EN 14491:2012

(Main)Dust explosion venting protective systems

Dust explosion venting protective systems

This European Standard specifies the basic requirements of design for the selection of a dust explosion venting protective system. The standard is one of a series including EN 14797, Explosion venting devices and EN 14460, Explosion resistant equipment. The three standards together represent the concept of dust explosion venting. To avoid transfer of explosions to other communicating equipment, one should also consider applying EN 15089 Explosion Isolation Systems.

This European Standard covers:

- vent sizing to protect an enclosure against the internal pressure effects of a dust explosion;

- flame and pressure effects outside the enclosure;

- recoil forces;

- influence of vent ducts;

- hybrid mixtures.

This European Standard is not intended to provide design and application rules against effects generated by detonation reactions or runaway exothermic reactions. This European Standard does not cover fire risks arising from materials either processed, used or released by the equipment or from materials that make up equipment and buildings. This European Standard does not cover the design, construction, testing and certification of explosion venting devices that are used to achieve explosion venting

Schutzsysteme zur Druckentlastung von Staubexplosionen

Diese Europäische Norm legt die grundlegenden Anforderungen an die konstruktive Gestaltung und für die Auswahl eines Schutzsystems zur Druckentlastung von Staubexplosionen fest. Diese Norm wurde im Rahmen der Reihe erstellt, zu der EN 14797, Einrichtungen zur Explosionsdruckentlastung, und EN 14460, Explosionsfeste Geräte, gehören. Die drei Normen zusammen bilden das Konzept der Druckentlastung von Staubexplosionen. Zur Vermeidung der Übertragung von Explosionen auf andere in Verbindung stehende Einrichtungen sollte auch EN 15089 Explosions Entkopplungssysteme beachtet und angewendet werden.

Diese Europäische Norm deckt Folgendes ab:

- Größe der Entlastungsöffnung, um gegen die inneren Druckauswirkungen einer Staubexplosion zu schützen;

- Auswirkungen von Flammen und von Druck außerhalb des Behälters;

- Rückstoßkräfte;

- Einfluss der Abblasrohre;

- hybride Gemische.

Diese Europäische Norm gibt keine Gestaltungs und Anwendungsvorschriften, durch die Auswirkungen von Detonationsreaktionen oder unkontrollierten exothermen Reaktionen vermieden werden können. Brand-gefahren, die entweder von den verarbeiteten Materialien, von den vom Gerät benutzten oder freigesetzten Materialien ausgehen oder die durch Materialien hervorgerufen werden, aus denen Geräte und Gebäude bestehen, sind nicht Gegenstand dieser Europäischen Norm. Konstruktive Gestaltung, Fertigung, Prüfung und Zertifizierung von Einrichtungen, die im Fall von Explosionen für die Druckentlastung verwendet werden, sind ebenfalls nicht Gegenstand dieser Europäischen Norm. )

Systèmes de protection par évent contre les explosions de poussières

La présente Norme européenne spécifie les exigences fondamentales se rapportant à la conception et au choix d'un système de protection par évent contre les explosions de poussières. La présente Norme européenne fait partie d'une série à laquelle appartiennent également l'EN 14797, Dispositifs de décharge d'explosion et l'EN 14460, Appareil résistant à l'explosion. Ensemble, ces trois normes illustrent le concept de protection par évent contre les explosions. Pour éviter la propagation de l'explosion à d'autres équipements communicants, il convient également de tenir compte de l'EN 15089, Systèmes d'isolement d'une explosion.

La présente Norme européenne traite des aspects suivants :

- le dimensionnement des évents pour la protection d'une enceinte contre les effets de la pression interne d'une explosion de poussières ;

- les effets de la flamme et de la pression à l'extérieur de l'enceinte ;

- les forces de recul ;

- l'influence des canalisations de décharge ;

- les mélanges hybrides.

La présente Norme européenne n'est pas destinée à fournir des règles de conception et d'application contre les effets engendrés par les réactions de détonation ou l'emballement des réactions exothermiques. Elle ne traite pas des risques d'incendie provenant soit des matériaux traités, utilisés ou émis par les appareils, soit des matériaux qui constituent les appareils et les bâtiments. Elle ne traite pas non plus de la conception, de la construction, des essais et de la certification des dispositifs de décharge d'explosion ).

Zaščitni sistemi za razbremenitev tlaka eksplozije prahu

Ta evropski standard določa osnovne zahteve glede oblike za izbor zaščitnega sistema za razbremenitev tlaka eksplozije prahu. Standard je eden iz serije standardov, ki vključujejo naprave za razbremenitev tlaka eksplozije iz standarda EN 14797 in opremo, odporno na eksplozije, iz standarda EN 14460. Ti trije standardi skupaj predstavljajo koncept razbremenitve tlaka eksplozije prahu. Da bi se preprečil prenos eksplozij na drugo komunikacijsko opremo, je treba preučiti tudi uporabo ločevalnih sistemov eksplozij iz standarda EN 15089. Ta evropski standard zajema: določitev velikosti oddušnika za zaščito okrova pred učinki notranjega tlaka eksplozije prahu; učinke plamena in tlaka zunaj okrova; sile odsunka; vpliv kanalov oddušnika. Namen tega evropskega standarda ni določiti pravil o obliki in uporabi za zaščito pred učinki reakcij detonacije ali eksotermnih reakcij brez nadzora. Ta evropski standard ne zajema nevarnosti požara zaradi materialov, ki jih oprema obdeluje, uporablja ali sprošča, ali materialov, iz katerih so oprema in zgradbe narejeni. Ta evropski standard ne zajema oblike, gradnje, preskušanja in certificiranja naprav za razbremenitev tlaka eksplozij, ki se uporabljajo za doseganje razbremenitve tlaka eksplozij.

General Information

- Status

- Published

- Publication Date

- 07-Aug-2012

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 03-Apr-2021

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 15-Aug-2012

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 16020:2011 - Explosion diverters - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 14797:2006 - Explosion venting devices - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

CEN/TR 16829:2016+AC:2019 - Fire and explosion prevention and protection for bucket elevators - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 14491:2012 - Dust explosion venting protective systems (CEN) specifies the basic design requirements for selecting dust explosion venting protective systems. It defines how to size vents and assess external effects to limit internal overpressure during a dust explosion in enclosures (vessels, silos, filters, cyclones, etc.). The standard forms part of a venting concept together with EN 14797 (explosion venting devices) and EN 14460 (explosion resistant equipment) and refers to EN 15089 when explosion isolation is needed.

Key topics and technical requirements

- Venting of enclosures: Principles for preventing unacceptable internal overpressure by providing weak/controlled venting areas.

- Vent sizing and geometry: Methods and parameters to calculate required and geometric vent areas, accounting for enclosure shape (L/D ratio), volume and distribution of vents.

- Dust explosion characteristics: Use of dust parameters such as KSt, (dp/dt)max and pmax in sizing and risk assessment.

- Special conditions: Guidance for pneumatic conveying (axial/tangential inlets), free-fall filling, hybrid mixtures (solid/gas mixtures) and elongated enclosures (L/D ≤ 20).

- Influence of vent ducts and design: Effects of ducts on vent performance and requirements for designing/locating vent ducts to avoid loss of effectiveness.

- External effects: Assessment of flame impingement, external overpressure, recoil forces and implications for personnel/adjacent plant and buildings (Annex D provides building-specific calculation guidance).

- Limitations: Not intended for protection against detonation or runaway exothermic reactions, nor for design/manufacture/test/certification of venting devices (covered by EN 14797). Fire risks from materials or building fabric are outside scope.

- Supplementary guidance: Informative annexes cover filters, cyclones, L/D estimation, deflectors and changes from the previous edition.

Practical applications and users

Who uses EN 14491:2012:

- Safety engineers and process designers sizing explosion vents for vessels, silos, cyclones and filters

- Plant managers and compliance officers implementing explosion protection measures

- Equipment manufacturers and integrators selecting vent locations and ducting

- Notified bodies, inspectors and consultants performing conformity assessment or risk audits

How it’s applied:

- Calculate required vent area using dust KSt and enclosure geometry

- Evaluate external hazard zones (flame/pressure) and recoil forces when siting vents

- Integrate with EN 14797 for device selection and EN 14460/EN 15089 for resistance and isolation strategies

Related standards

- EN 14797 - Explosion venting devices (device design & certification)

- EN 14460 - Explosion resistant equipment

- EN 15089 - Explosion isolation systems

- EN 13237 / EN 14034 - Terms and dust explosion testing methods

Keywords: EN 14491:2012, dust explosion venting protective systems, vent sizing, explosion venting, KSt, vent ducts, hybrid mixtures, explosion protection.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 14491:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Dust explosion venting protective systems". This standard covers: This European Standard specifies the basic requirements of design for the selection of a dust explosion venting protective system. The standard is one of a series including EN 14797, Explosion venting devices and EN 14460, Explosion resistant equipment. The three standards together represent the concept of dust explosion venting. To avoid transfer of explosions to other communicating equipment, one should also consider applying EN 15089 Explosion Isolation Systems. This European Standard covers: - vent sizing to protect an enclosure against the internal pressure effects of a dust explosion; - flame and pressure effects outside the enclosure; - recoil forces; - influence of vent ducts; - hybrid mixtures. This European Standard is not intended to provide design and application rules against effects generated by detonation reactions or runaway exothermic reactions. This European Standard does not cover fire risks arising from materials either processed, used or released by the equipment or from materials that make up equipment and buildings. This European Standard does not cover the design, construction, testing and certification of explosion venting devices that are used to achieve explosion venting

This European Standard specifies the basic requirements of design for the selection of a dust explosion venting protective system. The standard is one of a series including EN 14797, Explosion venting devices and EN 14460, Explosion resistant equipment. The three standards together represent the concept of dust explosion venting. To avoid transfer of explosions to other communicating equipment, one should also consider applying EN 15089 Explosion Isolation Systems. This European Standard covers: - vent sizing to protect an enclosure against the internal pressure effects of a dust explosion; - flame and pressure effects outside the enclosure; - recoil forces; - influence of vent ducts; - hybrid mixtures. This European Standard is not intended to provide design and application rules against effects generated by detonation reactions or runaway exothermic reactions. This European Standard does not cover fire risks arising from materials either processed, used or released by the equipment or from materials that make up equipment and buildings. This European Standard does not cover the design, construction, testing and certification of explosion venting devices that are used to achieve explosion venting

EN 14491:2012 is classified under the following ICS (International Classification for Standards) categories: 13.230 - Explosion protection. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14491:2012 has the following relationships with other standards: It is inter standard links to EN 14491:2006, EN 14491:2006/AC:2008, EN 14460:2006, EN 13237:2003, EN 15089:2009, EN 1127-1:2011, EN 16020:2011, EN 16770:2018, EN 12779:2015, EN 14797:2006, EN 16009:2011, EN 16985:2018, CEN/TR 16829:2016+AC:2019, CEN/TR 16829:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14491:2012 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 2014/34/EU, 94/9/EC; Standardization Mandates: M/BC/CEN/92/46. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14491:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Schutzsysteme zur Druckentlastung von StaubexplosionenSystèmes de protection par évent contre les explosions de poussièresDust explosion venting protective systems13.230Varstvo pred eksplozijoExplosion protectionICS:Ta slovenski standard je istoveten z:EN 14491:2012SIST EN 14491:2012en,fr,de01-oktober-2012SIST EN 14491:2012SLOVENSKI

STANDARDSIST EN 14491:2006/AC:2009SIST EN 14491:20061DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14491

August 2012 ICS 13.230 Supersedes EN 14491:2006English Version

Dust explosion venting protective systems

Systèmes de protection par évent contre les explosions de poussières

Schutzsysteme zur Druckentlastung von StaubexplosionenThis European Standard was approved by CEN on 30 June 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 14491:2012: ESIST EN 14491:2012

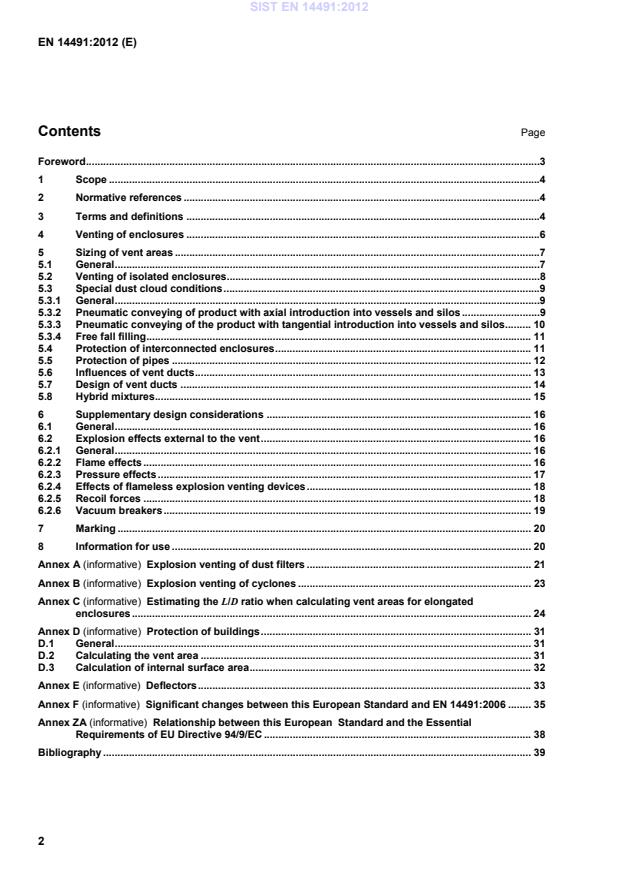

Explosion venting of dust filters . 21Annex B (informative)

Explosion venting of cyclones . 23Annex C (informative)

Estimating the L/D ratio when calculating vent areas for elongated enclosures . 24Annex D (informative)

Protection of buildings . 31D.1 General . 31D.2 Calculating the vent area . 31D.3 Calculation of internal surface area . 32Annex E (informative)

Deflectors . 33Annex F (informative)

Significant changes between this European Standard and EN 14491:2006 . 35Annex ZA (informative)

Relationship between this European

Standard and the Essential Requirements of EU Directive 94/9/EC . 38Bibliography . 39 SIST EN 14491:2012

1) This is covered in EN 14797. SIST EN 14491:2012

5 bar ≤ pmax ≤ 12 bar for a dust specific parameter of 300 bar·m·s-1 < KSt ≤ 800 bar·m·s–1; initial process conditions conditions prevailing inside the protected enclosure at the moment of ignition: absolute pressure ≤ 110 kPa; oxygen concentration ≤ 21 %; temperature between -20 °C and +60 °C;

NOTE 1 The formulae can be applied outside this temperature range if the explosion characteristics are corrected to the actual process conditions. length-to-diameter ratio of the vessel 1 ≤ L/D ≤ 20

NOTE 2 Examples for calculating L/D are given in Annex C. If one or more of the above conditions are not fulfilled the applicability of the above formula shall be verified. 5.3 Special dust cloud conditions 5.3.1 General Subclause 5.3 outlines vent area calculations for specific situations verified by testing. Vent areas, which have been sized in accordance with 5.3, can be used for these specific situations provided the parameters stay within the range of validity given for the formulae. 5.3.2 Pneumatic conveying of product with axial introduction into vessels and silos The following empirical formulae may be used to calculate the required vent area A for pneumatic filling of vessels where the filling line is axial near the centre of the roof. NOTE 1 A typical example is a silo filled from a pipe in the centre of the roof. For vessels with a height L ≤ 10 m: ))/log(1(DLYXA×+= in m2 (6) For vessels with a height L > 10 m: ))/log(1(1,0DLYXLA×+××=in m2 (7) with FStmax red,max red,Z011,0)7,3log5,5)6log6,8(/1(DKppDX×××+×−−××= (8) 27,1max red,0715,1−×=pY (9) where

L/D is the length-to-diameter ratio of the vessel;

NOTE 2 Examples for calculating L/D are given in Annex C. SIST EN 14491:2012

DF is the diameter of conveying pipe;

DZ is the effective diameter of the vessel and is calculated as follows: 34ZπVD= (10) The formulae are valid for: axially filling near the centre from above through one pipe with a diameter DF (in m) into a vessel/silo without obstructions (measurement devices are not taken into account); vessel volumes

10 m3 ≤ V ≤ 250 m3; maximum volume flow rate

2 500 m3/h; air conveying velocities

vL ≤ 30 m · s-1; diameter of the pipe

DF ≤ 0,3 m; static activation overpressure of pressure venting device

pstat ≤ 0,1 bar; maximum reduced explosion overpressure

0,1 bar < pred,max ≤ 2 bar; and pred,max shall be at least pstat + 2 times the tolerance range of pstat; maximum explosion overpressure

pmax ≤ 9 bar; dust specific characteristic

50 bar·m·s-1 ≤ KSt ≤ 300 bar·m·s-1. NOTE 3 The formulae can be used for vessels with integrated filters as long as the enveloping volume of the filter elements is less than 5 % of the overall vessel volume. The pressure resistance of these integrated filters needs to be at least equal to that of the vessel. Separate filters on top of the vessel with a chute into the vessel require explosion isolation and explosion venting of these filters. 5.3.3 Pneumatic conveying of the product with tangential introduction into vessels and silos The following empirical formulae may be used to calculate the required vent area A for pneumatic filling of vessels where the filling line is mounted tangential at the perimeter near the top of the silo. ))/log(1(DLYXA⋅+= in m2 (11) with +−−−=max red,Stmax red,Zlog)5,5()513,0)44(log)6,8(()1((pkKpkDX FStSt011,0)191,0)69(DKK×××+ (12) kpKeY27,1max red,129st166,0−××= (13) with k = 1 for 0,1 bar ≤ pred,max ≤ 1 bar; k = 2 for 1 bar < pred,max ≤ 1,7 bar. SIST EN 14491:2012

10 m3 ≤ V ≤ 120 m3; length/diameter ratio

L/D with 1 ≤ L/D ≤ 5; NOTE 1 Examples for calculating L/D are given in Annex C. maximum volume flow rate

2 500 m3/h; air conveying velocities of

vL ≤ 30·m · s–1; static activation overpressure of pressure venting device:

pstat ≤ 0,1 bar; maximum reduced explosion overpressure:

0,1 bar < pred,max ≤ 1,7 bar and pred,max shall be at least pstat + 2 times the tolerance range of pstat; maximum explosion overpressure:

pmax ≤ 9 bar; dust specific characteristic:

100 bar·m·s–1 ≤ KSt ≤ 220 bar·m·s–1; DZ is calculated according to Formula (10). Alternatively the calculation according to 5.3.2 may be used, taking into account the stated boundary conditions. NOTE 2 The formulae can be used for vessels with integrated filters as long as the enveloping volume of the filter elements is less than 5 % of the overall vessel volume. The pressure resistance of these integrated filters needs to be at least equal to that of the vessel. Separate filters on top of the vessel with a chute into the vessel require explosion isolation and explosion venting of these filters. 5.3.4 Free fall filling Formulae (6) to (10) may be used to calculate the required vent area in case a product enters the vessel by free fall (gravity) from, e.g. a rotary valve or screw feeder. The feed rate shall be limited to smaller or equal 8 000 kg·h–1 and the (equivalent) diameter of the feed opening has to be substituted for DF in the formulae. Apart from these requirements, the conditions remain the same as for the numerical formulae given in 5.3.2. NOTE The formulae can be used for vessels with integrated filters as long as the enveloping volume of the filter elements is less than 5 % of the overall vessel volume. The pressure resistance of these integrated filters needs to be at least equal to that of the vessel. Separate filters on top of the vessel with a chute into the vessel require explosion isolation and explosion venting of these filters. 5.4 Protection of interconnected enclosures 5.4.1 Vent areas determined by the Formulae (1) to (5) are too small if a dust explosion propagates from one vessel into another through a pipe. Increased turbulence, pressure piling and broad flame jet ignition may result in an increased explosion violence, especially with duct length > 6 m. This results in an elevated maximum reduced explosion overpressure. Measures for explosion isolation in the connecting pipe are therefore needed in most situations. SIST EN 14491:2012

is the required vent area without vent duct, in square-metres (m2); V

is the vessel volume of protected vessel, in cubic-metres (m3); l

is the length of vent duct, in metres (m). NOTE 1 For rectangular cross-sections use the hydraulic diameter. The Formula (17) is valid for vessel volumes

0,1 m3 < V < 10 000 m3; l/d ratio of vent duct

0,5 < l/d ≤ 20; l of vent duct

l ≤ 10 m; static activation overpressure of pressure venting device

0,1 bar ≤ pstat ≤ 0,2 bar; SIST EN 14491:2012

'max red,p ≤ 2 bar; maximum reduced explosion overpressure

0,1 bar < pred,max ≤ 2 bar; and pred,max shall be at least pstat + 2 times the tolerance range of pstat maximum explosion overpressure

5 bar < pmax < 12 bar and a dust specific characteristic 10 bar·m·s-1 < KSt < 400 bar·m·s-1, for metal dust KSt < 200 bar·m·s-1. If one of the following parameters: the maximum explosion overpressure, the dust specific characteristic, the static activation overpressure, is smaller than the one stated in the respective ranges of validity of the Formula (17), the formula shall be applied using the minimum values of that particular parameter given above. The influence of the vent duct upon the pressure increase is most pronounced when the flame propagation from the secondary explosion in the vent duct reaches the velocity of sound. This is valid for vent ducts with a length of 0,37max red,s564,4−==pll (18) Vent ducts with a length of l = ls have no additional effect upon the pressure increase. For vent ducts longer than ls, ls may be used in Formula (17) for calculating 'max red,p. Formula (18) is not valid for metal dusts. The other applications limits for Formula (17) also apply for Formula (18). NOTE 2 Experimental studies indicate that formulae (17) and (18) overestimate the influence of vent ducts for elongated vessels with the vent located as shown in Figure C.1. Reductions in the reduced explosion pressure are allowed as long as these are based on either published or experimental data that has been obtained from representative explosion venting trials.

5.7 Design of vent ducts

Vent ducts require at least the same design strength as the protected vessel. The explosion resistance of the duct shall be proven according to EN 14460. If an inspection door is provided near the venting device for maintenance, then the cover and closure shall have at least the same strength as the vent duct. A vent duct, between the protected vessel and the venting device is not covered by 5.6 and needs specific consideration. The venting device shall be placed directly on the protected vessel and not on the end of the vent duct. In principle, vent ducts downstream of pressure venting devices shall not be closed. However, light covers (weight < 0,5 kg/m2) are permissible, e.g., plastic sheets or panels in rubber mouldings, in order to prevent rain or snow from entering. The covers shall be thrown off at very low overpressure (less than 50 % of pstat, to be proven by tests). The vent cover shall not become a dangerous projectile. Vent duct configurations to which Formulae (17) and (18) can be applied are shown in Figure 1. SIST EN 14491:2012

Vent duct with gradual bend. (radius of curvature/duct diameter) > 2 Figure 1 — Vent duct design to which Formulae (17) and (18) apply Vent ducts which are characterised by a change of direction can be exposed to increased dynamic forces. This shall be reflected in their design. Vent duct configurations to which Formulae (17) and (18) cannot be applied are shown in Figure 2.

Vent duct areas less than vent area.

Vent duct area greater than vent area.

90° bend

45° bend Figure 2 — Vent duct designs to which Formulae (17) and (18) do not apply NOTE The vent duct designs in Figure 2 are not forbidden; rather Formulae (17) and (18) do not apply to them. These and other designs can be used as long as the predictions of the effects of the vent duct on the maximum reduced explosion overpressure are based on either published or experimental data that has been obtained from representative explosion venting trials. 5.8 Hybrid mixtures A hybrid mixture can be ignitable if the concentration of one of the fuel components, or even if all concentrations of each individual fuel component, are below their respective lower explosion limits. If the gas and solvent vapour concentration everywhere in the vessel is below 20 % of the lower explosion limit (LELgas,vapour), the hybrid mixture shall be assessed using the explosion indices of the dust present in the mixture. If products containing more than 0,5 % w/w flammable solvents are handled, the possibility of a hybrid mixture shall always be considered. If a hybrid mixture is present, Formulae (1) to (5) shall be used. The combustible dust shall have a KSt < 300 bar·m·s–1 and the combustible gas or solvent a KG < 100 bar·m·s–1. The following values shall be entered into Formulae (1) to (5): maximum explosion overpressure pmax = 10 bar; SIST EN 14491:2012

is the geometric vent area, in square-metres (m2); V

is the vessel volume, in cubic-metres (m3). The maximum external overpressure, pext,max can be expected at a distance FS25,0LR×= (23) where LF is the flame length, in metres (m), calculated by Formulae (19) or (20) in 6.2.2. SIST EN 14491:2012

is the recoil force, in kN; Av

is the geometric area of the vent, in square-metres (m2); pred,max is the maximum re

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...