EN 1366-7:2004

(Main)Fire resistance tests for service installations - Part 7: Conveyor systems and their closures

Fire resistance tests for service installations - Part 7: Conveyor systems and their closures

This part of EN 1634 specifies a method for determining the fire resistance of conveyor systems shutter (CSS) assemblies designed for installation within openings incorporated in vertical and/or horizontal separating elements, including the necessary sealing measures, if the conveyor systems shutters (CSS) are penetrated by parts of the conveyor tracks, by electrical cables or by pneumatic pipes.

Feuerwiderstandsprüfungen für Installationen - Teil 7: Förderanlagen und ihre Abschlüsse

Essais de résistance au feu des installations techniques - Partie 7: Fermetures de passages pour convoyeurs et bandes transporteuses

Preskusi požarne odpornosti servisnih inštalacij – 7. del: Sistemi tekočih trakov in njihove zapore

General Information

- Status

- Published

- Publication Date

- 29-Jun-2004

- Withdrawal Date

- 30-Dec-2004

- Technical Committee

- CEN/TC 127 - Fire safety in buildings

- Drafting Committee

- CEN/TC 127 - Fire safety in buildings

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 07-Nov-2024

- Completion Date

- 11-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Refers

EN 1366-3:2021+A1:2024 - Fire resistance tests for service installations - Part 3: Penetration seals - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 1366-7:2004 - Fire resistance tests for service installations - Part 7: Conveyor systems and their closures (CEN) specifies a standardized method to determine the fire resistance of closure and conveyor system assemblies (CSS) installed in openings of vertical or horizontal separating elements. The standard covers complete assemblies including frames/guides, anchoring, penetration seals and essential penetrating components such as conveyor tracks, electrical cables and pneumatic pipes.

This part of EN 1366 is intended to evaluate how a closure for a conveyor system contributes to the fire resistance of the separating element and to provide guidance on classification and durability where no other technical specification exists.

Key topics and technical requirements

- Scope and definitions: Terms like closure area, closure for a conveyor system, penetration seal, penetrating component, anchoring and associated supporting construction are defined to ensure consistent test setups.

- Test specimen: Full-size representative assemblies are required where possible; constrained sizes can be used up to furnace limits (typically 3 m × 3 m front opening). Penetrating components must be installed as they would be in practice.

- Test conditions:

- Heating: follow EN 1363-1 temperature–time curve; EN 1363-2 slow heating may apply for intumescent materials.

- Pressure: vertical (floor position) and raised installations have specified pressure regimes (e.g., floor installations: furnace pressure per EN 1363-1; raised installations: minimum (5 ± 2) Pa at bottom edge, top may exceed 20 Pa). Horizontal installations specify (20 ± 2) Pa measured 100 ± 10 mm below the specimen.

- Instrumentation & procedure: Instrumentation, conditioning, and detailed test procedure requirements align with EN 1363-1 and related clauses in EN 1366-7 (thermocouple arrangements, sealing, clearing/closing devices).

- Performance criteria, reporting & classification: Criteria for pass/fail, required test report contents and guidance for direct application of test results and classification are provided.

- Annexes: Normative annexes cover thermocouple placement and part-configuration rules; informative annex gives design and durability guidance.

Applications and users

EN 1366-7:2004 is used by:

- Fire testing laboratories for conducting standardized fire resistance tests on conveyor closures

- Manufacturers of conveyor systems, closures, seals and frames seeking certification or design validation

- Fire safety engineers, building designers and specifiers assessing penetration seals and fire compartments

- Certification bodies and authorities evaluating compliance with fire-resistance requirements in industrial and logistic buildings

- Facility managers and risk assessors planning safe conveyor penetrations through fire separations

Practical uses include rating conveyor pass-throughs, designing penetration seals, specifying anchoring and sealing systems, and supporting fire-resistance classification for building code compliance.

Related standards

- EN 1366 series (Parts 1–11) - Fire resistance tests for service installations

- EN 1363-1 / EN 1363-2 - General fire resistance test requirements and alternative procedures

- prEN 1366-3 - Penetration seals

- EN 1634-1 - Fire resistance tests for door and shutter assemblies

- EN 13501-2 - Fire classification using fire resistance test data

Keywords: EN 1366-7:2004, fire resistance tests, conveyor systems, conveyor closures, penetration seals, fire testing, CEN, fire-resisting assemblies.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 1366-7:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Fire resistance tests for service installations - Part 7: Conveyor systems and their closures". This standard covers: This part of EN 1634 specifies a method for determining the fire resistance of conveyor systems shutter (CSS) assemblies designed for installation within openings incorporated in vertical and/or horizontal separating elements, including the necessary sealing measures, if the conveyor systems shutters (CSS) are penetrated by parts of the conveyor tracks, by electrical cables or by pneumatic pipes.

This part of EN 1634 specifies a method for determining the fire resistance of conveyor systems shutter (CSS) assemblies designed for installation within openings incorporated in vertical and/or horizontal separating elements, including the necessary sealing measures, if the conveyor systems shutters (CSS) are penetrated by parts of the conveyor tracks, by electrical cables or by pneumatic pipes.

EN 1366-7:2004 is classified under the following ICS (International Classification for Standards) categories: 13.220.50 - Fire-resistance of building materials and elements. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1366-7:2004 has the following relationships with other standards: It is inter standard links to EN 1366-3:2021+A1:2024, EN ISO 13943:2023, EN 1191:2012, EN 1363-2:1999, EN 1366-2:2015, EN 520:2004+A1:2009, EN 1634-1:2014+A1:2018, EN 1363-1:2020, EN 12604:2017+A1:2020, EN 12779:2015, EN 13501-2:2023, EN 12101-3:2002, EN 13501-2:2007+A1:2009, EN 13501-2:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1366-7:2004 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/EXP. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1366-7:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Feuerwiderstandsprüfungen für Installationen - Teil 7: Förderanlagen und ihre AbschlüsseEssais de résistance au feu des installations techniques - Partie 7: Fermetures de passages pour convoyeurs et bandes transporteusesFire resistance tests for service installations - Part 7: Conveyor systems and their closures13.220.50Požarna odpornost gradbenih materialov in elementovFire-resistance of building materials and elementsICS:Ta slovenski standard je istoveten z:EN 1366-7:2004SIST EN 1366-7:2004en,fr,de01-oktober-2004SIST EN 1366-7:2004SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1366-7June 2004ICS 13.220.50English versionFire resistance tests for service installations - Part 7: Conveyorsystems and their closuresEssais de résistance au feu des installations techniques -Partie 7: Fermetures de passages pour convoyeurs etbandes transporteusesFeuerwiderstandsprüfungen für Installationen - Teil 7:Förderanlagen und ihre AbschlüsseThis European Standard was approved by CEN on 2 February 2004.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1366-7:2004: ESIST EN 1366-7:2004

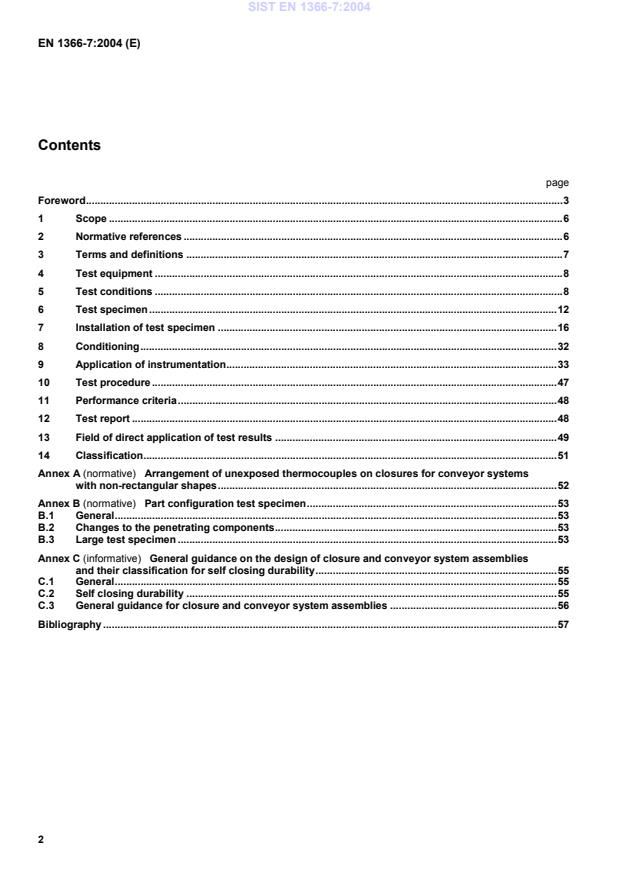

Arrangement of unexposed thermocouples on closures for conveyor systems with non-rectangular shapes.52 Annex B (normative)

Part configuration test specimen.53 B.1 General.53 B.2 Changes to the penetrating components.53 B.3 Large test specimen.53 Annex C (informative)

General guidance on the design of closure and conveyor system assemblies and their classification for self closing durability.55 C.1 General.55 C.2 Self closing durability.55 C.3 General guidance for closure and conveyor system assemblies.56 Bibliography.57

Ducts Part 2:

Fire dampers Part 31):

Penetration seals Part 41):

Linear joint seals Part 5:

Service ducts and shafts Part 61):

Raised access floors and hollow floors Part 7: Conveyor systems and their closures Part 81):

Smoke extraction ducts Part 91):

Single compartment smoke extraction ducts Part 101): Smoke control dampers Part 111): Fire protective systems for essential services Annex A and annex B are normative and annex C is informative.

1) In course of preparation.

Introduction This part of this European Standard was developed to provide a method of fire resistance testing for assessing the contribution of a closure for a conveyor system together with all its anchoring parts and the frame/guide included to the fire resistance of a separating element when penetrated by a conveyor system including any relevant penetrating components. Caution The attention of all persons concerned with managing and carrying out this fire resistance test is drawn to the fact that fire testing may be hazardous and that there is a possibility that toxic and/or harmful smoke and gases may be evolved during the test. Mechanical and operational hazards may also arise during the construction of the test elements or structures, their testing and disposal of test residues. An assessment of all potential hazards and risks to health should be made and safety precautions should be identified and provided. Written safety instructions should be issued. Appropriate training should be given to relevant personnel. Laboratory personnel should ensure that they follow written safety instructions at all times. SIST EN 1366-7:2004

1 Scope This part of this European Standard specifies a method of fire testing to determine the fire resistance of closure and conveyor system assemblies designed for installation within openings of separating elements, including any sealing necessary between the closure for a conveyor system and any penetrating components like conveyor tracks, electrical cables and pneumatic pipes being essential parts of the closure and conveyor system assembly together with the penetration seal. This part of European Standard is not applicable to other test methods required to fully assess closures for conveyor systems, e.g. test methods to evaluate the serviceability and reliable functioning of interconnected systems. The fire testing of fire dampers for heating and ventilation systems, fire doors and shutters for normal traffic paths and the movement of liquid and combustible gas, are specifically excluded from this European Standard. This European Standard is read in conjunction with EN 1363-1. In the absence of any European Technical Specification for closure and conveyor system assemblies, this European Standard gives advice on the classification of durability for closure and conveyor system assemblies. 2 Normative references This European Standard incorporates by dated or undated reference, provisions from other publications. These normative references are cited at the appropriate places in the text, and the publications are listed hereafter. For dated references, subsequent amendments to or revisions of any of these publications apply to this European Standard only when incorporated in it by amendment or revision. For undated references the latest edition of the publication referred to applies (including amendments). prEN 520, Gypsum plasterboards — Definitions, requirements and test methods. EN 1191, Windows and doors — Resistance to repeated opening and closing —Test method. EN 1363-1, Fire resistance tests — Part 1: General requirements. EN 1363-2, Fire resistance tests — Part 2: Alternative and additional procedures prEN 1366-3, Fire resistance tests for service installations — Part 3: Penetration seals. EN 1634-1, Fire resistance tests for door and shutter assemblies — Part 1: Fire doors and shutters. EN 12605, Industrial, commercial and garage doors and gates — Mechanical aspects — Test methods. EN 13501-2, Fire classification of construction products and building elements — Part 2: Classification using data from fire resistance tests, excluding ventilation services. EN ISO 13943, Fire safety — Vocabulary (ISO 13943:2000). SIST EN 1366-7:2004

Key

1 Furnace cover 2 Test frame 3 Supporting construction 4 Closure for a conveyor system 5 Penetration seal 6 Furnace floor 7

Controlled pressure position; maximum 20 Pa at the top of

the test specimen for arrangements at floor position

h

Height above furnace floor X

Pressure at height h above furnace floor a) to c) Different installations of the test specimen Figure 1 — Examples of different installations of closure and conveyor system assemblies in a vertical installation - pressure condition for floor position

Key

1 Furnace cover 2 Test frame 3 Supporting construction 4 Closure for a conveyor system 5 Penetration seal 6 Furnace floor 7 Controlled pressure position; minimum (5 ± 2) Pa at the

bottom of the test specimen for arrangements at raised

position h

Height above furnace floor hb

Height of the bottom edge of the test specimen

above floor level X

Pressure at height h above furnace floor a) to c) Different installations of the test specimen Figure 2 — Examples of different installations of closure and conveyor system assemblies in a vertical installation - pressure condition for raised position

Key

1 Ceiling 2 Wall construction 3 Penetration seal 4 Closure for a conveyor system 5 Floor on side Ι 6 Floor on side ΙΙ a) to c) Different installations of the closure and conveyor

system assembly h1

Height from the floor to the bottom of the closure and

conveyor system assembly from side Ι h2

Height from the floor to the bottom of the closure and

conveyor system assembly from side ΙΙ Figure 3 — Examples of different installations of closure and conveyor system assemblies in a vertical installation in practice – installation at different heights; floor on side ΙΙΙΙ and side ΙΙΙΙΙΙΙΙ at different heights

Key

1 Ceiling 2 Wall construction 3 Penetration seal 4 Closure for a conveyor system 5 Floor a) to b) Different installations of the closure and conveyor

system assembly

h

Height from the floor to the bottom of the closure and

conveyor system assembly from side Ι and side ΙΙ Figure 4 — Examples of different installations of closure and conveyor system assemblies in a vertical installation in practice – installation at different heights; floor on side ΙΙΙΙ and side ΙΙΙΙΙΙΙΙ at the same height

in two different directions to the supporting construction. NOTE 1 For clarity, penetrations and penetrating components (including conveyor systems) are not shown except for Figure 6 where penetrations are shown. SIST EN 1366-7:2004

Key

1 Vertical separating element 2 Closure for a conveyor system 3 Direction of fire exposure a) to c) Different installations of the test specimen Figure 5 — Closure and conveyor system assemblies; schematic arrangement with supporting construction, vertical installation; horizontal cross section SIST EN 1366-7:2004

Key

1 Horizontal separating element 2 Closure for a conveyor system 3 Penetration seal 4 Exposed duct/pipe part 5

Controlled pressure position together with level for

plate thermometer 6

Direction of fire exposure a) to e) Different arrangements of the test specimen Figure 6 — Closure and conveyor system assemblies; schematic arrangement with supporting construction, horizontal installation; vertical cross section SIST EN 1366-7:2004

Key

1 Closure for a conveyor system 2 Conveyor track 3 Separating device for the conveyor track 4

Clearing device to clear the closure area of any

Goods 5

Transported goods a) to d) Different arrangements of conveyor tracks around a

closure Figure 7 — Closure and conveyor system assemblies; schematic arrangements of conveyor tracks in the closure area

Key

1 Furnace cover 2 Vertical supporting construction 3 Conveyor track 4 Penetrating component 5 Penetration seal 6 Conveyor track 7 Penetrating component 8 Closure for a conveyor system 9 Test frame 10

Furnace floor 11

Controlled pressure position at the top of the highest

Test specimen; maximum pressure 20 Pa

h

Height above furnace floor X

Pressure at height h above furnace floor P

Pressure at the bottom of the top test specimen. If P

is at

least (5 ± 2) Pa, this test specimen will qualify

for a raised position Figure 8 — Example of multiple test specimens in a single vertical test construction – pressure condition as for floor position SIST EN 1366-7:2004

Key

1 Furnace cover 2 Vertical supporting construction 3 Conveyor track 4 Closure for a conveyor system 5 Penetrating components (e. g. a pipe) 6 Conveyor track 7 Furnace floor 8 Test frame 9 Example of a conveyor track profile 10 Penetration seal 11 Controlled pressure position at the top of the highest test

specimen; maximum pressure 20 Pa 12 Unexposed thermocouple 13 Direction of fire exposure

P Pressure at the bottom of the top test specimen. If P is at

least (5 ± 2) Pa, this test specimen will qualify for a

raised position Figure 9 — Example of multiple test specimens with penetrating components in a single vertical test construction – pressure condition as for floor position; positioning of thermocouples on the unexposed side of the penetrating components SIST EN 1366-7:2004

For a part configuration test specimen the penetration area to be tested shall be surrounded by at least 200 mm of closure leaf and/or closure frame and/or supporting construction as applicable to the particular detail (see

Figures 10 and 11). All sides of this part configuration test specimen shall be supported by the same supporting construction of at least 200 mm width as used for the full size test specimen unless in practice a smaller height at the bottom is required then this may be used (see also 7.2.3 and 7.3). The part of the closure of at least 200 mm width shall be fully restrained on all sides adjacent to the supporting construction. The cut off edge shall be prepared similar to the relevant edge of the original test specimen to allow for a good contact with the supporting construction. The gap between the closure and the penetration shall be as in practice together will the penetration detail. Pressure: a) Pressure condition for floor position (see Figure 10) The pressure P2 at the top of the part configuration test specimen shall be at least the same pressure as for the full size test specimen at the same appropriate vertical position. b) Pressure condition for raised position (see Figure 11) The pressure P2 at the bottom of the part configuration test specimen shall be at least the same pressure as for the full size test specimen at the same appropriate vertical position. NOTE The part configuration test specimen is particularly suitable for a test construction to incorporate more than one part configuration test specimen. SIST EN 1366-7:2004

Key

1 Furnace cover 2 Vertical supporting construction 3 Closure for a conveyor system 4 Conveyor track 5 Penetration seal 6 Penetrating components 7 Furnace floor 8 Test frame 9 Controlled pressure position at the top of the part

configuration test specimen; maximum pressure 20 Pa

(see also 7.6) a) Full size test specimen b) Part configuration test specimen

h Height above furnace floor P1 Pressure at the top of the full size test specimen P2 Pressure at the top of the part configuration test specimenX pressure at height h above furnace floor Figure 10 — Example for a part configuration test specimen with penetrating components in a single vertical test construction – pressure condition as for floor position SIST EN 1366-7:2004

Key

1 Furnace cover 2 Vertical supporting construction 3 Closure for a conveyor system 4 Conveyor track 5 Penetration seal 6 Penetrating components 7 Furnace floor 8 Test frame 9 Right leaf of closure 10 Left leaf of closure 11 Controlled pressure position at the bottom of the part

configuration test specimen (see also 7.6) a) Full size test specimen b) Part configuration test specimen

h Height above furnace floor hb Height of the bottom edge of the test specimen above

floor level P1 Pressure at the bottom of the full size test specimen P2 Pressure at the bottom of the part configuration test

specimen X Pressure at height h above furnace floor Figure 11 — Example for a part configuration test specimen with penetrating components in a single vertical test construction – pressure condition as for raised position SIST EN 1366-7:2004

Key

1 Furnace cover 2 Vertical supporting construction 3 Closure for a conveyor system 4 Uninterrupted duct or pipe penetration 5 Penetration seal 6 Furnace floor 7 Test frame 8 Controlled pressure position at the bottom edge of the part

configuration test specimen

h Height above furnace floor hb Height of the bottom edge of the test specimen above

floor level X Pressure at height h above furnace floor Figure 12 — Example for an uninterrupted duct or pipe penetration as a test specimen in a single vertical test construction – pressure condition as for raised position SIST EN 1366-7:2004

Key

1 Furnace cover 2 Vertical supporting construction 3 Penetration seal 4 Closure for a conveyor system 5 Unexposed part of separated duct/pipe 6 Exposed part of separated duct/pipe 7 Furnace floor 8 Test frame 9 Controlled pressure position at the top of the part

configuration test specimen

h Height above furnace floor X Pressure at height h above furnace floor Figure 13 — Example for a separated duct or pipe penetration as a test specimen in a single vertical test construction – pressure condition as for floor position SIST EN 1366-7:2004

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...