EN 15266:2007

(Main)Stainless steel pliable corrugated tubing kits in buildings for gas with an operating pressure up to 0,5 bar

Stainless steel pliable corrugated tubing kits in buildings for gas with an operating pressure up to 0,5 bar

This European Standard specifies the requirements for material, design, manufacture, testing, marking and documentation of stainless steel pliable corrugated gas tubing kits for buildings with a maximum operating pressure (MOP) less than or equal to 0,5 bar and a nominal size range from DN 10 to DN 50.

This document applies to stainless steel pliable corrugated gas tubing kits used for 1st, 2nd and 3rd family gases in residential, commercial and industrial gas installations.

This document does not apply to:

pliable tubing without cover;

corrugated safety metal hose assemblies for connection to moveable appliances.

This document does not cover the installation aspects of stainless steel pliable corrugated gas tubing kits.

Nichtrostende biegbare Wellrohrbausätze in Gebäuden für Gas mit einem Arbeitsdruck bis 0,5 bar

Diese Europaische Norm legt die Anforderungen an Werkstoff, Auslegung, Herstellung, Prufung, Kennzeich-nung

und Dokumentation von nichtrostenden biegbaren Wellrohrsystemen fur Gas in Gebauden und fur einen

maximalen Arbeitsdruck ¡Â0,5 bar fest, bei einem Nennweitenbereich von DN 10 bis DN 50.

Dieses Dokument gilt fur neu installierte Anlagen sowie fur Austausch, Erweiterung oder Anderung bestehen-der

Systeme fur Gase der 1., 2. und 3. Familie. Nichtrostende biegbare Wellrohrsysteme fur Gas konnen in

Verbindung mit anderen zugelassenen Rohrleitungssystemen fur Gas verwendet werden.

ANMERKUNG Festlegung von Gasen der 1., 2. und 3. Familie, siehe EN 437:2003.

Dieses Dokument gilt nicht fur:

.biegbare Wellrohrsysteme ohne Ummantelung;

.gewellte Sicherheits-Gasschlauchleitungen aus Metall fur den Anschluss von beweglichen Geraten.

Dieses Dokument behandelt keine Anforderungen bezogen auf den Einbau von nichtrostenden biegbaren

Wellrohrsystemen fur Gas, welche ortlichen und/oder nationalen Regelungen mit verbindlich vorgeschrie-

benen Festigkeits- und Dichtheitsprufungen vor der Inbetriebnahme unterliegen konnen.

Kits de tuyaux onduleux pliables en acier inoxydable pour le gaz dans les bâtiments avec une pression de service inférieure ou égale à 0,5 bar

La présente Norme européenne définit les prescriptions relatives au matériau, à la conception, à la fabrication, aux essais, au marquage et à la documentation des kits de tuyaux onduleux pliables en acier inoxydable pour le gaz dans les bâtiments avec une pression maximale de service (MOP) inférieure ou égale à 0,5 bar, et une gamme de diamètres nominaux compris entre DN 10 et DN 50.

Le présent document s'applique aux kits de tuyaux onduleux pliables en acier inoxydable destinés à être utilisés avec les première, deuxième et troisième familles de gaz dans les installations gaz pour le résidentiel, le commercial et l’industriel.

Le présent document ne s'applique pas :

aux tuyaux pliables sans protection ;

aux tuyaux métalliques flexibles onduleux de sécurité pour le raccordement d'appareils mobiles.

Le présent document ne traite pas des aspects liés à l'installation des kits de tuyaux onduleux pliables en acier inoxydable pour le gaz.

Upogljivi valoviti cevni kompleti iz nerjavnega jekla za plin v stavbah z delovnim tlakom do 0,5 bara

General Information

- Status

- Withdrawn

- Publication Date

- 08-May-2007

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 342 - Metal hoses, hose assemblies, bellows and expansion joints

- Drafting Committee

- CEN/TC 342/WG 1 - Hose assemblies and fittings

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 18-Dec-2024

- Completion Date

- 11-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 04-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN ISO 9227:2022 - Corrosion tests in artificial atmospheres - Salt spray tests (ISO 9227:2022) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 15266:2007 is a standard published by the European Committee for Standardization (CEN). Its full title is "Stainless steel pliable corrugated tubing kits in buildings for gas with an operating pressure up to 0,5 bar". This standard covers: This European Standard specifies the requirements for material, design, manufacture, testing, marking and documentation of stainless steel pliable corrugated gas tubing kits for buildings with a maximum operating pressure (MOP) less than or equal to 0,5 bar and a nominal size range from DN 10 to DN 50. This document applies to stainless steel pliable corrugated gas tubing kits used for 1st, 2nd and 3rd family gases in residential, commercial and industrial gas installations. This document does not apply to: pliable tubing without cover; corrugated safety metal hose assemblies for connection to moveable appliances. This document does not cover the installation aspects of stainless steel pliable corrugated gas tubing kits.

This European Standard specifies the requirements for material, design, manufacture, testing, marking and documentation of stainless steel pliable corrugated gas tubing kits for buildings with a maximum operating pressure (MOP) less than or equal to 0,5 bar and a nominal size range from DN 10 to DN 50. This document applies to stainless steel pliable corrugated gas tubing kits used for 1st, 2nd and 3rd family gases in residential, commercial and industrial gas installations. This document does not apply to: pliable tubing without cover; corrugated safety metal hose assemblies for connection to moveable appliances. This document does not cover the installation aspects of stainless steel pliable corrugated gas tubing kits.

EN 15266:2007 is classified under the following ICS (International Classification for Standards) categories: 23.040.01 - Pipeline components and pipelines in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15266:2007 has the following relationships with other standards: It is inter standard links to EN 15266:2024, EN ISO 11925-2:2026, EN 10226-1:2004, EN 10242:2025, EN ISO 6509-1:2014, EN ISO 11925-2:2020, EN 12165:2024, EN ISO 9227:2022, EN 13501-1:2002, EN 1775:1998, EN 751-1:1996, EN 751-2:1996, EN ISO 15721:2001, EN 682:2002, EN 10088-3:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15266:2007 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/131. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15266:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Upogljivi valoviti cevni kompleti iz nerjavnega jekla za plin v stavbah z delovnim tlakom do 0,5 baraNichtrostende biegbare Wellrohrbausätze in Gebäuden für Gas mit einem Arbeitsdruck bis 0,5 barKits de tuyaux onduleux pliables en acier inoxydable pour le gaz dans les bâtiments avec une pression de service inférieure ou égale a 0,5 barStainless steel pliable corrugated tubing kits in buildings for gas with an operating pressure up to 0,5 bar91.140.40Sistemi za oskrbo s plinomGas supply systems77.140.75Jeklene cevi in cevni profili za posebne nameneSteel pipes and tubes for specific useICS:Ta slovenski standard je istoveten z:EN 15266:2007SIST EN 15266:2007en,de01-junij-2007SIST EN 15266:2007SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 15266May 2007ICS 23.040.01 English VersionStainless steel pliable corrugated tubing kits in buildings for gaswith an operating pressure up to 0,5 barKits de tuyaux onduleux pliables en acier inoxydable pour legaz dans les bâtiments avec une pression de serviceinférieure ou égale à 0,5 barNichtrostende biegbare Wellrohrbausätze in Gebäuden fürGas mit einem Arbeitsdruck bis 0,5 barThis European Standard was approved by CEN on 17 February 2007.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2007 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 15266:2007: ESIST EN 15266:2007

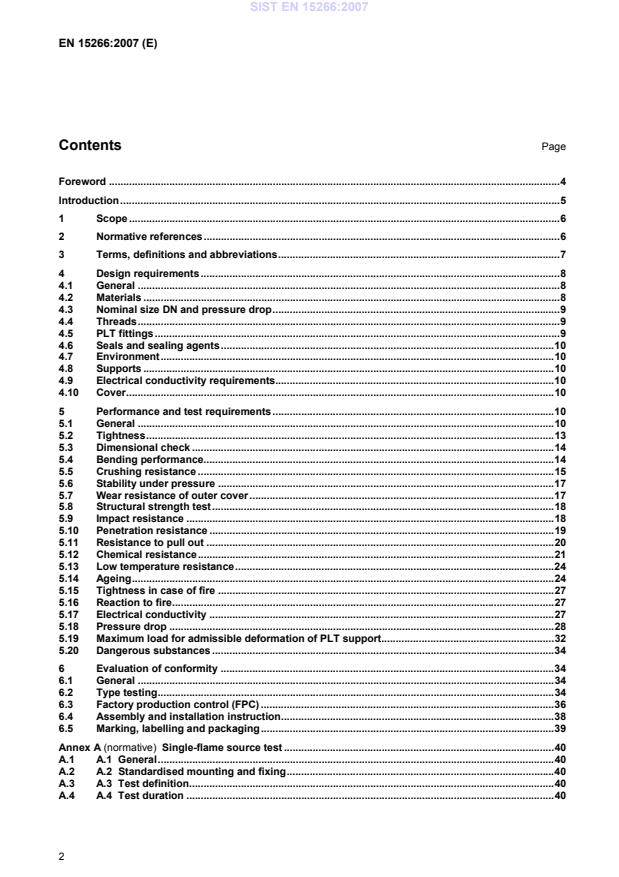

Single-flame source test.40 A.1 A.1

General.40 A.2 A.2

Standardised mounting and fixing.40 A.3 A.3

Test definition.40 A.4 A.4

Test duration.40 SIST EN 15266:2007

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive (89/106/EEC).44 ZA.1 Scope and relevant characteristics.44 ZA.2

Procedure for attestation of conformity of stainless steel pliable corrugated gas tubing kits.46 ZA.2.2 EC Certificate and declaration of conformity.48 ZA.3

CE marking and labelling.49 Bibliography.52

Introduction This European Standard contains the general safety requirements relating to the safety of persons, animals and property and the protection of their environment. The requirements of this standard concern designers, manufacturers, suppliers and importers of stainless steel pliable corrugated gas tubing kits for buildings. Installation and mandatory strength and tightness tests before commissioning should consider the local application regulations where they exist. This document is applicable to:

new installation pipework; replacements of existing installations; or extensions to existing installations. Stainless steel pliable corrugated gas tubing kits can be used in conjunction with other approved gas pipework. SIST EN 15266:2007

1 Scope This European Standard specifies the requirements for material, design, manufacture, testing, marking and documentation of stainless steel pliable corrugated gas tubing kits for buildings with a maximum operating pressure (MOP) less than or equal to 0,5 bar and a nominal size range from DN 10 to DN 50. This document applies to stainless steel pliable corrugated gas tubing kits used for 1st, 2nd and 3rd family gases in residential, commercial and industrial gas installations. This document does not apply to: pliable tubing without cover; corrugated safety metal hose assemblies for connection to moveable appliances. This document does not cover the installation aspects of stainless steel pliable corrugated gas tubing kits.

2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 437, Tests gases - Test pressures – Appliance categories EN 549, Rubber materials for seals and diaphragms for gas appliances and gas equipment EN 682, Elastomeric seals – Materials requirements for seals used in pipes and fittings carrying gas and hydrocarbon fluids EN 751-1, Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases and hot water - Part 1: Anaerobic jointing compounds EN 751-2, Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases and hot water - Part 2: Non-hardening jointing compounds

EN 751-3, Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases and hot water - Part 3: Unsintered PTFE tapes EN 1363-1:1999, Fire resistance tests – Part 1: General requirements EN 1775:1998, Gas supply - Gas pipework for buildings - Maximum operating pressure ≤ 5 bar - Functional recommendations EN 10028-7, Flat products made of steels for pressure purposes – Part 7: Stainless steels EN 10088-3, Stainless steels - Part 3: Technical delivery conditions for semi-finished products, bars, rods, wire, sections and bright products of corrosion resisting steels for general purposes EN 10226-1, Pipe threads where pressure tight joints are made on the threads - Part 1: Taper external threads and parallel internal threads - Dimensions, tolerances and designation EN 10242, Threaded pipe fitting in malleable cast iron SIST EN 15266:2007

corrugated tubing capable of being bent easily by hand a limited number of times, covered with a tubular outer sheath by the manufacturer at the time of production 3.2 PLT kit pliable tubing with its related components obtained or specified from one manufacturing source having design and performance responsibility for the kit 3.3 bend radius radius measured to the centre line of the pliable tubing 3.4 PLT fitting unique fitting using mechanical attachment methods, in which tightness is achieved with or without seals, excluding other joining methods such as welding, brazing, soldering or gluing 3.4.1 end fitting PLT fitting intended to join pliable tubing to an external component 3.4.2 coupling PLT fitting intended to join two sections of pliable tubing SIST EN 15266:2007

3.4.4 manifold PLT fitting designed to join 4 or more sections of pliable tubing 3.5 seal any part intended to provide tightness within a PLT fitting 3.6 sleeve tubular outer sheath intended to protect the connection between the pliable tubing and a PLT fitting from corrosion or mechanical damage 3.7 PLT support element used to attach the PLT kit to the structure of the building 3.8 rated flow rate

flow rate at a given pressure drop, under standard reference conditions 3.9 family group of products produced by one manufacturer for which test results for one product of that group are representative of the characteristics for the whole group

3.10 gas 1st, 2nd and 3rd family gases as defined in EN 437

NOTE These gases are commonly referred to as manufactured gases, natural gas and liquefied petroleum gases.

4 Design requirements 4.1 General Where additional components are required to complete the PLT kit, these components shall be provided or specified by the kit manufacturer. 4.2 Materials Materials for the manufacture of a PLT kit shall be selected from Table 1 and on the basis of their related suitability for fabrication, e.g. welding, cold forming, etc. as appropriate, and the conditions under which they will be used. SIST EN 15266:2007

Table 1 — Materials Component Material Pliable tubing Cover Stainless steel according to EN 10028-7: 1.4306, 1.4541, 1.4404, 1.4401, 1.4571

Synthetic material a PLT fittings Stainless steel according to EN 10088-3, copper alloys according to EN 12164 and EN 12165 PLT manifold/tees Stainless steel according to EN 10088-3, copper alloys according to EN 12164 and EN 12165 Malleable cast iron according to EN 10242 types W 400-05; W 350-04; B 350-10 or B 300-06 Supports Metallic corrosion resistant material a

see 4.10

4.3 Nominal size DN and pressure drop The nominal size of a PLT kit shall be selected from the DNs given in EN ISO 10380:2003, Table 2. The nominal size range shall be from DN 10 to DN 50. The minimum bore size of the pliable tubing shall be at least 98 % of the nominal size DN in mm. The manufacturer shall declare the related pressure drop (see 5.18) for each nominal size DN (see 6.4). 4.4 Threads End fittings shall have terminating threads according to EN 10226-1.

Integrated threads within the mechanical attachment of the PLT fittings shall not be compatible with

EN 10226-1.

4.5 PLT fittings 4.5.1 General PLT fittings shall provide a tight connection to the pliable tubing. PLT fittings, whether surface finished or not, shall be manufactured from materials listed in Table 1. Copper alloys shall be selected from EN 12164 and/or EN 12165 and shall contain at least 57 % copper and not more than 3,5 % lead. 4.5.2 Stress corrosion All fittings and components of copper alloy shall be resistant to stress corrosion. Stress corrosion resistance shall be determined in accordance with ISO 6957 (pH 9,5). 4.5.3 Dezincification All copper alloys components shall resist dezincification. If an alloy contains more than 10 % of zinc, its corrosion behaviour shall be assessed according to

EN ISO 6509. SIST EN 15266:2007

4.7 Environment PLT kit components shall be resistant to any corrosive agent reasonably foreseen in the conditions of the declared intended use.

They shall be durable to climatic conditions according to 5.14 for a reasonably economic working life. They shall withstand a temperature range of – 40 °C to 60 °C. NOTE The manufacturer should advise in his installation instructions that where exposed, sections of PLT kits can be protected against excessive mechanical force that can cause damage. Casing/trunking can be used to fulfil this requirement. 4.8 Supports Supports shall be made of materials mechanically and chemically non aggressive with the other components of the PLT kit with which they are in contact. Supports shall be designed to carry the system load for a minimum of 30 min in case of fire. The standard temperature/time curve shall be as given in EN 1363-1:1999, Figure 7. The manufacturer shall supply installations instructions that give the correct support design for the kit supplied. The instructions shall also emphasize the need to design the support fixings to the structure in such a way that maintains the integrity of the system in case of fire for a period not less than the period for which the supports are designed to carry the system load.

4.9 Electrical conductivity requirements PLT kit components shall be electrically conductive, see 5.17. NOTE The manufacturer should advise in his installation instructions that equipotential bonding should be in accordance with local application regulations.

4.10 Cover The cover shall satisfy the tests according to 5.4, 5.7, 5.12, 5.13, 5.14 and 5.16.

If the materials of the cover contain corrosive agents or ingredients such as sulphur or chlorine, such agents shall not be released during manufacturing process or during intended service conditions. For the purpose of safety, the prevailing colour of the cover shall be yellow, e.g. RAL 1004, 1016, 1018. 5 Performance and test requirements 5.1 General 5.1.1 Introduction The number and the type of PLT kit samples to be tested, the tests and the compliance criteria shall be as given in 6.2.2, Table 11. SIST EN 15266:2007

Tests results shall only apply to components of the same design and same material.

Table 2 — Test requirements Nominal size

to be tested a Family Qualified diameters DN DN 12 X DN 10 - DN 12 - DN 15 DN 25 Y DN 20 - DN 25 - DN 32 DN 50 Z DN 40 - DN 50 a If these sizes are not available, the largest DN in the relevant family shall be tested.

The tests shall be performed under ambient conditions. If not otherwise indicated the following tolerances shall apply: atmospheric pressure: (+/- 0,1) mbar; flow rate: (+/- 5)%; temperature above 125°C: (+/- 10)°C; dimensions: (+/- 0,1) mm; air pressure: (+/- 5)%; ambient temperature: (+/- 1)°C; time: (+/- 0,1)%; sample length: (-1/+3)%. 5.1.2 Type of PLT kit samples

The PLT kit samples used in the following tests shall be assembled in accordance with the manufacturers’ instructions. Prior to assembling, each length of the pliable tubing shall be tested according to 5.3. Depending on the test, Type 1 samples (see Figure 1) or Type 2 samples (see Figure 2) shall be used.

Type 1: End fitting – pliable tubing – end fitting SIST EN 15266:2007

Figure 1 — PLT sample Type 1 Type 2: End fitting – pliable tubing – coupling – pliable tubing – end fitting Dimensions in millimetres

Figure 2 — PLT sample Type 2 SIST EN 15266:2007

1 2 3 4 5 Clause of this standard A Tightness test

A - - - - 5.2 B Dimensional check B - - - - 5.3 C Bending performance B A C A - 5.4 D Crushing resistance B A D A B 5.5 E Stability under pressure B A E A - 5.6 F Wear resistance of outer cover F - - - - 5.7 G Structural strength B A G A - 5.8 H Impact resistance B A H A - 5.9 I Penetration resistance B A I A - 5.10 J Resistance to pull out B A J A - 5.11 K Chemical resistance A K A - - 5.12 L Low temperature resistance A L A - - 5.13 M Ageing A M A - - 5.14 N Tightness in case of fire A N A - - 5.15 O Reaction to fire O - - - - 5.16 P Electrical conductivity P - - - - 5.17 Q Pressure drop A Q - - - 5.18 R Maximum load for admissible deformation R - - - - 5.19 Example Test H is preceded by tests B and A and followed by test A.

5.2 Tightness 5.2.1 Tightness for test samples 5.2.1.1 Requirements The PLT kit shall be tight when tested in accordance with the method given in 5.2.1.2. The initial tightness test shall be performed with the cover in place. For the final tightness test, the cover shall be removed in order that it does not contribute to the achievement of the tightness.

5.2.1.2 Test method When held under water and containing air at a pressure of 2 bar the leakage rate of a test sample shall not exceed 10 cm3/h. NOTE A helium leakage rate not exceeding (7 x 10-3) mbar l/s is equivalent to the above requirement. SIST EN 15266:2007

5.2.2.1 Requirements The PLT shall be tight when tested in accordance with the method given in 5.2.2.2. The tightness test shall be performed just prior to the cover being applied. Any operation after the cover being applied which may influence the tightness shall require retesting with the cover in place. 5.2.2.2 Test method When held under water and containing air at a pressure of 2 bar the leakage rate of a PLT shall not exceed 10 cm3/h per 25 m. NOTE A helium leakage rate not exceeding (7x 10-3) mbar l/sec is equivalent to the above requirement.

5.3 Dimensional check

5.3.1 Requirements When subjected to the following test method, every sample length of pliable tubing shall show no sign of inner diameter restriction. 5.3.2 Test method A metal sphere or gauge, calibrated to (98 + 0/- 0,5) % of the DN shall pass through the length. 5.4 Bending performance 5.4.1 Requirements After being bent through 12 cycles in accordance with 5.4.2, PLT samples shall be leak tight when tested in accordance with 5.2.1.2 and there shall be no visible cracks in the cover. 5.4.2 Test method The samples shall be subjected to a bend test as shown in Figure 3. With one end rigidly fixed the other shall be moved to a starting position A in a circular arc around a former having a radius calculated from the bend radius (pliable test) as given in EN ISO 10380:2003, Table 2, type 3, until the tubing is in intimate contact with the full length of the arc of the former. Throughout the test, the sample shall be pressurised with air at a pressure of 500 mbar. The PLT sample shall be bent 12 times through an arc of 180°, the first cycle comprises one bend starting in a position A moving through B to the end position C, the second cycle being a movement from position C through B to the end position A. The longitudinal seam weld shall be located in accordance with position 3 (see Figure 3). If helical welding is used, the orientation of the weld shall be ignored. The test frequency shall be between 5 cycles/min and 15 cycles/min. SIST EN 15266:2007

Key

r former radius R bend radius 1 pressure sensor 2 end fittings 3 weld seam orientation Figure 3 — Bending test configuration 5.5 Crushing resistance 5.5.1 Requirements When tested in accordance with 5.5.2, the bore size of the pliable tubing shall not be reduced by more than 15 % of its nominal size DN, and it shall remain tight. 5.5.2 Test method The internal diameter shall be determined by using the method described in 5.3.2 before the crushing test. The corrugated part of the PLT kit sample shall be placed on a hard flat support surface. A load of

4000 N shall be gradually applied on a square steel plate of 150 mm side positioned on the PLT kits sample. After a stabilisation time of 5 min, the load shall be removed. subject 2 samples of Type 1 to a crushing test as shown in Figure 4; subject 2 samples of Type 1 to a crushing test as shown in Figure 5.

Side view SIST EN 15266:2007

Key

1 crushing direction 2 seam weld 3 steel plate Figure 4 — Crushing test configuration 1

Dimensions in millimetres

Key

1 crushing direction 2 seam weld Figure 5 — Crushing test configuration 2 SIST EN 15266:2007

Key r 0,5 mm Detail A Test head

Figure 6 — Test configuration of wear resistance outer cover

5.8

Structural strength test 5.8.1 Requirements When subjected to an internal pressure following the test method described in 5.8.2 a PLT kit sample shall remain tight when tested in accordance with 5.2.1.2. Elongation of the PLT kit sample shall be acceptable.

5.8.2 Test method Subject the unrestrained sample to an internal pressure of 15 bar in a straight position for a period of

(300 +10/- 0) s.

If this test is carried out using water, the sample shall be dried prior to the tightness test.

5.9 Impact resistance 5.9.1 Requirements A PLT kit sample subjected to an impact of 30 J applied onto its PLT coupling shall remain tight when tested in accordance with 5.2.1.2. SIST EN 15266:2007

a)

b) – Detail A Key 1 mass 2 guide tube with a loose fit

Figure 7 — Impact test 5.10 Penetration resistance 5.10.1 Requirements When subjected to the test method as described in 5.10.2, a PLT kit sample shall remain tight when tested in accordance with 5.2.1.2. SIST EN 15266:2007

a)

b) Detail A Key

1 striker

2 guide tube with a loose fit

Figure 8 — Penetration resistance test configuration 5.11 Resistance to pull out 5.11.1 Requirements When subjected to the test method described in 5.11.2 a PLT kit sample shall remain tight. SIST EN 15266:2007

5.12 Chemical resistance 5.12.1 Requirements When subjected to the corrosion tests described in 5.12.2, PLT kit samples shall show: no visual signs of blistering or cracking on the pliable tubing cover; no visual signs of corrosion or cracking on the pliable tubing with its cover removed; no visual signs of corrosion on the PLT fittings, which could affect the safe performance of the product. The PLT kit samples shall remain tight when tested in accordance with 5.2.1.2. 5.12.2 Test method 5.12.2.1 General For each test, a PLT kit sample shall be bent over a cylindrical former whose diameter is calculated using the radius given in EN ISO 10380:2003, Table 2, type 3, to obtain a U bend sample as shown in Figure 9. The sample shall be partially immersed in the appropriate solution for the specified time. The sample shall be fitted with sleeves if prescribed by the manufacturer's installation instructions. SIST EN 15266:2007

Key

1 plugged end fitting

2 sleeve (if prescribed) 3 coupling 4 test solutions, given in Tables 4 and 5

R bend radius Figure 9 — Chemical resistance test configuration 5.12.2.2 Household cleaning agent test 5.12.2.2.1 Test requirements The requirements of 5.12.1 shall apply. 5.12.2.2.2 Test method The test method shall be as given in Table 4. SIST EN 15266:2007

Table 4 — Household cleaning agent test Solution type Chloric bleach (9 % by volume sodium hypochlorite) Test procedure - Rinse slowly, for 10 s, a volume of around 100 cm3 of the test solution over each fitting (tubing downward); - Immerse the sample in 150 mm of solution at (20 ± 1) °C for (72 ± 1) h; - Rinse the PLT kit sample with de-ionised water; - Visually inspect the cover; - Remove the cover and visually inspect the pliable tubing over its entire length.

5.12.2.3 Hydrochloric acid test 5.12.2.3.1 Test requirements The requirements of 5.12.1 shall apply. 5.12.2.3.2 Test method The test method shall be as given in Table 5. Table 5 — Hydrochloric acid test Solution type Hydrochloric acid (4% by volume) Test procedure - Rinse slowly, for 10 s, a volume of around 100 cm3 of the test solution over each fitting (tubing downward); - Immerse the sample in 150 mm of solution at (20 ± 1) °C for (72 ± 1) h; - Rinse the PLT kit sample with de-ionised water; - Visually inspect the cover; - Remove the cover and visually inspect the pliable tubing over its entire length.

5.12.2.4 Salt spray test 5.12.2.4.1 Test requirements The requirements of 5.12.1 shall apply. 5.12.2.4.2 Test method The test method shall be as given in Table 6.

Test procedure - Place the PLT kit sample in the salt spray chamber for (96 ± 1) h at (35 ± 1) °C The intensity of the spray shall be such that, for each 80 cm2 of the horizontal collecting surface, (2 ± 1) ml of solution are collected per hour; - Rinse the PLT kit sample with de-ionised water; - Visually inspect the cover. - Remove the cover and visually inspect the pliable tubing over its entire length.

5.13 Low temperature resistance 5.13.1 Requirements When subjected to 3 freezing cycles as described in 5.13.2, a PLT kit sample shall remain tight when tested in accordance with 5.2.1.2 and the covering shall not show any sign of cracking, colour change, marking change and any other detrimental effect. 5.13.2 Test method A PLT kit sample shall be bent over a cylindrical former whose diameter is calculated using the radius given in EN ISO 10380:2003, Table 2 type 3, to obtain a U bend sample. The tightness test shall be carried out in accordance with 5.2.1.2. The sample shall be placed in an appropriate chamber and the temperature reduced to - 40 °C for a period of 12 h. The sample shall be removed and allowed to warm to room temperature. This procedure shall be repeated 2 further times to yield 3 cycles in total. The sample shall be subjected to a visual examination and the tightness test shall be carried out in accordance with 5.2.1.2. 5.14 Ageing 5.14.1 Requirements When subjected to 7 ageing cycles, as described in 5.14.2, the cover shall not show any sign of cracking, colour change, marking change or any other detrimental effect and the PLT kit sample shall remain tight when tested in accordance with 5.2.1.2. 5.14.2 Test method The 24 hour ageing test detailed in Table 7 shall be performed continuously 7 times on the same PLT kit sample. The sample shall be subjected to a visual examination and the tightness test shall be carried out in accordance with 5.2.1.2.

(W/m2) 1 0 10 20 20 0 96% 0 10 30 20 0 -1 0 2 30 50 0 -20 -1 From 96% to 0% 0 3 50 90 -20 -20 0 0% 0 4 90 127,5 -20 55 2 From 0% to 95% 0 5 127,5 187,5 55 55 0 95% 0 6 187,5 190 55 60 2 From 95% to 40% 0 7 190 250 60 60 0 40% 9,5 8 250 290 60 20 -1 From 40% to 96% 0 9 290 300 20 20 0 96% 0 300 320 20 0 -1 0 10 320 340 0 -20 -1 From 96% to 0% 0 11 340 380 -20 -20 0 0% 0 12 380 420 -20 60 +2 From 0% to 40% 0 13 420 1400 60 60 0 40% 9,5 14 1400 1440 60 20 -1 From 40% to 0% 0

Key

A

step 1: rain / humidity 96 % B step 3: cold / humidity 0% C step 5: warm / humidity 95% D step 7: UV / humidity 40% E step 9: rain / humidity 96% F step 11: cold / humidity 0% G step 13: UV / humidity 40%

temperature cycle x time (minute) y temperature (°C) Figure 10 — Ageing test diagram

The UV energy received by the sample shall be 9,5 W/m2 in the wavelength range between 400 nm and 300 nm. The rain used in the test shall consist of de-ionised water with a pH of 7 and a temperature of 20 °C. The water pouring shall be performed by means of an appropriate device to allow the droplets of water to fall down onto the samples. The water flow shall be sufficient to maintain the wetness of the sample.

5.15.2 Test method Subject the sample to EN 1775:1998, Annex A, procedure A or B. The manufacturer shall declare the procedure used. Prior to the test the cover between the fittings shall be removed from the PLT kit sample.

5.16 Reaction to fire 5.16.1 Requirements

The reaction to fire of the pliable tubing shall be classified according to EN 13501-1 after being tested to 5.16.2. NOTE 1

PLT fittings are classified A1 ‘no contribution to fire’, in accordance with Commission decision 96/603/EEC of 4 October 1996, and are therefore not tested for reaction to fire. NOTE 2

Seals encased in PLT fittings are classified A1 ‘no contribution to fire’, in accordance with Commission decision 96/603/EEC of 4 October 1996, and are therefore not tested for reaction to fire. 5.16.2 Test procedure Pliable tubing subjected to the ignitability test according to the requirements of EN 13501-1:2002, Table 1, shall be tested in accordance with EN ISO 11925-2. The test configuration is given in Annex A.

Pliable tubing subjected to the single burning item test according to the requirements of EN 13501-1:2002,

Table 1, shall be tested in accordance with EN 13823. The test configuration is given in Annex B.

5.17 Electrical conductivity 5.17.1 Requirements A PLT kit shall be electrically conductive. The value of resistance shall not exceed those specified in

Table 8. 5.17.2 Test method The test method shall be carried out as follows: 1) Pass a current of 25 A and 12 V, derived from a DC source or an AC source of 50 to 60 Hz, between both end fittings of a PLT kit sample;

2) Measure the voltage drop; 3) Calculate the resistance from the voltage drop and the current.

5.18 Pressure drop 5.18.1 Requirements The values of the maximum pressure drop, at the intended operating pressures, declared by the manufacturer for each component of the PLT kit shall be validated by the test method given in 5.18.2. 5.18.2 Test rig description The tests shall be conducted using clean dry air. The air source shall ensure a stabilized flow rate within an accuracy of ± 2%. The pressure regulator as shown in Figure 11 shall be capable of maintaining the test pressure within an accuracy of ± 2 %. The thermocouple shall be capable of measuring the temperature of the air flow with an accuracy of

± 2 %. The pressures gauges/sensors shall be capable of measuring the range of pressures used to an accuracy of ± 2 %. A differential pressure gauge/sensor shall be used to read the differential pressure between the inlet and outlet pressures. A flow meter of positive displacement (quantity meter) or inferential type (rate meter) shall be used. The meter shall have an accuracy at full scale of

± 2 % and shall be capable of measuring any given flow rate within ± 5 %. NOTE

Flow meters calibrated for atmospheric pressure that are designed to operate without a requirement for back pressure may not require flow correction using a final pressure measurement and flow valve. Rigid piping used for the test apparatus piping upstream and downstream of the PLT kit sample shall have a bore equal to or greater than the internal diameter of the pliable tubing sample tested. The piezometer ring as shown in Figure 12 shall be located at points 10.d upstream and downstream from the inlet and outlet connections. The straight run of pipe upstream and downstream of the PLT kit sample prior to any connection shall not be less than 20.d (where d = diameter of PLT +0,5/ -0 mm) and shall be designed to make flow as smooth as possible, without adding turbulence. PLT kit samples shall be connected to the test apparatus piping using the appropriate sized PLT end fitting and the supply pressure sh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...