EN 14373:2005

(Main)Explosion suppression systems

Explosion suppression systems

This European Standard describes the basic requirements for the design and application of explosion suppression systems. This European Standard also specifies a method for evaluating the effectiveness and the scale up of explosion suppression systems against defined explosions. It gives the criteria for alternative test apparatus used to undertake explosion suppression efficacy tests and criteria to be applied in defining the safe operating regime of an explosion suppression system.

It covers:

general requirements for explosion suppression components;

evaluating the effectiveness of an explosion suppression system;

evaluating the scale up of an explosion suppression system;

evaluation and development of design tools for explosion suppression systems;

instructions for installation of an explosion suppression system;

maintenance instructions for an explosion suppression system.

This European Standard is applicable only to explosion suppression systems intended for the protection of closed, or essentially closed, enclosures in which an explosion may result as a consequence of ignition of an explosible mixtures, e.g. dust-air mixtures, gas(vapour)-air mixtures, dust-gas(vapour)-air mixtures and mists.

This European Standard is not applicable for explosions of materials listed below, or for mixtures containing some of those materials:

unstable materials that are liable to dissociate;

explosive materials;

pyrotechnic materials;

pyrophoric materials.

NOTE For the listed materials expert advice is required.

Explosions-Unterdrückungssysteme

Diese Europäische Norm beschreibt die Grundanforderungen für die Konstruktion und Anwendung von Explosions-Unterdrückungssystemen. Diese Europäische Norm legt außerdem ein Verfahren zur Beurteilung der Wirksamkeit und Reichweite von Explosions-Unterdrückungssystemen bei bestimmten Explosionen fest. Die Norm gibt Kriterien für alternative Prüfeinrichtungen an, die bei Prüfungen zur Wirksamkeit der Explosions-Unterdrückung gelten, und sie enthält Kriterien, die bei der Festlegung des sicheren Arbeitsbereichs eines Explosions-Unterdrückungssystems anzuwenden sind.

Sie behandelt:

- allgemeine Anforderungen an Komponenten für Explosions-Unterdrückung;

- Bewerten des Leistungsvermögens eines Explosions-Unterdrückungssystems;

- Bewerten der Reichweite eines Explosions-Unterdrückungssystems;

- Bewertung und Entwicklung einer Konstruktionsanleitung für Explosions-Unterdrückungssysteme;

- Anweisungen für den Einbau eines Explosions-Unterdrückungssystems;

- Instandhaltungsanweisungen für ein Explosions-Unterdrückungssystem.

Diese Europäische Norm gilt nur für Explosions-Unterdrückungssysteme, die zum Schutz von geschlossenen oder im Wesentlichen geschlossenen Gehäusen vorgesehen sind, in denen eine Explosion durch die Zündung eines explosionsfähigen Gemisches, z. B. Staub/Luft-Gemischen, Gas(Dampf)/Luft-Gemischen, Staub/Gas(Dampf)/ Luft-Gemischen und Nebeln, entstehen kann.

Diese Europäische Norm ist nicht anwendbar bei Explosionen von nachstehend aufgeführten Stoffen oder Gemischen, die diese Stoffe enthalten:

- instabile Stoffe, die möglicherweise zerfallen können;

- Explosivstoffe;

- pyrotechnische Materialien;

- pyrophore Stoffe.

ANMERKUNG Für die aufgeführten Stoffe ist ein Sachverständigengutachten erforderlich.

Systèmes de suppression d'explosion

La présente Norme européenne décrit les exigences minimales concernant les composants de suppression des explosions pour la conception et l’application des systèmes de suppression des explosions. La présente norme spécifie également une méthode d’évaluation de l’efficacité et de l’extrapolation des systèmes de suppression des explosions par rapport à des explosions définies. Elle fournit les critères des appareillages d’essai alternatifs utilisés pour réaliser des essais d’efficacité de suppression des explosions ainsi que les critères à appliquer pour définir le régime de fonctionnement en toute sécurité d’un système de suppression des explosions.

La présente norme couvre :

- exigences générales concernant les composants de suppression des explosions ;

- l'évaluation de l'efficacité d'un système de suppression des explosions ;

- l'évaluation de l’extrapolation d'un système de suppression des explosions ;

- évaluation et développement d’outils de conception pour les systèmes de suppression des explosions ;

- instructions pour l'installation d'un système de suppression des explosions ;

- instructions concernant la maintenance d'un système de suppression des explosions.

La présente Norme européenne s'applique uniquement aux systèmes de suppression des explosions destinés à protéger des enveloppes fermées ou notablement fermées, dans lesquelles une explosion peut être la conséquence de l'inflammation de mélanges explosibles, par exemple mélanges poussière-air, mélanges gaz (vapeur)-air, mélanges poussière-gaz (vapeur)-air et brouillards.

La présente norme ne s'applique pas aux explosions des matières énumérées ci-dessous ou aux mélanges contenant certaines de ces matières :

- matières non stables susceptibles de se dissocier ;

- matières explosives ;

- matières pyrotechniques ;

- matières pyrophoriques.

NOTE Pour les matières énumérées, l'avis d'un expert est requis.

Sistemi za dušenje eksplozij

General Information

- Status

- Withdrawn

- Publication Date

- 04-Oct-2005

- Withdrawal Date

- 10-Feb-2026

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 03-Nov-2021

- Completion Date

- 11-Feb-2026

- Directive

- Harmonized Standard2014/34/EU - Directive 2014/34/EU Of The European Parliament And Of The Council of 26 February 2014 on the harmonisation of the laws of the Member States relating to equipment and protective systems intended for use in potentially explosive atmospheres (recast)OJ Ref: HARMONIZIRAN, C 126, C 126, C 126, C 126, C 126, C OJ Date: 08-Apr-2016

Not Harmonized94/9/EC - Equipment and protective systems intended for use in potentially explosive atmospheres (ATEX)OJ Ref: C 57, C 57, C 57, C 57, C 57, C 57, C 57, C 57, C, OJ Date: 09-Mar-2006

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 14373:2005 is a standard published by the European Committee for Standardization (CEN). Its full title is "Explosion suppression systems". This standard covers: This European Standard describes the basic requirements for the design and application of explosion suppression systems. This European Standard also specifies a method for evaluating the effectiveness and the scale up of explosion suppression systems against defined explosions. It gives the criteria for alternative test apparatus used to undertake explosion suppression efficacy tests and criteria to be applied in defining the safe operating regime of an explosion suppression system. It covers: general requirements for explosion suppression components; evaluating the effectiveness of an explosion suppression system; evaluating the scale up of an explosion suppression system; evaluation and development of design tools for explosion suppression systems; instructions for installation of an explosion suppression system; maintenance instructions for an explosion suppression system. This European Standard is applicable only to explosion suppression systems intended for the protection of closed, or essentially closed, enclosures in which an explosion may result as a consequence of ignition of an explosible mixtures, e.g. dust-air mixtures, gas(vapour)-air mixtures, dust-gas(vapour)-air mixtures and mists. This European Standard is not applicable for explosions of materials listed below, or for mixtures containing some of those materials: unstable materials that are liable to dissociate; explosive materials; pyrotechnic materials; pyrophoric materials. NOTE For the listed materials expert advice is required.

This European Standard describes the basic requirements for the design and application of explosion suppression systems. This European Standard also specifies a method for evaluating the effectiveness and the scale up of explosion suppression systems against defined explosions. It gives the criteria for alternative test apparatus used to undertake explosion suppression efficacy tests and criteria to be applied in defining the safe operating regime of an explosion suppression system. It covers: general requirements for explosion suppression components; evaluating the effectiveness of an explosion suppression system; evaluating the scale up of an explosion suppression system; evaluation and development of design tools for explosion suppression systems; instructions for installation of an explosion suppression system; maintenance instructions for an explosion suppression system. This European Standard is applicable only to explosion suppression systems intended for the protection of closed, or essentially closed, enclosures in which an explosion may result as a consequence of ignition of an explosible mixtures, e.g. dust-air mixtures, gas(vapour)-air mixtures, dust-gas(vapour)-air mixtures and mists. This European Standard is not applicable for explosions of materials listed below, or for mixtures containing some of those materials: unstable materials that are liable to dissociate; explosive materials; pyrotechnic materials; pyrophoric materials. NOTE For the listed materials expert advice is required.

EN 14373:2005 is classified under the following ICS (International Classification for Standards) categories: 13.230 - Explosion protection. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14373:2005 has the following relationships with other standards: It is inter standard links to EN 14373:2021, EN 1127-1:1997, EN 13673-1:2003, EN 13237:2003, EN 13673-2:2005, EN 14034-4:2004, EN 14994:2007, EN 14034-3:2006, EN 14491:2006, EN 14034-1:2004, EN 14034-2:2006, EN 16985:2018, EN 12779:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14373:2005 is associated with the following European legislation: EU Directives/Regulations: 2014/34/EU, 94/9/EC; Standardization Mandates: M/BC/CEN/92/46. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14373:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Explosion suppression systemsSistemi za dušenje eksplozijSystemes de suppression d'explosionExplosions-Unterdrückungssysteme13.230Varstvo pred eksplozijoExplosion protectionICS:SIST EN 14373:2006enTa slovenski standard je istoveten z:EN 14373:200501-februar-2006SIST EN 14373:2006SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14373October 2005ICS 13.230 English VersionExplosion suppression systemsSystèmes de suppression d'explosionExplosionsunterdrückungs-SystemeThis European Standard was approved by CEN on 16 August 2005.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2005 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14373:2005: E

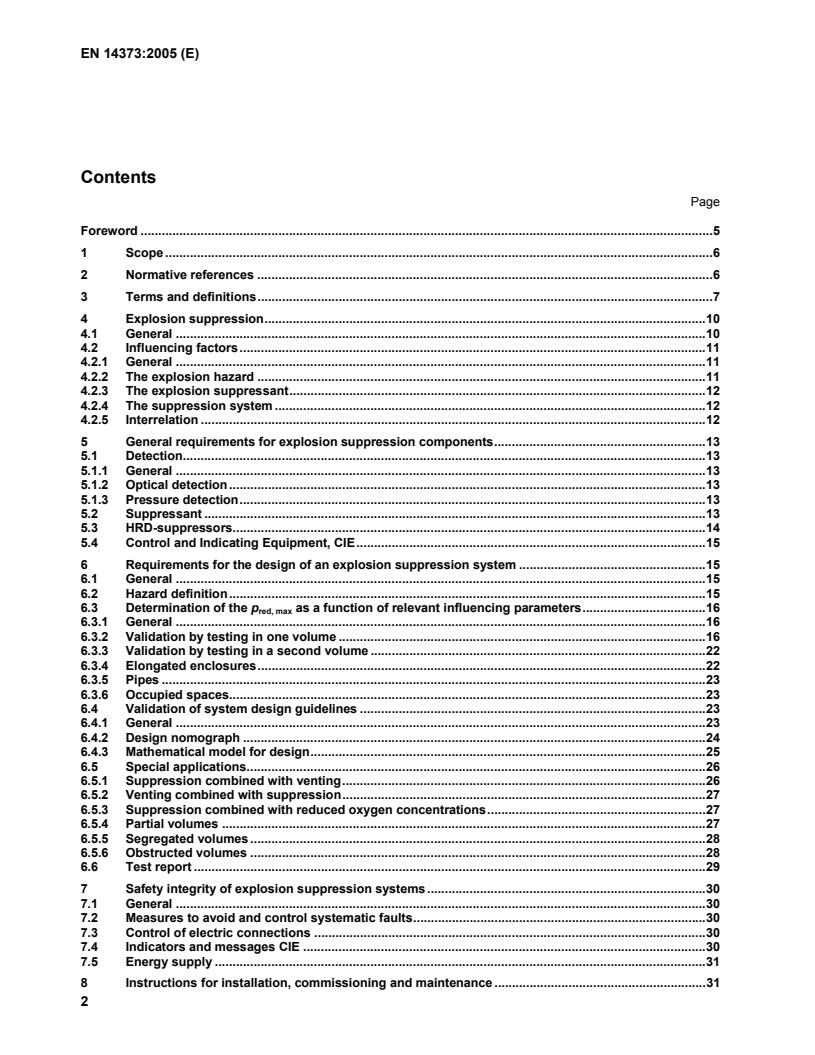

Page Foreword.5 1 Scope.6 2 Normative references.6 3 Terms and definitions.7 4 Explosion suppression.10 4.1 General.10 4.2 Influencing factors.11 4.2.1 General.11 4.2.2 The explosion hazard.11 4.2.3 The explosion suppressant.12 4.2.4 The suppression system.12 4.2.5 Interrelation.12 5 General requirements for explosion suppression components.13 5.1 Detection.13 5.1.1 General.13 5.1.2 Optical detection.13 5.1.3 Pressure detection.13 5.2 Suppressant.13 5.3 HRD-suppressors.14 5.4 Control and Indicating Equipment, CIE.15 6 Requirements for the design of an explosion suppression system.15 6.1 General.15 6.2 Hazard definition.15 6.3 Determination of the pred, max as a function of relevant influencing parameters.16 6.3.1 General.16 6.3.2 Validation by testing in one volume.16 6.3.3 Validation by testing in a second volume.22 6.3.4 Elongated enclosures.22 6.3.5 Pipes.23 6.3.6 Occupied spaces.23 6.4 Validation of system design guidelines.23 6.4.1 General.23 6.4.2 Design nomograph.24 6.4.3 Mathematical model for design.25 6.5 Special applications.26 6.5.1 Suppression combined with venting.26 6.5.2 Venting combined with suppression.27 6.5.3 Suppression combined with reduced oxygen concentrations.27 6.5.4 Partial volumes.27 6.5.5 Segregated volumes.28 6.5.6 Obstructed volumes.28 6.6 Test report.29 7 Safety integrity of explosion suppression systems.30 7.1 General.30 7.2 Measures to avoid and control systematic faults.30 7.3 Control of electric connections.30 7.4 Indicators and messages CIE.30 7.5 Energy supply.31 8 Instructions for installation, commissioning and maintenance.31

Development of nomograph type design guidelines.35 A.1 General.35 A.2 Design nomograph.35 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 94/9/EC of 23 March 1994.39 Bibliography.42 Figures: Figure 1 — Pressure behaviour versus time for a normal and suppressed explosion.11 Figure 2 — Effectiveness of suppressant.14 Figure 3 — Pressure behaviour and pressure rate of pressure rise versus concentration for a normal and suppressed explosion.17 Figure 4 — Maximum reduced explosion pressure, pred, max behaviour versus maximum explosion constant, Kmax.18 Figure 5 — Maximum reduced explosion pressure, pred, max

behaviour versus activation pressure, pa.20 Figure 6 — Maximum reduced explosion pressure, pred, max behaviour versus number of HRD-suppressors, HRDs20 Figure 7 — Maximum reduced explosion pressure, pred, max behaviour versus dispersion agent pressure ps.21 Figure 8 — Design nomograph for a specific explosion suppression system.24 Figure 9 — Calculated maximum reduced explosion overpressure versus measured maximum reduced explosion overpressure for pred, max values up to 0,5 bar.25 Figure 10 — Calculated maximum reduced explosion overpressure versus measured maximum reduced explosion overpressure for pred, max values above 0,5 bar.26 Figure 11 — Example of an enclosure where an explosive concentration prevails only in the lower section.28 Figure A.1— Design nomograph for a specific explosion suppression system.36 Figure A.2 — Design guideline for a fuel range.37 Figure A.3 — Volume limits of the design guideline for a fuel range.37

dispersion device device fitted on a HRD-Suppressor and designed to spread the suppressant throughout the volume to be protected 3.14 enclosure

3.14.1 compact enclosure cubic enclosure enclosures having a length (height) to diameter ratio of less than 2 3.14.2 elongated enclosures enclosures with length (height) to diameter ratio of 2 to 10 3.14.3 pipe construction with a ratio length (height) to diameter greater than 10 3.15 combination systems

3.15.1 suppression combined with venting system combining the technology of explosion suppression with explosion venting 3.15.2 venting combined with suppression system designed to minimise flame ejection out of an explosion vent 3.15.3 reduced oxygen concentration combined with suppression system where a reduced oxygen concentration is used to minimise the explosion intensity and suppression is used to suppress the reduced explosion intensity 3.16 design strength of enclosure p (plant strength)

3.16.1 explosion resistant enclosures enclosures and equipment, inclusive of attached pipelines, which are designed in accordance with CEN-regulation, such that the expected explosion pressure can be withstood without permanent deformation 3.16.2 explosion shock resistant enclosures enclosures and equipment, inclusive of attached pipelines, which are designed in accordance with CEN-regulation such that they will resist the anticipated overpressure of an explosion. Unlike the criteria for explosion resistant enclosures, with explosion shock resistant enclosures some plastic deformation is allowable. In designing these enclosures, a higher utilisation of the strength of the material of construction is assumed

Key 1 Activation of the suppression system 2 Closed enclosure explosion 3 Suppressed explosion Y Explosion overpressure p, in bar X Time t, in s Figure 1 — Pressure behaviour versus time for a normal and suppressed explosion For most practical applications of explosion suppression the worst case maximum suppressed explosion pressure, pred, max that can result is determined. Provided that this suppressed explosion pressure is lower than the process equipment design strength and provided further that suppression is achieved with a sufficient margin of safety, effective explosion suppression can be assured. 4.2 Influencing factors 4.2.1 General The effectiveness of an explosion suppression system depends on the parameters listed in 4.2.2 to 4.2.4. 4.2.2 The explosion hazard a) Volume of enclosure (free volume, V); b) shape of enclosure (surface area and length (height) to diameter ratio); c) explosible material (gas, dust, flammable liquids, mixtures thereof); d) homogeneity and intrinsic turbulence of the explosive atmosphere; e) induced turbulence caused by interaction of the combustion wave with internal obstacles and reflected pressure waves; f) initial pressure; g) temperature condition; h) explosibility parameters of explosible materials: 1) maximum explosion overpressure, pmax;

Key 1 Less effective suppressant 2 Effective suppressant 3 Very effective suppressant X pa (bar) Y pred, max (bar) Figure 2 — Effectiveness of suppressant The application of a suppressant is dependent upon how effective it is at suppressing an explosion. Testing shall be used to determine the effectiveness and performance of the suppressant, thus quantifying the applicability of the suppressant. The following parameters shall be considered when selecting a suppressant: a) any adverse reaction with the process products; b) toxicity levels of the suppressant relating to occupational exposure limits; c) temperature stability of the suppressant. In addition the following properties shall be taken into account where necessary: d) Will the suppressant have to be food compatible? e) Will the suppressant cause the onset of corrosion? f) Is the suppressant environmentally friendly? g) Can the suppressant be easily removed from the process? 5.3 HRD-suppressors HRD-suppressors are available in a range of sizes. Suppressant is stored in a container which is typically pressurised. A rapidly actuated container opening mechanism provides almost instantaneous unimpeded release for the suppressant, which is expelled by propelling agent and discharged through an appropriate dispersion device, if required, into the process equipment. HRD-suppressors that utilise a large diameter outlet have superior suppression capability over those that rely on high dispersion agent pressure alone to expel the suppressant agent. The HRD-suppressor and the dispersion system have an important influence on suppression effectiveness. The performance of HRD-suppressors with specific mounting adapters and dispersion system as appropriate shall be proven through tests (Clause 6). The number and distribution of HRD-suppressors are dependent upon the geometric size and shape of the enclosure to be protected and are crucial to achieving the best suppression performance. The application of HRD-suppressor(s) shall allow for the most effective discharge of suppressant, taking into account the following:

1. series 250 g m-3, 500 g m-3, 750 g m-3

2. series

500 g m-3

3. series

500 g m-3

a) b) Key 1 unsuppressed explosion 2 suppressed explosion NOTE The activation pressure pa and the number of suppressors (suppressant charge) are constant. Figure 3 — Pressure behaviour and pressure rate of pressure rise versus concentration for a normal and suppressed explosion The suppression system shall be prepared (dispersion agent pressure, suppressant charge) and installed on the test apparatus in accordance with the manufacturer‘s recommendations. 6.3.2.1.2 Variation of maximum explosion constant, Kmax To determine the range (limit) of application of a particular explosion suppression system against explosion hazards in a chosen test volume, a series of evaluations shall be undertaken against different explosions of increasing severity by varying Kmax (see Figure 4).

Key X ×sbarm maxK Y pred,max (bar)

NOTE The activation pressure pa and the number of HRD-suppressors (suppressant charge) are constant. Figure 4 — Maximum reduced explosion pressure, pred, max behaviour versus maximum explosion constant, Kmax The variation of Kmax values shall be obtained as follows: a) Dust as a fuel: Using dusts with different Kmax values or by using the same dust and varying the ignition delay time, tv, and the concentration, C, to obtain different rates of pressure rise in order to simulate different Kmax values. b) Gas as a fuel: Evaluating the performance of a suppression system in tests with propane will be satisfactory for vapours of many industrial solvents. Where the burning characteristics of the gas or vapour are greater than that of propane, the performance of the suppression system shall be evaluated using a test gas or vapour with equal or higher explosion characteristics. For turbulent conditions, the standard turbulence test method with turbulence varied by varying the ignition delay shall be used (see EN 26184-3). c) Hybrid mixtures as a fuel: For hybrid mixtures, the gas under turbulent conditions and the dust are investigated separately, and the worst case taken as the criterion for the efficacy of the suppression system (see EN 26184-3). d) Mists as a fuel: For mists a test procedure analogous to that used for dust shall be chosen. It is necessary to confirm that the test methodology used produces a mist with droplet size distribution equivalent to or smaller than occurs in the plant equipment for such testing to be considered valid (see also EN 26184-3).

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...