliés

Cette partie de la présente norme prEN 10083, qui complète la Partie 1, précise les exigences techniques de

livraison des :

- demi-produits formés à chaud, comme par exemple les blooms, billettes et brames (voir NOTES 2 et 3 du

prEN 10083-1:2006, Article 1) ;

- barres (voir NOTE 2 du prEN 10083-1:2006, Article 1) ;

- fils machine ;

- larges plats ;

- tôles/feuillards et bandes laminés à chaud ;

- pièces forgées (voir NOTE 2 du prEN 10083-1:2006, Article 1) ;

fabriqués à partir d'aciers non alliés à trempe directe pour les produits trempés et revenus et d'aciers non alliés par

trempe au chalumeau et par induction et livrés dans l'un des états de traitement thermique donnés pour les

différents types de produits dans le Tableau 1, lignes 2 à 7, et dans l'un des états de surface donnés dans le

Tableau 2.

D'une manière générale, ces aciers sont destinés à la fabrication de pièces mécaniques trempées et revenues ou,

à la fabrication de pièces mécaniques trempées par induction ou au chalumeau mais ils peuvent être également en

partie utilisés à l'état normalisé.

Les exigences en matière de propriétés mécaniques données dans la présente Norme européenne sont limitées

aux dimensions données dans les Tableaux 9 et 10.

NOTE La présente norme ne s'applique pas aux produits en acier brillant. Les produits en acier brillant font l'objet des

normes EN 10277-1 et EN 10277-5.

Dans certains cas particuliers, les variations ou additifs par rapport aux conditions techniques de livraison peuvent

faire l'objet d'un accord au moment de l'appel d'offres et de la commande (voir Annexe A).

Jekla za poboljšanje - 2. del: Tehnični dobavni pogoji za nelegirana jekla

General Information

- Status

- Withdrawn

- Publication Date

- 01-Aug-2006

- Withdrawal Date

- 10-Feb-2026

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 20-Jun-2018

- Completion Date

- 11-Feb-2026

Not Harmonized89/106/EEC - Construction products

Not Harmonized97/23/EC - Pressure equipment

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 28-Jan-2026

- Refers

EN ISO 643:2024 - Steels - Micrographic determination of the apparent grain size (ISO 643:2024) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Sponsored listings

Frequently Asked Questions

EN 10083-2:2006 is a standard published by the European Committee for Standardization (CEN). Its full title is "Steels for quenching and tempering - Part 2: Technical delivery conditions for non alloy steels". This standard covers: This part of EN 10083, in addition to Part 1, specifies the technical delivery requirements for: semi-finished products, hot formed, e.g. blooms, billets, slabs (see NOTES 2 and 3 in EN 10083-1:2006, Clause 1), bars (see NOTE 2 in EN 10083-1:2006, Clause 1), rod, wide flats, hot-rolled strip and sheet/plate, forgings (see NOTE 2 in EN 10083-1:2006, Clause 1), manufactured from the direct hardening non alloy steels for quenching and tempering and the non alloy flame and induction hardening steels and supplied in one of the heat treatment conditions given for the different types of products in Table 1, lines 2 to 7, and in one of the surface conditions given in Table 2. The steels are generally intended for the manufacture of quenched and tempered, flame or induction hardened machine parts, but can also be used in the normalized condition. The requirements for mechanical properties given in this document are restricted to the sizes given in Table 9 and Table 10. NOTE This document does not apply for bright steel products. For bright steel products EN 10277-1 and EN 10277-5 apply. In special cases, variations in these technical delivery requirements or additions to them may be agreed at the time of enquiry and order (see Annex A).

This part of EN 10083, in addition to Part 1, specifies the technical delivery requirements for: semi-finished products, hot formed, e.g. blooms, billets, slabs (see NOTES 2 and 3 in EN 10083-1:2006, Clause 1), bars (see NOTE 2 in EN 10083-1:2006, Clause 1), rod, wide flats, hot-rolled strip and sheet/plate, forgings (see NOTE 2 in EN 10083-1:2006, Clause 1), manufactured from the direct hardening non alloy steels for quenching and tempering and the non alloy flame and induction hardening steels and supplied in one of the heat treatment conditions given for the different types of products in Table 1, lines 2 to 7, and in one of the surface conditions given in Table 2. The steels are generally intended for the manufacture of quenched and tempered, flame or induction hardened machine parts, but can also be used in the normalized condition. The requirements for mechanical properties given in this document are restricted to the sizes given in Table 9 and Table 10. NOTE This document does not apply for bright steel products. For bright steel products EN 10277-1 and EN 10277-5 apply. In special cases, variations in these technical delivery requirements or additions to them may be agreed at the time of enquiry and order (see Annex A).

EN 10083-2:2006 is classified under the following ICS (International Classification for Standards) categories: 77.140.10 - Heat-treatable steels. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 10083-2:2006 has the following relationships with other standards: It is inter standard links to EN 10083-2:1991 + A1:1996, EN ISO 642:2024, EN ISO 643:2024, EN ISO 14284:2022, EN ISO 377:2017, EN 10160:1999, EN ISO 6506-1:2014, EN ISO 9443:2018, CEN/TR 10261:2023, EN 10163-2:2004, EN 10027-1:2016, EN ISO 683-2:2018, EN ISO 3887:2023, EN 10308:2001, EN 10020:2000. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 10083-2:2006 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC, 97/23/EC; Standardization Mandates: M/071, M/120, M/BC/CEN/86/1. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 10083-2:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

6,67(16/29(16.,QRYHPEHU67$1'$5'-HNOD]DSREROMãDQMHGHO7HKQLþQLGREDYQLSRJRML]DQHOHJLUDQDMHNOD6WHHOVIRUTXHQFKLQJDQGWHPSHULQJ3DUW7HFKQLFDOGHOLYHU\FRQGLWLRQVIRUQRQDOOR\VWHHOV !"#$%&'( )&!*- . 5HIHUHQþQDãWHYLOND6,67(1HQ,&6

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 10083-2August 2006ICS 77.140.10Supersedes EN 10083-2:1991

English VersionSteels for quenching and tempering - Part 2: Technical deliveryconditions for non alloy steelsAciers pour trempe et revenu - Partie 2: Conditionstechniques de livraison des aciers non alliésVergütungsstähle - Teil 2: Technische Lieferbedingungenfür unlegierte StähleThis European Standard was approved by CEN on 30 June 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2006 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 10083-2:2006: E

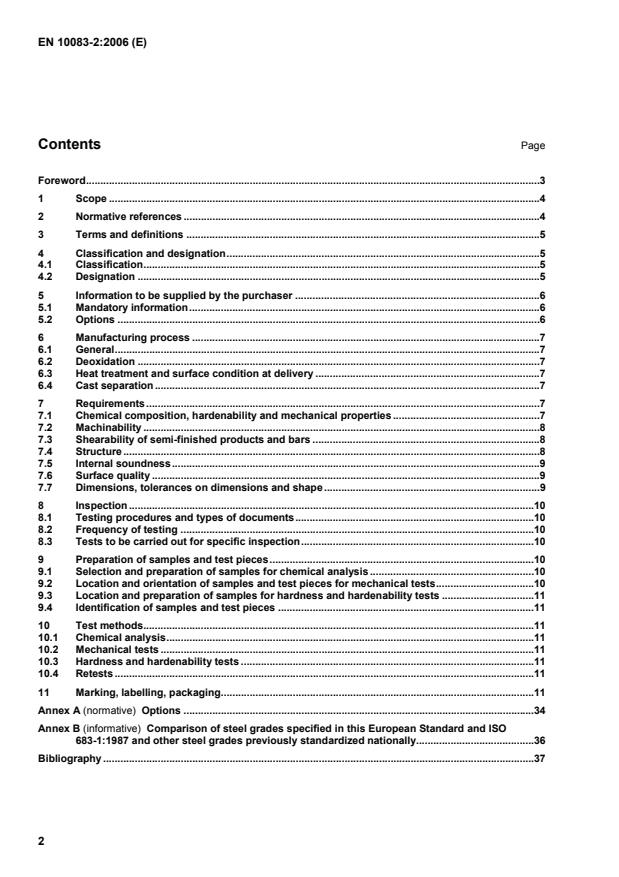

Options.34 Annex B (informative)

Comparison of steel grades specified in this European Standard and ISO 683-1:1987 and other steel grades previously standardized nationally.36 Bibliography.37

EN 10083-1:1991 +A1:1996, Quenched and tempered steels – Part 1: Technical delivery conditions for special steels EN 10083-2: 1991 +A1:1996, Quenched and tempered steels – Part 2: Technical delivery conditions for unalloyed quality steels

EN 10083-3:1995, Quenched and tempered steels – Part 3: Technical delivery conditions for boron steels and of EURONORM 86-70, Flame and induction hardening steels – Quality specifications According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

This document does not apply for bright steel products. For bright steel products EN 10277-1 and EN 10277-5 apply. In special cases, variations in these technical delivery requirements or additions to them may be agreed at the time of enquiry and order (see Annex A). 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 10002-1, Metallic materials – Tensile testing – Part 1: Method of test at ambient temperature

EN 10020, Definition and classification of grades of steel EN 10027-1, Designation systems for steels – Part 1: Steel names EN 10027-2, Designation systems for steel – Part 2: Numerical system EN 10045-1, Metallic materials – Charpy impact test – Part 1: Test method EN 10083-1:2006, Steels for quenching and tempering – Part 1: General technical delivery conditions EN 10160, Ultrasonic testing of steel flat product of thickness equal or greater than 6 mm (reflection method) EN 10163-2, Delivery requirements for surface condition of hot-rolled steel plates, wide flats and sections – Part 2: Plate and wide flats

EN 10083-1:2006, Figure 1 or Figures 2 and 3 (see also footnote a in Table 1). For steel plates > 10 mm thickness and bars > 100 mm diameter in the normalized condition (+N), it may be agreed at the time of enquiry and order that instead of the tensile test the hardness test is performed at the same region, where otherwise the sample for the tensile test piece would be taken from. The hardness test should be performed and from this so that the tensile strength values can be calculated according to EN ISO 18265. The calculated tensile strength shall comply to Table 10. 7.1.5 Surface hardness For the surface hardness of special steels after flame and induction hardening, the specifications in Table 11 apply. 7.2 Machinability All steels delivered in the soft annealed (+A) condition are machinable. Where improved machinability is required, the grades with a specified sulphur range should be ordered and/or with a specific treatment to improve machinability (e.g. Ca treatment), see also Table 3, footnote c. 7.3 Shearability of semi-finished products and bars 7.3.1 Under suitable conditions (avoiding local stress peaks, pre-heating, application of blades with a profile adapted to that of the product, etc.), all steels are shearable in the soft-annealed (+A) and normalized (+N) condition. 7.3.2 Steel grades C45, C45E, C45R, C50E, C50R, C55, C55E, C55R, C60, C60E, C60R and 28Mn6 (see Table 8) and the corresponding grades with requirements on hardenability (see Tables 5 to 7) are also shearable under suitable conditions if they are supplied in the "treated to improve shearability (+S)" condition with the hardness requirements as specified in Table 8. 7.3.3 Under suitable conditions, steel grades C22E, C22R, C35, C35E, C35R, C40, C40E and C40R (see

Table 8) and the corresponding grades with hardenability requirements (see Tables 5 to 7) are shearable in the untreated condition. Shearability may also be assumed for steel grades C45, C45E and C45R with dimensions greater than 80 mm and in the untreated condition. 7.4 Structure 7.4.1 Unless otherwise agreed at the time of enquiry and order, the grain size shall be left to the discretion of the manufacturer. If a fine grain structure is required in accordance with a reference treatment, special requirement A.3 shall be ordered.

EN ISO 3887. 7.6.5 If suitability of bars and rods for bright drawing is required, this shall be agreed at the time of enquiry and order. 7.6.6 The removal of surface defects by welding shall only be permitted with the approval of the customer or his or her representative. If surface discontinuities are repaired, the method and maximum depth of removal shall be agreed at the time of enquiry and order. 7.7 Dimensions, tolerances on dimensions and shape The nominal dimensions, tolerances on dimensions and shape for the product shall be agreed at the time of enquiry and order, if possible, with reference to the dimensional standards applicable (see EN 10083-1:2006, Annex D).

8.1 Testing procedures and types of documents 8.1.1 Products complying with this document shall be ordered and delivered with one of the inspection documents as specified in EN 10204. The type of document shall be agreed upon at the time of enquiry and order. If the order does not contain any specification of this type, a test report shall be issued. 8.1.2 For information to be included in a test report, see EN 10083-1:2006, 8.1.2. 8.1.3 For information to be included in an inspection certificate, see EN 10083-1:2006, 8.1.3. 8.1.4 Unless otherwise agreed at the time of the order, inspection of the surface quality and dimensions shall be carried out by the manufacturer. 8.2 Frequency of testing 8.2.1 Sampling Sampling shall be in accordance with Table 12. 8.2.2 Test units The test units and the extent of testing shall be in accordance with Table 12. 8.3 Tests to be carried out for specific inspection 8.3.1 Verification of hardenability, hardness and mechanical properties For steels being ordered without hardenability requirements, i.e. without the symbol +H, +HH or +HL in the designation, the hardness requirements or mechanical properties given for the relevant heat-treatment condition in Table 1, Column 8, subclause 2, shall with the following exception be verified. The requirement given in Table 1, footnote a (mechanical properties of reference test pieces), is only to be verified if supplementary requirement A.1 or A.2 is ordered. For special steels being ordered with the symbol +H, +HH or +HL in the designation (see Tables 5 to 7), unless otherwise agreed, only hardenability requirements according to Tables 5, 6 or 7 shall be verified. 8.3.2 Visual and dimensional inspection A sufficient number of products shall be inspected to ensure compliance with the specification. 9 Preparation of samples and test pieces 9.1 Selection and preparation of samples for chemical analysis The preparation of samples for product analysis shall be in accordance with EN ISO 14284. 9.2 Location and orientation of samples and test pieces for mechanical tests 9.2.1 Preparation of samples Preparation of samples shall be in accordance with Table 12 and EN 10083-1:2006, 9.2.1. 9.2.2 Preparation of test pieces

10.3.3 Surface hardness The surface hardness of steels after flame or induction hardening (see Table 11) shall be determined in accordance with EN ISO 6508-1, scale C. 10.4 Retests See EN 10083-1:2006, 10.4 11 Marking, labelling, packaging The manufacturer shall mark the products or the bundles or boxes in a suitable way so that it is possible to determine the cast, the steel grade and the origin of the delivery (see A.7).

1 2 3 4 5 6 7 8 9 x indicates applicable for Applicable requirements if the steel is ordered with the designation given in Table 3 Tables 5, 6 or 7 (special steels only) 1 Heat treatment condition at delivery Symbol Semi- finished products Bars Rod Flat products Hammerand dropforgings 8.1 8.2 9.1 9.2 9.3 2 Untreated none or +U x x x x x a

3 Treated to improve shearability +S x x - x - Table 8 column +Sa 4 Soft annealed+A x x x xb x

Maximum hardness Table 8 column +Aa 5 Normalizedc +N - x - xb x Table 10

Hardenability values according to Table 5, 6 or 7 6 Quenched and tempered +QT - x x xb x

Chemical composition according to Tables 3 and 4

Mechanical properties according to Table 9

As in columns 8.1 and 8.2 (see footnote b in Table 3) Not Applicable 7 Others Other treatment conditions, e.g. certain annealing conditions to achieve a certain structure may be agreed at the time of enquiry and order. The treatment condition annealed for spheroidal carbide (+AC) as required for cold upsetting and cold extrusion is covered by EN 10263-4. a For deliveries in the untreated condition and in the "treated to improve shearability" and "soft annealed" condition, the mechanical properties specified in Tables 9 and 10 shall be

achievable for the ruling end cross-section after appropriate heat treatment (for verification on reference test piec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...