EN 1279-6:2018

(Main)Glass in building - Insulating glass units - Part 6: Factory production control and periodic tests

Glass in building - Insulating glass units - Part 6: Factory production control and periodic tests

This document describes the routine factory production control, the periodic testing and inspection and test methods to verify that an insulating glass unit (IGU) conforms to the system description.

Glas im Bauwesen - Mehrscheiben-Isolierglas - Teil 6: Werkseigene Produktionskontrolle und wiederkehrende Prüfungen

Dieses Dokument beschreibt die routinemäßige werkseigene Produktionskontrolle, die wiederkehrenden Prüfungen und die Überwachung sowie die Prüfverfahren, um zu verifizieren, dass ein Mehrscheiben Isolierglas (MIG) mit der Systembeschreibung übereinstimmt.

Verre dans la construction - Vitrage isolant - Partie 6: Contrôle de production en usine et essais périodiques

La présente Norme européenne décrit les contrôles de routine de la production en usine, les essais et contrôles périodiques et les méthodes d’essai afin de vérifier que le vitrage isolant est conforme à la description du système.

Steklo v gradbeništvu - Izolacijsko steklo - 6. del: Notranja kontrola proizvodnje in periodični preskusi

Ta standard EN opisuje notranjo kontrolo proizvodnje, periodične preskuse, nadzor in preskusne metode, s katerimi se zagotovi, da je izolacijsko steklo s skladu z opisom sistema.

General Information

- Status

- Published

- Publication Date

- 24-Jul-2018

- Withdrawal Date

- 30-Jan-2019

- Technical Committee

- CEN/TC 129 - Glass in building

- Drafting Committee

- CEN/TC 129/WG 4 - Insulating glass units

- Current Stage

- 9092 - Decision on results of review/2YR ENQ - revise - Review Enquiry

- Start Date

- 13-Mar-2025

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 24-Dec-2014

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 15434-1:2023 - Bonding sealants - Part 1: Bonded glazing sealants for direct light exposure - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 1279-6:2018 (CEN) defines the factory production control (FPC) and periodic testing procedures for insulating glass units (IGUs) used in building façades and windows. The standard describes routine inspection, sampling, test methods and reporting required to verify that an IGU conforms to its documented system description. EN 1279-6 supports consistent quality assurance across manufacturing, testing laboratories and certification bodies.

Key Topics and Requirements

- Factory production control system

- Organization, responsibilities, management representative and management review

- Personnel competence, documentation and record-keeping

- Equipment and testing

- Requirements for inspection and testing equipment used in production and verification

- Handling of non-complying materials/products and corrective actions

- Inspection & periodic testing

- Frequency, sampling rules and inspection procedures to confirm conformity to the system description

- Specific tests for moisture penetration index, gas concentration and related acceptance criteria

- Annexed test methods and checks

- Normative inspection and testing tables for IGUs

- Procedures for adhesion tests (e.g., leaded light strips, flexible spacers), sealant adhesion and hardness, two-component sealant mixing checks

- Desiccant checks (water adsorption capacity, matrix adhesion), spacer tightness (welded hollow spacers)

- Reference method for dew point measurement inside IGUs

- Reporting and corrective action

- Required reporting formats and steps to address non-conformities discovered during periodic testing

Applications and Who Uses It

EN 1279-6:2018 is intended for practical use by:

- IGU manufacturers implementing or maintaining factory production control and quality management

- QA/QC managers and production supervisors setting sampling plans and testing schedules

- Testing laboratories performing gas-concentration, dew point and adhesion tests according to the standard’s methods

- Certification bodies and inspectors verifying conformity to IGU system descriptions

- Architects, façade contractors and specifiers seeking assurance that manufactured IGUs meet documented performance and durability checks

Practical applications include establishing routine inspection programs, choosing appropriate test methods for sealants/desiccants/spacers, documenting conformity, and implementing corrective actions to reduce failures (fogging, gas loss, sealant failure).

Related Standards

- EN 1279-6 is part of the EN 1279 series for insulating glass units and should be used alongside other parts of that series and relevant national building glazing standards. For full compliance and technical limits, consult the complete EN 1279-6:2018 text and the associated parts of the EN 1279 series.

Frequently Asked Questions

EN 1279-6:2018 is a standard published by the European Committee for Standardization (CEN). Its full title is "Glass in building - Insulating glass units - Part 6: Factory production control and periodic tests". This standard covers: This document describes the routine factory production control, the periodic testing and inspection and test methods to verify that an insulating glass unit (IGU) conforms to the system description.

This document describes the routine factory production control, the periodic testing and inspection and test methods to verify that an insulating glass unit (IGU) conforms to the system description.

EN 1279-6:2018 is classified under the following ICS (International Classification for Standards) categories: 81.040.20 - Glass in building. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1279-6:2018 has the following relationships with other standards: It is inter standard links to EN 1279-6:2002, EN 1279-1:2018, EN 1279-4:2018, EN 1279-2:2018, EN 10204:2004, EN 15434-1:2023, EN 13022-1:2014, EN 14420-8:2013, EN 1279-3:2018, EN 1096-3:2012, EN 1279-4:2002, EN 13022-1:2006+A1:2010, EN 1279-3:2002, EN 1279-1:2004, EN 1279-5:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1279-6:2018 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 88/609/EEC; Standardization Mandates: M/135, M/135_AM1. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1279-6:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Glas im Bauwesen - Mehrscheiben-Isolierglas - Teil 6: Werkseigene Produktionskontrolle und wiederkehrende PrüfungenVerre dans la construction - Vitrage isolant - Partie 6: Contrôle de production en usine et essais périodiquesGlass in building - Insulating glass units - Part 6: Factory production control and periodic tests81.040.20Steklo v gradbeništvuGlass in buildingICS:Ta slovenski standard je istoveten z:EN 1279-6:2018SIST EN 1279-6:2018en,fr,de01-oktober-2018SIST EN 1279-6:2018SLOVENSKI

STANDARDSIST EN 1279-6:20041DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1279-6

July

t r s z ICS

z sä r v rä t r Supersedes EN

s t y {æ xã t r r tEnglish Version

Glass in building æ Insulating glass units æ Part

xã Factory production control and periodic tests Verre dans la construction æ Vitrage isolant æ Partie

xã Contrôle de production en usine et essais périodiques Glas im Bauwesen æ MehrscheibenæIsolierglas æ Teil

xã Werkseigene Produktionskontrolle und wiederkehrende Prüfungen This European Standard was approved by CEN on

z March

t r s zä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s z CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s t y {æ xã t r s z ESIST EN 1279-6:2018

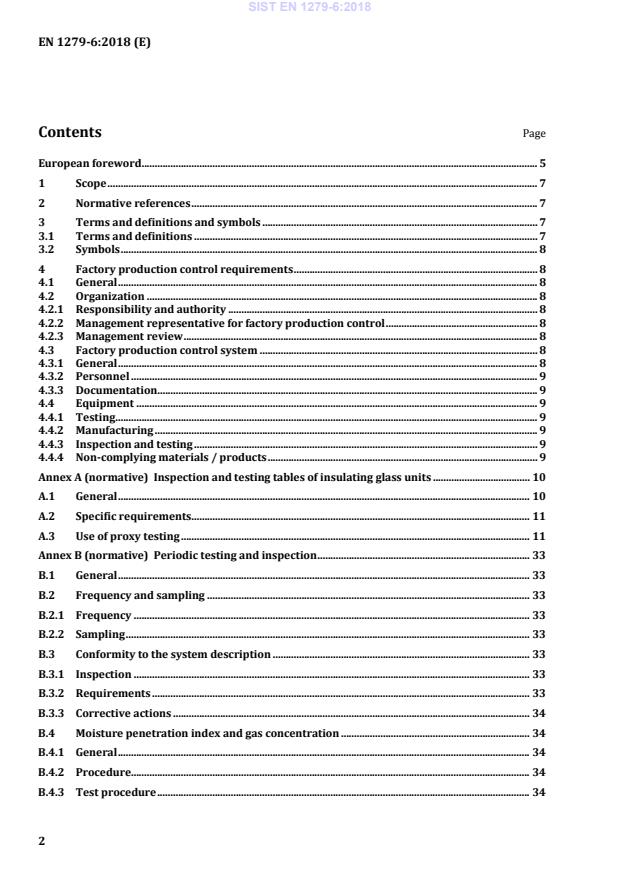

Inspection and testing tables of insulating glass units . 10 A.1 General . 10 A.2 Specific requirements . 11 A.3 Use of proxy testing . 11 Annex B (normative)

Periodic testing and inspection . 33 B.1 General . 33 B.2 Frequency and sampling . 33 B.2.1 Frequency . 33 B.2.2 Sampling . 33 B.3 Conformity to the system description . 33 B.3.1 Inspection . 33 B.3.2 Requirements . 33 B.3.3 Corrective actions . 34 B.4 Moisture penetration index and gas concentration . 34 B.4.1 General . 34 B.4.2 Procedure. 34 B.4.3 Test procedure . 34 SIST EN 1279-6:2018

Adhesion test for leaded light strip . 36 C.1 Purpose . 36 C.2 Equipment . 36 C.3 Test specimen . 36 C.4 Procedure . 36 C.5 Test report . 37 Annex D (informative)

Sealant, adhesion measurements . 38 D.1 General . 38 D.2 Standard method . 38 D.2.1 Instruments . 38 D.2.2 Test specimens . 38 D.2.2.1 Glass-glass specimen . 38 D.2.2.2 Spacer-spacer specimen . 39 D.2.3 Test procedure . 39 D.2.4 Test report . 39 D.3 Other methods . 39 D.3.1 Tensile test . 39 D.3.2 Butterfly test . 40 Annex E (informative)

Sealants, hardness measurements . 41 E.1 General . 41 E.2 Instruments . 41 E.3 Test specimen . 41 E.4 Measurement . 42 E.5 Report . 42 Annex F (informative)

Two component sealants: check on the thoroughness of mixing . 43 F.1 Purpose . 43 F.2 Test specimen . 43 F.3 Test procedure . 43 F.4 Report . 43 Annex G (informative)

Tightness check of hollow spacer closed by welding on the back . 44 G.1 Purpose . 44 SIST EN 1279-6:2018

Desiccant, water adsorption capacity check . 45 H.1 General . 45 H.2 Determination of the water adsorption capacity of desiccant in bulk . 45 H.2.1 Principle . 45 H.2.2 Equipment . 45 H.2.3 Method . 45 H.3 Determination of the water adsorption capacity of polymeric matrix incorporating desiccant . 46 Annex I (informative)

Desiccant Matrix Adhesion test in u-channels . 47 I.1 General . 47 I.2 Materials . 47 I.3 Test procedure . 47 I.4 Requirement . 47 Annex J (informative)

Adhesion tests for insulating glass units with prefabricated flexible spacer incorporating desiccant. 48 J.1 Adhesion test of spacer to sealant. 48 J.1.1 General . 48 J.1.2 Materials . 48 J.1.3 Test preparation and procedure . 48 J.1.4 Requirements . 48 J.2 Wet out strain and shear test . 49 J.2.1 Materials . 49 J.2.2 Test procedure . 49 J.2.3 Requirements . 53 Annex K (informative)

Reference method for dew point temperature measurement . 54 K.1 General . 54 K.2 Apparatus and materials . 54 K.3 Procedure. 54 Bibliography . 56

IEC Electropedia: available at http://www.electropedia.org/

ISO Online browsing platform: available at http://www.iso.org/obp SIST EN 1279-6:2018

Ireq moisture penetration index requirement

Ti initial moisture content

Tf final moisture content

4 Factory production control requirements 4.1 General The factory production control system shall consist of procedures, regular inspections and tests and/or assessments and the use of the results to control incoming materials or components (raw and other), equipment, the production process and the product. NOTE A factory production control system conforming to EN ISO 9001 [1] and made specific to the requirements of this annex is deemed to satisfy the requirements of this annex. 4.2 Organization 4.2.1 Responsibility and authority The responsibility, authority and the interrelation of all personnel who manage, perform and verify work affecting quality shall be defined, particularly for personnel who need the organizational freedom and authority to: a) initiate action to prevent the occurrence of product non-conformity; b) identify and record any product quality problems. 4.2.2 Management representative for factory production control The manufacturer shall appoint a management representative who, irrespective of other responsibilities, shall have defined authority and responsibility for ensuring that the requirements of this document are implemented and maintained. 4.2.3 Management review The production control system shall be reviewed by the manufacturer’s management at appropriate intervals in accordance with the manufacturer’s control system to ensure its continuing suitability and effectiveness. Records of such reviews shall be maintained for a minimum period of 10 years. 4.3 Factory production control system 4.3.1 General The manufacturer shall establish and maintain a documented system as a means of ensuring that the product conforms to EN 1279. The following requirements shall be fulfilled. SIST EN 1279-6:2018

Inspection and testing tables of insulating glass units A.1 General The inspection and tests are given in Table A.1 and the random sample inspection plan are detailed in Table A.2. Table A.1 — Required Inspection and tests for particular designs of IGUs and for particular designs of components for IGUs Inspection table A.3 A.4 A.5 A.6 A.7 A.8 A.9 A.10 A.11 A.12 IGU systems a All Gas filled Outer seal Inner seal spacer Cold Hot Rigid hollow Hot appliedb Prefabricatedb U-channel Metal strip B2 X WR X X X X

B3 X WR WR WR

X

B4 X WR X X WR

X

B5 X WR X X WR

X

B6 X

X X: mandatory, WR: where relevant, a: for systems of IGUs, refer to EN 1279-1:2018, Annex B. b: in the case the hot applied flexible spacer is also a prefabricated flexible spacer, both tables shall be applied Table A.2 — Reference random sample inspection plan for finished IGUs (control plan to be made by the manufacturer) Lot or day's production Number of test pieces for inspections 2 – 15 2 16 – 25 3 26 – 90 5 91 – 150 8 151 – 500 13 501 – 1 200 20 1 201 – 9 999 32 SIST EN 1279-6:2018

to carry out some tests simultaneously to production, if sufficient controls are incorporated into the FPC to allow change/replacement if a test failure occurs. Inspections in product control section can be performed during production, if the FPC contains the relevant instructions. The product control section of the tables refer to the reference random sample inspection plan in Table A.2. NOTE Plans with the same statistical accuracy (e.g. based on ISO 2859-1) can be used. When the inspection of a lot or a day's production reveals more than the acceptable number of occurrences which exceed the absolute limits described in the system description in accordance with EN 1279-1:2018, all the IGUs of the lot or day's production shall be re-inspected. Any IGUs which exceed the absolute limit(s) shall be repaired or re-manufactured. The control plan shall be made by the manufacturer. When a manufacturing process is such that one or more of the listed inspections or tests are not applicable or physically not possible, the relevant inspection or test shall be adapted or ignored. In such case any adaption or omission shall be documented in the FPC with justification. A.3 Use of proxy testing A manufacturer may employ a test method/method of evaluation other than those referred to in Tables A.1 and A.2. However, it shall be the manufacturer’s responsibility to prepare suitable documentation describing such tests and their correlation with the recommended method to ensure that the appropriate characteristic is as declared. SIST EN 1279-6:2018

1.1 Packaging and label Visual See purchase specification Each batch No 1.2 Identification (glass/coated glass, according to relevant standards) Visual See purchase specification Each batch Yes 1.3 Dimensions (length/width/shape/thickness when applicable) Measurement See purchase specification Each batch: 1 sample No 2 Inserts of any kind

2.1 Packaging and label Visual See purchase specification Each batch No 2.2 Dimensions Measurement See purchase specification Each batch: 2 samples/type Yes 2.3 Appearance Visual See purchase specification Each batch: 1 sample/type Yes 2.4 Volatile content (only if no information from supplier is available) See EN 1279-4:2018, Annex H See purchase specification Each batch: 2 samples/type Yes 3 Leaded light strip

3.1 Packaging and label Visual See purchase specification Each batch: 1 No 3.2 Dimensions Measurement See purchase specification Each batch: 2 samples Yes 3.3 Adhesion Adhesion test (Annex C) See purchase specification Each batch: 2 samples Yes 3.4 Volatile content (only if no information from supplier is available) See EN 1279-4:2018, Annex H See purchase specification Each batch: 2 samples Yes SIST EN 1279-6:2018

4.1 Packaging and label Visual See purchase specification Each batch: 1 No 5 Cutting oil

5.1 Packaging and label Visual See purchase specification Each batch: 1 No 6 Washing machine additive

6.1 Packaging and label Visual See purchase specification Each batch: 1 No Section 2: Production control Ref. Material, inspection or test Recommended method (decision by manufacturer) Requirement Recommended frequency (decision by manufacturer) Record 1 Cutting of glass (if relevant)

1.1 Type of glass Visual See relevant specifications Each pane No 1.2 Cutting quality Visual See relevant specifications Each pane No 1.3 Dimensions Measurement See relevant specifications 1 pane/shift and line Yes 1.4 Thickness Visual See relevant specifications Each pane No 1.5 Edge deletion (when and if relevant) visual See relevant specifications Each pane No 2 Washing efficiency

2.1 Quality of rinsing water Resistivity / conductivity See internal specification 1 per shift and machine No 2.2 Dry and clean glass edge and surface Visual No visible contamination Each pane No 3 Assembly

3.1 Glass components or type of used glasses Visual See label Random inspection plan (Table A.2) No 3.2 Glass defects visual See EN 1279-1:2018, Annex F Random inspection plan (Table A.2) No 3.3 Position of spacer frame Visual See system description Each IGU No SIST EN 1279-6:2018

1.1 Glass components or type of used glasses Visual See label Random inspection plan (Table A.2) Yes 1.2 Dimensions of IGU (length, width and total thickness, shift of edges), position of spacer frame Measurement See relevant specifications Random inspection plan (Table A.2) Yes 1.3 Glass defects Visual See EN 1279-1:2018, Annex F Random inspection plan (Table A.2) Yes 1.4 Marking Visual See product description Random inspection plan (Table A.2) Yes 1.5 Flatness (immediately after sealing the unit) Visual No remarkable deviation Random inspection plan (Table A.2) Yes 1.6 Fogging (This test is relevant when no information exist on the volatile contents of the relevant components) EN 1279-4:2018, Annex C No visible fogging - Once per year, or more if relevant - When relevant component change Yes Yes SIST EN 1279-6:2018

1.1 Packaging and label Visual See purchase specification Each batch: 1 No 2 Gas or gas mixture

2.1 Packaging, label Visual See purchase specification Each batch: 1 No Section 2: Production control Ref. Material, inspection or test Recommended method (decision by manufacturer) Requirement Recommended frequency (decision by manufacturer) Record 1 Gas filling

1.1 Operation of filling system Machinery adjustment See production manual Per shift: 1 No 1.2 Closing of gas fill hole Visual See production manual Each IGU No Section 3: Product control Ref. Materials, inspection or test Recommended method (decision by manufacturer) Requirement tolerances are expressed in % absolute Recommended frequency (decision by manufacturer) Record 1 Gas filling

1 Gas concentration (ci) Measurement ci = ci,o (+10

¨á

« w %) 1 per 1 000 units with a minimum of

3 units/24 h and line, or 1 unit/day when production is less than 100 units/24 h and line Yes SIST EN 1279-6:2018

1.1 Packaging and label Visual See purchase specification Each batch No 1.2 Shelf-life Visual Suppliers' specification Each batch: 1 No 1.3.a a Adhesion on glass (IGU type A) See Annex D Refer to D.3.1 or D.3.2 Each batch: 1 sample Yes Adhesion on spacer See Annex D Refer to D.2 Each batch: 1 sample Yes 1.3.b a Adhesion on glass (IGU type B and C) Tensile test EN 1279-4:2018, Annex A without ageing EN 13022-1 Each batch: 1 sample Yes 1.4 a Hardness: may be combined with 1.3, and see further, Section 2: Production control, line 1.5 of this table See Annex E See product description Each batch: 1 samples/type Yes 1.5 a Volatile content (only if no information from supplier is available) See EN 1279-4:2018, Annex H See product description Each batch: 1 samples/type Yes SIST EN 1279-6:2018

1.1 Adhesion on glass and spacer (type A)b Annex D D.3.1 or D.3.2 1 per shift and line Yes 1.2 Adhesion on glass and spacer (type B and C) Tensile test at initial state EN 1279-4:2018, Annex A Cohesive rupture > 90 % Per shift: 3 samples per glass surface type (including coated glass) Yes 1.3 Mixing ratio See equipment- and sealant specifications See sealant specification Minimum 2 per year and when changes of materials occurs. Yes 1.4 Thoroughness of mixing Mixing check (Annex F) No marbling Per shift: 1sample Yes 1.5 Hardness Hardness test (Annex E) See product description Per shift: 1 sample Yes 1.6 Contamination Visual Absence of contamination Each packaging unit No Section 3: Product control Ref. Inspection or test Recommended method (decision by manufacturer) Requirement Recommended frequency (decision by manufacturer) Record 1 Outer sealant

1.1 Occurrences exceeding absolute limits Visual and measurement See product description Random inspection plan (Table A.2) Yes a

If no information of the supplier is available. b

Butterfly test is recommended. SIST EN 1279-6:2018

1.1 Packaging and label Visual See purchase specification Each batch: 1 No 1.2 Shelf life Visual Supplier's specification Each batch: 1 No 1.3 Appearance Visual See purchase specification Each batch: 1 Yes 1.4 Temperature of application Supplier information See purchase specification Each batch: 1 Yes 1.5 Adhesion: may be combined with line 2.2 of Section 2: Production Control, of this table Annex D See, D.3.2 Each batch: 1 samples Yes 1.6 Volatile content (only if no information from supplier is available)) or fogging test (only if no information from supplier is available) See EN 1279-4:2018, Annex H or C See product description Each batch: 1 samples/type Yes 2 Alternative assembly aids (where used) e.g. hot melt inner seal/spacer adhesive

2.1 Packaging and label Visual See purchase specification Each batch: 1 No 2.2 Shelf life Visual Supplier's specification Each batch: 1 No 2.3 Temperature of application (spacer adhesive only) Supplier information See purchase specification Each batch: 2 samples/type No SIST EN 1279-6:2018

1.1 Continuity Visual Supplier's recommendation Continually No 1.2 Application at corners Visual Supplier's recommendation Continually No 1.3 Dosage (if hot melt spacer adhesive) Visual Supplier's recommendation Per shift: 1 time 2 samples No 1.4 Contaminations in the bonding area Visual No contamination Continually No 2 Hot melt outer sealant

2.1 Temperature of application at nozzle Measurement Supplier's recommendation Beginning, middle and end of shift Yes 2.2 Adhesion on glass and spacer Measurement: Annex D See, D.3.2 Beginning, middle and end of shift Yes 2.3 Air inclusions (use samples of line 2.2 adhesion) Visual No significant inclusions Beginning, middle and end of shift No 2.4 Contamination Visual See purchase specification Each batch: 1sample No 2.5 Air bubbles Visual See purchase specification Each batch: 1sample No 2.6 Completion of junctions Visual See product description Continually No 2.7 Equalization (parallelism of panes) Visual See product description Per shift: 1 time 2 samples No Section 3: Product control Ref. Inspection or test Recommended method (decision to be made by manufacturer) Requirement Recommended frequency (decision to be made by manufacturer) Record 1 Outer sealant

1.1 Occurrences exceeding absolute limits Visual and measurement See product description Random inspection plan (Table A.2) Yes SIST EN 1279-6:2018

1.1 Packaging and label Visual See purchase specification Each batch: 1sample No 1.2 Penetration (if there is no information from supplier) ISO 2137

See purchase specification Each batch: 2 samples/type No 1.3 Volatile content (only if no information from supplier) See EN 1279-4:2018, Annex H See purchase specification Each batch: 2 samples/type Yes Section 2: Production control Ref. Material, inspection or test Recommended method (decision by manufacturer) Requirement Recommended frequency (decision by manufacturer) Record 1 Inner sealant

1.1 Continuity Visual See product description Continually No 1.2 Thread at corners Visual See product description Continually No 1.3 Extruded behaviour and shape Visual See product description Continually No 1.4 Contamination in the bonding area Visual See product description Continually No 1.5 Amount of extruded material Measurement See product description 1 per shift and spacer type used Yes SIST EN 1279-6:2018

1.1 Occurrences exceeding absolute limits Visual See product

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...