EN 16770:2018

(Main)Safety of woodworking machines - Chip and dust extraction systems for indoor installation - Safety requirements

Safety of woodworking machines - Chip and dust extraction systems for indoor installation - Safety requirements

This document deals with all significant hazards, hazardous situations and events as listed in Clause 4, relevant for chip and dust extraction systems for indoor use designated to be connected to woodworking machines, when they are used as intended and under the conditions foreseen by the manufacturer, including reasonably foreseeable misuse.

This document does not apply to:

a) extraction systems with a nominal volume flow rate above 8 000 m3 h−1 and/or a volume of the dust loaded part of the dust extractor above 3,5 m3;

b) vacuum cleaners according to EN 60335-2-69;

c) extraction systems with fans installed in the dust loaded part;

d) extraction equipment (e.g. extraction hoods, ducts) within a woodworking machine, i.e. up to and including the outlet to which the extraction system is connected;

e) extraction systems designed for dust with KST values above 200 bar ms−1, minimum ignition energy below 10 mJ and/or lower explosion level below 30 g m−3;

f) extraction systems designed for aspiration of explosive atmospheres, e.g. dust load > 50 % lower explosion level;

g) systems designed for extraction of machines with a higher risk of causing ignition sources.

This document is not applicable to machines which are manufactured before the date of its publication as a European Standard.

Sicherheit von Holzbearbeitungsmaschinen - Absauganlagen für Holzstaub und Späne für Innenaufstellung - Sicherheitstechnische Anforderungen

Sécurité des machines pour le travail du bois - Systèmes d'extraction de copeaux et de poussières pour installation en intérieur - Prescriptions de sécurité

Le présent document traite de tous les phénomènes dangereux, situations et événements dangereux significatifs, tels qu'énumérés dans l'Article 4, applicables aux systèmes d'extraction de copeaux et poussières utilisés en intérieur, conçus pour être raccordés aux machines à bois, lorsqu’ils sont utilisés comme prévu et dans les conditions prévues par le fabricant, incluant une mauvaise utilisation raisonnablement prévisible.

Le présent document ne s’applique pas aux :

a) systèmes d'extraction ayant un débit volumique nominal supérieur à 8 000 m³ h-1 et/ou un volume de la partie chargée en poussières de l'extracteur de poussières supérieur à 3,5 m³ ;

b) aspirateurs conformes à l'EN 60335-2-69 ;

c) systèmes d'extraction dont les ventilateurs sont installés dans la partie chargée en poussières ;

d) équipements d'extraction (par exemple, buses de captage, conduits) situés dans une machine à bois, c'est-à-dire jusqu’à et y compris la sortie à laquelle le système d'extraction est raccordé ;

e) systèmes d'extraction conçus pour les poussières d’indice KST supérieur à 200 bar m s-1, une énergie minimale d'inflammation inférieure à 10 mJ et/ou un niveau inférieur d'explosivité inférieur à 30 g m−³ ;

f) systèmes d'extraction conçus pour l'aspiration des atmosphères explosives, par exemple, une charge de poussière > 50 % au niveau inférieur d'explosivité ;

g) systèmes conçus pour l'extraction des machines présentant un risque plus important de génération de sources d'inflammation.

Le présent document n’est pas applicable aux machines qui ont été fabriquées avant sa date de publication comme Norme européenne.

Varnost lesnoobdelovalnih strojev - Odsesovalni sistemi za lesne odrezke in prah za notranjo inštalacijo - Varnostne zahteve

Ta dokument obravnava vse pomembne nevarnosti, nevarne okoliščine ter dogodke iz točke 4 v zvezi z odsesovalnimi sistemi za lesne odrezke in prah za notranjo uporabo, ki so predvideni za priključitev na stroje, zasnovane za rezanje masivnega lesa (vključno s trdim lesom), lesnih materialov ter lesu podobnih materialov, kadar se uporabljajo v skladu s predvidenim namenom in v pogojih, ki jih predvidi proizvajalec, vključno z razumno pričakovano nepravilno uporabo.

Ta evropski standard se ne uporablja za:

a) odsesovalne sisteme z nazivnim pretokom nad 8000 m³/h in/ali prostornino s prahom obremenjenega predela izločevalnika prahu nad 3,5 m³;

b) sesalnike v skladu s standardom EN 60335-2-69/A2:2013;

c) odsesovalne sisteme z ventilatorji, nameščenimi v predelu, obremenjenem s prahom;

d) odsesovalno opremo (npr. odsesovalni pokrovi, vodi) v notranjosti lesnoobdelovalnega stroja, tj. do in vključno z odvodom, na katerega je priključen odsesovalni sistem;

e) odsesovalne sisteme, zasnovane za prah z vrednostmi KST nad 200 bar ms-1, najmanjšo vžigno energijo pod 10 mJ in/ali nižjo stopnjo eksplozivnosti pod 30 g/m³;

f) odsesovalne sisteme, zasnovane za aspiracijo eksplozivnih atmosfer, npr. obremenitev prahu > 50 % nižje stopnje eksplozivnosti;

g) sisteme, zasnovane za izločanje iz strojev z večjim tveganjem povzročitve virov vžiga;

h) silose.

Ta evropski standard se ne uporablja za stroje, ki so bili proizvedeni pred objavo tega dokumenta kot standarda EN.

General Information

- Status

- Published

- Publication Date

- 18-Sep-2018

- Withdrawal Date

- 30-Mar-2019

- Technical Committee

- CEN/TC 142 - Woodworking machines - Safety

- Drafting Committee

- CEN/TC 142/WG 10 - Chip and dust extraction systems

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 03-Mar-2024

- Completion Date

- 03-Mar-2024

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN ISO 19085-1:2017 - Woodworking machines - Safety - Part 1: Common requirements (ISO 19085-1:2017) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 16770:2018 - Safety of woodworking machines: Chip and dust extraction systems for indoor installation - Safety requirements. This CEN standard specifies safety requirements for chip and dust extraction systems intended to be connected to woodworking machines for indoor use (recirculating air). It addresses all significant hazards listed in Clause 4 when systems are used as intended and under reasonably foreseeable misuse. The standard supports the EU Machinery Directive (2006/42/EC) and is intended for manufacturers, installers and safety assessors.

Key exclusions (important to note)

- Systems with nominal flow > 8 000 m3/h or dust-volume > 3.5 m3

- Vacuum cleaners per EN 60335-2-69

- Systems with fans located in the dust-loaded part

- Extraction equipment integral to a woodworking machine (up to the machine outlet)

- Systems for highly reactive or explosive dusts (e.g., KST > 200 bar·m/s, MIE < 10 mJ, LEL < 30 g/m3)

- Systems for extraction of explosive atmospheres or from machines with higher ignition risk

- Machines manufactured before the standard’s publication date

Key Topics

EN 16770:2018 covers technical and safety aspects including:

- Risk assessment and control systems: Requirements for reliable control logic, emergency stop, fan start/stop behaviour and safety-related parts of control systems (ref. EN ISO 13849-1, EN ISO 12100).

- Mechanical protection: Guards, prevention of drawing-in, shearing and crushing hazards.

- Fire and explosion prevention: Measures to avoid ignition sources, prevent material accumulation in ducting, and limit fire spread. Annexes include active ignition detection/suppression and fire suppression systems.

- Dust and hazardous-substance control: Separation performance, emission limits and performance indication (see EN 1093 parts). Measurement procedures (vacuum, cleaning interval, residual dust) are specified.

- Noise and ergonomics: Design-stage noise reduction, measurement and declaration (EN ISO 4871, EN ISO 11201) and ergonomic considerations for safe operation and maintenance.

- Electrical, pneumatic and stability requirements: Safe cabling, IP protection, pneumatic safety (EN ISO 4414) and structural stability.

- Information for use: Marking, installation, operation and maintenance instructions required from the manufacturer.

Applications

- Design and manufacture of fixed indoor chip and dust extraction systems for woodworking shops

- Safety assessment and conformity demonstration for CE marking under the Machinery Directive

- Specification and procurement of extraction systems by woodworking businesses, integrators and system installers

- Development of maintenance and cleaning regimes to reduce fire and dust risks

Who should use this standard

- Extraction system manufacturers and designers

- Woodworking machine builders and integrators

- Health & safety managers, plant engineers and maintenance teams

- Notified bodies, regulators and conformity assessment bodies

Related standards

- EN 12779 (fixed installation extraction systems)

- EN 1093-6 / EN 1093-7 (separation efficiency)

- EN ISO 12100, EN ISO 13849-1, EN ISO 11201 (risk, control systems, noise)

- EN 1127-1, EN 14460, EN 14491 (explosion/fire protection)

Keywords: EN 16770:2018, chip and dust extraction systems, woodworking machine safety, dust extraction safety requirements, indoor extraction systems, fire prevention, noise reduction, separation efficiency.

Get Certified

Connect with accredited certification bodies for this standard

Gozdarski inštitut Slovenije

Slovenian Forestry Institute. Forest management certification support, timber testing.

Sponsored listings

Frequently Asked Questions

EN 16770:2018 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of woodworking machines - Chip and dust extraction systems for indoor installation - Safety requirements". This standard covers: This document deals with all significant hazards, hazardous situations and events as listed in Clause 4, relevant for chip and dust extraction systems for indoor use designated to be connected to woodworking machines, when they are used as intended and under the conditions foreseen by the manufacturer, including reasonably foreseeable misuse. This document does not apply to: a) extraction systems with a nominal volume flow rate above 8 000 m3 h−1 and/or a volume of the dust loaded part of the dust extractor above 3,5 m3; b) vacuum cleaners according to EN 60335-2-69; c) extraction systems with fans installed in the dust loaded part; d) extraction equipment (e.g. extraction hoods, ducts) within a woodworking machine, i.e. up to and including the outlet to which the extraction system is connected; e) extraction systems designed for dust with KST values above 200 bar ms−1, minimum ignition energy below 10 mJ and/or lower explosion level below 30 g m−3; f) extraction systems designed for aspiration of explosive atmospheres, e.g. dust load > 50 % lower explosion level; g) systems designed for extraction of machines with a higher risk of causing ignition sources. This document is not applicable to machines which are manufactured before the date of its publication as a European Standard.

This document deals with all significant hazards, hazardous situations and events as listed in Clause 4, relevant for chip and dust extraction systems for indoor use designated to be connected to woodworking machines, when they are used as intended and under the conditions foreseen by the manufacturer, including reasonably foreseeable misuse. This document does not apply to: a) extraction systems with a nominal volume flow rate above 8 000 m3 h−1 and/or a volume of the dust loaded part of the dust extractor above 3,5 m3; b) vacuum cleaners according to EN 60335-2-69; c) extraction systems with fans installed in the dust loaded part; d) extraction equipment (e.g. extraction hoods, ducts) within a woodworking machine, i.e. up to and including the outlet to which the extraction system is connected; e) extraction systems designed for dust with KST values above 200 bar ms−1, minimum ignition energy below 10 mJ and/or lower explosion level below 30 g m−3; f) extraction systems designed for aspiration of explosive atmospheres, e.g. dust load > 50 % lower explosion level; g) systems designed for extraction of machines with a higher risk of causing ignition sources. This document is not applicable to machines which are manufactured before the date of its publication as a European Standard.

EN 16770:2018 is classified under the following ICS (International Classification for Standards) categories: 79.120.10 - Woodworking machines. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16770:2018 has the following relationships with other standards: It is inter standard links to EN 60204-1:2006, EN 60529:1991, EN 50525-2-21:2011, EN ISO 8321-1:2002, EN ISO 4414:2010, EN ISO 13849-1:2023, EN ISO 12100:2010, EN ISO 19085-1:2017, EN 14460:2006, EN ISO 13850:2015, EN ISO 14119:2025, EN 1127-1:2019, EN ISO 13732-1:2008, EN 1037:1995+A1:2008, EN ISO 4871:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16770:2018 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16770:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Varnost lesnoobdelovalnih strojev - Odsesovalni sistemi za lesne odrezke in prah za notranjo inštalacijo - Varnostne zahteveSicherheit von Holzbearbeitungsmaschinen - Absauganlagen für Holzstaub und Späne für Innenaufstellung - Sicherheitstechnische AnforderungenSécurité des machines pour le travail du bois - Installations d'extraction de copeaux et de poussières - Prescriptions de sécuritéSafety of woodworking machines - Chip and dust extraction systems for indoor installation - Safety requirements79.120.10Lesnoobdelovalni strojiWoodworking machinesICS:Ta slovenski standard je istoveten z:EN 16770:2018SIST EN 16770:2018en,fr,de01-december-2018SIST EN 16770:2018SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16770

September

t r s z ICS

y {ä s t rä s r English Version

Safety of woodworking machines æ Chip and dust extraction systems for indoor installation æ Safety requirements Sécurité des machines pour le travail du bois æ Systèmes d 5extraction de copeaux et de poussières pour installation en intérieur æ Prescriptions de sécurité

Sicherheit von Holzbearbeitungsmaschinen æ Absauganlagen für Holzstaub und Späne für Innenaufstellung æ Sicherheitstechnische Anforderungen This European Standard was approved by CEN on

{ April

t r s zä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s z CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s x y y rã t r s z ESIST EN 16770:2018

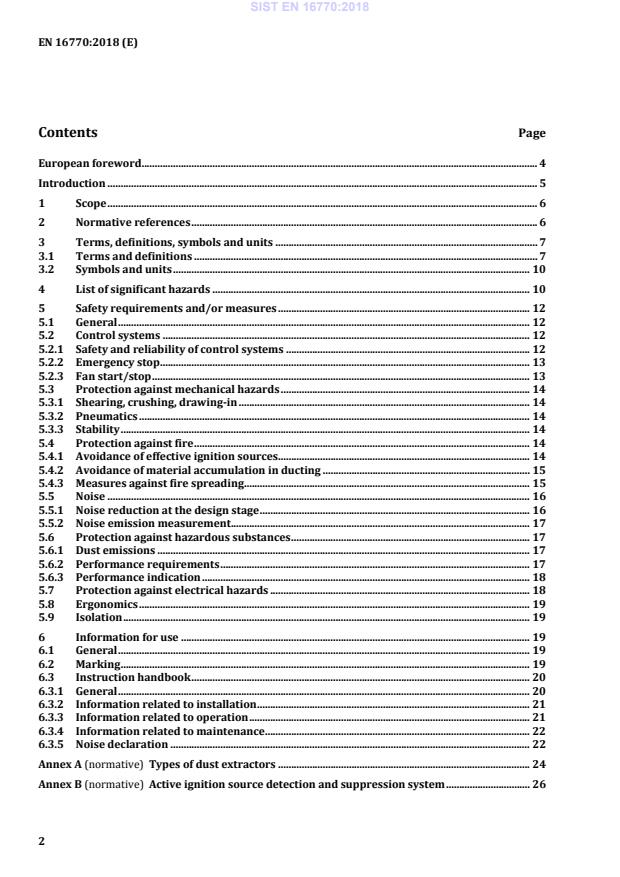

Types of dust extractors . 24 Annex B (normative)

Active ignition source detection and suppression system . 26 SIST EN 16770:2018

Fire suppression system . 28 Annex D (informative)

Noise reduction at the design stage . 29 D.1 General . 29 D.2 Noise sources . 29 D.3 Measures to reduce noise . 29 D.4 Impacts from chips and dust . 30 Annex E (normative)

Measurement of vacuum, cleaning interval and residual dust content . 31 Annex F (informative)

Interface to woodworking machinery . 32 Annex ZA (informative)

Relationship between this European Standard and the essential requirements of Directive 2006/42/EC aimed to be covered . 33 Bibliography . 36

machine manufacturers (small, medium and large enterprises); —

health and safety bodies (regulators, accident prevention organizations, market surveillance, etc.). When provisions of this type C standard are different from those, which are stated in type A or B standards, the provisions of this type C standard take precedence over the provisions of other standards, for machines that have been designed and built in accordance with the provisions of this type C standard. The requirements of this document are directed to manufacturers and their authorized representatives of chip and dust extraction systems. This document also includes information to be provided by the manufacturer to the user. SIST EN 16770:2018

1 This document is impacted by the stand-alone amendment EN 60204-1:2006/A1:2009. 2 This latest edition of document is impacted by the stand-alone amendments EN 60529:1991/A1:2000 and EN 60529:1991/A2:2013. SIST EN 16770:2018

´woodworking µ particles with a particle size

¶ 0,5 mm 3.1.6 shaving chip with a typical length of above 15 mm and a low thickness compared to other dimensions 3.1.7 extraction ducting all parts of the ducting between the extraction points and the dust extractor consisting of main and branch and machine connection ducts, gate valves and fire gates 3.1.8 main duct duct to the dust extractor to which branch ducts or connection ducts are connected 3.1.9 fan component within the dust extractor which produces the volume flow rate necessary for extracting chips and dust from the woodworking machines 3.1.10 filter element part of the dust extractor for the removal of chips and dust from the air SIST EN 16770:2018

À 3.1.22 stationary dust extractor dust extractor designed to be installed on a floor or secured to a fixed structure SIST EN 16770:2018

Pa Temperature T °C KST value KST bar ms «1 Material load

g m «3 Minimum ignition energy MIE mJ Minimum ignition temperature MIT °C Lower explosion level LEL g m «3 Dust content

mg m-3 Capacity C pF Current l A Sound pressure level LpA dB(A) 4 List of significant hazards This clause contains all significant hazards, hazardous situations and events (see EN ISO 12100:2010), identified by risk assessment as significant for the machines as defined in the scope and which require action to eliminate or reduce the risk. This document deals with these significant hazards by defining safety requirements and/or measures or by reference to relevant standards. These hazards are listed in Table 2 in accordance with EN ISO 12100:2010, Annex B. If gaseous pollutants occur at the working area, they will be partly removed from the working area by the extraction system for wood dust and chips. However, the gaseous pollutants are not separated by the extraction system for dust and chips. The explosion risk on dust extractors covered by this standard is reduced to a fast combustion only due to the following design properties: — there is just a limited crude air volume compared to the total volume of the dust extractor; — the geometry of the crude air volume hinders the combustion process; — the ratio between surface and volume of the crude air part deflates the combustion process. SIST EN 16770:2018

requirements Applicable clauses of this standard Subclause of EN ISO 12100:2010 Origin a Potential consequences b

1 Mechanical hazards — instability; — moving parts; — rotating parts; — stored energy; — crushing; — drawing-in or trapping; — entanglement; — shearing; 5.3.1 5.3.3 6.2.3 a) 6.2.6 6.2.10 6.3.5.2 6.3.5.4 2 Electrical hazards — electrostatic phenomena; — parts which have become live under fault conditions; — electrocution; — fire; — (electric) shock; 5.7 6.2.9 6.3.3.2 6.3.5.4 6.4.4 6.4.5 3 Thermal hazards — explosion; — flame; — objects or materials with a high temperature; — burn; — fire spreading; 5.4 6.2.4 b) 6.2.8 c) 4 Noise hazards — exhausting system; — scraping surfaces; — unbalanced rotating parts; — whistling pneumatics; — discomfort; — permanent hearing loss; — stress; — tinnitus; — tiredness; — accidents due to interference with speech communication and acoustic signals; 5.5 6.2.3 c) 6.2.8 c) 6.3.1 6.3.4.2 6.4.3 6.4.5.1 b) and c) SIST EN 16770:2018

requirements Applicable clauses of this standard Subclause of EN ISO 12100:2010 Origin a Potential consequences b

7 Material/ substance hazards — biological and microbiological (viral or bacterial) agent; — dust; — flammable materials; — breathing difficulties, suffocation; — cancer; — explosion; — fire; — fire spreading; — poisoning; — sensitization; 5.4 5.6 6.2.3 b) 6.2.3 c) 6.2.4 a) 6.3.4.4 6.4.5.1 c) 6.4.5.1 g) 8 Ergonomics — effort; — posture. — discomfort; — musculoskeletal disorder. 5.8 6.2.7 6.2.8 6.2.11.8 a A single origin of a hazard can have several potential consequences. b For each type of hazard or group of hazards, some potential consequences can be related to several origins of hazard. 5 Safety requirements and/or measures 5.1 General The chip and dust extraction system shall comply with the safety requirements and/or protective measures of this clause. In addition, the system shall be designed in accordance with the principles of EN ISO 12100:2010 for hazards relevant but not significant, and which are not dealt with in this document (e.g. sharp edges). For guidance in connection with risk reduction by design, see EN ISO 12100:2010, 6.2 and for safeguarding measures, see EN ISO 12100:2010, 6.3. 5.2 Control systems 5.2.1 Safety and reliability of control systems Control systems shall be designed in compliance with the principles of EN ISO 13849-1. The following safety-relevant functions shall correspond to a minimum performance level (PL) according to EN ISO 13849-1: — emergency stop PL c (see 5.2.2); — mode selection PL b (see 5.2.3); — interlocking of movable guards with hazardous moving parts PL c (see 5.3.1); — interlocking of fire suppression system with: SIST EN 16770:2018

¶ 10 pF, e.g. tension belts for filter hoses, earthing is not necessary. NOTE 4 Conductive or dischargeable filter media are not required for wood dust because the minimum ignition energy of combustible dusts is > 3 mJ. Dust extractors of type C 2 or D according to Annex A shall additionally be equipped with an active ignition source detection and suppression system according to Annex B. Verification: By checking the relevant documentation and visual inspection. 5.4.2 Avoidance of material accumulation in ducting Ducting shall be designed in such a way that accumulation of material does not occur. The conveying air velocity in all parts of the ducting shall be sufficient to avoid accumulation of material in the ducts. Bends, branch ducts, inspection doors, dampers, gate valves, fire-gates etc. integrated in ducting shall not hinder continuous material transportation. NOTE The minimum conveying air velocity depends on the material load, the moisture content, the particle size of the chip and dust. Table 3 shows minimum conveying air velocities of material with a moisture content

¶ 15 %. Table 3 — Minimum conveying air velocity of material with a moisture content

15 %

dust chips shavings material load < 30 g m «3 < 50 g m «3 < 50 g m «3 minimum conveying air velocity 12 ms «1 15 ms «1 18 ms «1 Verification: By visual inspection, checking the relevant documents, measuring the air velocities and functional testing. 5.4.3 Measures against fire spreading The housing of the dust extractor including the bins shall be made of materials of low flammability or non-flammable materials. Dust extractors with a volume of the dust loaded part above 0,8 m3 shall be equipped with a suitable back pressure flap at the inlet (see Figure A.1) that fulfils the following requirements: a) pressure shock resistance higher than or equal to the pressure shock resistance of the dust extractor; SIST EN 16770:2018

· 200 mbar; g) equipped with an automatic fire suppression system (e.g. with water) according to Annex C. In case of the detection of a fire, the fire suppression system shall: 1) activate the fire suppression, 2) stop the fan, 3) stop the filter cleaning device; 4) stop the discharge system. An automatic restart of the dust extractor shall be prevented. Manual activation of the automatic suppression system shall also be possible. The fire suppression system shall work even with activated emergency stop and / or deactivated main switch. The requirements listed in Annex C shall be fulfilled. NOTE The dimension of the fire hose coupling depends on local specifications. For dust extractors of type C 1 according to Annex A, an interlocking of fan and filter cleaning device shall be provided to avoid cleaning during operation of the fan. Verification: By visual inspection, functional testing of the fire suppression system and checking of the relevant drawings. 5.5 Noise 5.5.1 Noise reduction at the design stage Dust extractors shall be designed and constructed so that risks resulting from the emission of airborne noise are reduced to the lowest level taking account of technical progress and the availability of means of reducing noise, in particular at source. NOTE 1 The main noise sources and measures to reduce noise of chip and dust extraction systems are described in Annex D. NOTE 2 According to the current state of the art, it is possible to design extractors so that the A-weighted emission sound pressure level, measured according to the noise test code given in EN ISO 11201:2010, 9.5 without chips and dust does not exceed 75 dB(A). SIST EN 16770:2018

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...